Method for removing inclusions by means of determining height of vertical section of continuous casting machine for extra-thick slabs

A technology of extra-thick slab and vertical height, which is applied in the field of removing the inclusions inside the extra-thick slab, and can solve problems such as increasing the bulge of the casting slab, increasing the cost of the continuous casting machine and project construction investment, and increasing internal cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with drawings and embodiments.

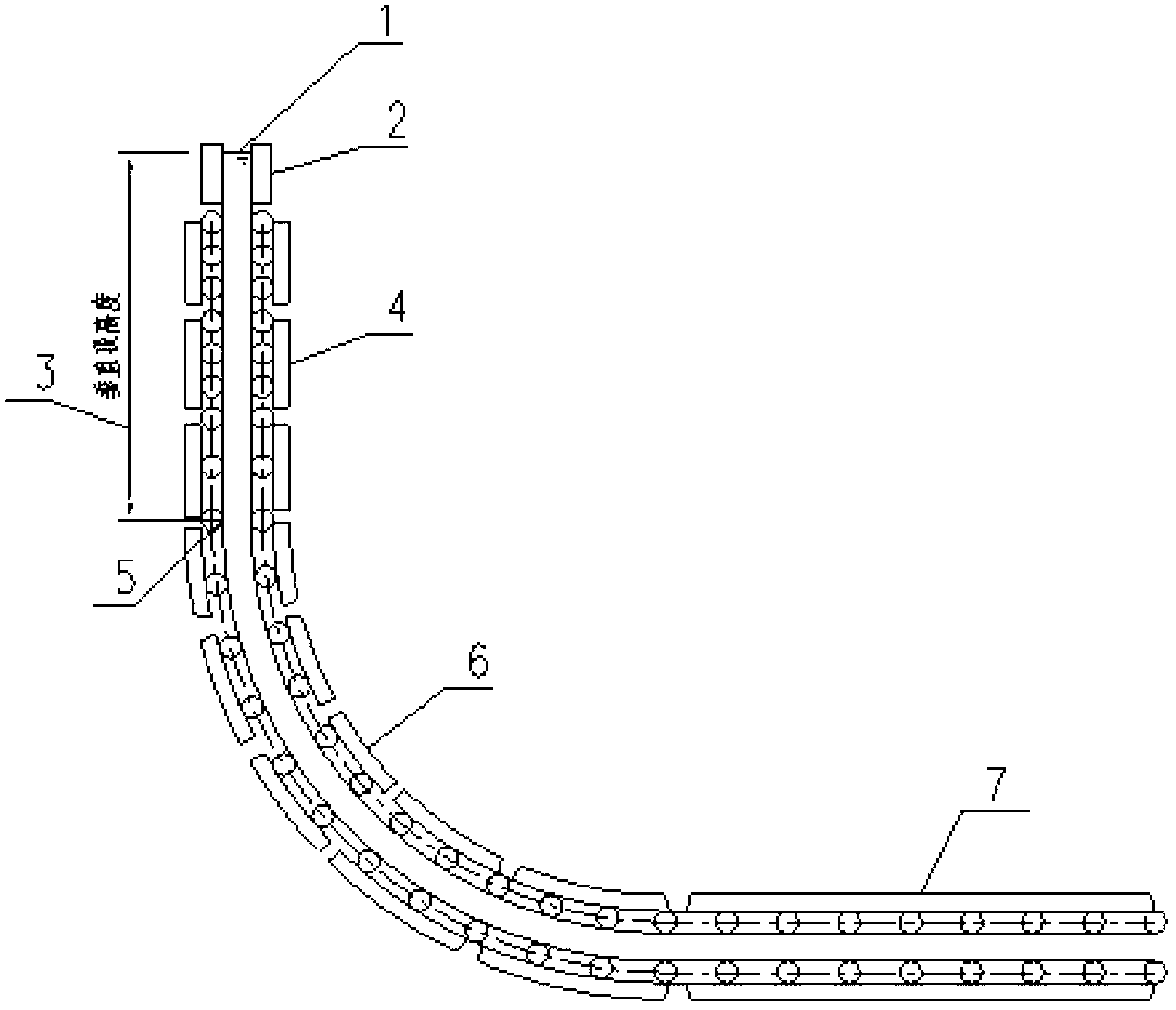

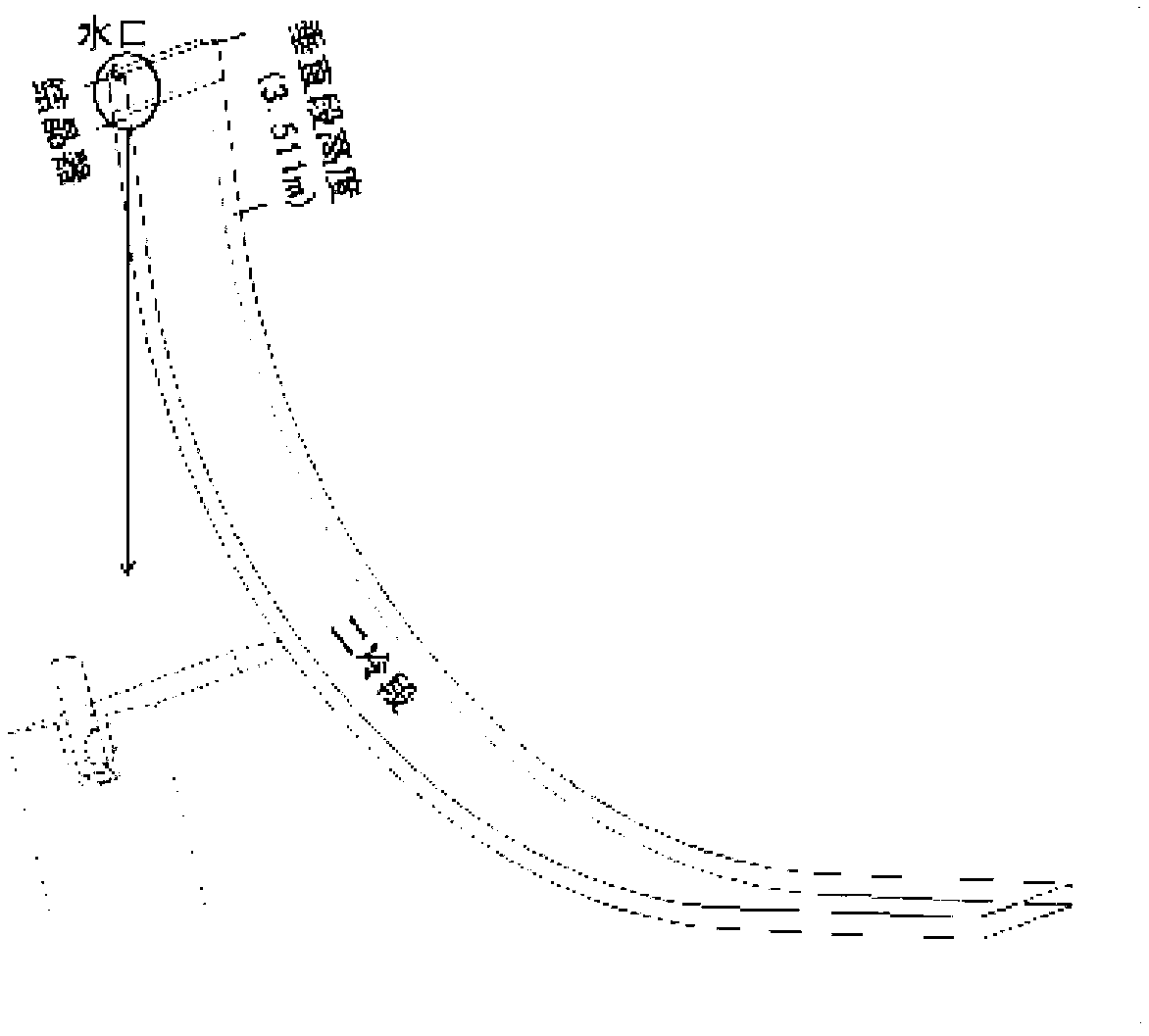

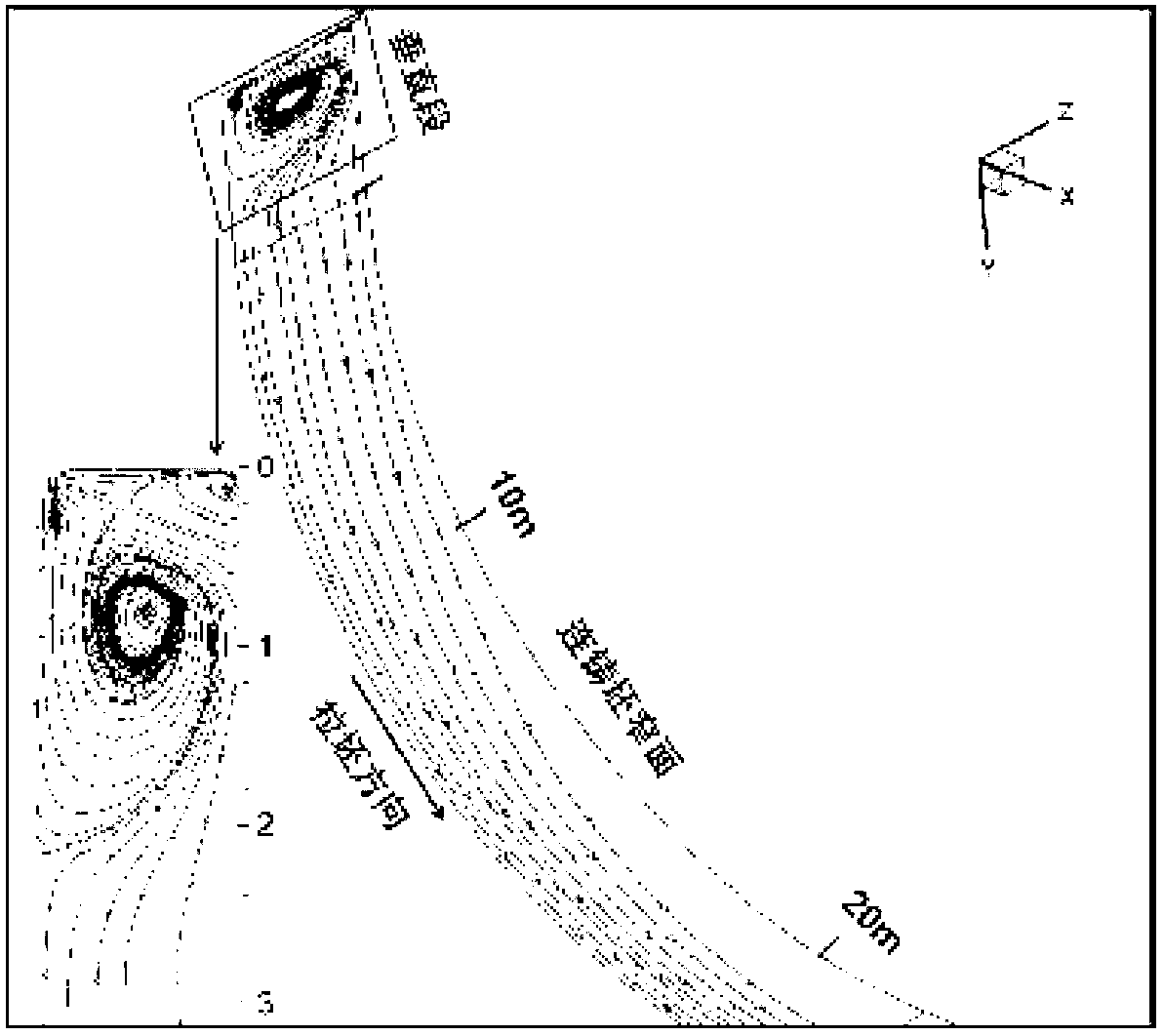

[0049] A method for determining the height of the vertical section of an extra-thick slab continuous casting machine to remove inclusions, including a straight-arc continuous casting machine, which includes a vertical support guide section 4, an arc support guide section 6, and a horizontal support guide Section 7, a mold 2 is set at the entrance of the vertical support and guide section 4. During the continuous casting process, the molten steel surface 1 is located in the mold, and the position below the mold 2 is the secondary cooling zone. The vertical support and guide section 4 is the vertical section The height 3 is the distance from the top of the crystallizer 2 to the bending point 5, such as figure 1 As shown, the determination steps are as follows:

[0050] 1) It is assumed that when the straight arc continuous casting machine produces continuous casting slab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com