Control method of rolling of central hole defect of continuously-cast thick blank

A technology of center hole and control method, applied in rolling mill control device, metal rolling, metal rolling, etc., can solve rough guidance, difficult to produce practical general guidance, can not reflect the influence of rolling parameters and rolling effect, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

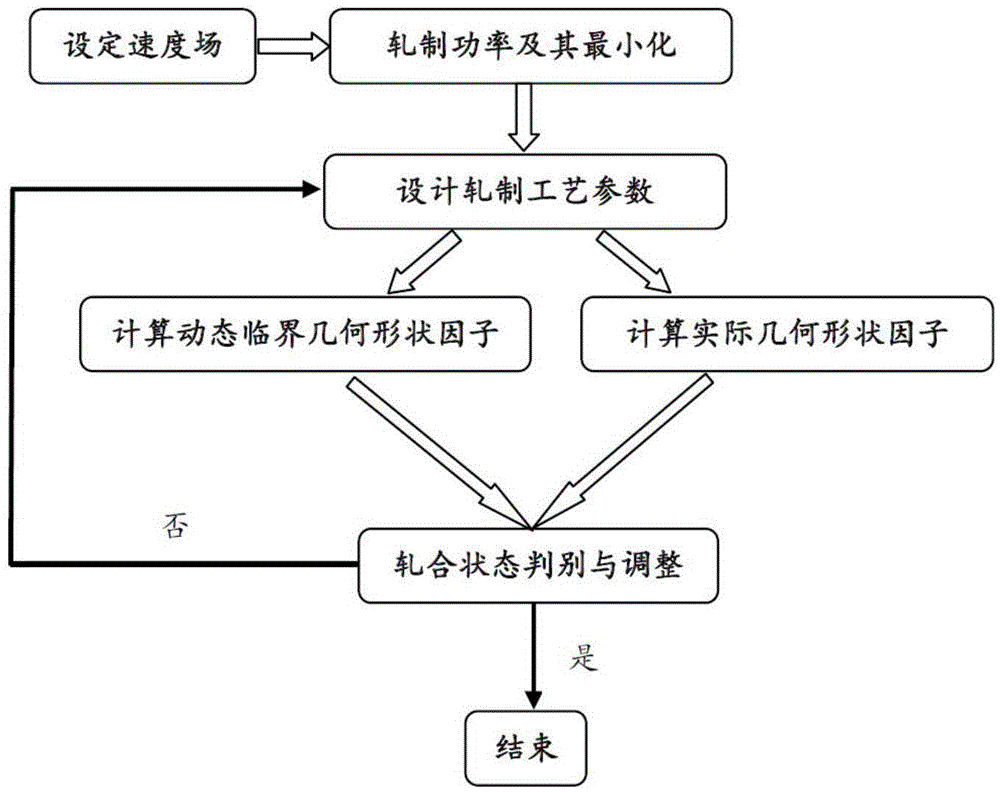

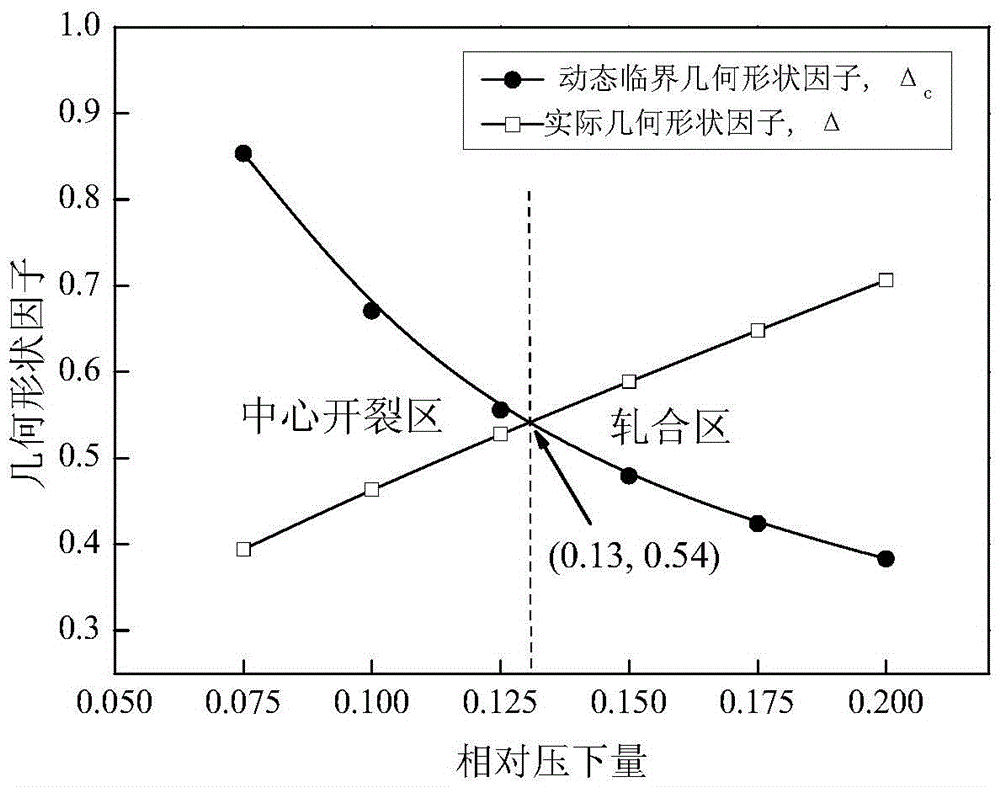

[0041] combine figure 1 As shown, the rolling control method for the center hole defect of the continuous casting slab includes the following steps.

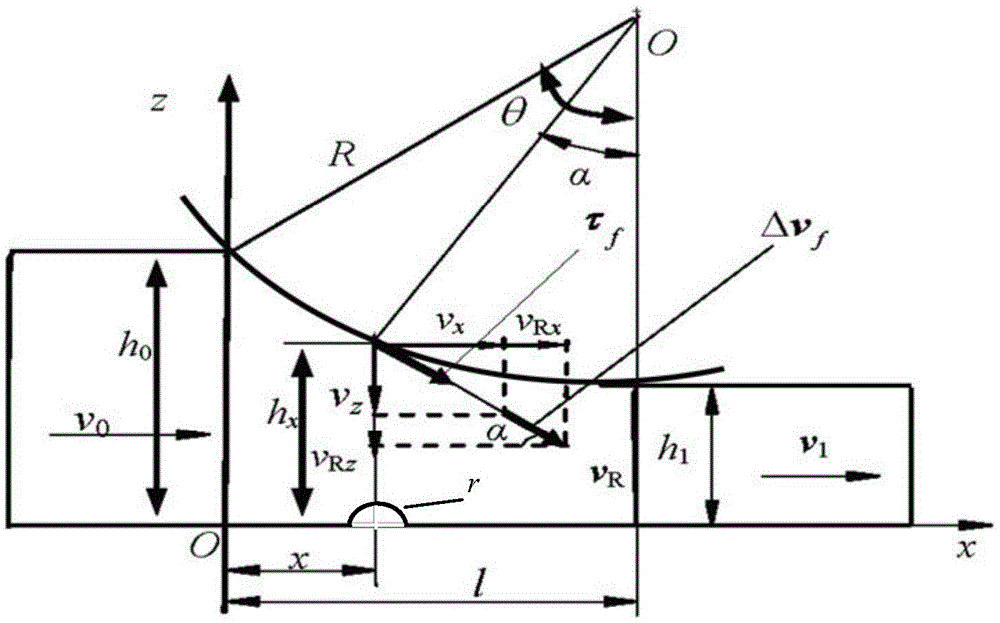

[0042] (1) Set the velocity field

[0043] According to the geometric characteristics of the circular hole in the center of the rolled piece, when the radius of the roll is R, the half-thickness of the rolled piece at the entrance is h 0 , the outlet half-thickness is h 1 , the inlet velocity v 0 , the half-thickness of the rolled piece in the deformation zone is h x , the length of the deformation zone is l, and the bite angle is θ, such as figure 2 As shown, the permissible velocity field and strain rate field of the circular hole defect movement are set as follows:

[0044] v x = U ( h x - r ) b , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com