A Calcium Treatment Method in the Vacuum Process of Rh Refining Furnace

A refining furnace and calcium treatment technology, applied in the field of iron and steel metallurgy, can solve the problems of secondary oxidation of molten steel, contaminated molten steel, exposed molten steel, etc., achieve sufficient denaturation, improve cleanliness, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

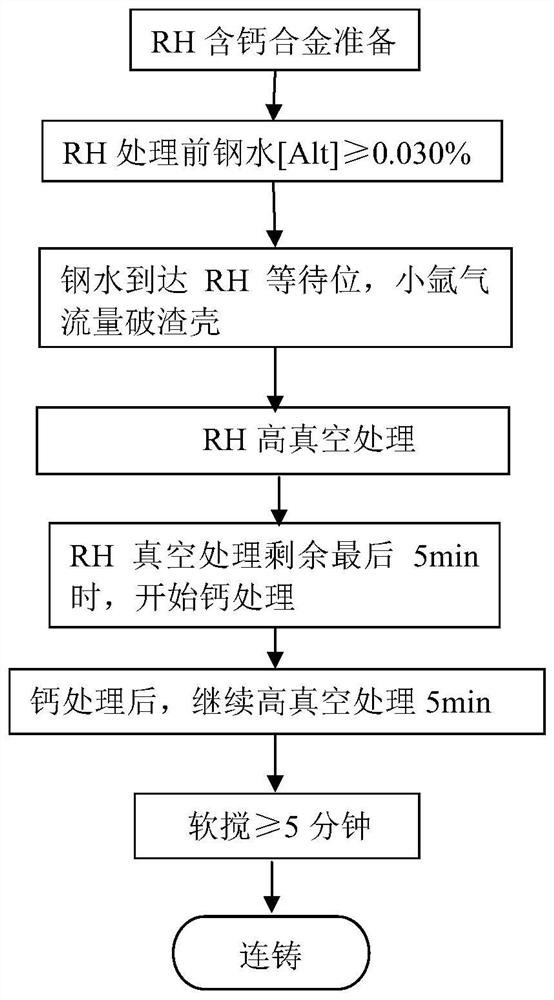

Method used

Image

Examples

Embodiment

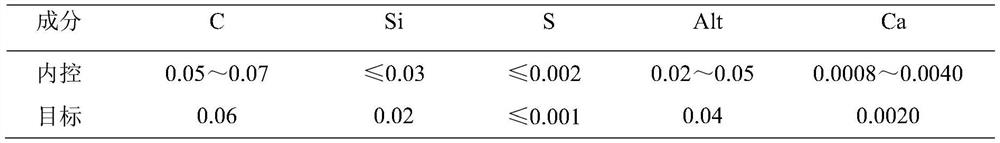

[0021] In this embodiment, X70 steel is selected, produced in a 150-ton RH vacuum refining furnace, and calcium-silicon alloy is used for calcium treatment. The main chemical composition of the steel is shown in Table 1. The entire smelting process is controlled as follows:

[0022] Table 1 X70 chemical composition (%)

[0023]

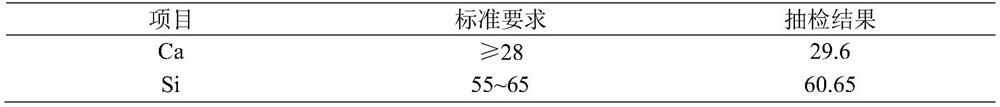

[0024] (1) Calcium silicon alloy preparation. The composition of silicon-calcium alloy is shown in Table 2.

[0025] Table 2 Calcium silicon alloy composition (%)

[0026]

[0027] Particle size: (10-50) mm is 96%, (0-10) mm is 1%, (50-60) mm is 3%.

[0028] (2) RH actually arrived at the molten steel composition. See Table 3.

[0029] Table 3 RH Arrival Molten Steel Composition (%)

[0030]

[0031] (3) RH vacuum calcium treatment, the vacuum degree is 98Pa, and 50Kg of silicon-calcium alloy is added to each furnace. After the addition, the vacuum degree is kept at 150Pa for 5 minutes. During the whole vacuum process, the flow rate of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com