Patents

Literature

31results about How to "Moderate elongation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

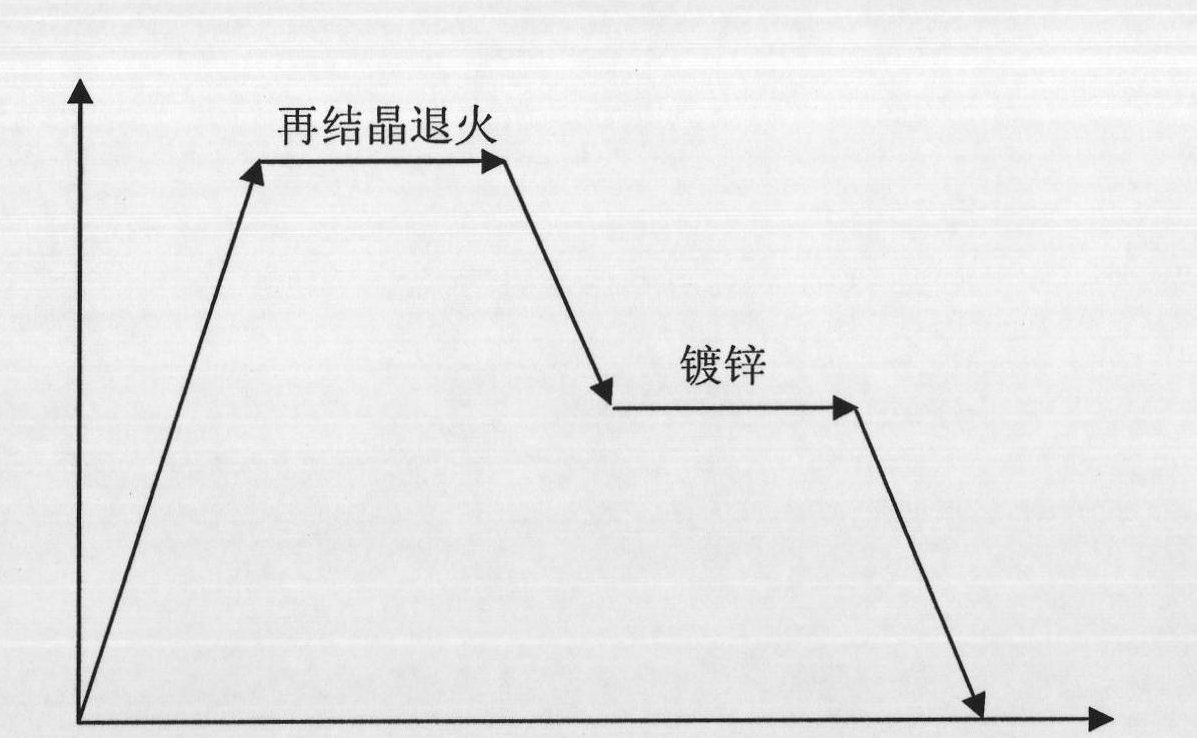

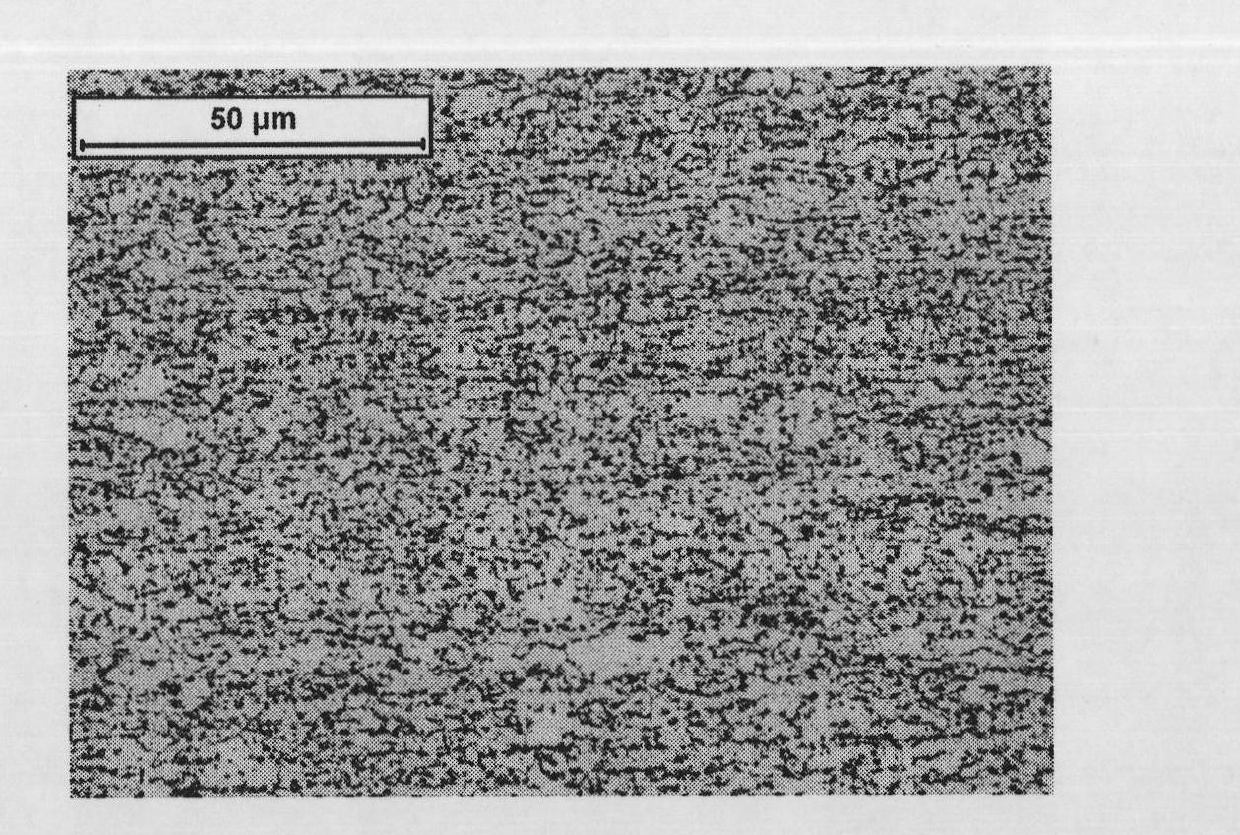

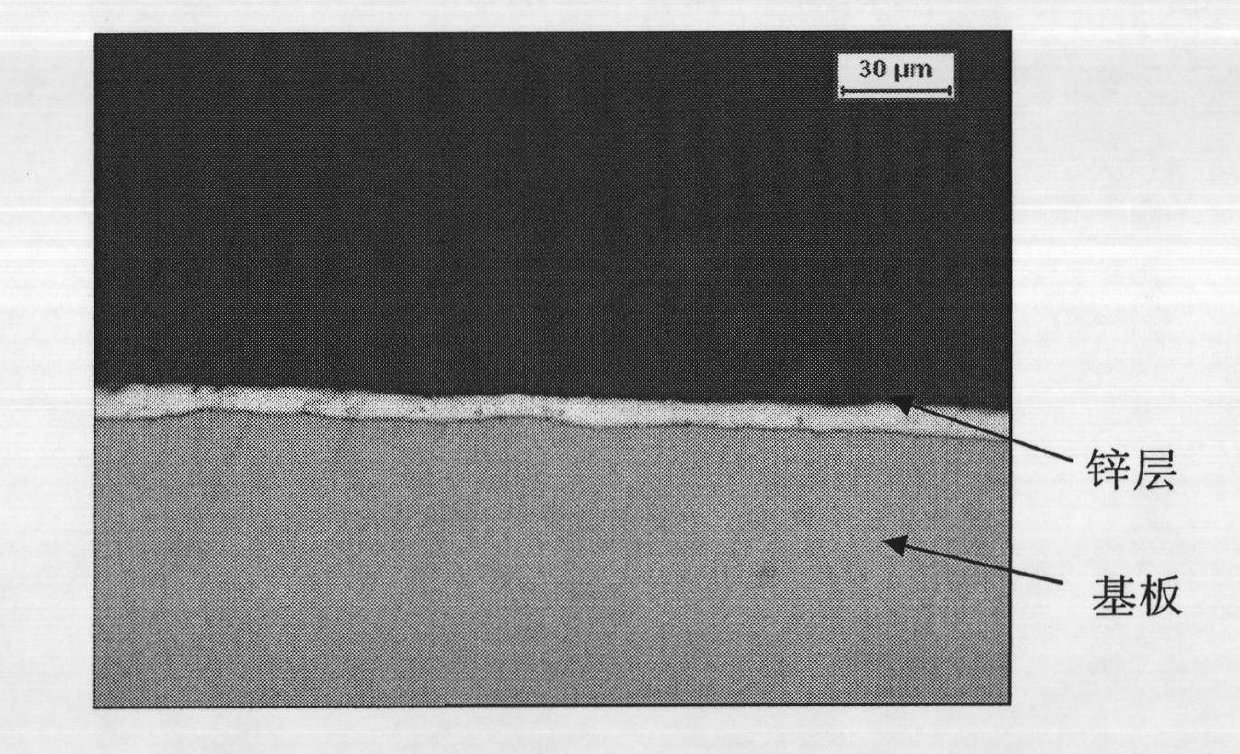

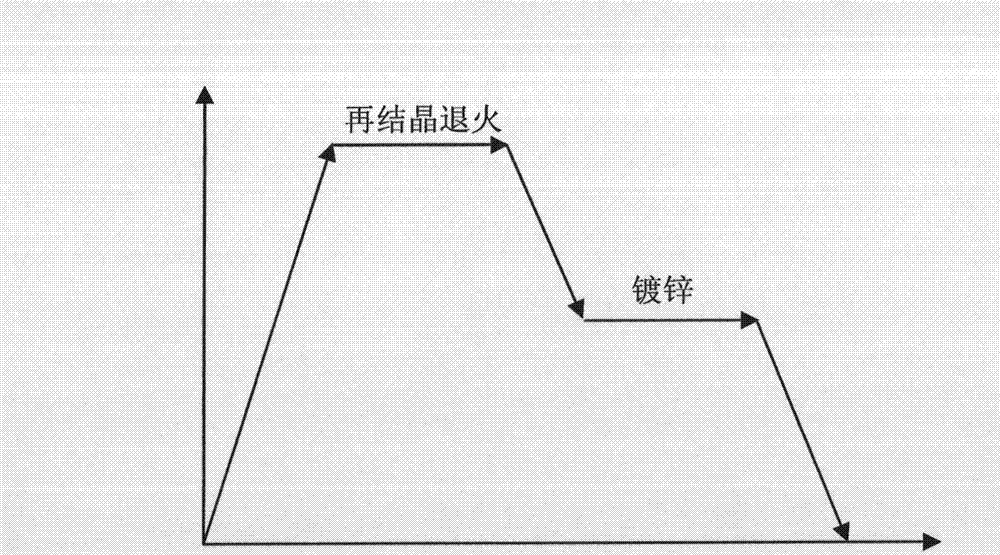

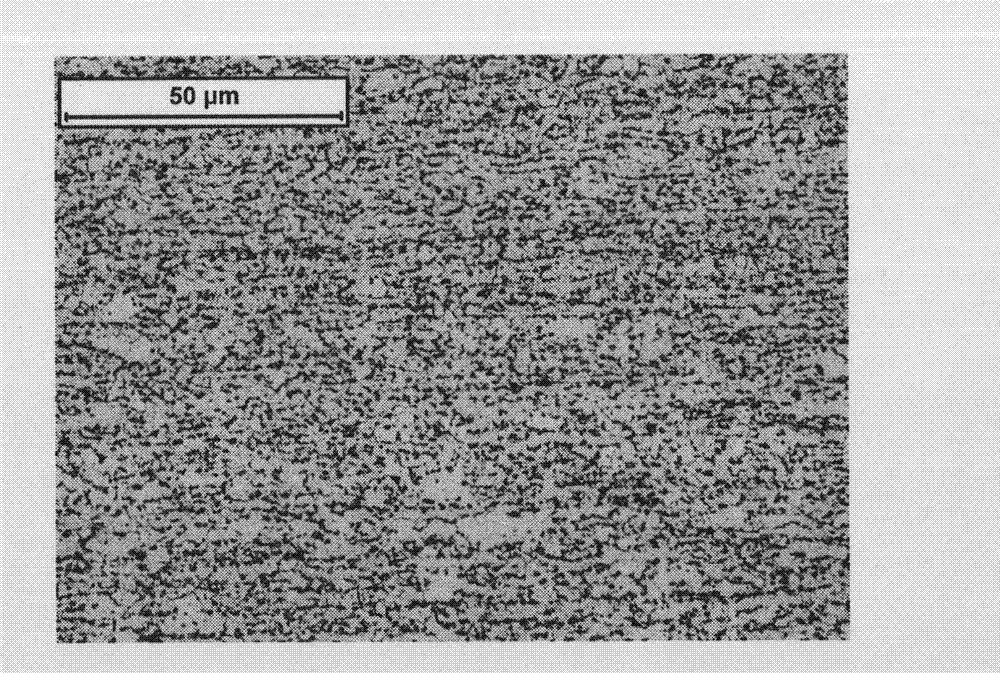

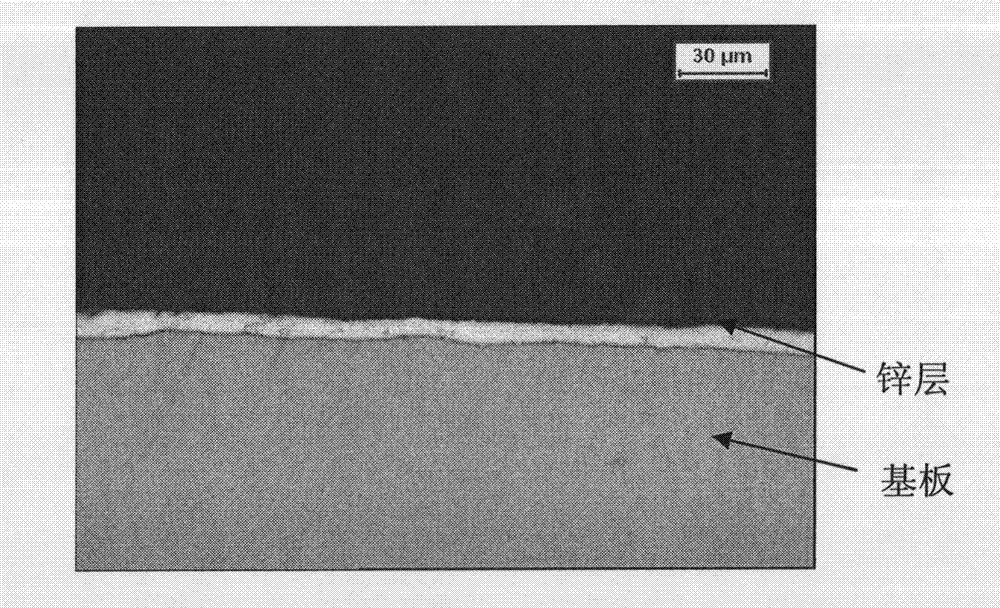

High-strength cold-rolled hot-galvanized precipitation reinforced steel and manufacturing method thereof

ActiveCN102199723AGood welding performancePremium surface qualityTemperature control deviceMetal rolling arrangementsSheet steelImpurity

The invention discloses a high-strength cold-rolled hot-galvanized precipitation reinforced steel plate and a manufacturing method thereof. The steel plate comprises the following components: 0.09 to 0.12 weight percent of C, less than or equal to 0.05 weight percent of Si, 0.8 to 1.8 weight percent of Mn, less than or equal to 0.02 weight percent of P, less than or equal to 0.01 weight percent of S, less than or equal to 0.008 weight percent of N, 0.02 to 0.06 weight percent of Al, 0.05 to 0.08 weight percent of Nb and Ti and the balance of Fe and inevitable impurities. The microstructure ofthe steel plate is ferrite and second phase particles, wherein the diameter of the second phase particles is about less than 6 mu m, the yield strength is 500 to 600MPa, the tensile strength is 570 to 710MPa, and the total coefficient of elongation is over 14 percent (80 gauge length and transverse stretching). The hot-galvanized steel plate has high welding performance and surface quality and can be widely used in automotive structural membranes.

Owner:BAOSHAN IRON & STEEL CO LTD

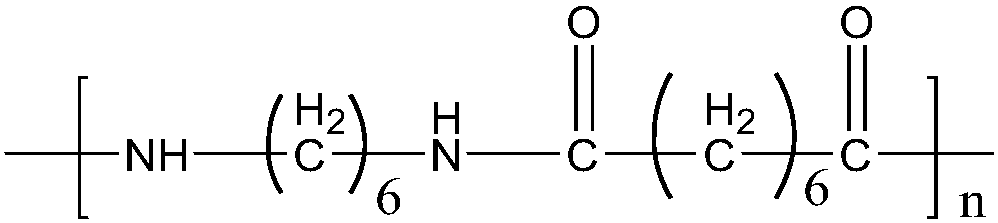

Binder for electrode material containing semi-ipn of polyvinyl alcohol and polyurethane and lithium secondary battery employed with the same

ActiveUS20100047693A1High bonding strengthImprove electrolyte resistanceSilver accumulatorsConductive materialInterpenetrating polymer networkCurrent collector

Provided is a binder for an electrode mix containing a semi-interpenetrating polymer network (semi-IPN) of polyvinyl alcohol and polyurethane, wherein the polyurethane is mixed to crosslink with the polyvinyl alcohol to form semi-IPN, and a lithium secondary battery comprising the same. The binder has superior adhesion to the electrode, excellent electrolyte resistance and improved elongation percentage, and therefore it is possible to prevent exfoliation or separation of electrode active materials from current collectors which occurs during repeated charge / discharge cycles. As a result, the capacity or power out of secondary batteries can be maintained at a constant level.

Owner:LG CHEM LTD

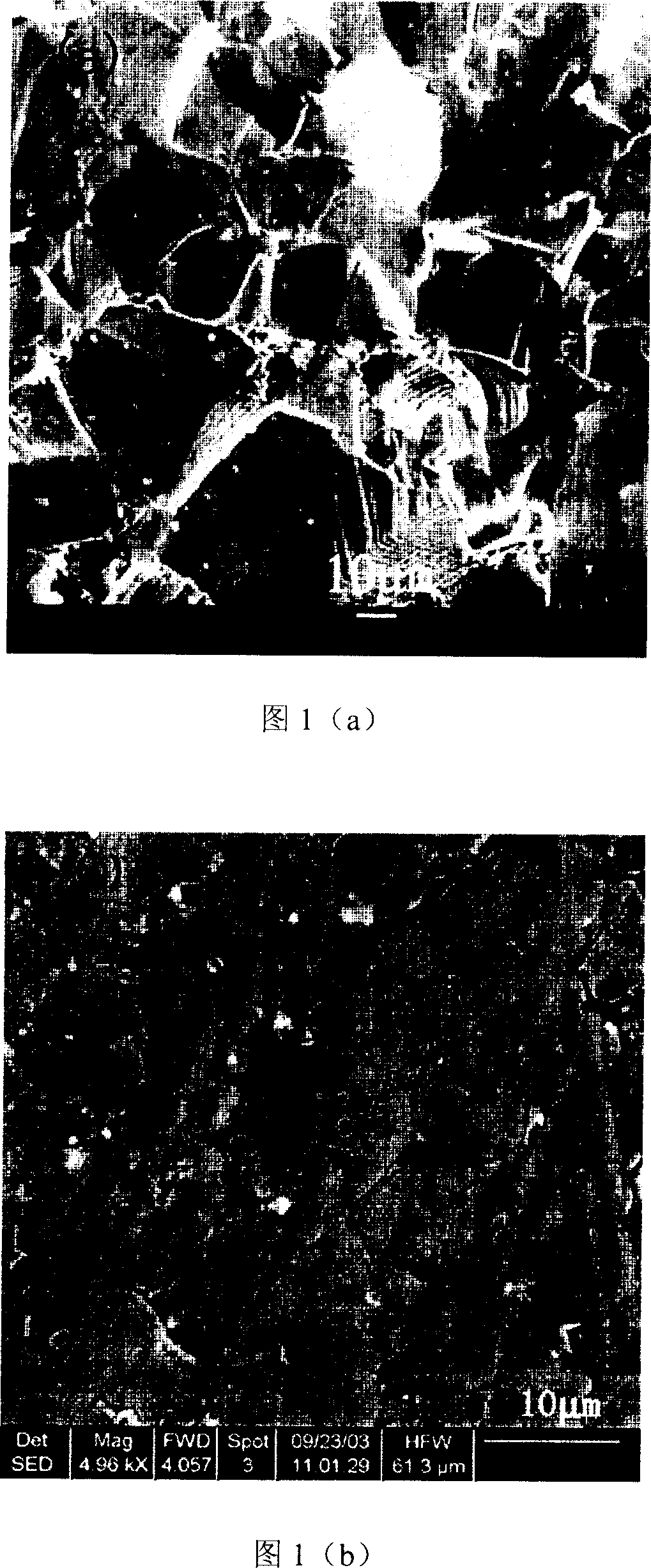

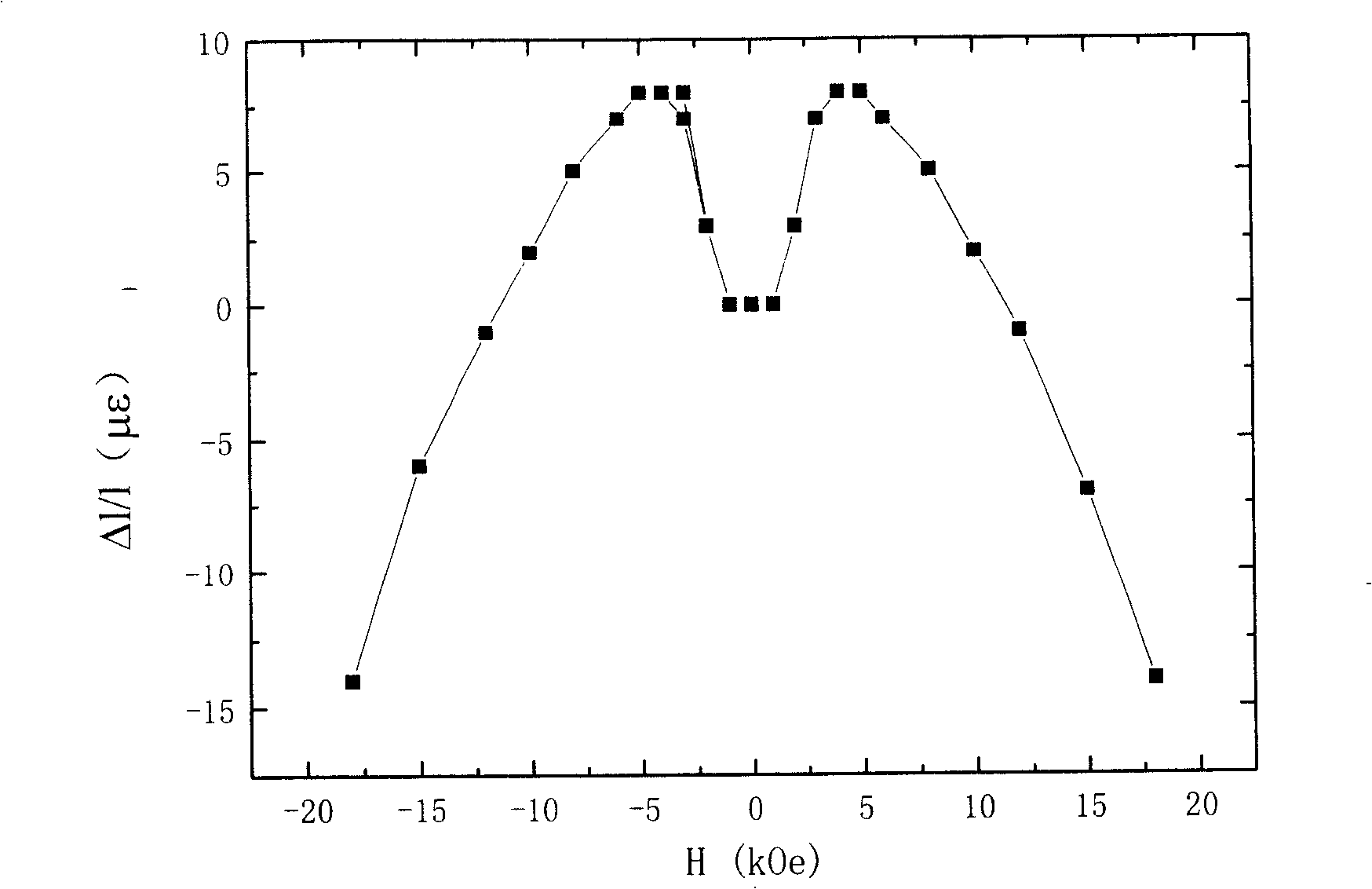

Method for preparing rolling anisotropic magnetic powder and magnet

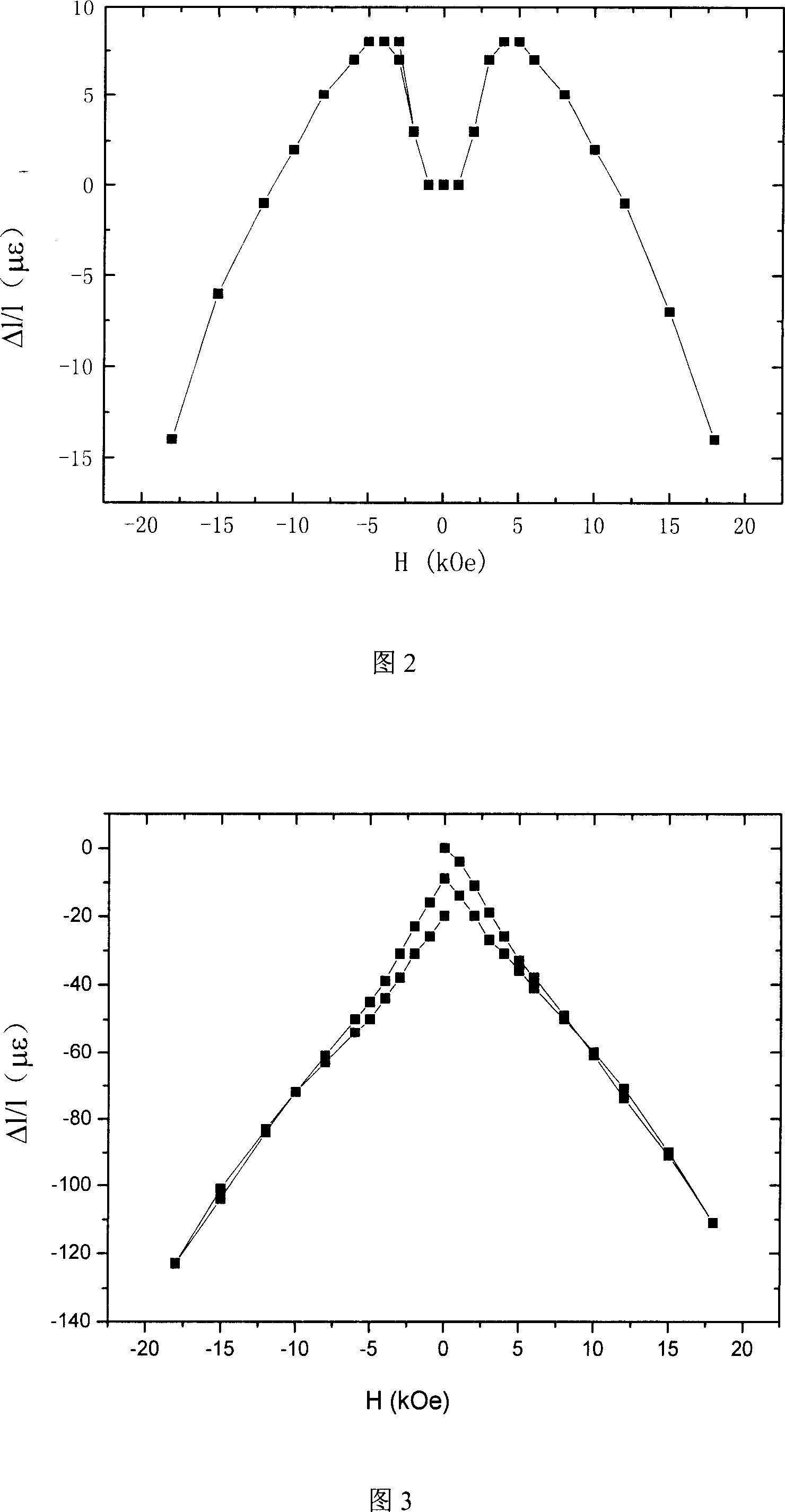

ActiveCN1937111AHigh residual magnetic inductionImprove coercive forceInorganic material magnetismInductances/transformers/magnets manufactureExtensibilitySingle crystal

Using specific technique of rapid hardening slice produces alloy based on neodymium (or praseodymium) iron. Then, through reaction of gas-solid phase, crumbling procedure produces RxFe100-x-y-zMyIz magnetic powder. The magnetic powder is single crystal grain in sheet form with average grain size as 1-3 micro. The magnetic powder produced by the disclosed technique possesses anisotropy of magnetocrystalline under action of external magnetic field as well as rolling anisotropy and stress anisotropy. Based on three kinds of anisotropy, the invention discloses method for preparing high performance flexible rubber magnet with rolling anisotropy. The prepared flexible magnet possesses excellent magnetism, flat surface, good cohesiveness, and feasible mechanical properties including tensile strength, extensibility, and rigidity as well as characteristics of temperature resisting, moisture resistance, oil proof and anticorrosion.

Owner:NINGXIA MAGVALLEY NOVEL MATERIALS TECH CO LTD

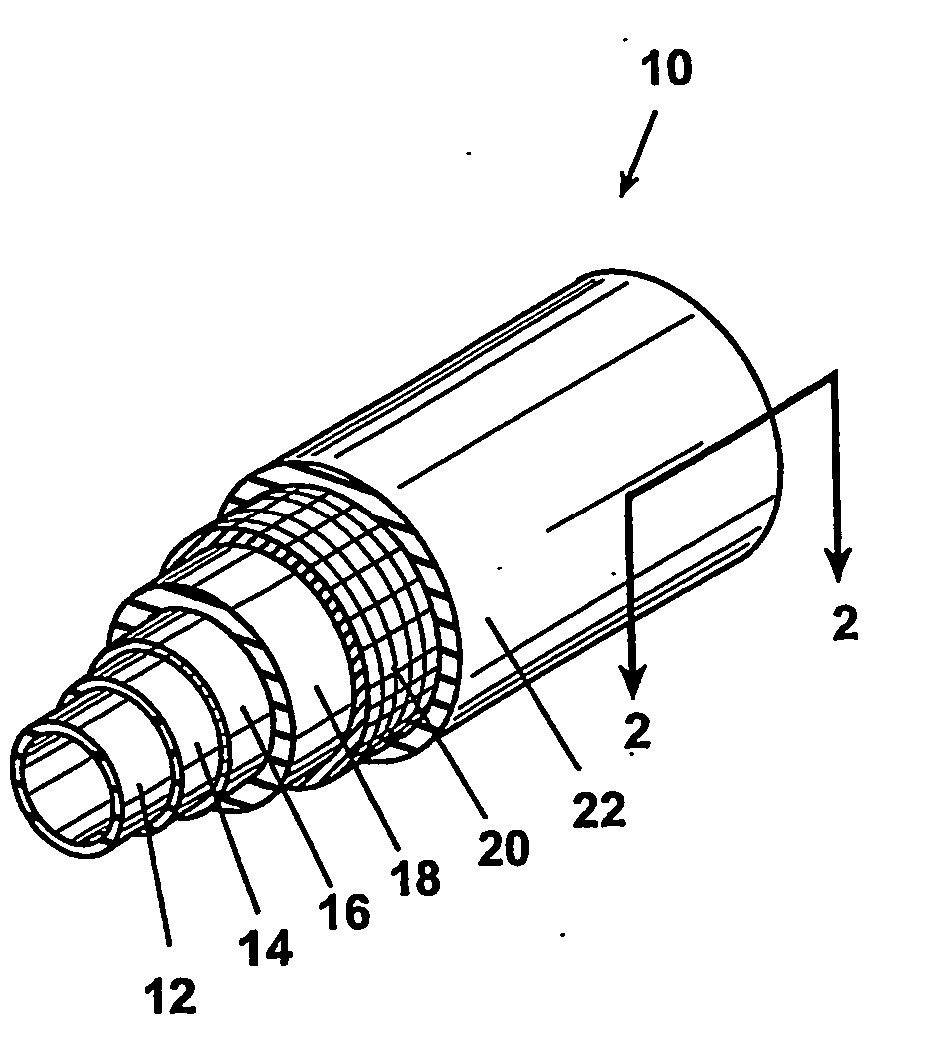

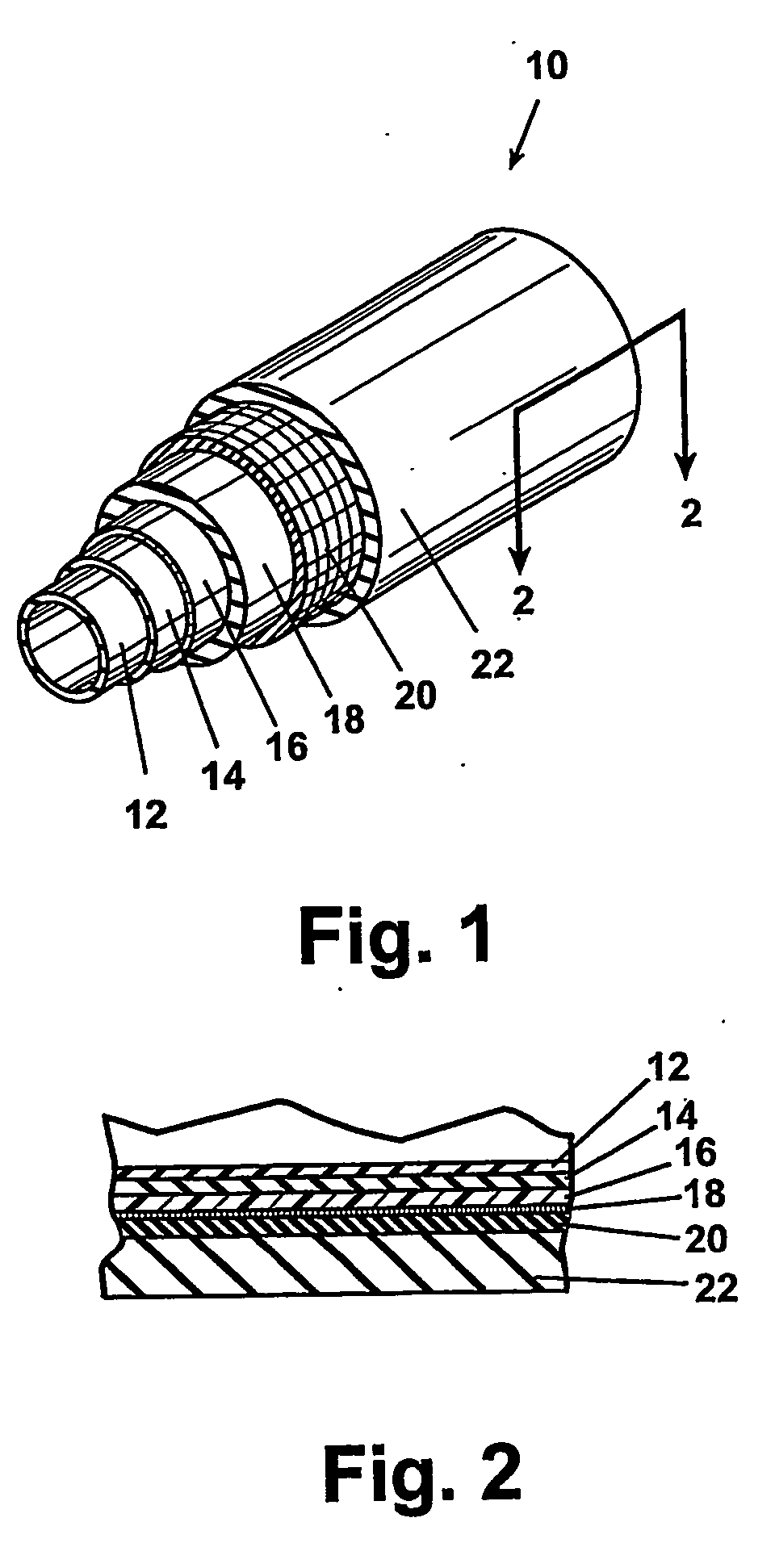

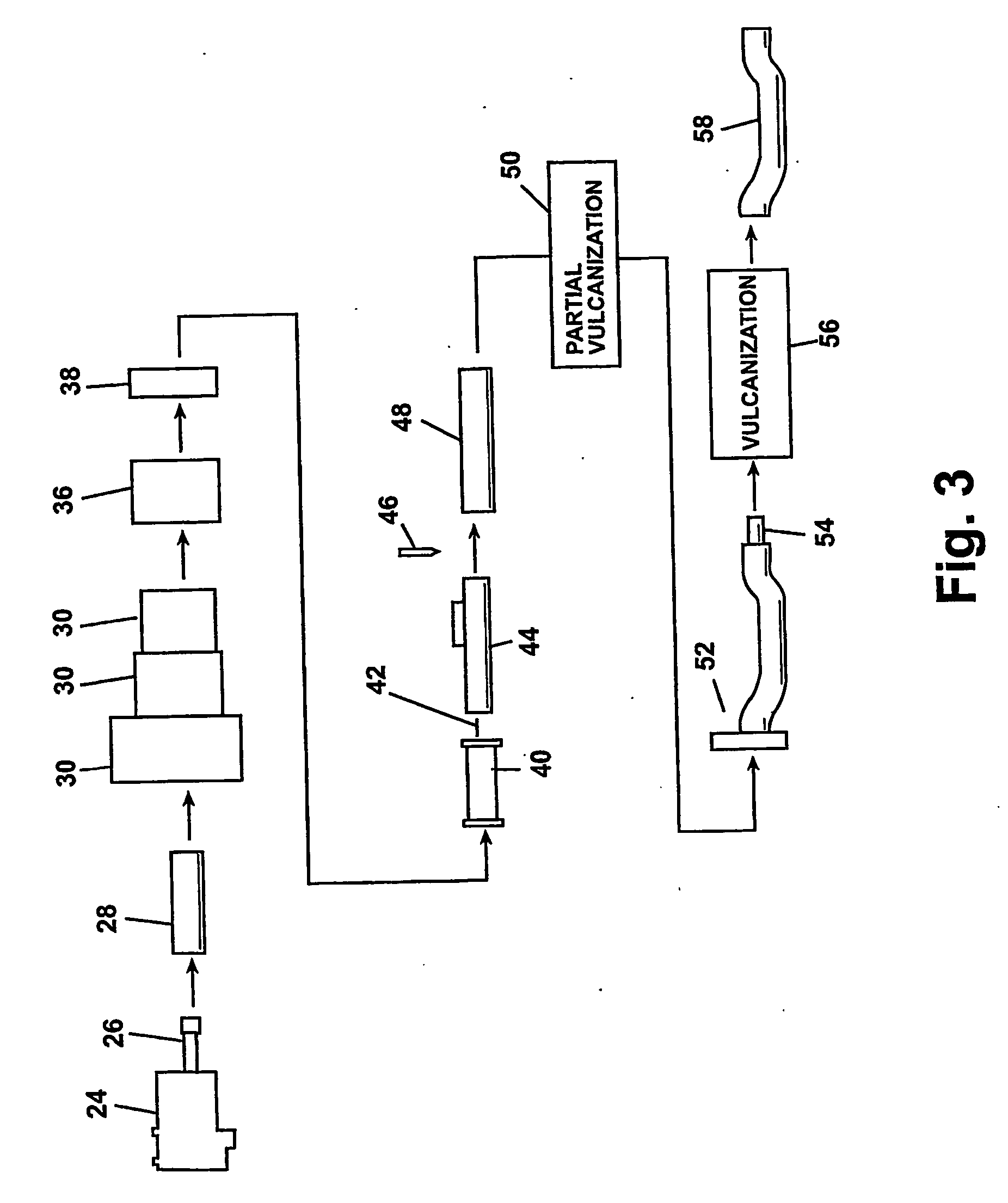

Fuel filler hose

InactiveUS20070065616A1Improve impermeabilityReduce penetrationSynthetic resin layered productsFlexible pipesElastomerThermoplastic

A flexible tubular article for transport of volatile hydrocarbons permitting only negligible escape of such vapors comprises: (a) a relatively thin, inner layer of an elastomeric form of an FKM fluoropolymer, and (b) one of more relatively thin intermediate layer of a thermoplastic form of an THV fluoropolymer extruded in tubular form over the inner FKM layer, the FKM inner layer and the intermediate THV layers together having a transverse thickness sufficient to present a substantial barrier to volatile hydrocarbon escape, and (c) a durable outer layer of an elastomeric polymer bonded to the outside surface of the intermediate layer and being coextensive therewith. The intermediate layers having increasing amounts of fluorine content and at least on the intermediate layers comprises a THV grade 800.

Owner:CADILLAC RUBBER & PLASTICS +1

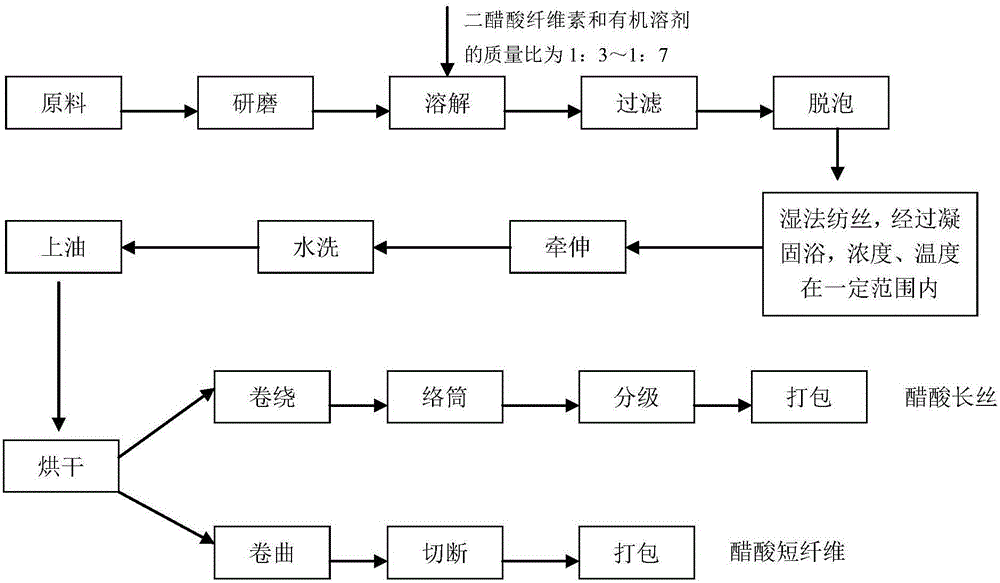

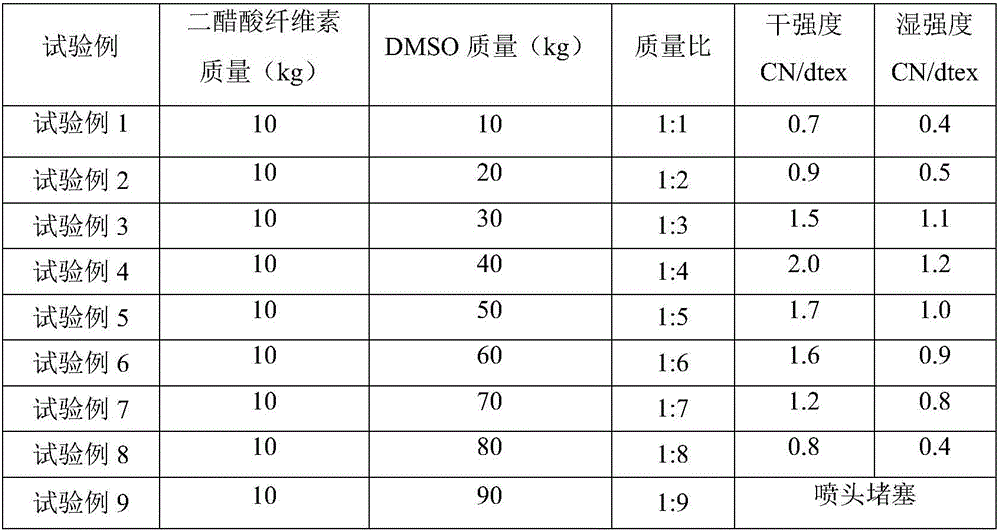

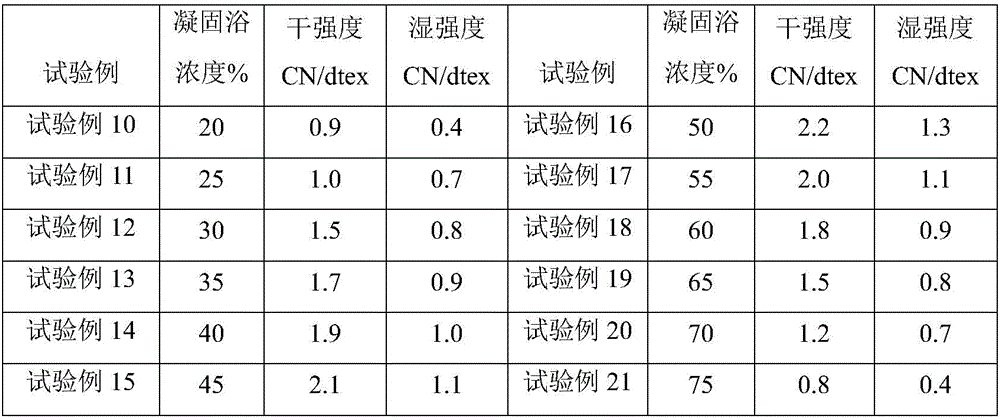

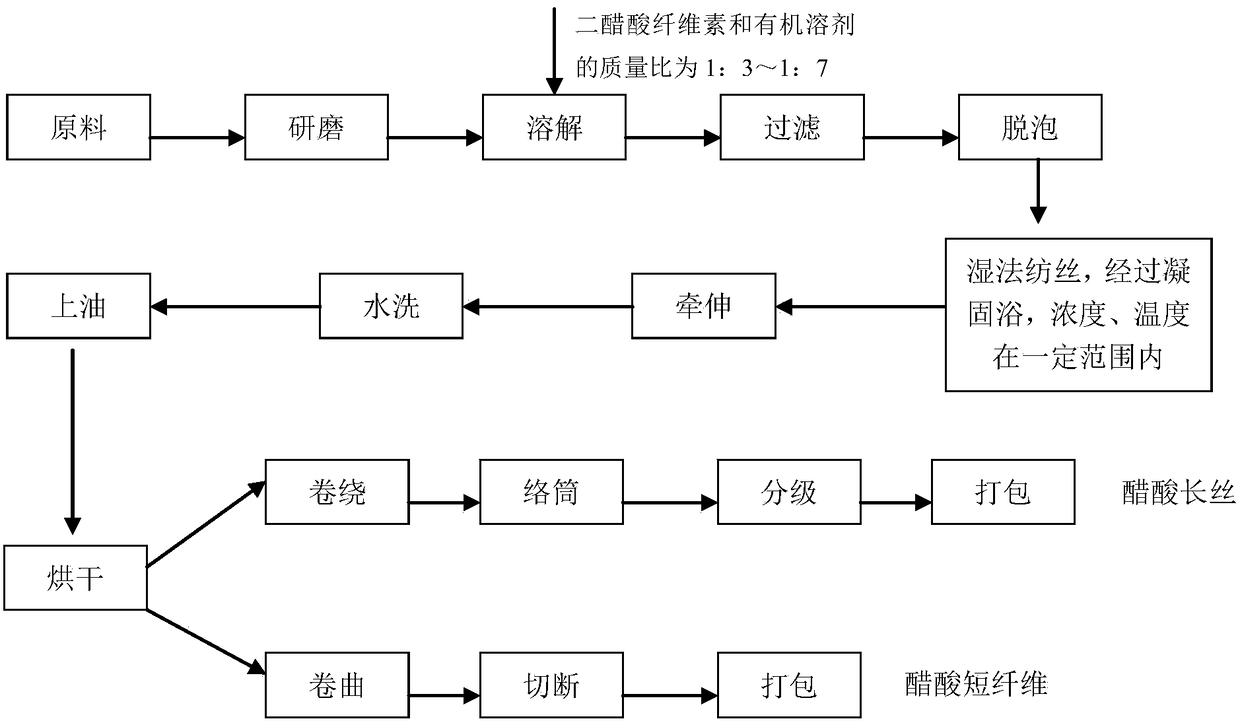

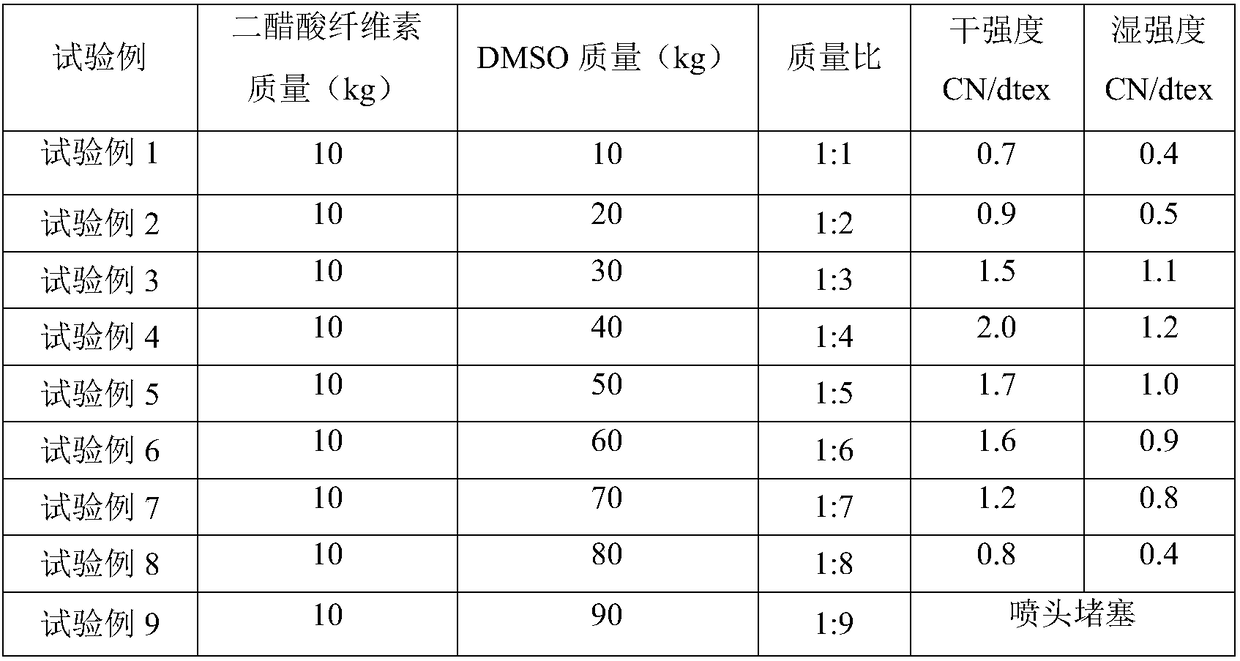

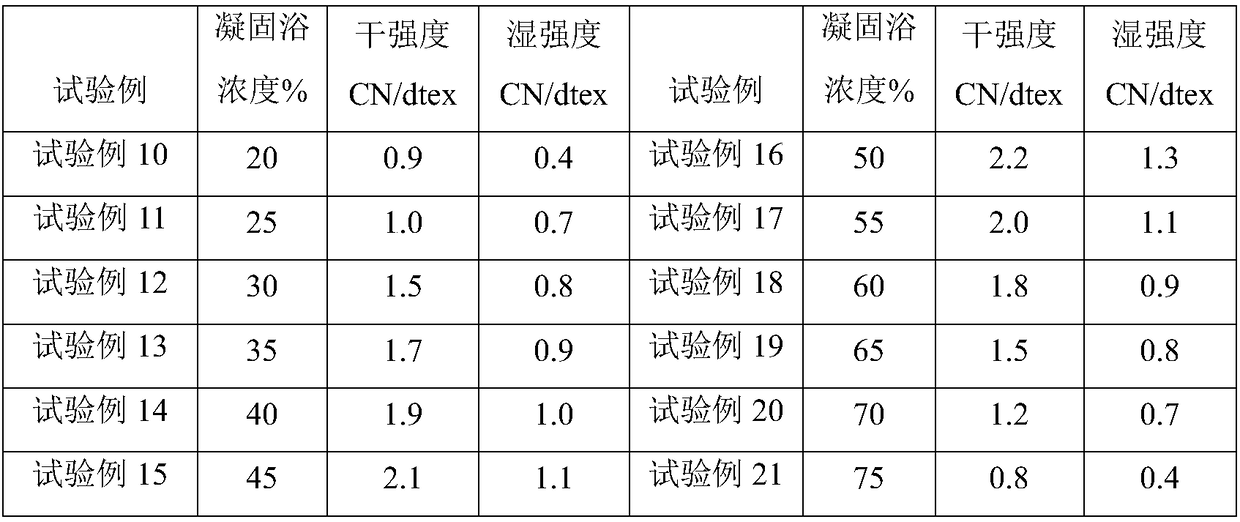

Wet spinning method for preparing cellulose acetate fiber

ActiveCN106012076AReduce pollutionImprove production environmentArtificial filaments from cellulose derivativesFiberCellulose diacetate

The invention discloses a wet spinning method for preparing cellulose acetate fiber. The wet spinning method comprises the following steps: grinding solid cellulose diacetate, of which the degree of acetylation is 2.1 to 2.8 and the water content is 1 to 7 percent, into powder; adding the cellulose diacetate powder and an organic solvent into a dissolving tank, and carrying out sufficient stirring for mixing, and raising the temperature for dissolution, wherein the mass ratio of the cellulose diacetate powder to the organic solvent ranges from 1:3 to 1:7, the dissolving time is 0.5 to 8 hours, and the dissolving temperature is 35 to 120 DEG C; filtering and deforming a dope obtained after dissolution to obtain a spinning dope; after the spinning dope passes through a metering pump and a filter, spraying the filtered spinning dope from spinneret orifices to enter a coagulation bath to obtain nascent fiber, wherein the concentration of the coagulation bath is 25 to 70%, and the temperature is 20 to 90 DEG C; preparing a finished acetate fiber product from the nascent fiber through drafting, washing, oiling and drying. The cellulose acetate fiber prepared according to the method disclosed by the invention has excellent indexes, good mechanical properties, and remarkably improved dry strength and wet strength; the preparation process is simple, feasible, and easy to control; the solvent cost is low.

Owner:吉林富博纤维研究院有限公司

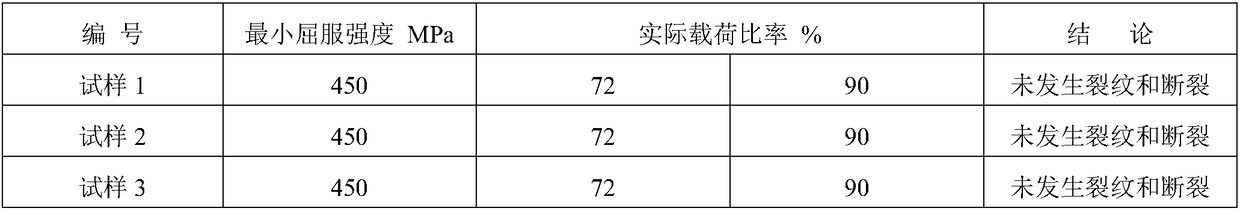

Making method of nine-striped car child seat safety woven belt

InactiveCN103088588AHigh strengthImprove wear resistanceFibre treatmentSelvedgesNon toxicityWear resistance

The invention relates to a making method of a nine-striped car child seat safety woven belt. The method mainly comprises the following steps: warping warps on a special device in a specific tension environment, respectively putting warped beams on a special weaving machine, weaving, and carrying out a dyeing and finishing operation on a special dyeing and finishing device under a specific technological condition to obtain the nine-striped car child seat safety woven belt. Compared with car child seat safety woven belts made in the prior art, the nine-striped car child seat safety woven belt made through adopting the making method has the advantages of high strength, good abrasion resistance, moderate elongation rate, high light resistance, non-toxicity, good flame resistance, good edge self-lock thread running resistance and the like, so the nine-striped car child seat safety woven belt provides a high safety guarantee for babies and children in motor vehicles.

Owner:SHANGHAI ACE WEBBING

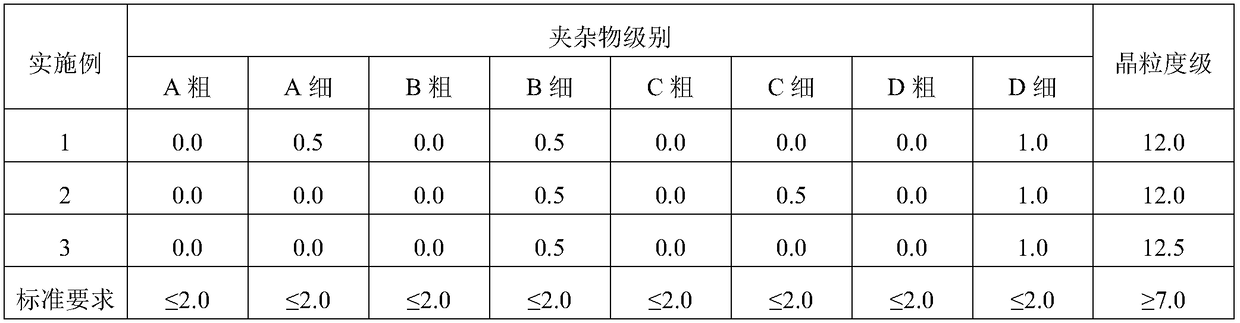

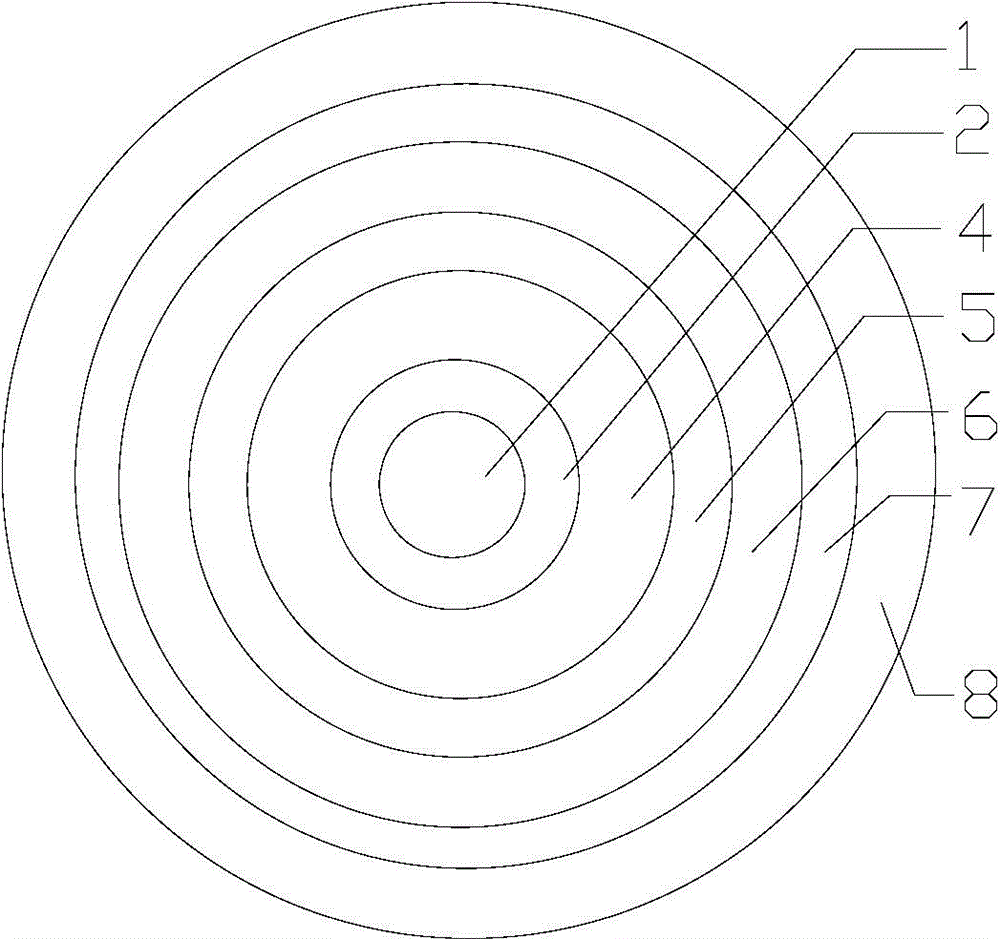

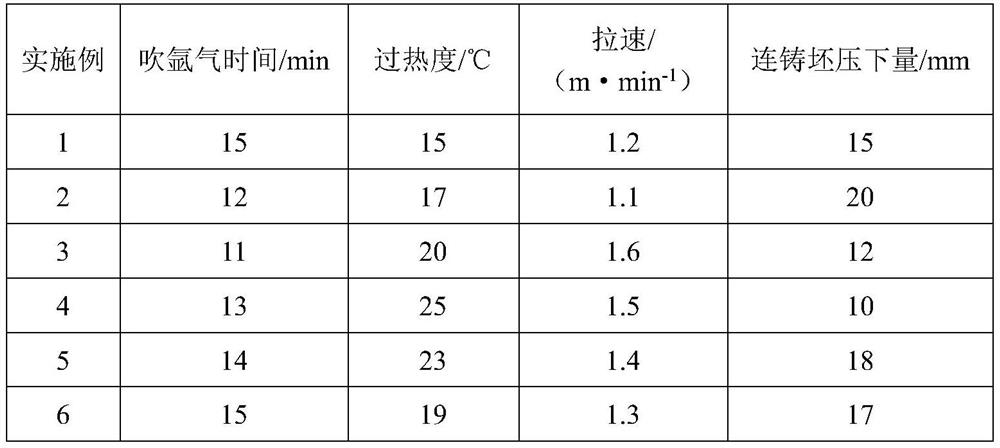

Acidic corrosion resistant X60MS pipeline steel and preparation method thereof

InactiveCN108411194AGood welding performanceImproved anti-HIC performanceProcess efficiency improvementGas emission reductionMetallurgyEnergy consumption

The invention discloses acidic corrosion resistant X60MS pipeline steel. The acidic corrosion resistant X60MS pipeline steel comprises the following components of, by weight percent, 0.05-0.07% of C,0.10-0.20% of Si, 0.90-1.10% of Mn, less than or equal to 0.010% of P, less than or equal to 0.002% of S, 0.020-0.030% of Nb, 0.010-0.020% of Ti, 0.020-0.040% of Al and 0.20-0.30% of Cr. The inventionfurther discloses a preparation method of the acidic corrosion resistant X60MS pipeline steel. According to the acidic corrosion resistant X60MS pipeline steel and the preparation method thereof, theweldability, the HIC resistance and the drop hammer tearing resistance of the X60MS pipeline steel are improved; the production efficiency of the X60MS pipeline steel is improved substantially; energy consumption and the production cost are lowered; the service life is prolonged; the transportation safety of petroligenic natural gas is improved; and the requirements of socioeconomic development are met advantageously.

Owner:BAOTOU IRON & STEEL GRP

Method for preparing five-stripe secure fabric tape for automobile children's seat

InactiveCN106337233AHigh strengthImprove wear resistanceWarping machinesLiquid/gas/vapor removalState of artSafety control

The invention relates to a method for preparing five-stripe secure fabric tape for automobile children's seat. The method comprises following steps: first, warp is subjected to beam-warping under specific tension environment on a special device; then the well warped warp beams are installed on a special weaving machine for weaving; finally, dyeing and finishing are processed on a special dyeing and finishing machine with a specific technology to obtain products. Compared with the prior art, the secure fabric tape for automobile children's seats prepared by the method of the invention has high strength, good wear resistance, moderate elongation percentage, high light resistance, good flame resistance, edge self-locking line type thread off prevention and is nontoxic; better safety control is provided for babies and children who take the automobiles.

Owner:SHANGHAI ACE WEBBING

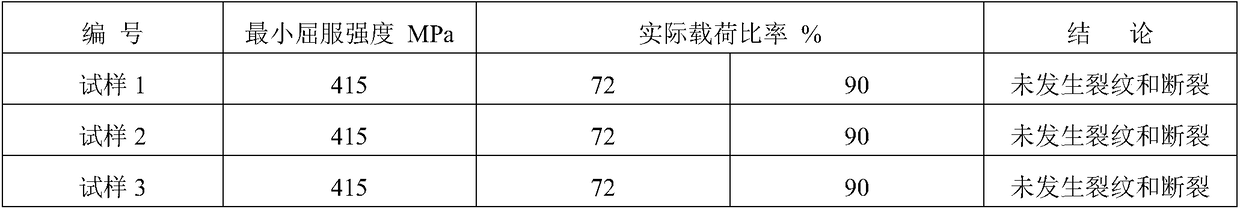

Preparation method for acetate fiber through dry-wet process

InactiveCN104032399AHigh degree of polymerizationModerate elongationArtificial filaments from cellulose solutionsWater contentSolvent

The invention discloses a preparation method for acetate fiber through a dry-wet process. The preparation method comprises: taking glacial acetic acid with the water content of 1-15% as a solvent, preparing a solution of acetate fiber with the concentration of 12%-24%, wherein the acetate fiber has the substitution degree of 2.0-2.9 and the polymerization degree of 300-800, stirring at 30-80 DEG C for 2-6 h for dissolving, so as to form a cellulose acetate spinning solution; extruding the deaerated spinning solution through a spinning head, making through an air layer with the thickness of 50-500 mm and sending into coagulation bath with a temperature of 20-60 DEG C, so as to form nascent fiber; and then performing stretching, water washing, drying, oiling and other post-treatment technologies, so as to prepare an acetate fiber finished product. The preparation method is used to produce acetate fiber, the finished product has relatively high polymerization degree, relatively good mechanical properties and relatively wide application fields, also production-equipment investment is relatively low and pollution is relatively less in the production process.

Owner:NANTONG CELLULOSE FIBERS CO LTD +1

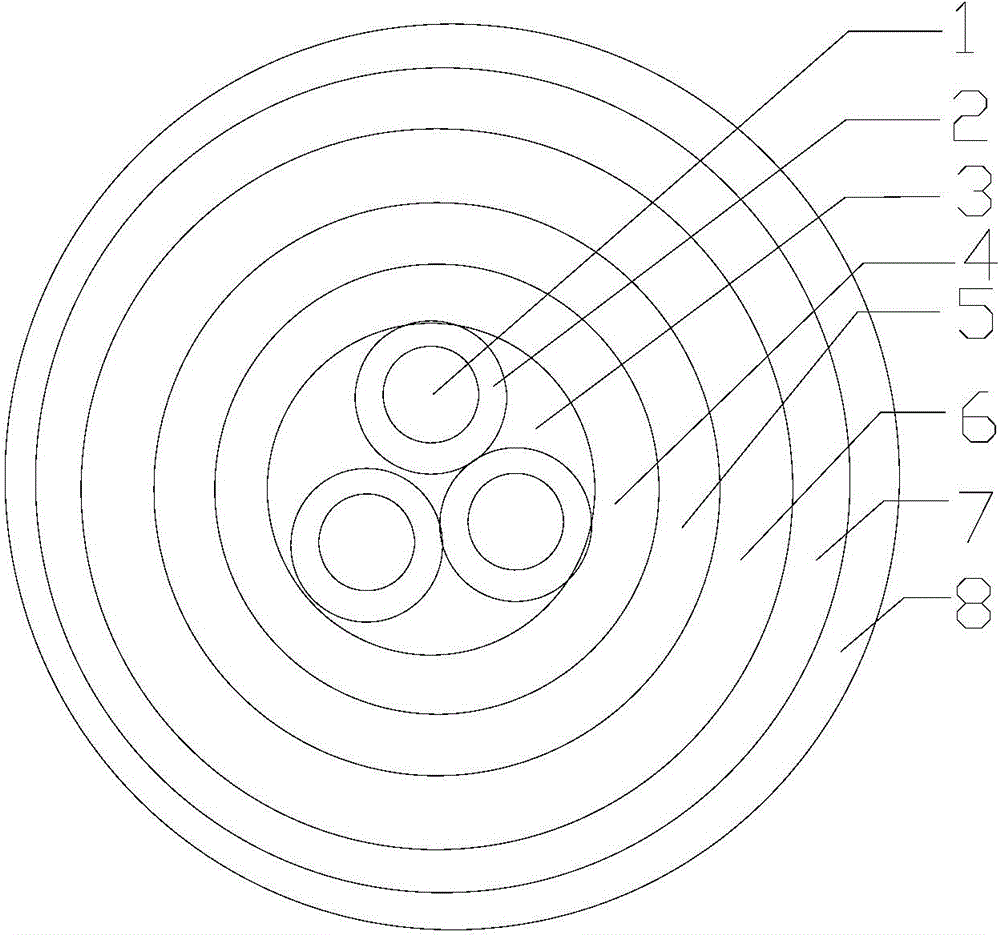

Safe and flexible fire resistant cable

InactiveCN104700933AReduce weightImprove cooling effectClimate change adaptationFlexible cablesFiberElectrical conductor

The invention relates to a safe and flexible fire resistant cable comprising a conductor, a wrapping fire-resistant mica tape, a wrapping ceramic fiber tape or filling ceramic fiber rope combined with the wrapping ceramic fiber tape, an extrusion coating corrupted aluminium tube, an extruded polymer precursor, a wrapping fire isolating layer and an extruded halogen-free low-smoke flame retardant sheath; the wrapping ceramic fiber tape coats the conductor to form a cable guide wire, and the wrapping fire-resistant mica tape, the wrapping ceramic fiber tape or filling ceramic fiber rope combined with the wrapping ceramic fiber tape, the extrusion coating corrupted aluminium tube, the extruded polymer precursor, the wrapping fire isolating layer and the extruded halogen-free low-smoke flame retardant sheath coat the cable guide wire from interior to exterior sequentially. Compared with the prior art, the safe and flexible fire resistant cable has the advantages of softness, lightness, small section area, fine heat radiation, large carrying flow and waterproof and moisture proof performances.

Owner:SHANGHAI SPECIAL WIRE & CABLE GROUP

Double-sided reinforced mica tape with films and method for manufacturing double-sided reinforced mica tape

ActiveCN103419443AReduce manufacturing costImprove surface wear resistanceSynthetic resin layered productsLaminationOrganic filmBreaking strength

The invention relates to a double-sided reinforced mica tape with films. The mica tape sequentially comprises a first organic film layer, a first adhesive layer, mica paper, a second adhesive layer and a second organic film layer from bottom to top. The double-sided reinforced mica tape with the films has the advantages that the double-sided reinforced mica tape is low in manufacturing cost, high in surface abrasion resistance, sufficient in strength and proper in elongation, and an insulating property of the mica paper cannot be destroyed even when the double-sided reinforced mica tape is burned; as tested by experiments, the tensile strength of the mica tape is higher than or equal to 30N, the breaking strength of the mica tape is higher than or equal to 100N, and the mica tape can be used for motors.

Owner:晟大科技(南通)有限公司

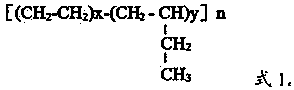

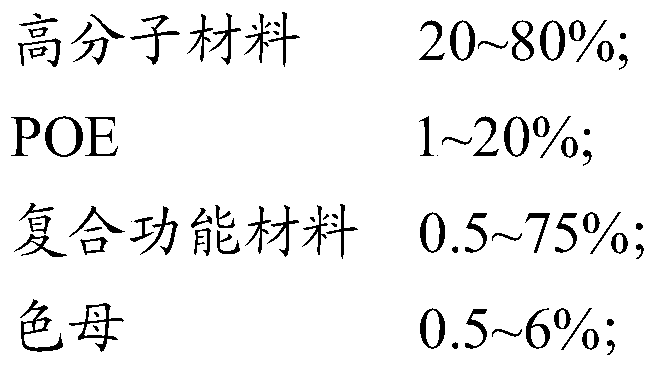

Strong film and preparation method and application thereof

The invention provides a strong film and a preparation method and an application thereof, which belong to the technical field of coiled materials. The strong film of the invention includes, by mass, the following components: 20-80% of high molecular materials; 1-20% of POE; 0.5-75% of composite functional materials; and 0.5-6% of color masterbatch; the high molecular materials are PP and / or HDPE;and the composite functional materials are one or more of functional masterbatch which is synergistically modified by mica and glass fiber, carbon fiber materials and polyester fiber materials. The strong film adopts the composite functional materials and cooperates with other components to make the film have the advantages of high strength, excellent high temperature resistance, small shrinkage,moderate elongation rate, good heat aging performance, and the like.

Owner:庞志清

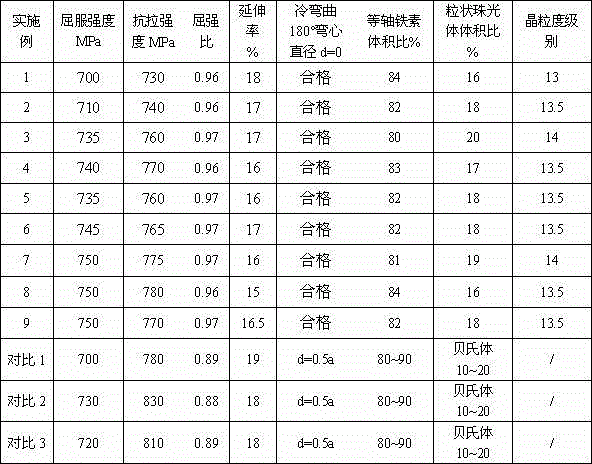

Binder for electrode material containing semi-IPN of polyvinyl alcohol and polyurethane and lithium secondary battery employed with the same

ActiveUS7960056B2High bonding strengthImprove electrolyte resistanceSilver accumulatorsConductive materialPower flowPolyvinyl alcohol

Provided is a binder for an electrode mix containing a semi-interpenetrating polymer network (semi-IPN) of polyvinyl alcohol and polyurethane, wherein the polyurethane is mixed to crosslink with the polyvinyl alcohol to form semi-IPN, and a lithium secondary battery comprising the same. The binder has superior adhesion to the electrode, excellent electrolyte resistance and improved elongation percentage, and therefore it is possible to prevent exfoliation or separation of electrode active materials from current collectors which occurs during repeated charge / discharge cycles. As a result, the capacity or power out of secondary batteries can be maintained at a constant level.

Owner:LG CHEM LTD

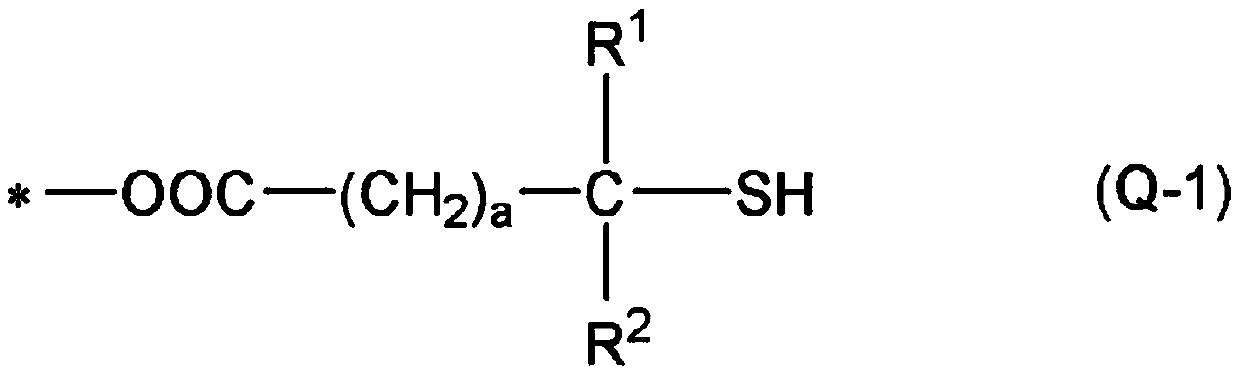

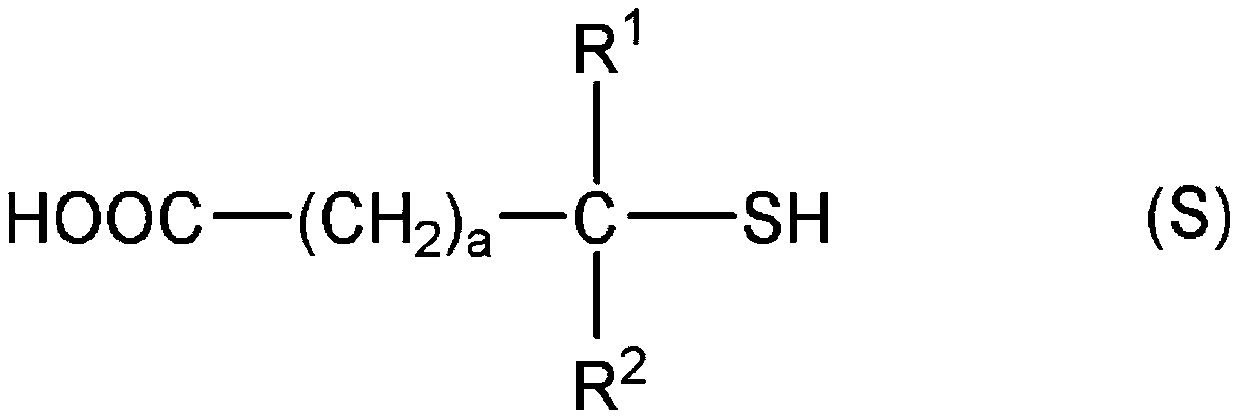

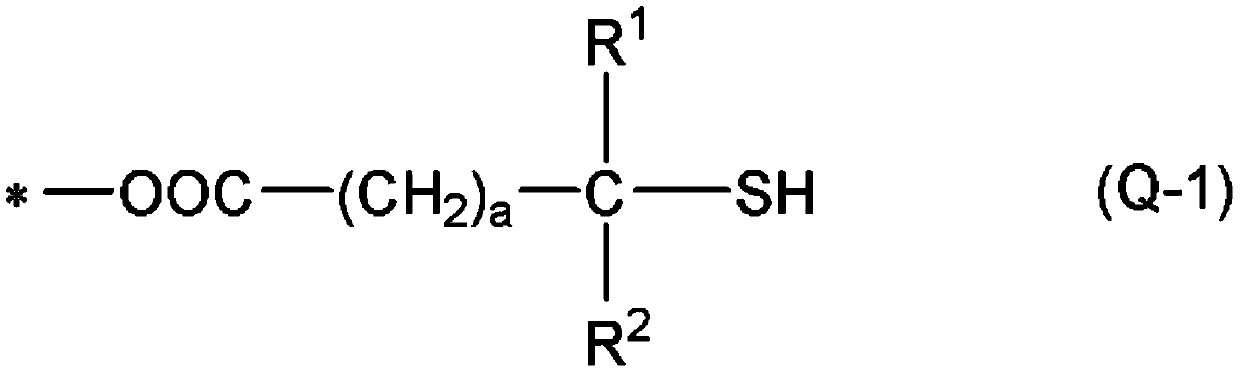

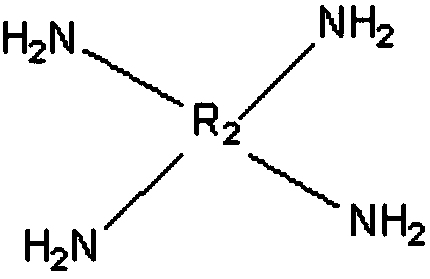

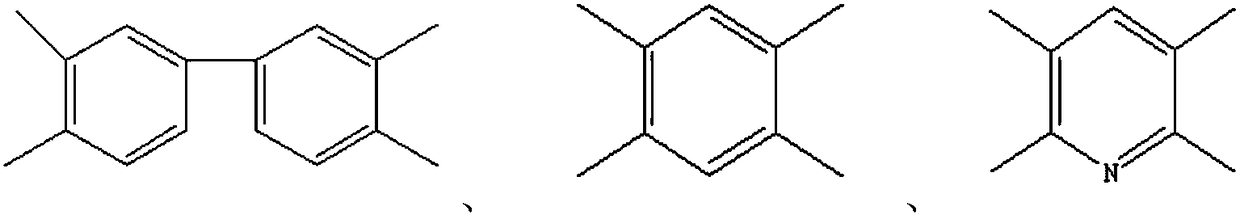

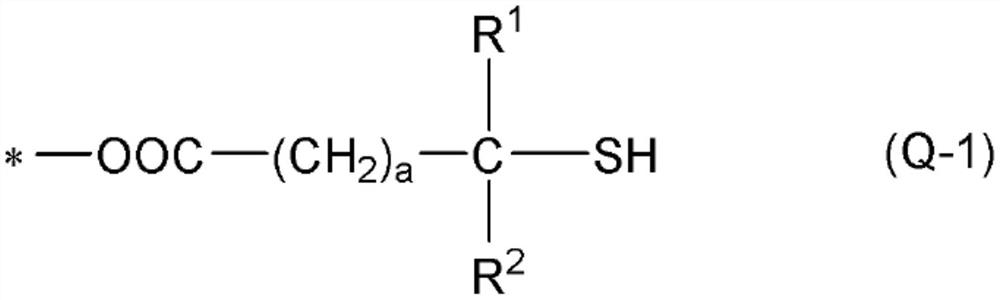

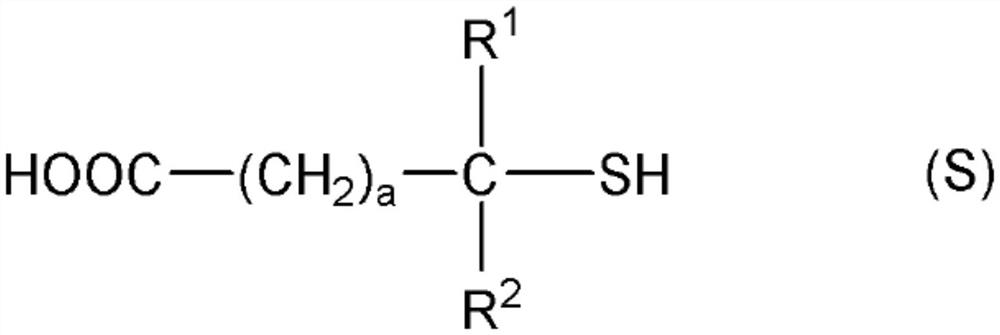

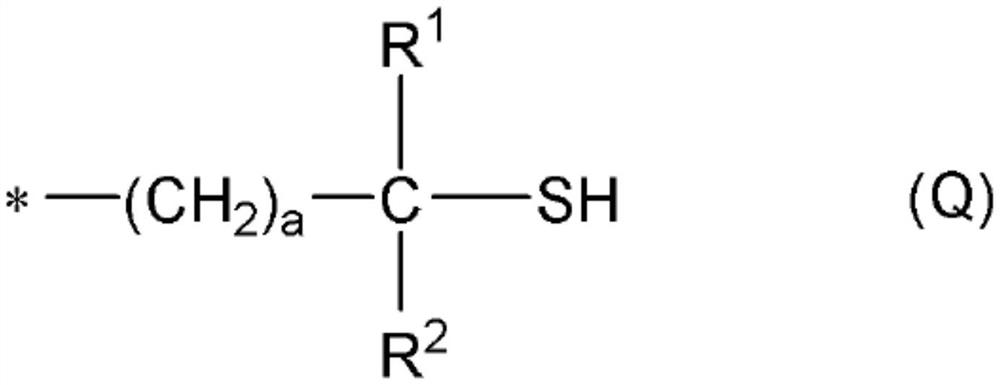

Radical-polymerizable resin composition

A radical-polymerizable resin composition which comprises one or more metal-containing compounds (A) selected from among metal soaps (A1) and metal complexes (A2) having a beta-diketone skeleton, oneor more thiol compounds (B) selected from among secondary thiol compounds (B1) and tertiary thiol compounds (B2), a radical-polymerizable compound (C), and an elastomer (D), and which can be stably cured not only under dry conditions but also in water or seawater or on wet bases, that is, stably cured on dry surfaces, on surfaces immersed in water or seawater, or on wet surfaces; a prepreg sheet obtained by prepolymerizing the radical-polymerizable resin composition; a curable material for preventing concrete flaking which comprises the radical-polymerizable resin composition; a primer; a radical-polymerizable coating composition; and a material for restoring inorganic structures.

Owner:RESONAC CORP

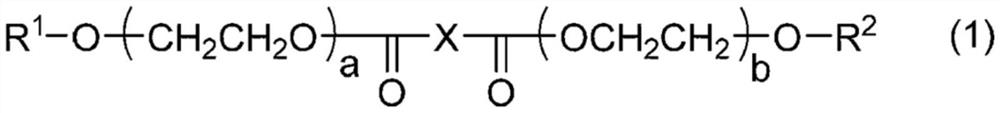

Acidic-corrosion-resistant X65MS pipeline steel and preparation method thereof

InactiveCN108265225AAppropriate yield ratioModerate elongationFurnace typesMetal rolling arrangementsMo elementCorrosion resistant

The invention discloses acidic-corrosion-resistant X65MS pipeline steel which comprises the following components in percentage by weight: 0.04-0.06% of C, 0.10-0.20% of Si, 1.20-1.40% of Mn, no more than 0.010% of P, no more than 0.002% of S, 0.030-0.040% of Nb, 0.010-0.020% of Ti, 0.020-0.040% of Al, 0.20-0.30% of Cr, 0.10-0.20% of Cu and 0.10-0.20% of Ni. The invention further discloses a preparation method of the acidic-corrosion-resistant X65MS pipeline steel. According to the acidic-corrosion-resistant X65MS pipeline steel and the preparation method, the Mn content is lowered, no expensive Mo element is added, and the alloy cost is relatively low, thereby being beneficial to wide popularization and application.

Owner:BAOTOU IRON & STEEL GRP

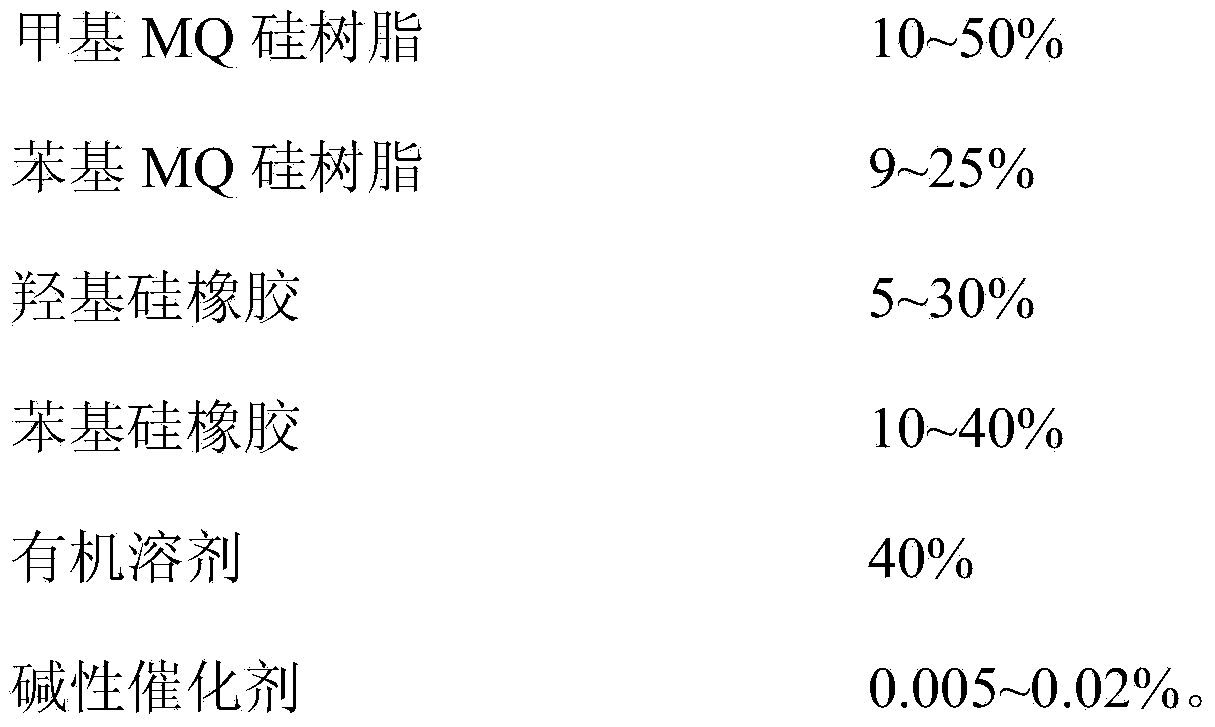

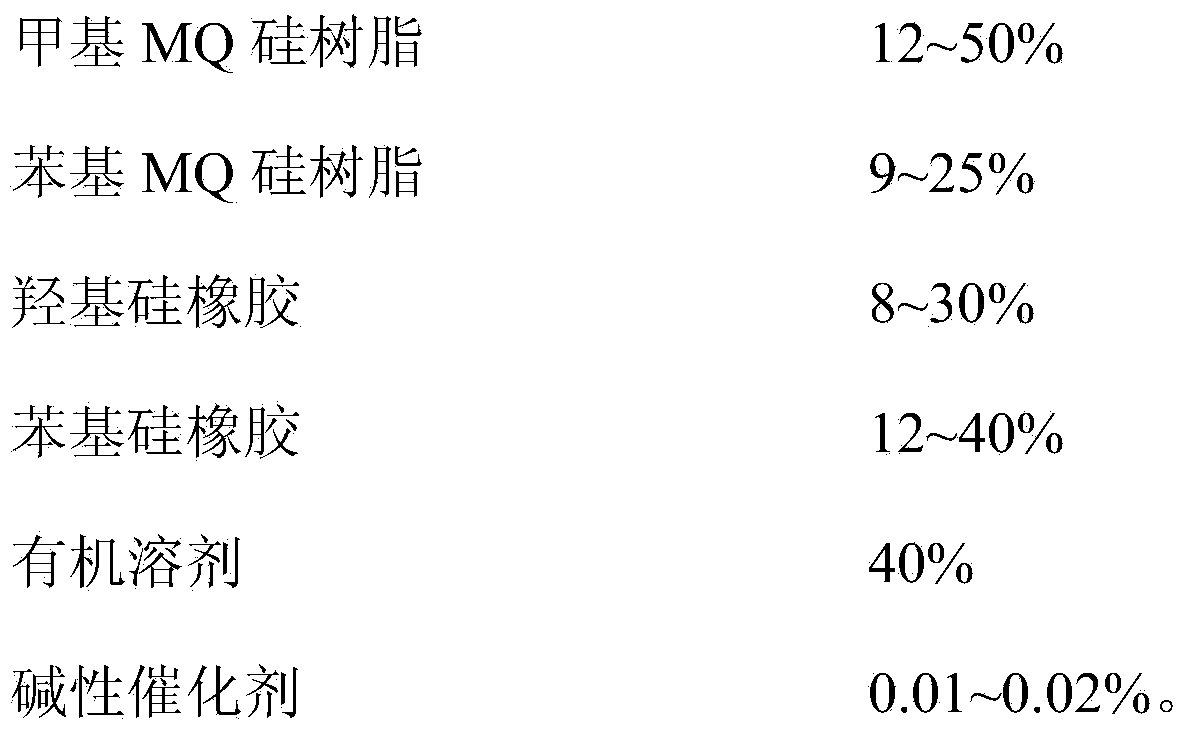

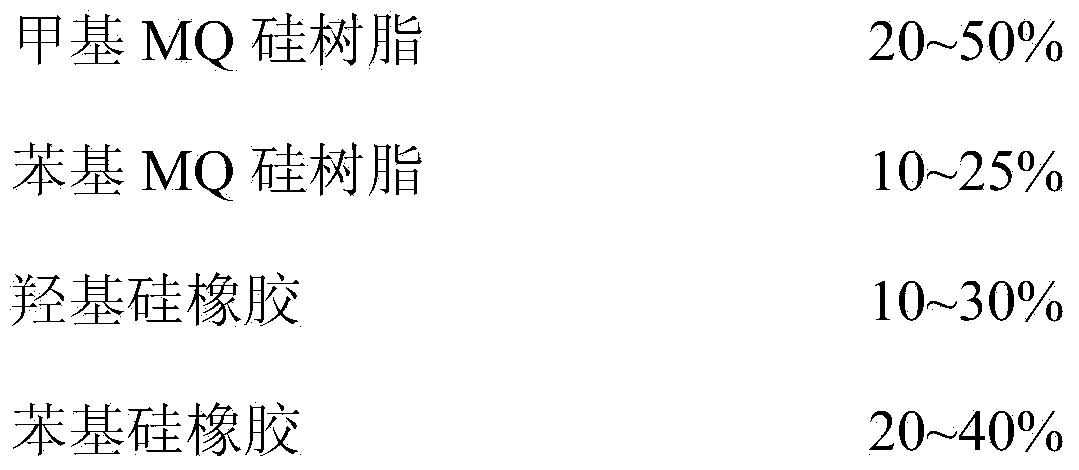

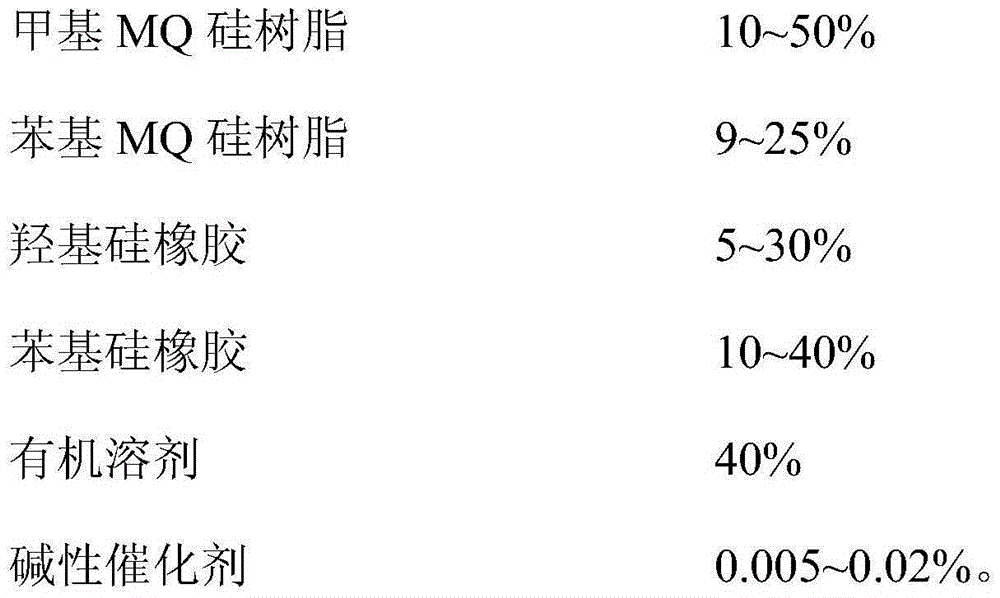

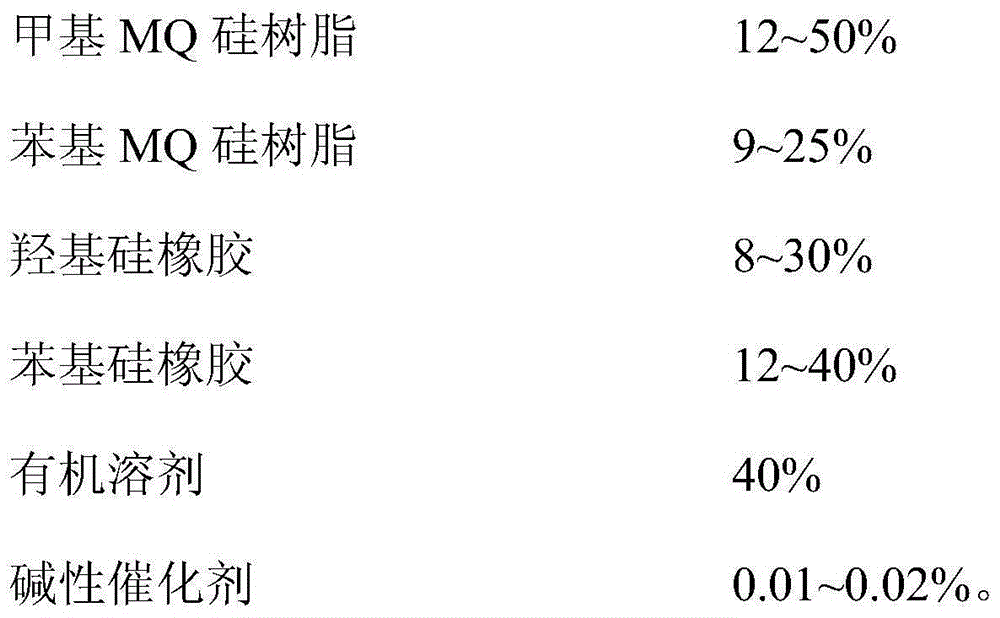

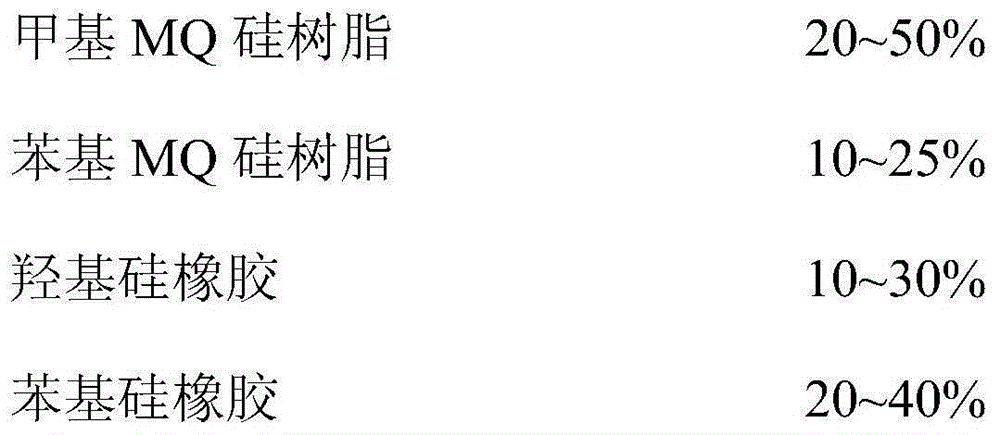

Silicon resin composition for nuclear motor mica tape and application thereof

The invention relates to a silicon resin composition for nuclear motor mica tape. The silicon resin is mainly prepared by the following raw materials which comprise, by mass percent, 10-50% of methyl MQ silicon resin, 9-25% of phenyl MQ silicon resin, 5-30% of hydroxyl silicone rubber, 10-40% of phenyl silicone rubber, 40% of organic solvents and 0.005-0.02% of basic catalysts. The nuclear motor mica tape using the silicon resin composition is low in product production cost, high in surface abrasive resistance, good in flame retardant performance, self-extinguishing resistance and insulating performance and resistant to high temperature and radiation, and has sufficient strength and proper ductility.

Owner:晟大科技(南通)有限公司

Method for preparing ten-stripe secure fabric tape for automobile children's seat

InactiveCN106337234AHigh strengthImprove wear resistanceWarping machinesLiquid/gas/vapor removalSafety controlSelf locking

The invention relates to a method for preparing a ten-stripe secure fabric tape for an automobile children's seat. The method comprises following steps: first, warp is subjected to beam-warping under specific tension environment on a special device; then the well warped warp beams are installed on a special weaving machine for weaving; finally, dyeing and finishing are processed on a special dyeing and finishing machine with specific technology to obtain products. Compared with the prior art, the secure fabric tape for automobile children's seats prepared by the method of the invention has high strength, good wear resistance, moderate elongation percentage, high light resistance, good flame resistance, edge self-locking line type thread off prevention and is nontoxic; better safety control is provided for babies and children who take the automobiles.

Owner:SHANGHAI ACE WEBBING

Novel technological process for processing waste hot transfer carbon belt

InactiveCN101328280AAvoid pollutionGuaranteed purityPlastic recyclingEnergy inputThermal transferSeparation technology

The invention relates to an effective separation techonolgical process. The process can change various substances contained of a waste thermal transfer carbon ribbon into recoverable components, so as to solve the difficult problems of environmental pollution, safety and so on facing thermal transfer carbon ribbons. The novel technologic process for treating the waste thermal transfer carbon ribbon comprises formula compositions of a separating and cleaning liquid, design principle and process parameters of cleaning equipment special for the waste thermal transfer carbon ribbon, design of a carbon powder recovery system, design principle of a cleaning liquid recycling utilization system, volatilization control and recovery principle of the separating and cleaning liquid, a regenerated substance utilization method and so on; and the scientific combination of the process contents forms a set of process procedures used to novelly, effectively, and reliably treat the waste thermal transfer carbon ribbon, and achieves the aims of effectively recovering the waste thermal transfer carbon ribbon, eliminating environmental pollution, protecting environment and saving resources. The technology process belongs to the environmental protection and resource regeneration technical field.

Owner:许秀峰 +2

Double-sided reinforced mica tape with films and method for manufacturing double-sided reinforced mica tape

ActiveCN103419443BReduce manufacturing costImprove surface wear resistanceSynthetic resin layered productsLaminationOrganic filmBreaking strength

Owner:晟大科技(南通)有限公司

A kind of wet spinning preparation method of acetate fiber

ActiveCN106012076BReduce pollutionImprove production environmentArtificial filaments from cellulose derivativesFiberCellulose diacetate

The invention discloses a wet spinning method for preparing cellulose acetate fiber. The wet spinning method comprises the following steps: grinding solid cellulose diacetate, of which the degree of acetylation is 2.1 to 2.8 and the water content is 1 to 7 percent, into powder; adding the cellulose diacetate powder and an organic solvent into a dissolving tank, and carrying out sufficient stirring for mixing, and raising the temperature for dissolution, wherein the mass ratio of the cellulose diacetate powder to the organic solvent ranges from 1:3 to 1:7, the dissolving time is 0.5 to 8 hours, and the dissolving temperature is 35 to 120 DEG C; filtering and deforming a dope obtained after dissolution to obtain a spinning dope; after the spinning dope passes through a metering pump and a filter, spraying the filtered spinning dope from spinneret orifices to enter a coagulation bath to obtain nascent fiber, wherein the concentration of the coagulation bath is 25 to 70%, and the temperature is 20 to 90 DEG C; preparing a finished acetate fiber product from the nascent fiber through drafting, washing, oiling and drying. The cellulose acetate fiber prepared according to the method disclosed by the invention has excellent indexes, good mechanical properties, and remarkably improved dry strength and wet strength; the preparation process is simple, feasible, and easy to control; the solvent cost is low.

Owner:吉林富博纤维研究院有限公司

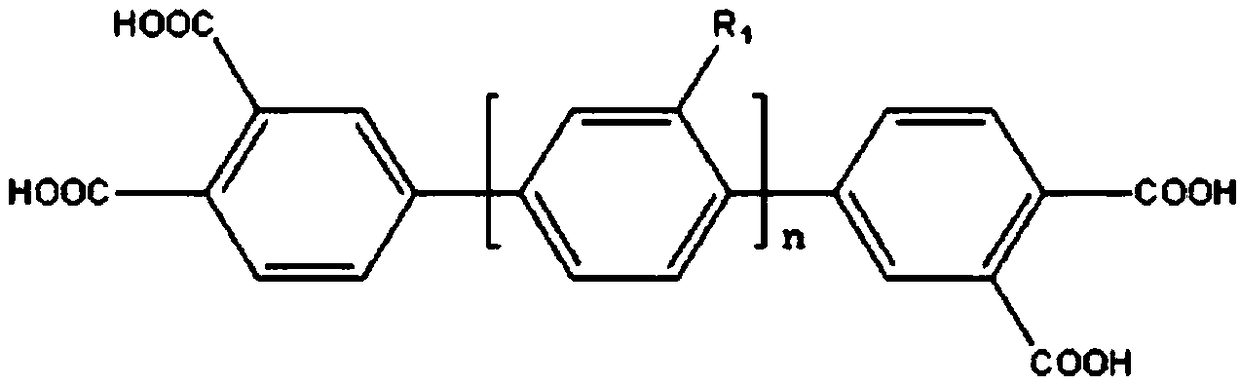

Preparation method of electrospun high-performance polyphenylene derivative nanofibers

ActiveCN106480530BImprove toughnessHigh strengthMonocomponent polyamides artificial filamentBenzeneOligomer

Owner:JIANGXI NORMAL UNIV

Electrospun nylon 66/pva/boric acid nanofiber and preparation method thereof

ActiveCN106480519BHigh tensile strengthImprove filtering effectFilament/thread formingArtificial filament heat treatmentFiberNylon 66

Owner:JIANGXI NORMAL UNIV

Radical polymerizable resin composition

Radical polymerizable resin composition, prepreg sheet obtained by prepolymerizing the same, curable material for preventing concrete spalling containing radical polymerizable resin composition, primer, radical polymerizable coating composition , and an inorganic structure restoration material, wherein the radically polymerizable resin composition contains: at least one metal-containing compound ( A); one or more thiol compounds (B) selected from secondary thiol compounds (B1) and tertiary thiol compounds (B2); radically polymerizable compound (C); and elastomer (D), above The radically polymerizable resin composition can be used even under dry conditions, in water and seawater, and on a wet substrate, that is, on a dry surface, a surface immersed in water or seawater, and a wet surface. Solidifies stably.

Owner:RESONAC CORPORATION

Method for preparing rolling anisotropic magnetic powder and magnet

ActiveCN100437842CHigh residual magnetic inductionImprove coercive forceInorganic material magnetismInductances/transformers/magnets manufactureExtensibilitySingle crystal

Using specific technique of rapid hardening slice produces alloy based on neodymium (or praseodymium) iron. Then, through reaction of gas-solid phase, crumbling procedure produces RxFe100-x-y-zMyIz magnetic powder. The magnetic powder is single crystal grain in sheet form with average grain size as 1-3 micro. The magnetic powder produced by the disclosed technique possesses anisotropy of magnetocrystalline under action of external magnetic field as well as rolling anisotropy and stress anisotropy. Based on three kinds of anisotropy, the invention discloses method for preparing high performance flexible rubber magnet with rolling anisotropy. The prepared flexible magnet possesses excellent magnetism, flat surface, good cohesiveness, and feasible mechanical properties including tensile strength, extensibility, and rigidity as well as characteristics of temperature resisting, moisture resistance, oil proof and anticorrosion.

Owner:NINGXIA MAGVALLEY NOVEL MATERIALS TECH CO LTD

High-strength cold-rolled hot-galvanized precipitation reinforced steel and manufacturing method thereof

ActiveCN102199723BGood welding performancePremium surface qualityTemperature control deviceMetal rolling arrangementsSheet steelImpurity

The invention discloses a high-strength cold-rolled hot-galvanized precipitation reinforced steel plate and a manufacturing method thereof. The steel plate comprises the following components: 0.09 to 0.12 weight percent of C, less than or equal to 0.05 weight percent of Si, 0.8 to 1.8 weight percent of Mn, less than or equal to 0.02 weight percent of P, less than or equal to 0.01 weight percent of S, less than or equal to 0.008 weight percent of N, 0.02 to 0.06 weight percent of Al, 0.05 to 0.08 weight percent of Nb and Ti and the balance of Fe and inevitable impurities. The microstructure of the steel plate is ferrite and second phase particles, wherein the diameter of the second phase particles is about less than 6 mu m, the yield strength is 500 to 600MPa, the tensile strength is 570 to 710MPa, and the total coefficient of elongation is over 14 percent (80 gauge length and transverse stretching). The hot-galvanized steel plate has high welding performance and surface quality and can be widely used in automotive structural membranes.

Owner:BAOSHAN IRON & STEEL CO LTD

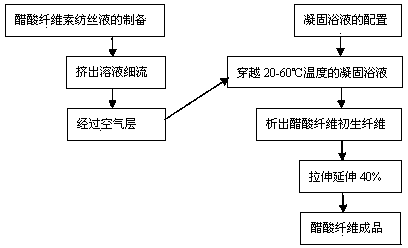

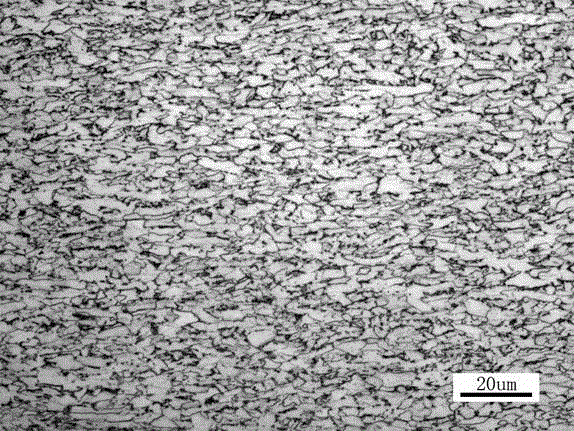

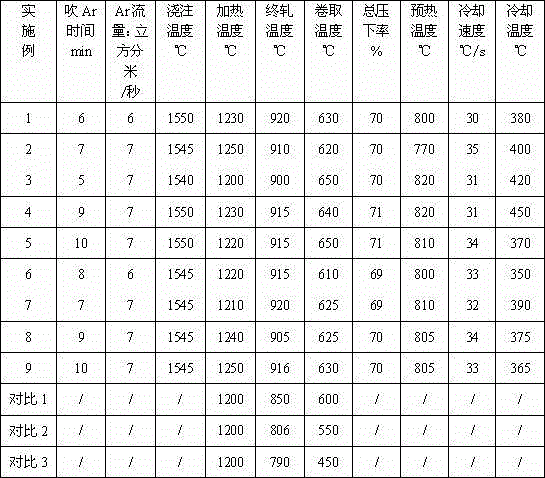

Steel with yield ratio of 0.9 or more used for ultra-fine grain slideway and production method thereof

InactiveCN102719736BHigh yield ratioGuaranteed shape stabilityTemperature control deviceUltra fineYield ratio

The invention relates to a steel with the yield ratio of 0.9 or more used for an ultra-fine grain slideway and a production method thereof. The steel mainly comprises the following components in percentage by weight: 0.03-0.07% of C, less than or equal to 0.03% of Si, 0.50-0.80% of Mn, 0.02-0.07% of Al, less than or equal to 0.03% of P, less than or equal to 0.015% of S, 0.02-0.07% of Nb, less than or equal to 0.06% of Mo and the balance of Fe and impurities. The production steps comprise hot metal desulphurization, converter smelting, ladle argon blowing, continuous casting, casting blank heating, hot rolling, reeling, ordinary scouring, cold rolling, continuous annealing, and leveling for stand-by. The defects that the existing same-level high-strength steel is low in yield and the specification and the welding of hot rolling materials are difficult to meet are overcome. The yield ratio of the steel disclosed by the invention achieves 0.9 or more, the grain size of the steel achieves 13 or more, and a steel plate has high yield ratio, appropriate elongation and good spot welding property.

Owner:武汉钢铁有限公司

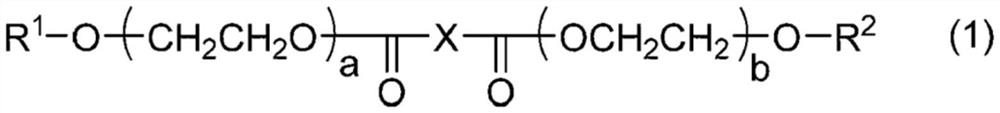

polyurethane resin composition

ActiveCN111699217BModerate hardnessModerate compatibilityPlastic/resin/waxes insulatorsOther chemical processesPolymer sciencePolyol

The object of the present invention is to provide a polyurethane resin having excellent compatibility and workability and excellent cooling and heating cycle characteristics using a polybutadiene polyol having a hydroxyl value of 60 mgKOH / g or less. The present invention relates to a polyurethane resin composition containing (A) a polyisocyanate compound, (B) a polyol compound, (C) an inorganic filler, and (D) a plasticizer, the (B) polyol compound comprising (b1 ) a polybutadiene polyol having a hydroxyl value of 60 mgKOH / g or less, containing (C) 50 to 85 mass % of an inorganic filler, and (D) 1 to 30 mass % of a plasticizer relative to 100 mass % of the polyurethane resin composition. quality%.

Owner:三悠瑞克株式会社

A kind of x70m hot-rolled steel plate for thin-gauge gas transmission straight seam welded pipe and its manufacturing method

ActiveCN112981258BKeep vacuum degassing timeImprove plastic toughnessGas emission reductionChemical compositionSeam welding

Owner:ANGANG STEEL CO LTD

A kind of silicone resin composition for nuclear power mica belt and its application

ActiveCN103440903BImprove adhesionIncrease stickinessPlastic/resin/waxes insulatorsMicaOrganic solventWear resistance

The invention relates to a silicon resin composition for nuclear motor mica tape. The silicon resin is mainly prepared by the following raw materials which comprise, by mass percent, 10-50% of methyl MQ silicon resin, 9-25% of phenyl MQ silicon resin, 5-30% of hydroxyl silicone rubber, 10-40% of phenyl silicone rubber, 40% of organic solvents and 0.005-0.02% of basic catalysts. The nuclear motor mica tape using the silicon resin composition is low in product production cost, high in surface abrasive resistance, good in flame retardant performance, self-extinguishing resistance and insulating performance and resistant to high temperature and radiation, and has sufficient strength and proper ductility.

Owner:晟大科技(南通)有限公司

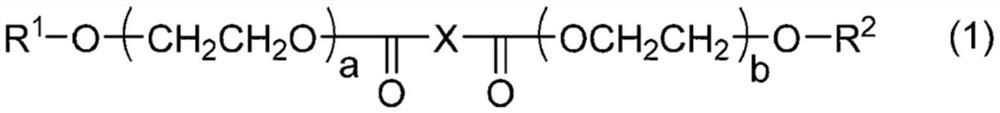

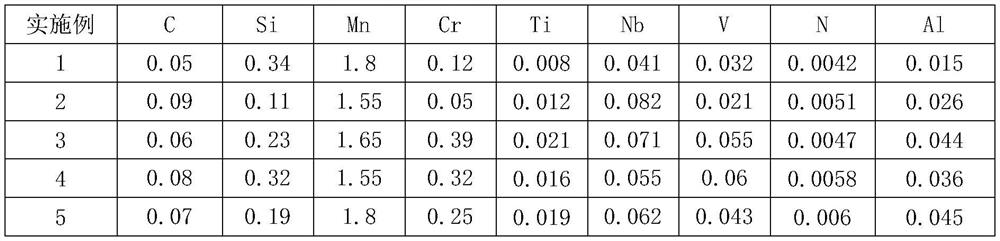

Thin-gauge X70M hot-rolled steel plate for gas transmission longitudinal welded pipe and manufacturing method

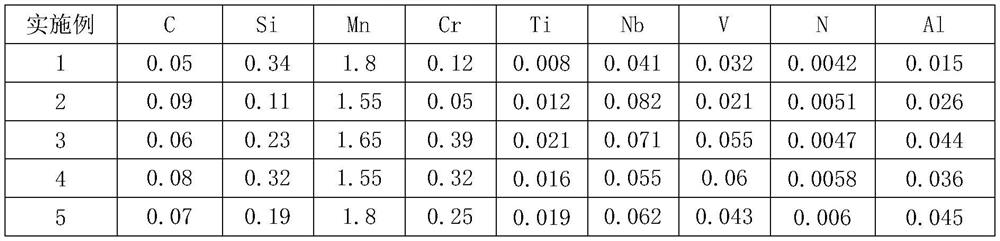

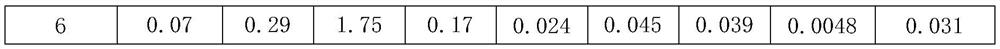

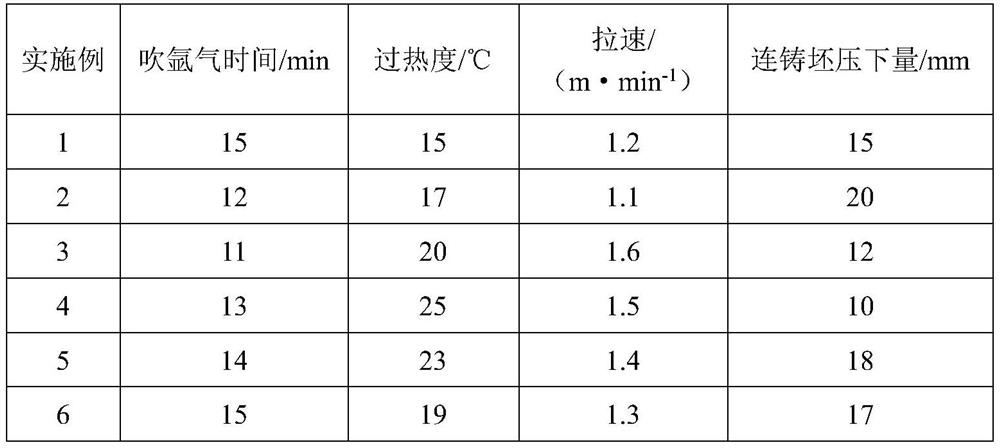

ActiveCN112981258ALow P and S contentKeep vacuum degassing timeGas emission reductionChemical compositionPipe

The invention relates to a thin-gauge X70M hot-rolled steel plate for a gas transmission longitudinal welded pipe and a manufacturing method thereof. The steel plate comprises the following chemical components in percentage by weight of 0.05%-0.09% of C, 0.10%-0.35% of Si, 1.50%-1.80% of Mn, less than or equal to 0.020% of P, less than or equal to 0.015% of S, 0.04%-0.09% of Nb, 0.008%-0.0250% of Ti, 0.015%-0.045% of Al, less than or equal to 0.4% of Cr, 0.020%-0.06% of V, 0.0041%-0.006% of N and the balance of Fe and inevitable impurities. The produced steel plate is suitable for manufacturing the X70M longitudinal welded pipe for a natural gas conveying pipeline with the pipe diameter being phi 1422 mm and the wall thickness being 10-18 mm.

Owner:ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com