Wet spinning method for preparing cellulose acetate fiber

A technology for cellulose acetate and wet spinning, applied in the field of spinning, can solve the problems of incapable of large-scale production and application, high energy consumption, expensive ionic solvent, etc., achieves excellent indicators, good mechanical properties, and improves production environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

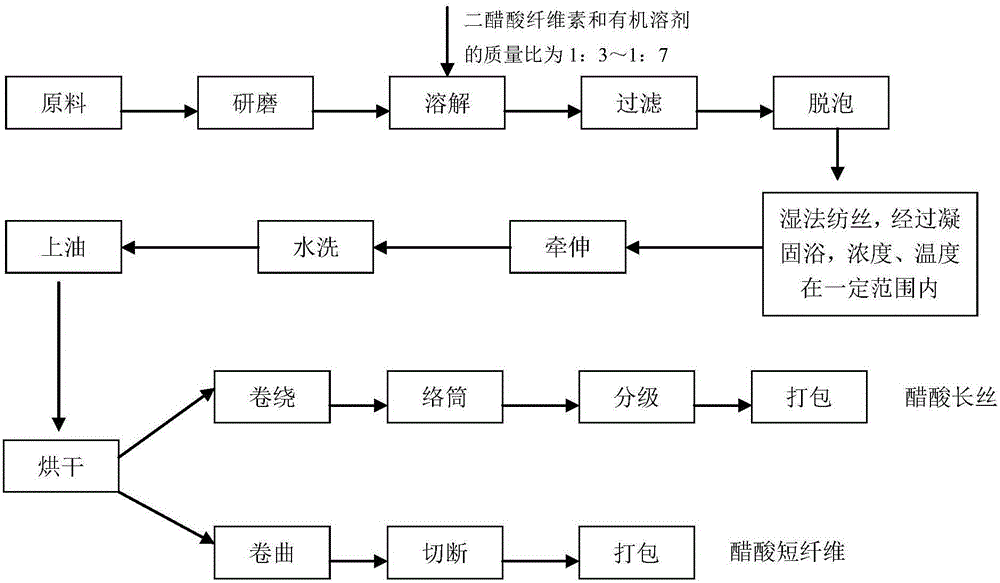

Method used

Image

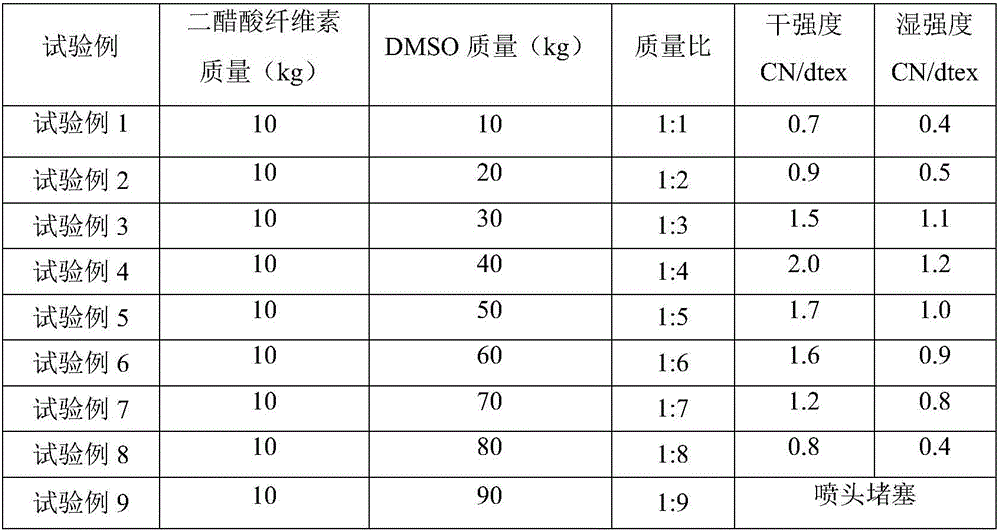

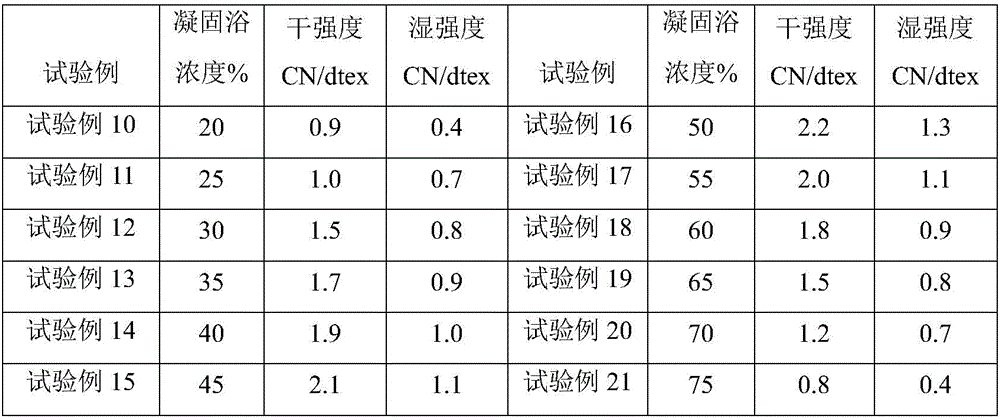

Examples

Embodiment 1

[0037] (1) the degree of esterification of 5kg granular blocks is 2.1, and the cellulose diacetate with a water content of 1% is ground into powder;

[0038] (2) Add cellulose diacetate powder and 30kg of DMAC solvent into the dissolution tank, stir and mix thoroughly, heat up and dissolve, the dissolution temperature is 35°C, and the dissolution time is 8 hours;

[0039] (3) After degassing and filtering, the spinning stock solution is formed;

[0040] (4) The spinning stock solution at 15°C is sprayed out from the spinneret hole after being passed through a metering pump and a filter, and enters a coagulation bath, which is a DMAC aqueous solution with a concentration of 25% and a temperature of 20°C to form nascent fibers;

[0041] (5) As-spun fibers are drawn, washed, oiled, dried, wound, and graded to form acetate fiber finished products, and the total draft ratio of the drafting process is 0.5.

[0042] The index of the obtained acetate fiber finished product: the dry str...

Embodiment 2

[0044] (1) the degree of esterification of 5kg grains is 2.8, and the cellulose diacetate with a water content of 7% is ground into powder;

[0045] (2) Add cellulose diacetate powder and 35kg of DMAC solvent into the dissolution tank, stir and mix thoroughly, heat up and dissolve, the dissolution temperature is 100°C, and the dissolution time is 0.5 hours;

[0046] (3) After degassing and filtering, the spinning stock solution is formed;

[0047] (4) The spinning stock solution at 100°C is sprayed out from the spinneret hole after being passed through a metering pump and a filter, and enters a coagulation bath, which is a DMAC aqueous solution with a concentration of 70% and a temperature of 90°C to form primary fibers;

[0048] (5) As-spun fibers are drawn, washed, oiled, dried, wound, and graded to form acetate fiber finished products, and the total draft ratio of the drafting process is 7.

[0049] The index of the obtained acetate fiber finished product: the dry strength...

Embodiment 3

[0051] (1) the degree of esterification of 10kg grains is 2.5, and the cellulose diacetate with a water content of 4% is ground into powder;

[0052] (2) Add cellulose diacetate powder and 35kg DMF solvent into the dissolving tank, fully stir and mix, heat up and dissolve, the dissolving temperature is 40°C, and the dissolving time is 3 hours;

[0053] (3) After degassing and filtering, the spinning stock solution is formed;

[0054] (4) The spinning dope at 40°C is sprayed out from the spinneret hole after being passed through a metering pump and a filter, and enters a coagulation bath, which is a DMF aqueous solution with a concentration of 30% and a temperature of 25°C to form primary fibers;

[0055] (5) As-spun fibers are drawn, washed, oiled, dried, wound, and graded to form acetate fiber finished products, and the total draft ratio of the drafting process is 1.

[0056] The index of the obtained acetate fiber finished product: the dry strength is 2.0CN / dtex, the wet st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com