Destressing warhead-curve-shaped aluminum alloy thin-walled cylinder and machining process of destressing warhead-curve-shaped aluminum alloy thin-walled cylinder

A curve-shaped, thin-walled cylinder technology, applied in the field of warhead curve-shaped aluminum alloy thin-walled cylinder and its processing technology, can solve the problems of easily reducing the welding strength of the weld, incomplete stress relief, etc., to improve the structural strength and fatigue life of the material, The effect of removing residual tensile stress and eliminating residual tensile stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in detail below in conjunction with accompanying drawing:

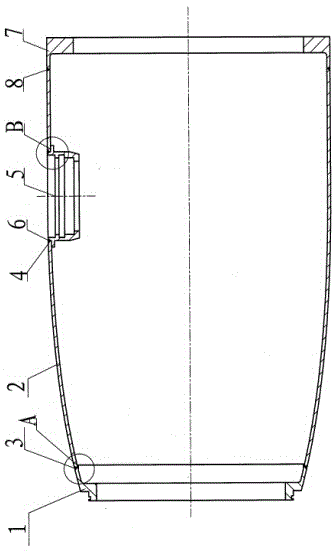

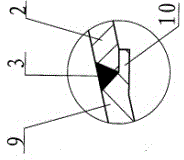

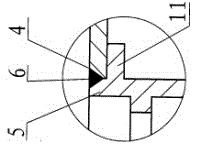

[0027] A thin-walled aluminum alloy cylinder with a curved warhead shape for stress relief, comprising a thin-walled cylinder body 2 with a curved warhead shape, a front flange 1 and a rear flange 7, and a warhead curve is arranged on the rear end side of the front flange 1. The front end of the thin-walled cylinder 2 is butted with an annular cylinder 9, an annular bevel 10 is provided on the rear end of the annular cylinder 9, and an annular cylinder 9 is provided on the rear end side of the front flange 1. Between the annular bevel 10 and the front end of the thin-walled cylindrical body 2 in the curved shape of the warhead, a vertically forward annular welding seam 3 is arranged, and a hole seat hole 4 is arranged on the cylinder wall of the thin-walled cylindrical body 2 in the curved shape of the bullet head. The outer wall of the seat 5 is provided with a positioning an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com