Manufacturing method for casting metal lithium target

A metal lithium and target material technology, which is applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems of low pass rate of flaw detection, shrinkage cavity, porosity, etc., so as to improve the pass rate of flaw detection. High density, simple and convenient process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] In the present invention, the preparation method comprises:

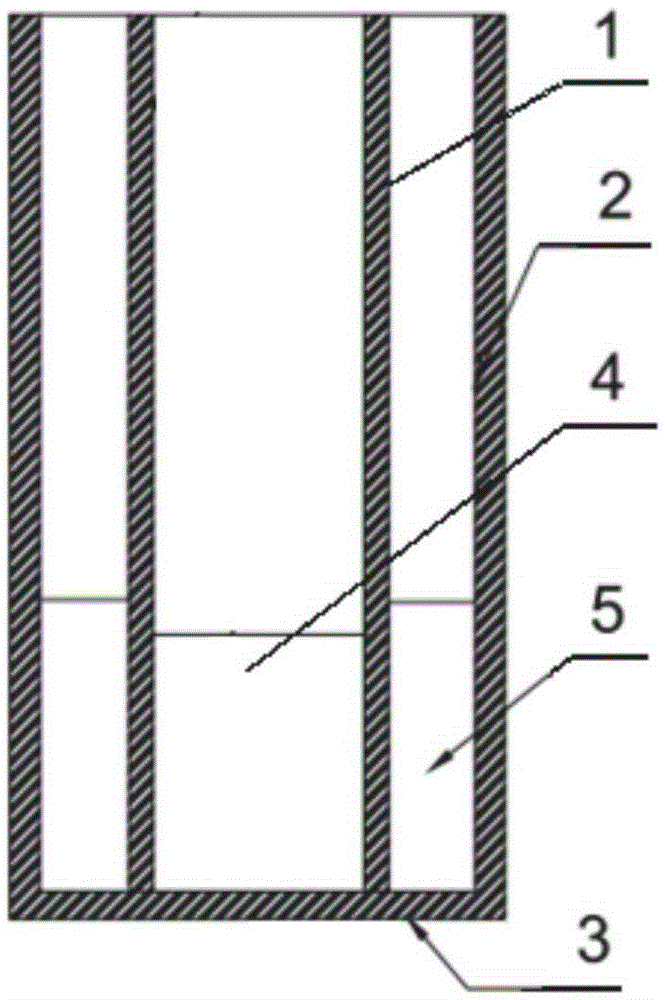

[0022] 1) Prepare the casting mold of metal lithium according to the required size, as attached figure 1 As shown, wherein, the middle part of the mold 2 is a stainless steel liner 1, and the stainless steel liner 1 is used to inject cooling liquid 4, and there is a casting metal lithium 5 for liquid metal lithium in the interlayer between the mold 2 and the stainless steel liner 1 , after solidification and forming, the shape is processed to form a metal lithium rotating target of the target size;

[0023] 2) Take the solid metal lithium of the required quality as a raw material, heat it to make it melt into a liquid state, and prepare for the casting process;

[0024] 3) In the temperature range of 200-230°C, slowly pour liquid cast metal lithium from above the mold. During the process of pouring metal lithium, slowly inject cooling liquid into the central stainless steel liner, the purpose is to make the ...

Embodiment 1

[0031] According to the required size, the inner diameter of the stainless steel liner 1 is 125mm, the outer diameter is 133mm, and the inner diameter of the mold 2 is 151mm. Take the required quality of solid metal lithium as the raw material, heat it to melt it into a liquid state, and at a temperature of 200°C Casting is carried out under the mold, that is, slowly pouring liquid metal lithium into the interlayer between the stainless steel liner 1 and the mold 2 from above the mold at a speed of 8kg / min. During the process of pouring metal lithium, in the stainless steel liner Slowly pour the cooling liquid, the time lag does not exceed 2min, the cooling liquid injection speed is 10L / min, the liquid cast metal lithium is solidified and formed to form a metal lithium target, the purpose is to make the liquid metal lithium slowly directional cooling and solidification from bottom to top, This is beneficial to eliminate the lower pores and shrinkage cavities; after all the soli...

Embodiment 2

[0033] According to the required size, the inner diameter of the stainless steel liner 1 is 125mm, the outer diameter is 133mm, and the inner diameter of the mold 2 is 160mm. Take the required quality of solid metal lithium as the raw material, heat it to melt it into a liquid state, and at a temperature of 250°C Casting, that is, slowly pouring liquid pouring metal lithium into the interlayer between the stainless steel liner 1 and the mold 2 from above the mold at a speed of 8kg / min, during the process of pouring metal lithium, slowly pouring into the stainless steel liner The cooling liquid is poured in, the time lag is not more than 2min, and the injection speed of the cooling liquid is 8L / min. The liquid cast metal lithium is solidified and formed to form a metal lithium target. The purpose is to make the liquid metal lithium slowly and directionally cool and solidify from bottom to top. It is beneficial to eliminate the lower air holes and shrinkage cavities; after all so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com