Wide and thick plate continuous casting machine dry capping method

A continuous casting machine and wide and thick plate technology, which is applied in the field of dry capping of wide and thick plate continuous casting machines and continuous casting final casting capping technology, and can solve the problems of poor quality of tail blanks of wide and thick plate continuous casting machines, low flaw detection pass rate, and metal harvesting. Low rate and other problems, to achieve the effect of improving the pass rate of flaw detection and improving the surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

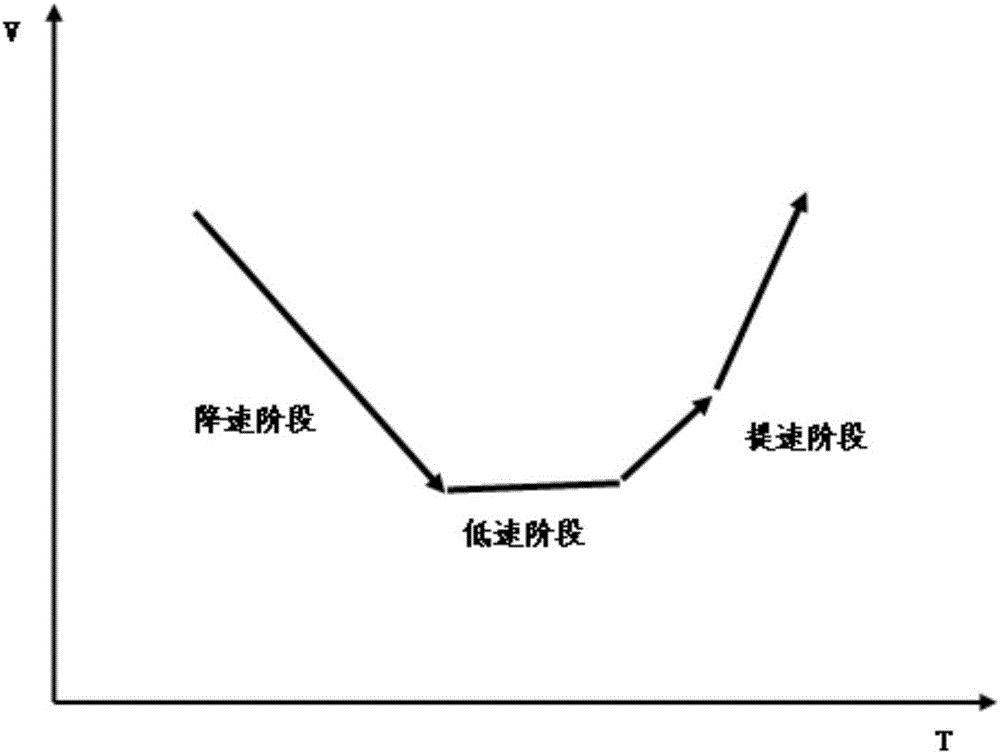

Embodiment 1

[0018] A steel mill adopts the method of the present invention for continuous casting slabs of medium-carbon low-alloy steel of 250mm*(1800-2400)mm. After the pouring cycle is completed and the ladle is stopped, the molten steel level in the tundish is measured. For the tonnage of the bale, when the remaining molten steel in the middle bag is 18t, the drawing speed will be uniformly reduced from the target pulling speed of 0.95m / min to 0.25m / min; when the remaining molten steel in the middle bag is 4t, the stopper shall be closed to stop pouring and at the same time The pulling speed is reduced to 0.15m / min, and the operation is maintained at a uniform speed. At this stage, no slag is added, but no slag removal operation is carried out; when the tailstock runs to the lower mouth of the mold, the speed is increased evenly according to the acceleration of 0.05m / min every 30s. When the pulling speed reaches 0.5m / min, the acceleration is increased by 0.1m / min every 20s to reach the ...

Embodiment 2

[0019] A steel mill adopts the method of the present invention for continuous casting slabs of medium-carbon low-alloy steel of 180mm*(1600-1800)mm. After the pouring cycle is completed, the molten steel level in the tundish is measured and the For the tonnage of the bale, when the remaining molten steel in the tundish is 16t, the drawing speed will be uniformly reduced from 1.1m / min to 0.25m / min; when the remaining molten steel in the tundish is 3t, the stopper will be closed to stop pouring, and the The pulling speed is reduced to 0.2m / min, and the operation is maintained at a constant speed. At this stage, no slag is added, but no slag removal operation; when the tailstock runs to the lower mouth of the crystallizer, the speed is increased evenly according to the acceleration of 0.05m / min every 20s. When the pulling speed reaches 0.5m / min, the acceleration is increased by 0.1m / min every 20s to reach the target pulling speed 1.2m / min. The tail billet is in weak cooling mode, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com