Patents

Literature

90results about How to "High wet and dry strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

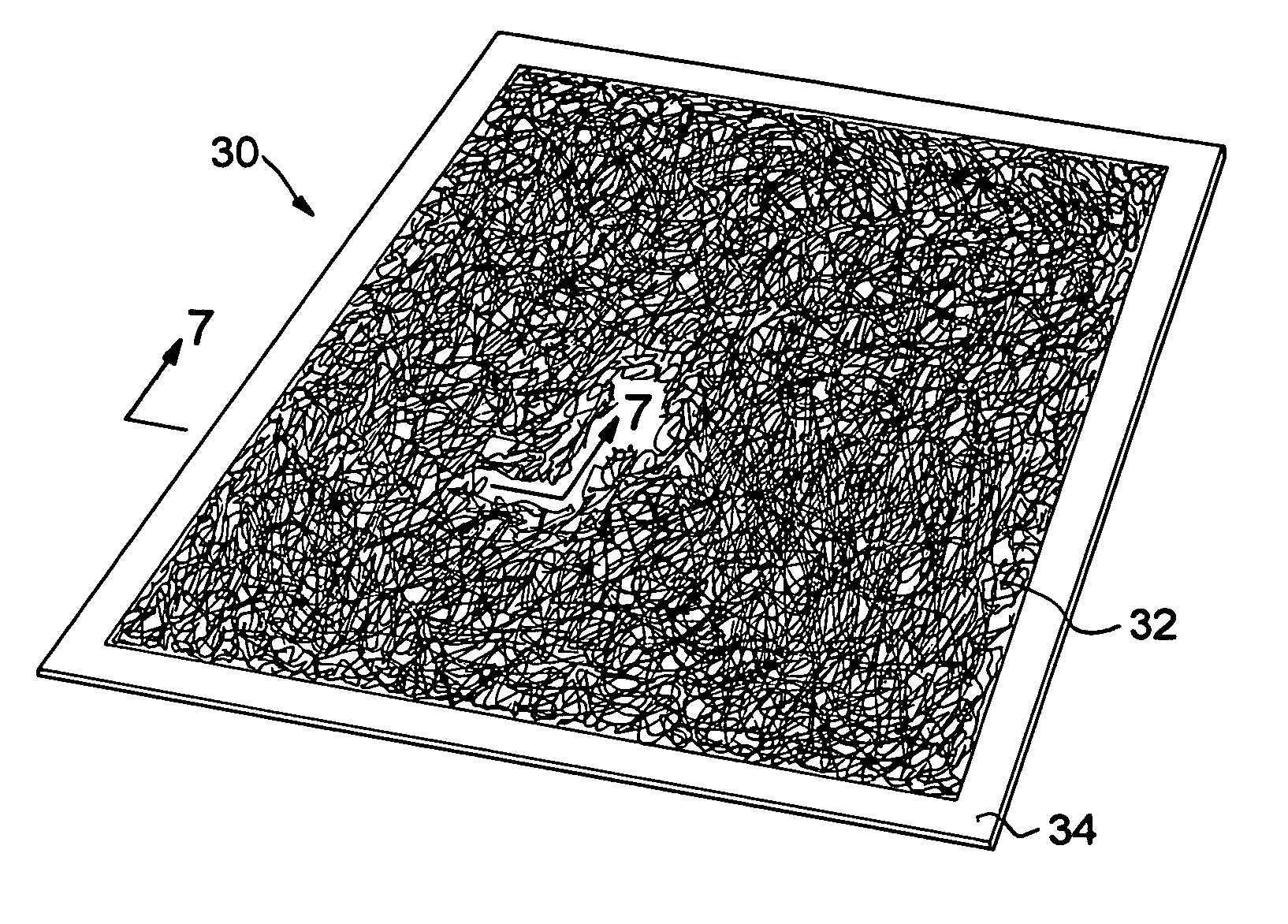

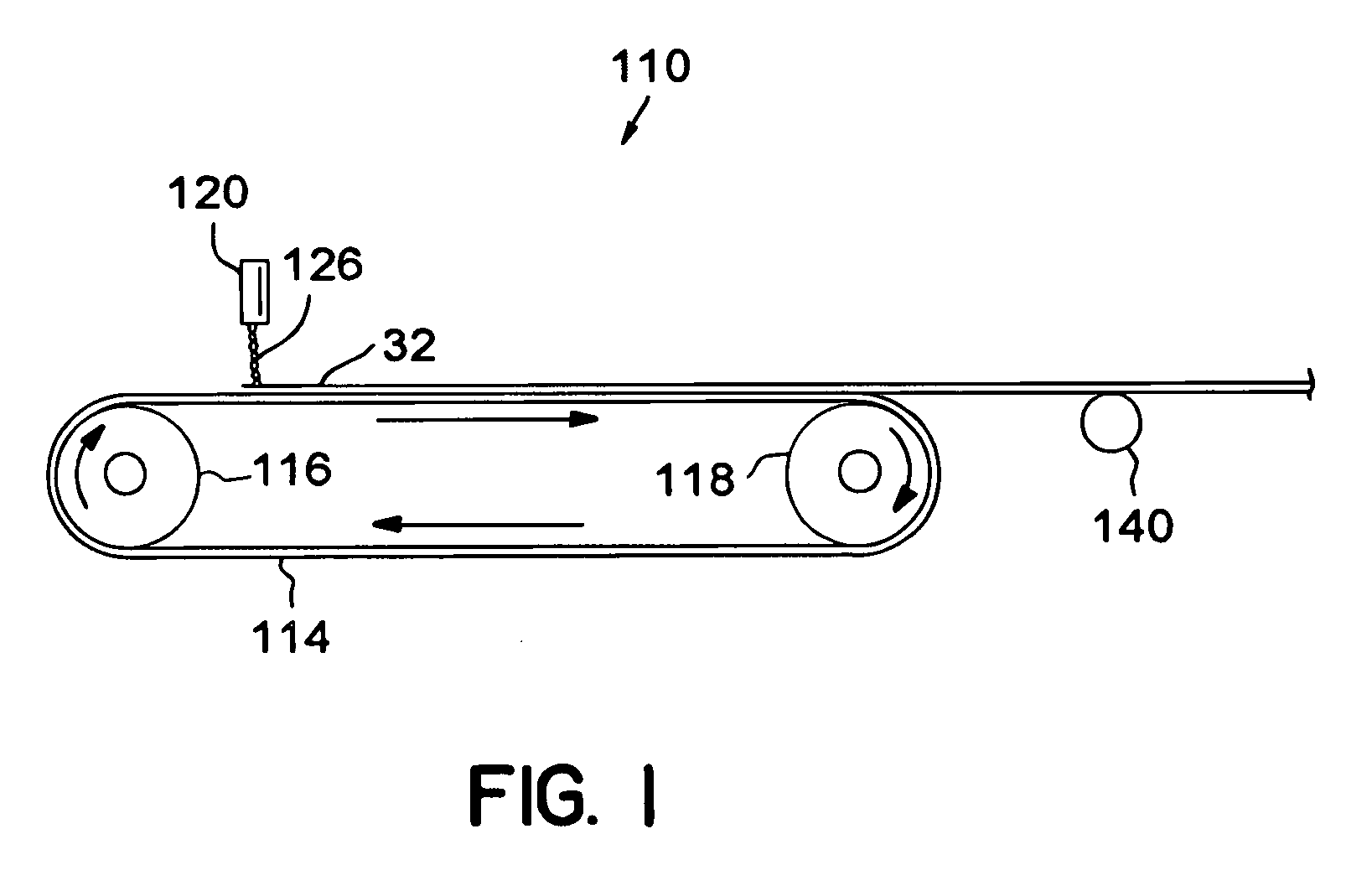

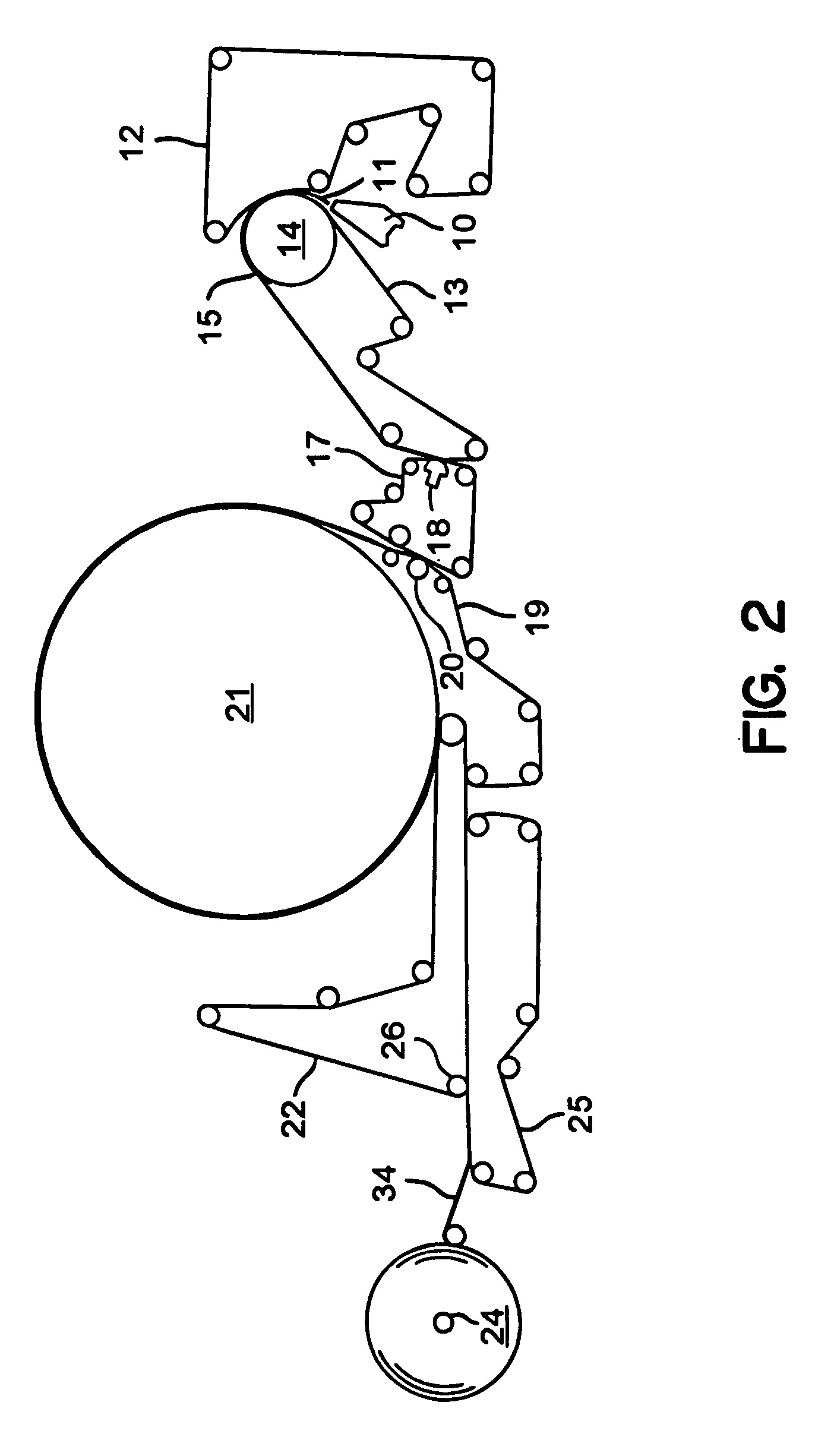

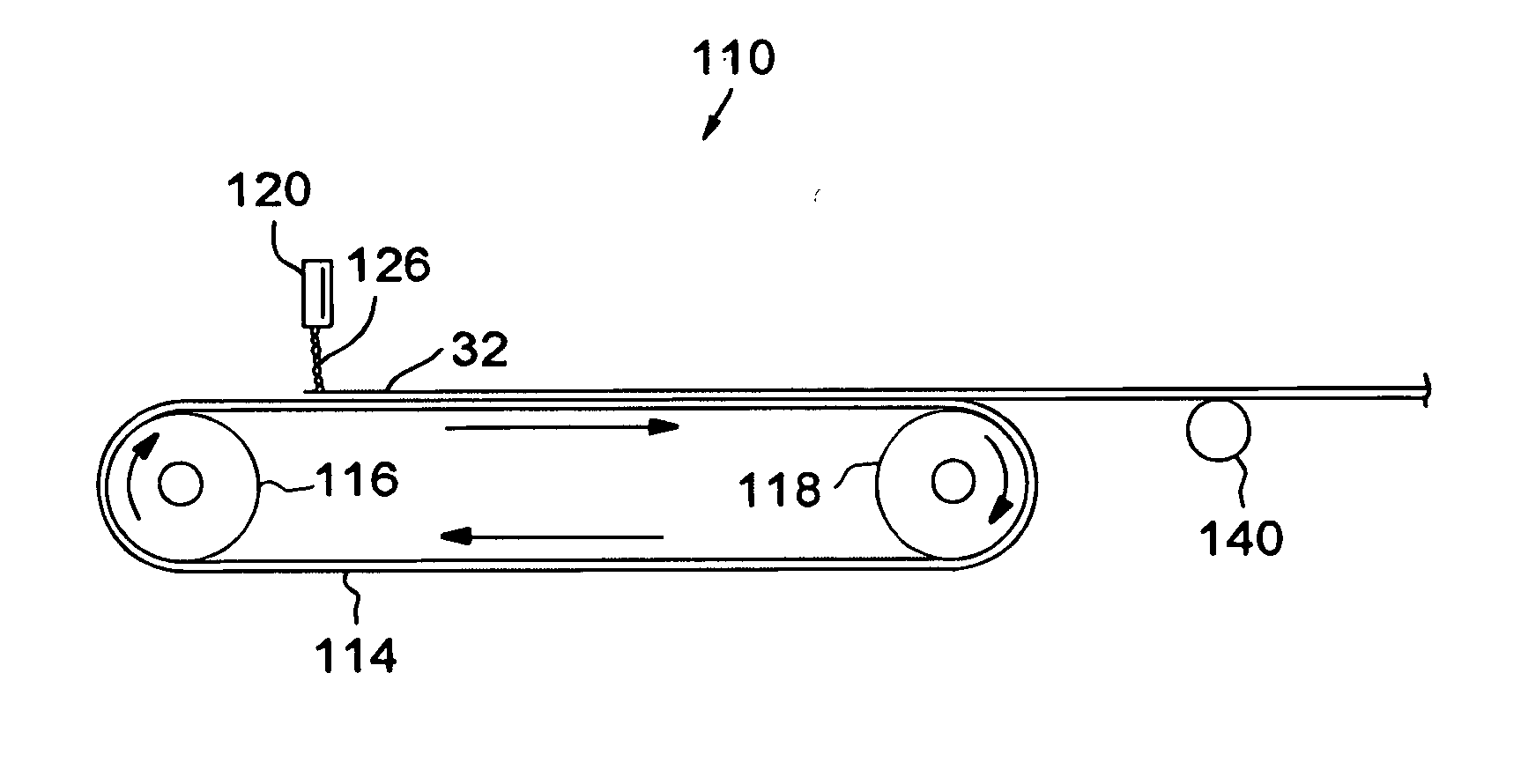

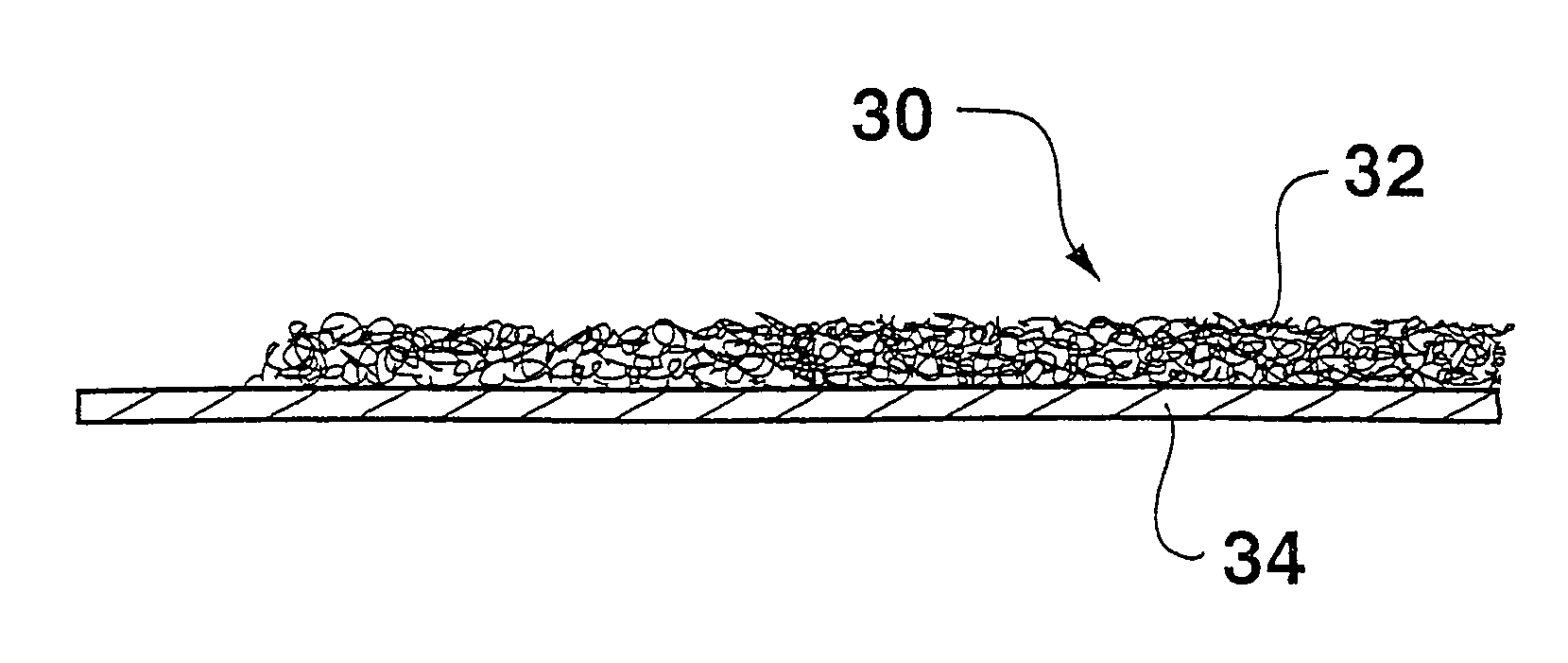

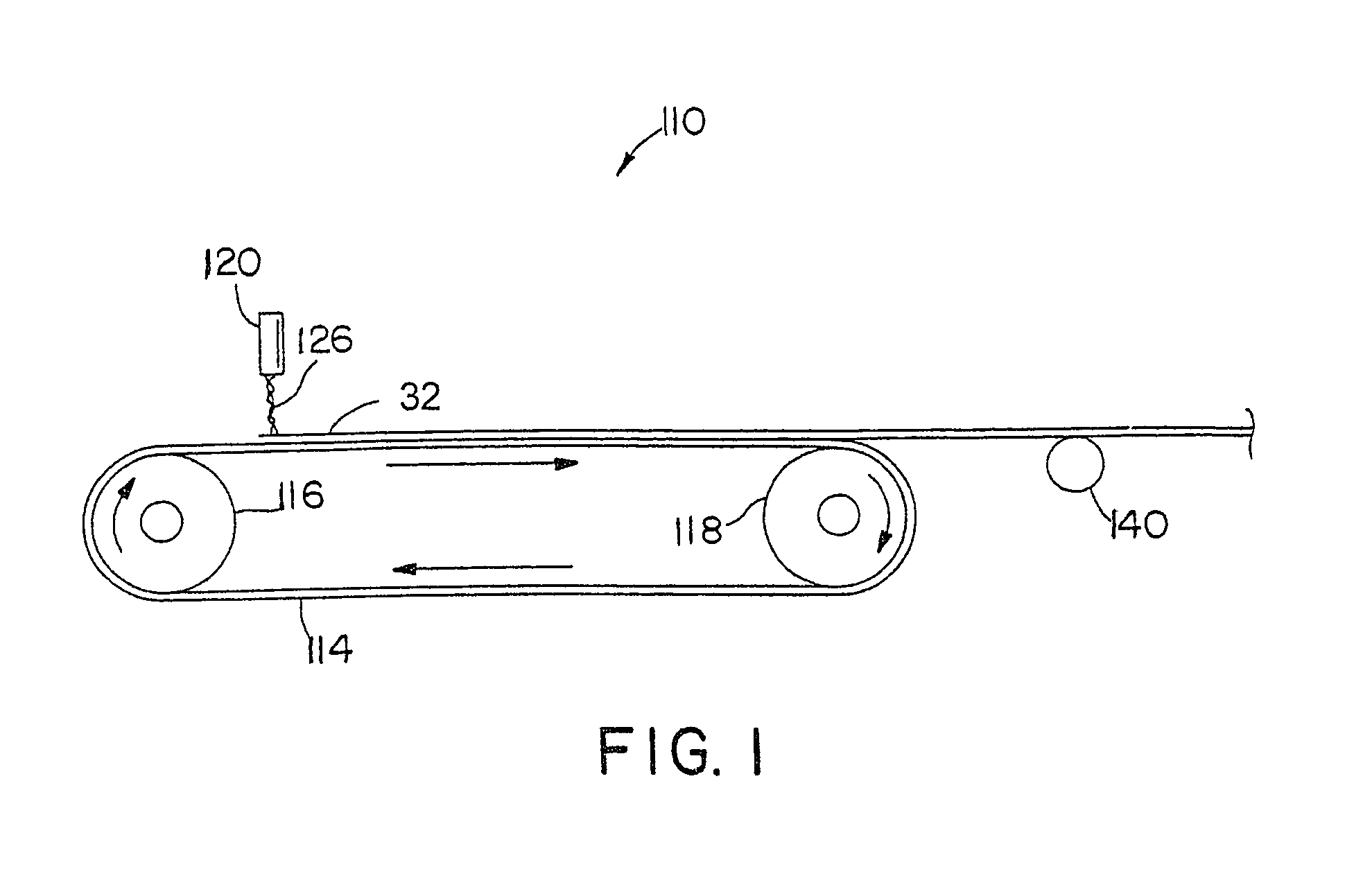

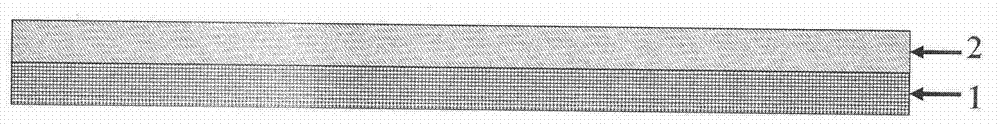

Disposable scrubbing product

InactiveUS20050130536A1High yieldResists effect of waterPersonal careCarpet cleanersEngineeringFibrous layer

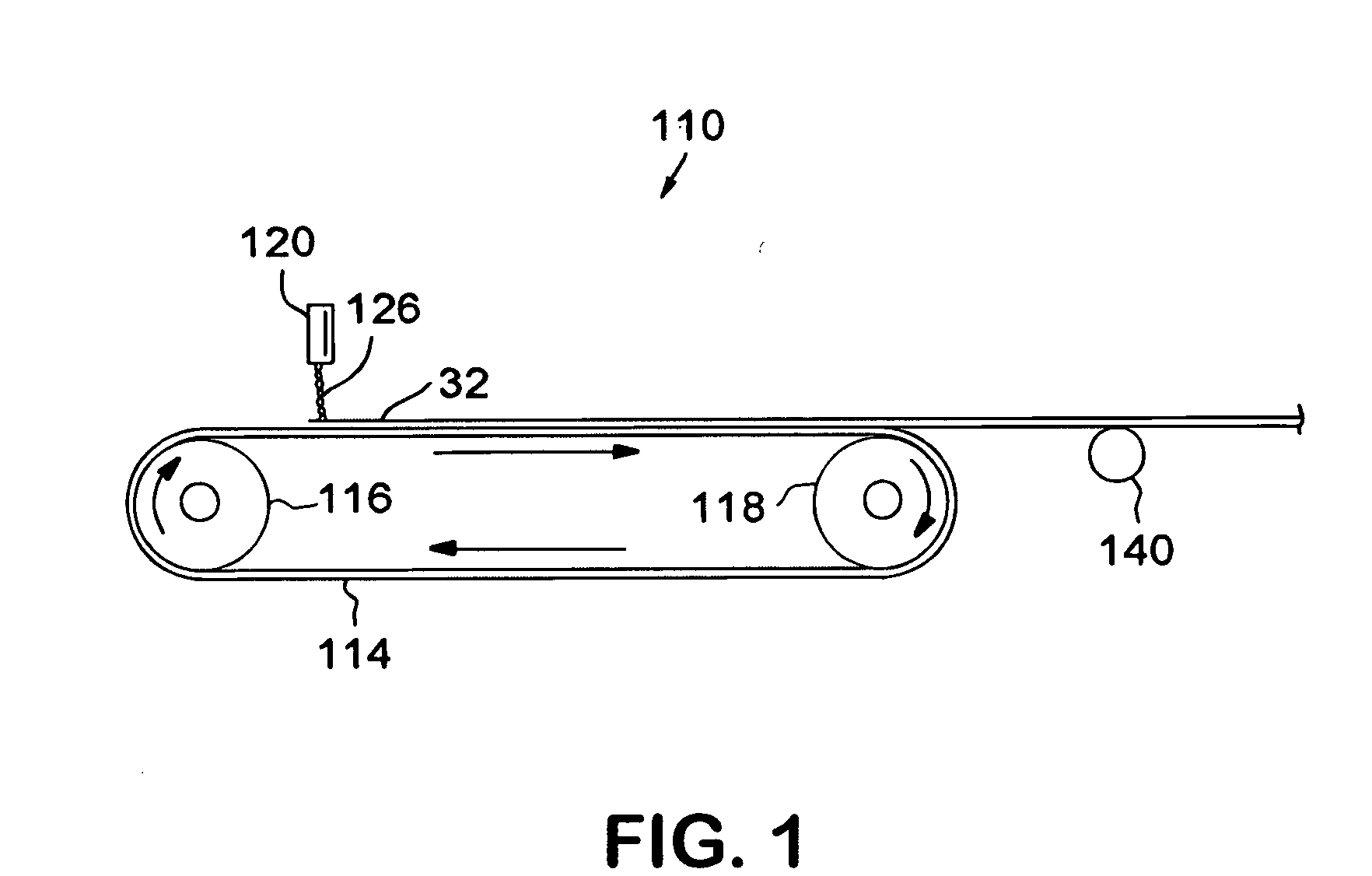

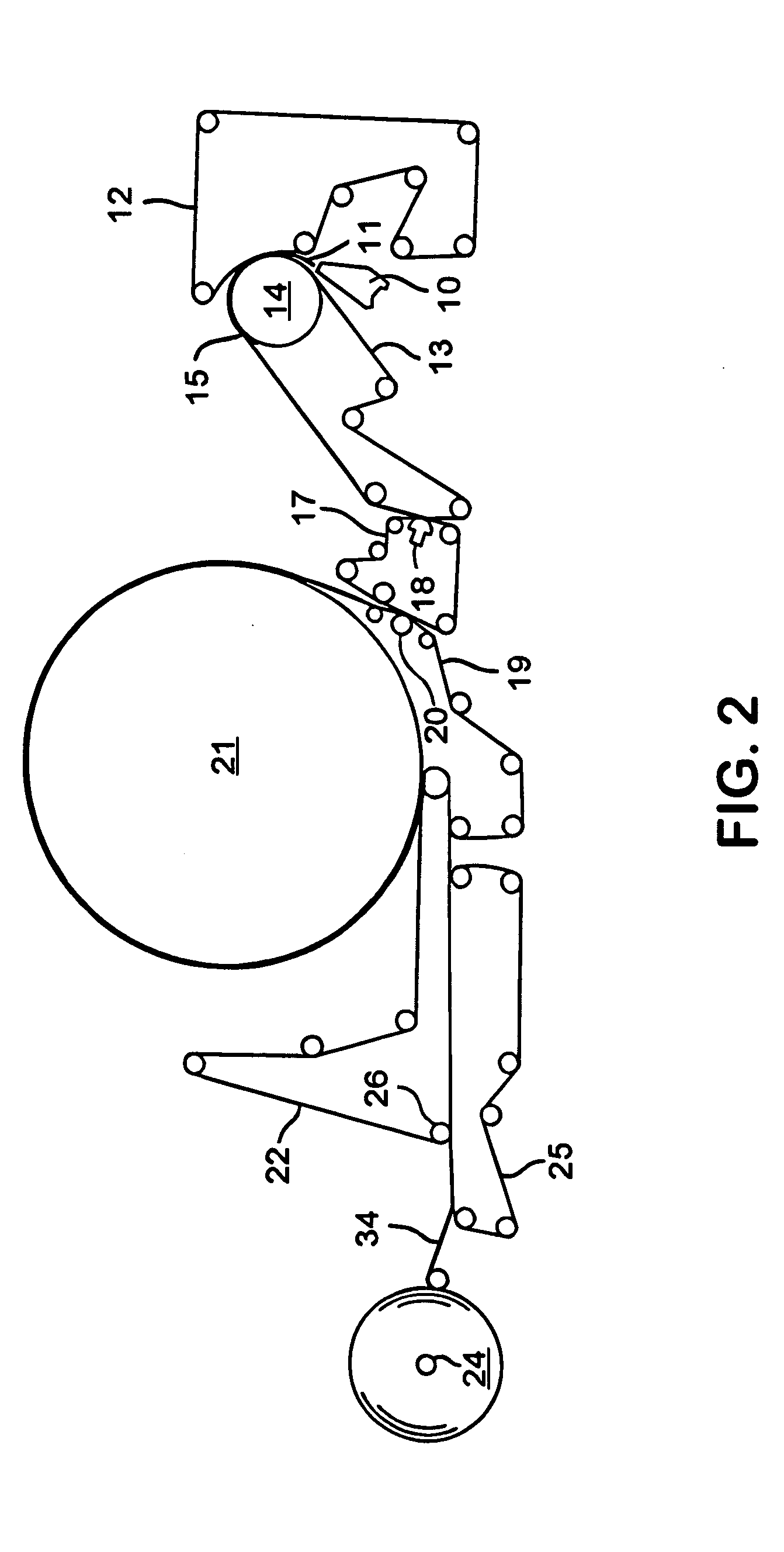

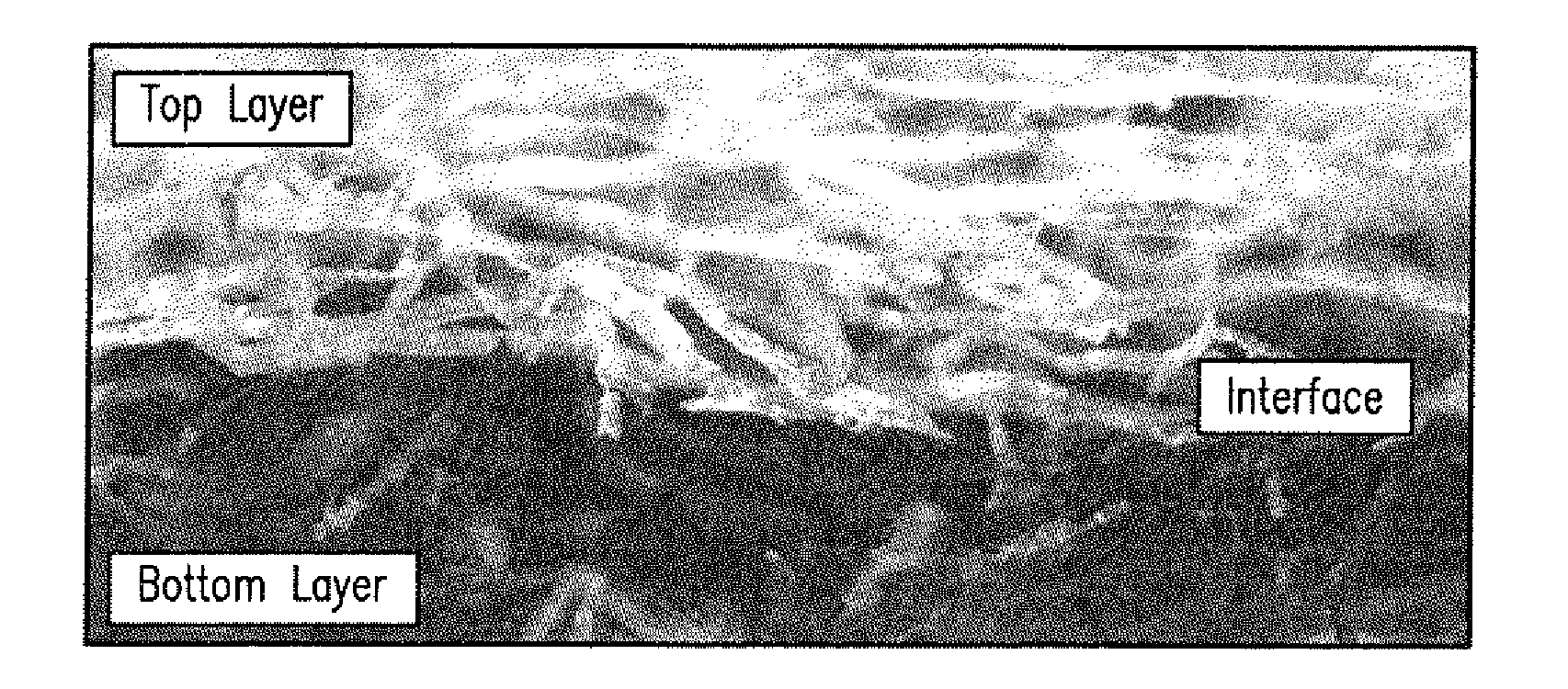

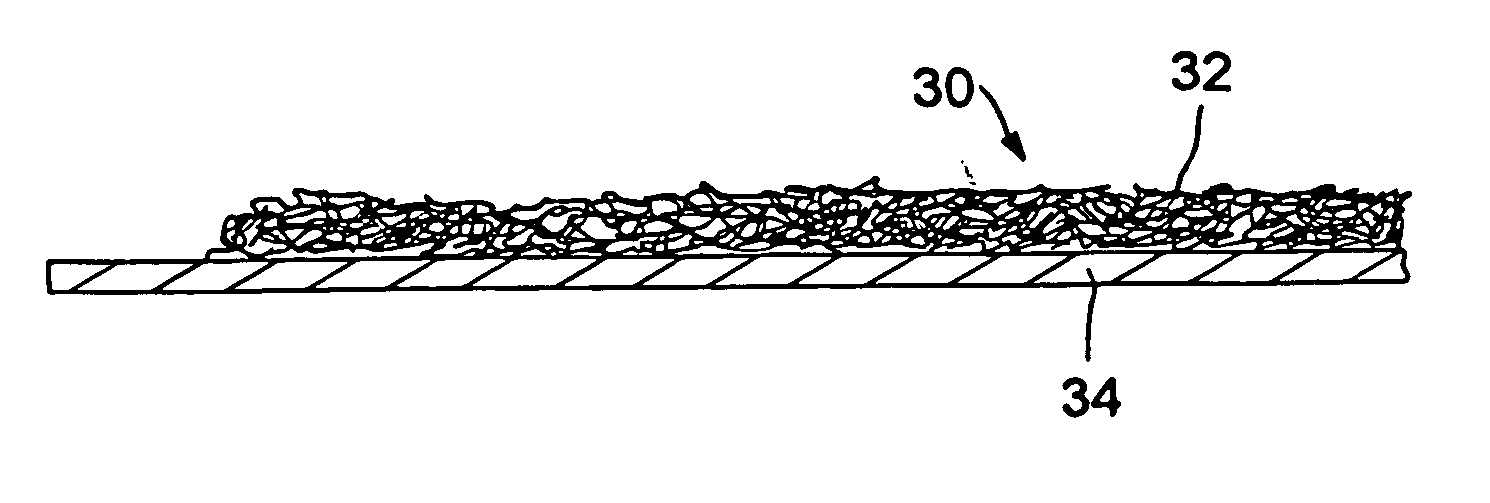

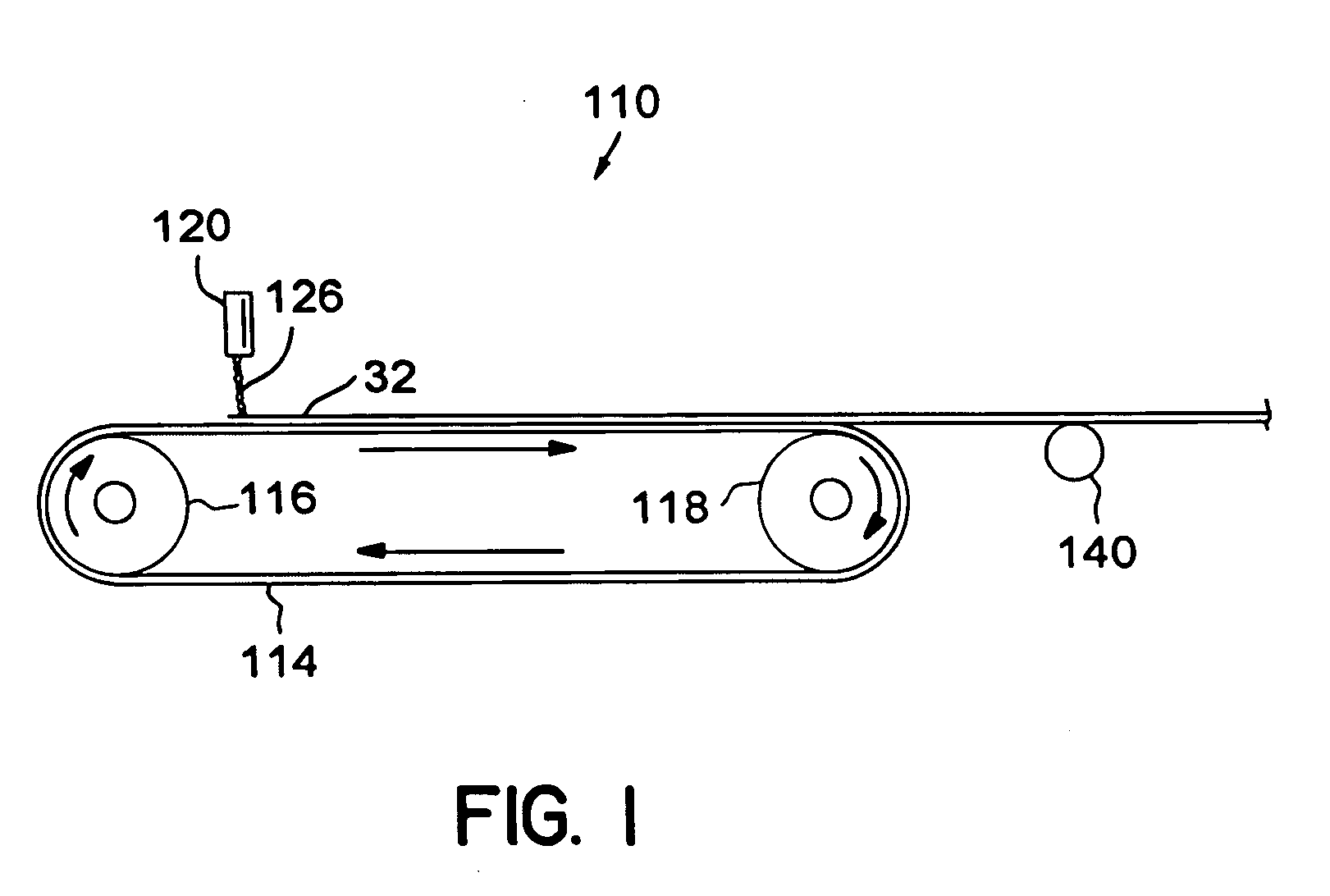

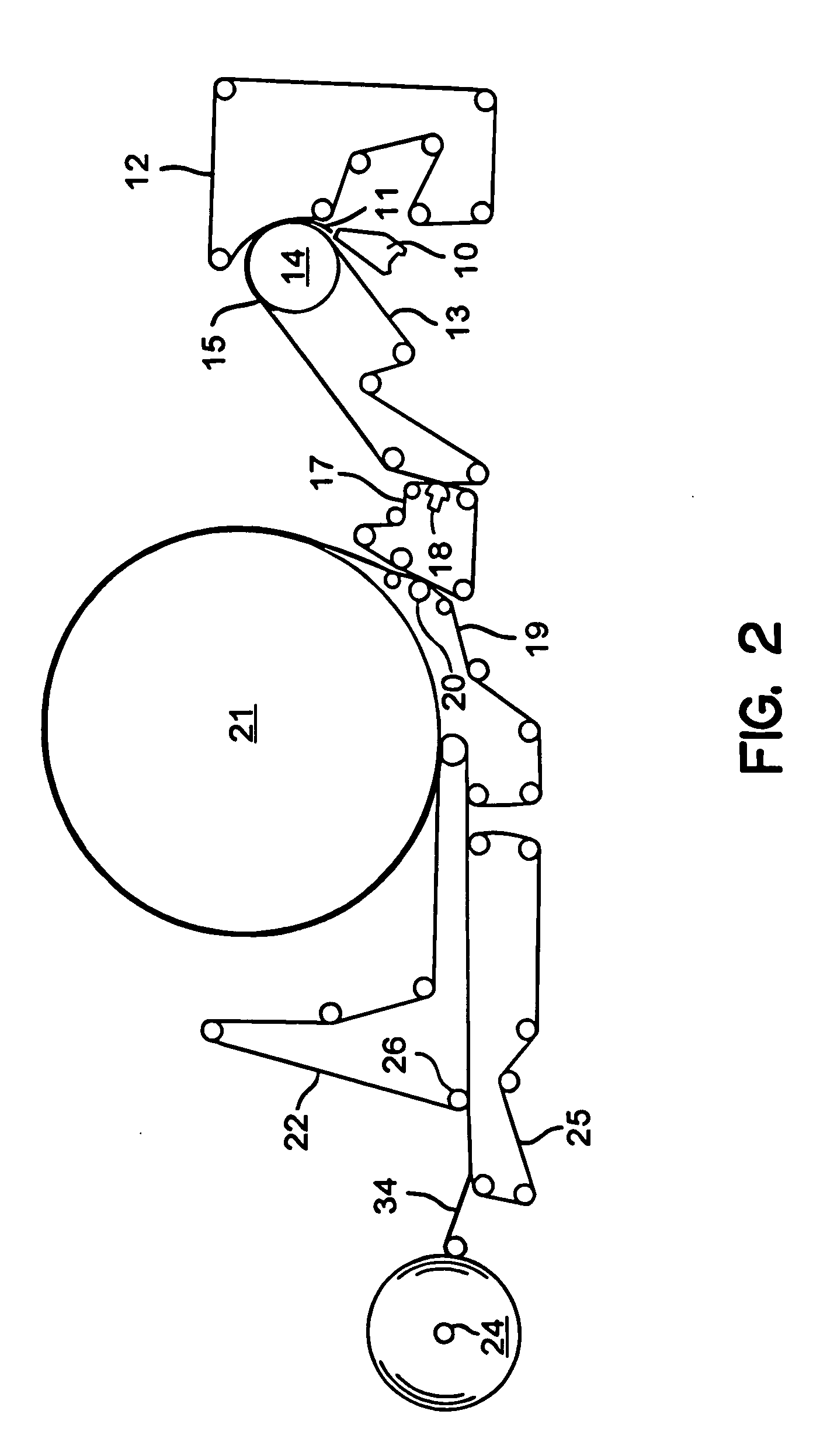

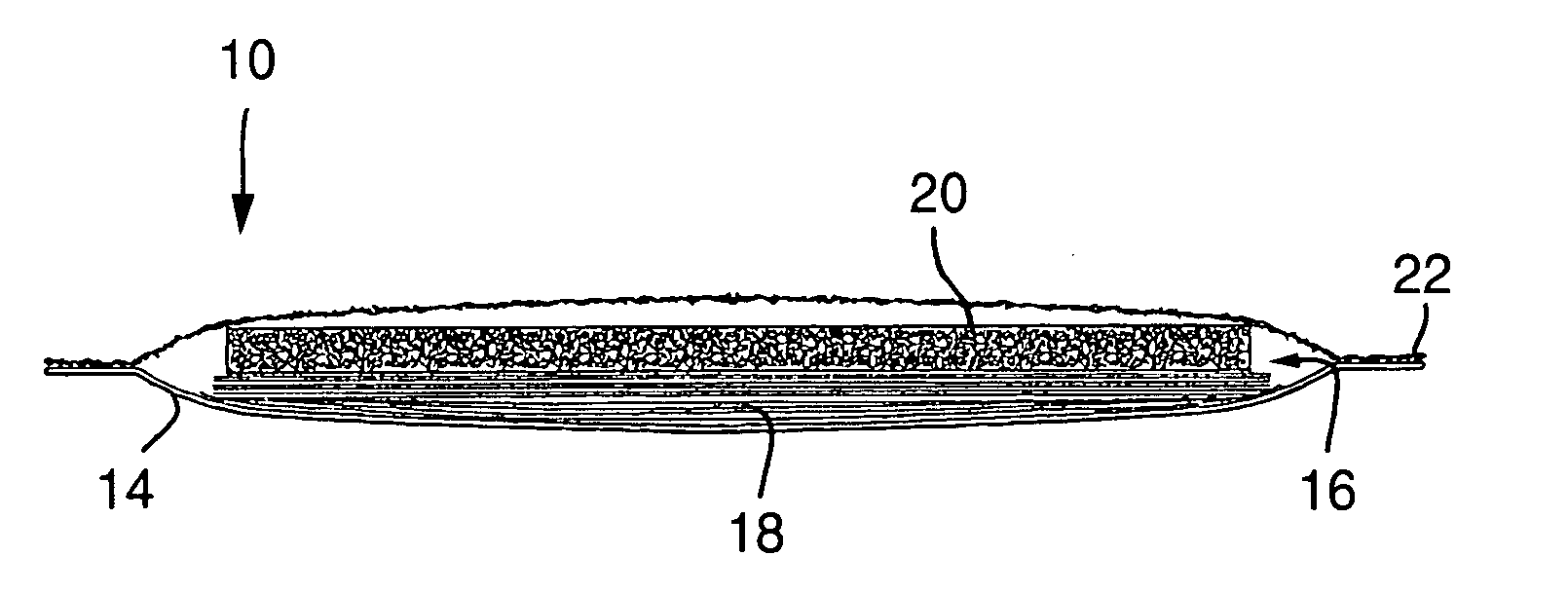

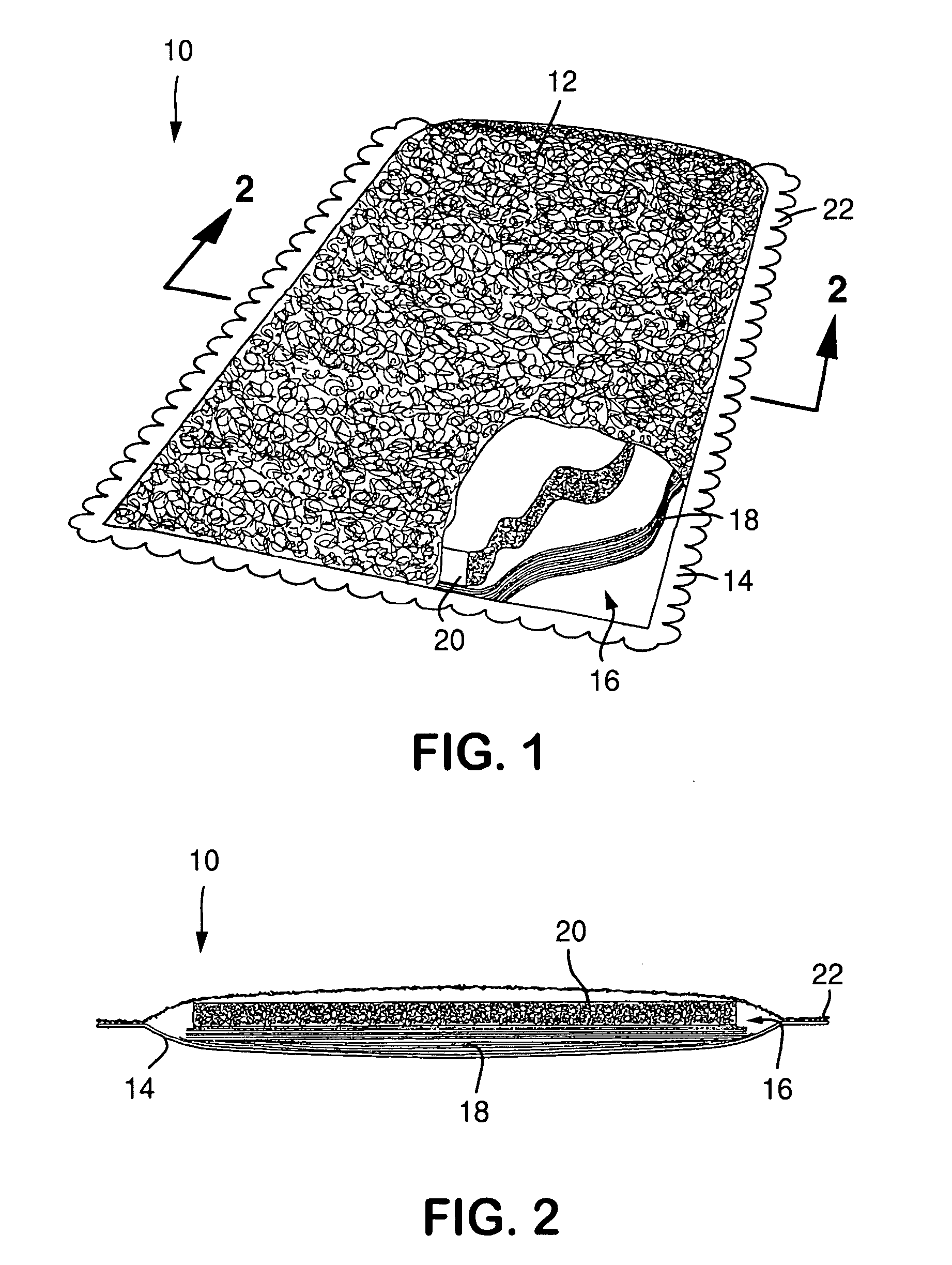

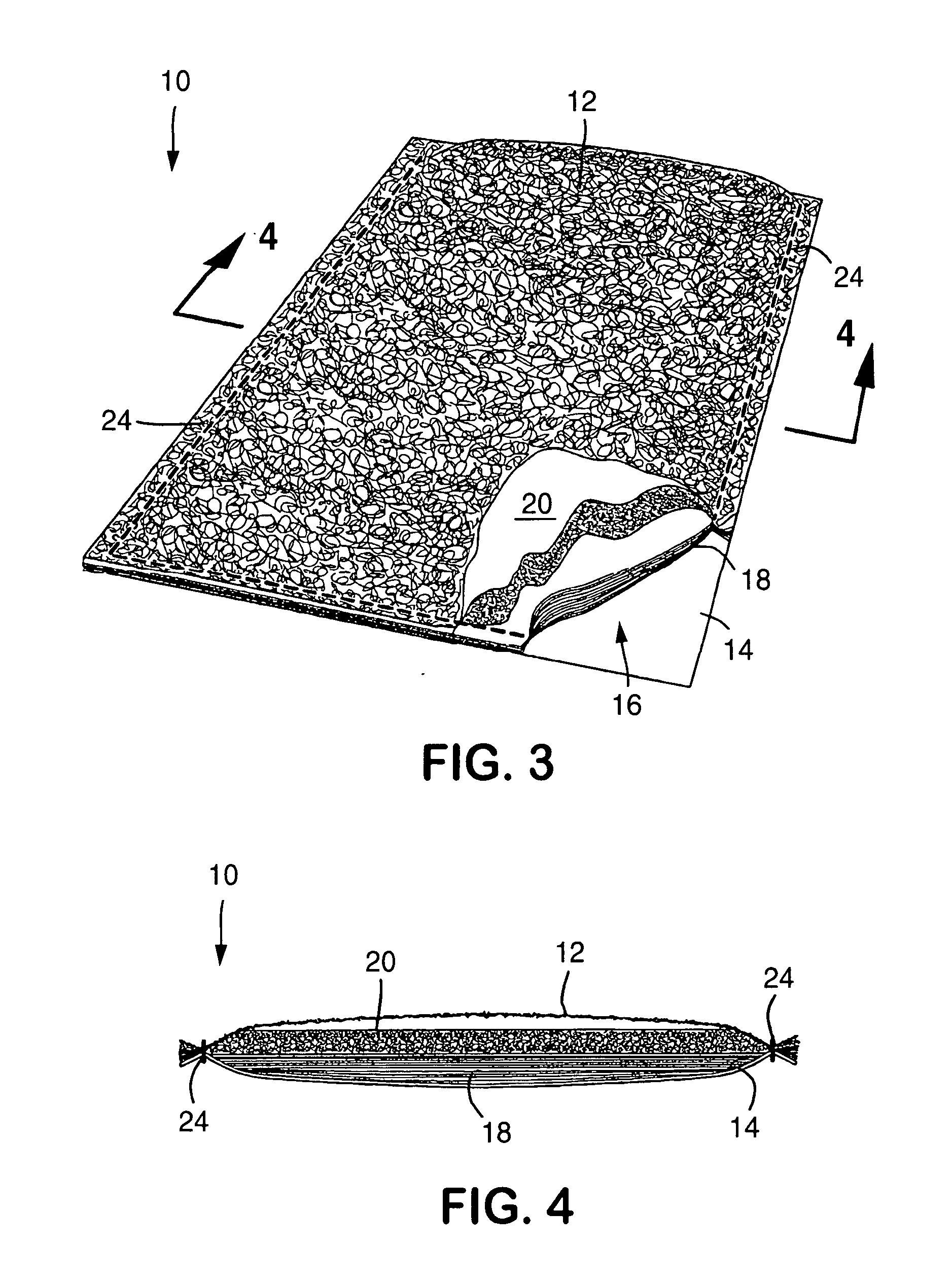

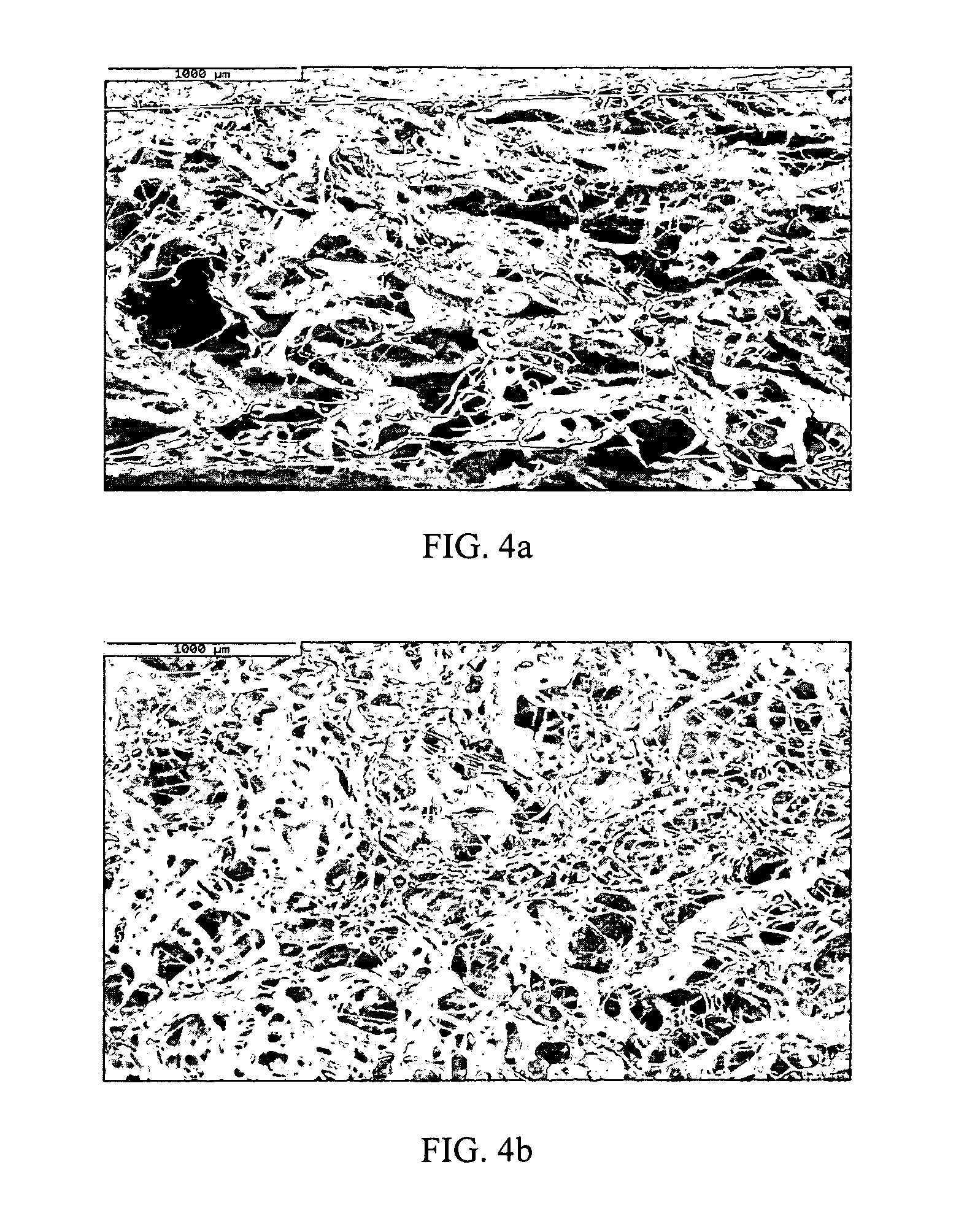

The present invention discloses a disposable scrubbing product for use in household cleaning or personal care applications. In one embodiment, the present invention is directed to a cleaning tool including a handle and a rigid base to which the scrubbing product of the present invention may be attached to form a convenient cleaning tool. The scrubbing product of the invention is a multi-layer laminate product and generally includes at least two distinct layers, an abrasive layer and an absorbent fibrous layer such as a layer tissue made from papermaking fibers, a layer of coform, an airlaid web, or combinations thereof. The abrasive layer is formed primarily of polymeric fibers in a disordered or random distribution as is typical of fibers deposited in meltblown or spunbond processes so as to form an open, porous structure. In one embodiment, the abrasive layer comprises multifilamentary aggregate fibers. In one embodiment, the absorbent fibrous layer is an uncreped, through dried paper web.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Composite structures containing tissue webs and other nonwovens

InactiveUS20050136772A1Resists effect of waterMaintain stiffnessPersonal careCarpet cleanersEngineeringPolymer

The present invention discloses a disposable scrubbing product for use in household cleaning or personal care applications. In one embodiment, the present invention is directed to a cleaning tool including a handle and a rigid base to which the scrubbing product of the present invention may be attached to form a convenient cleaning tool. The scrubbing product of the invention is a multi-layer laminate product and generally includes at least two distinct layers, an abrasive layer and an absorbent fibrous layer such as a tissue layer made from papermaking fibers. The abrasive layer is formed primarily of polymeric fibers in a disordered or random distribution as is typical of fibers deposited in meltblown or spunbond processes so as to form an open, porous structure. In one embodiment, an anchoring agent, such as synthetic fibers, are incorporated into the tissue layer that form a bond with the abrasive layer when forming a laminate in accordance with the present invention.

Owner:KIMBERLY-CLARK WORLDWIDE INC

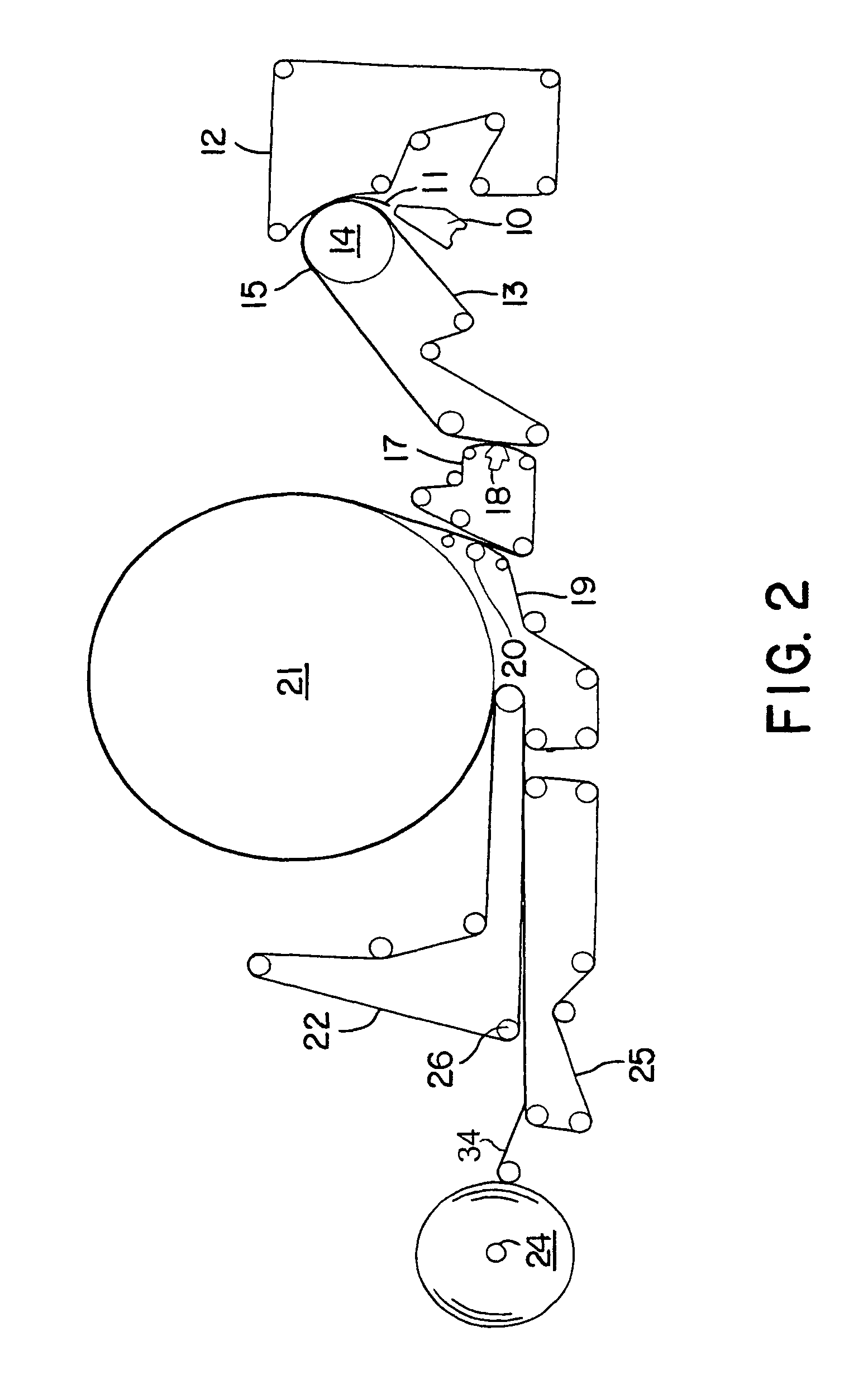

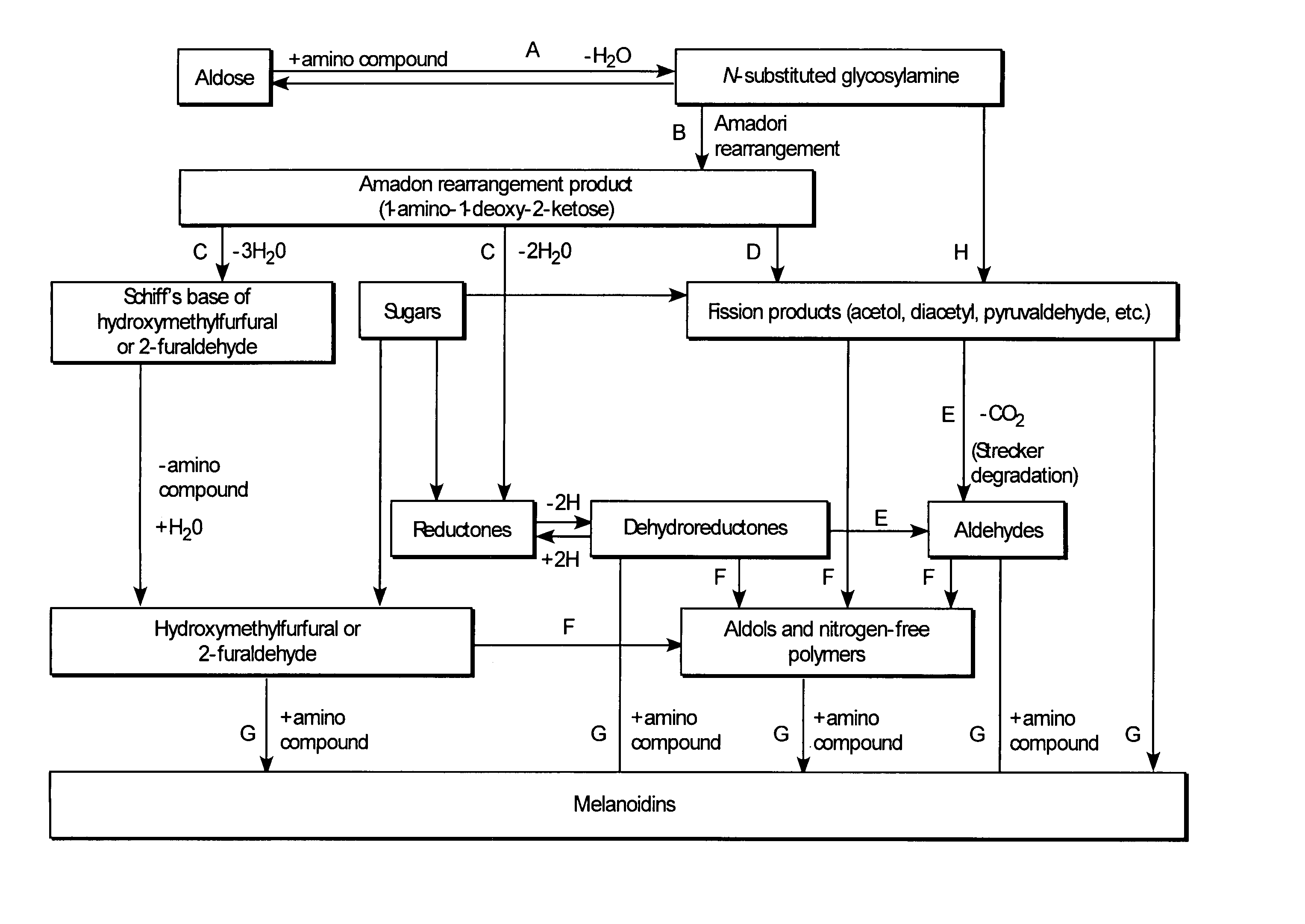

Method for increasing the strength of a cellulosic product

InactiveUS7090745B2Increased amine contentSure easyNatural cellulose pulp/paperSpecial paperCellulosePolymer science

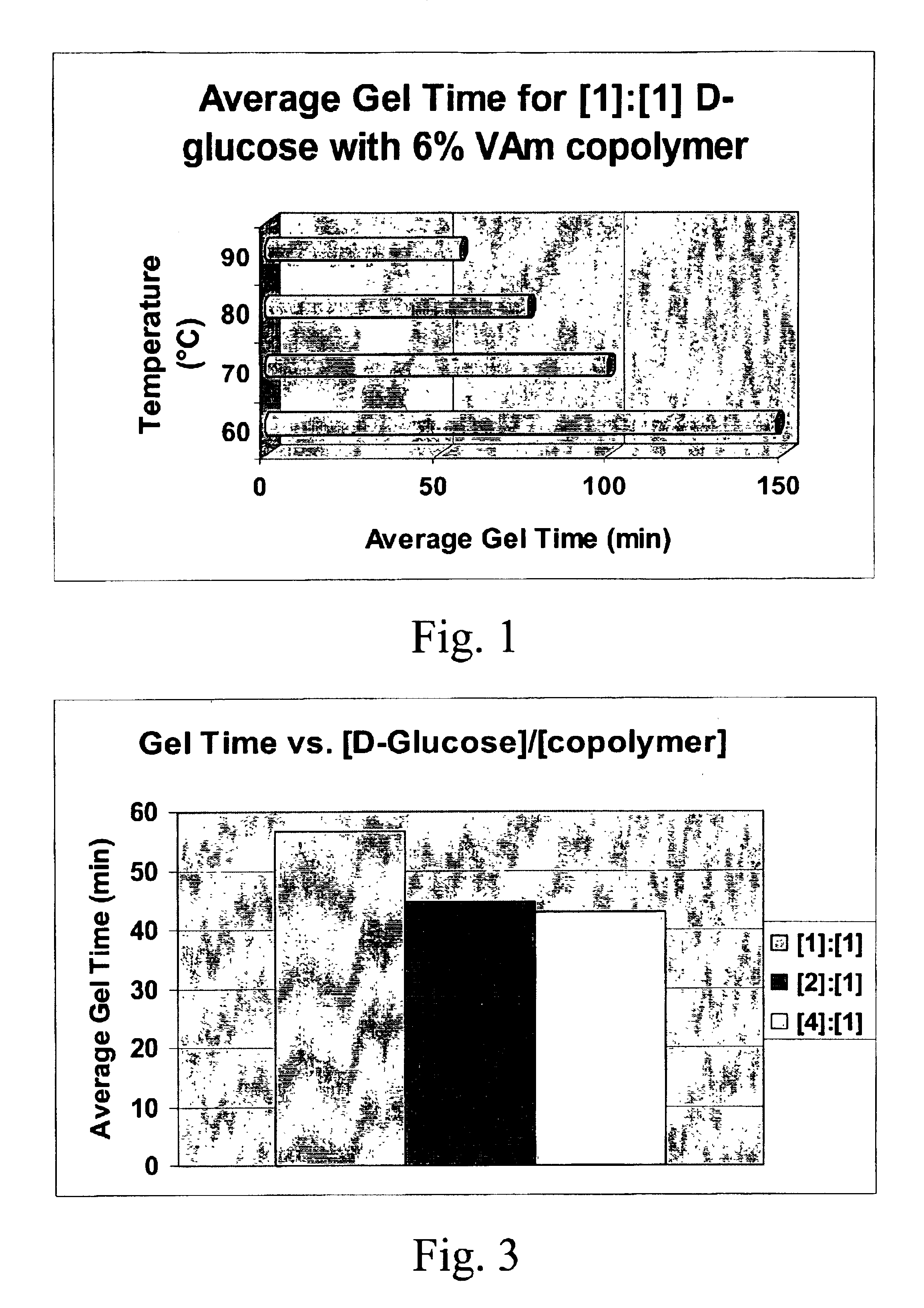

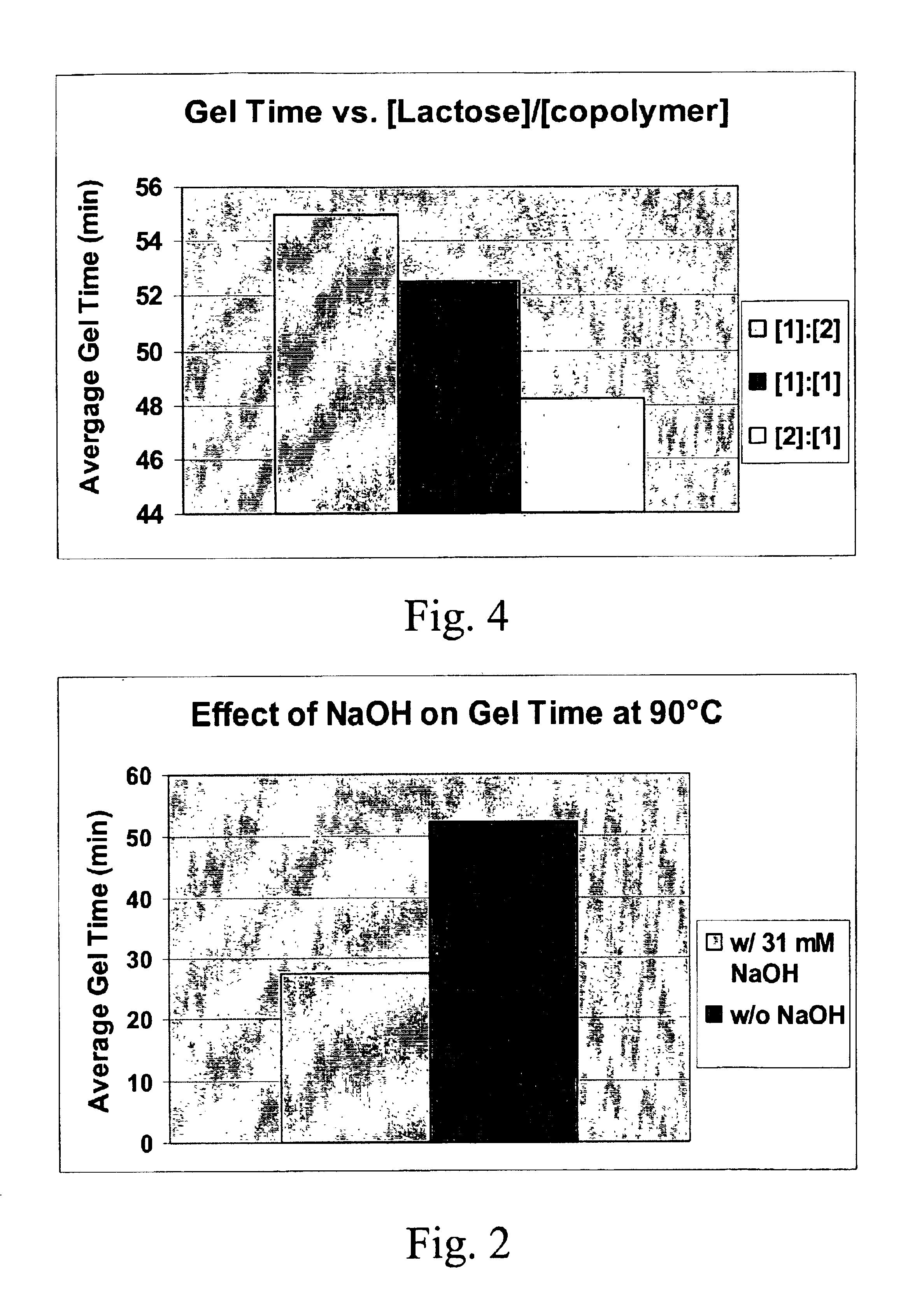

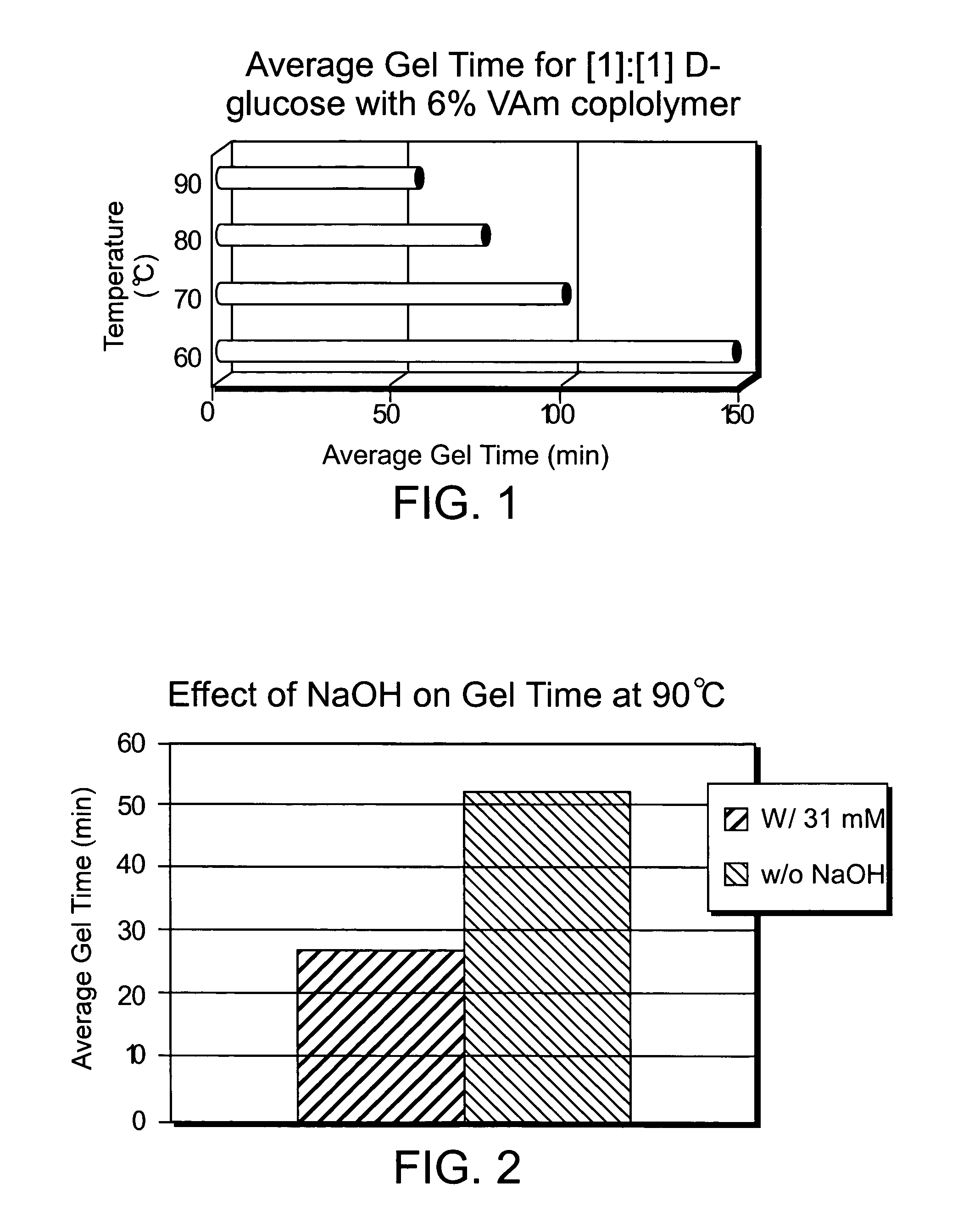

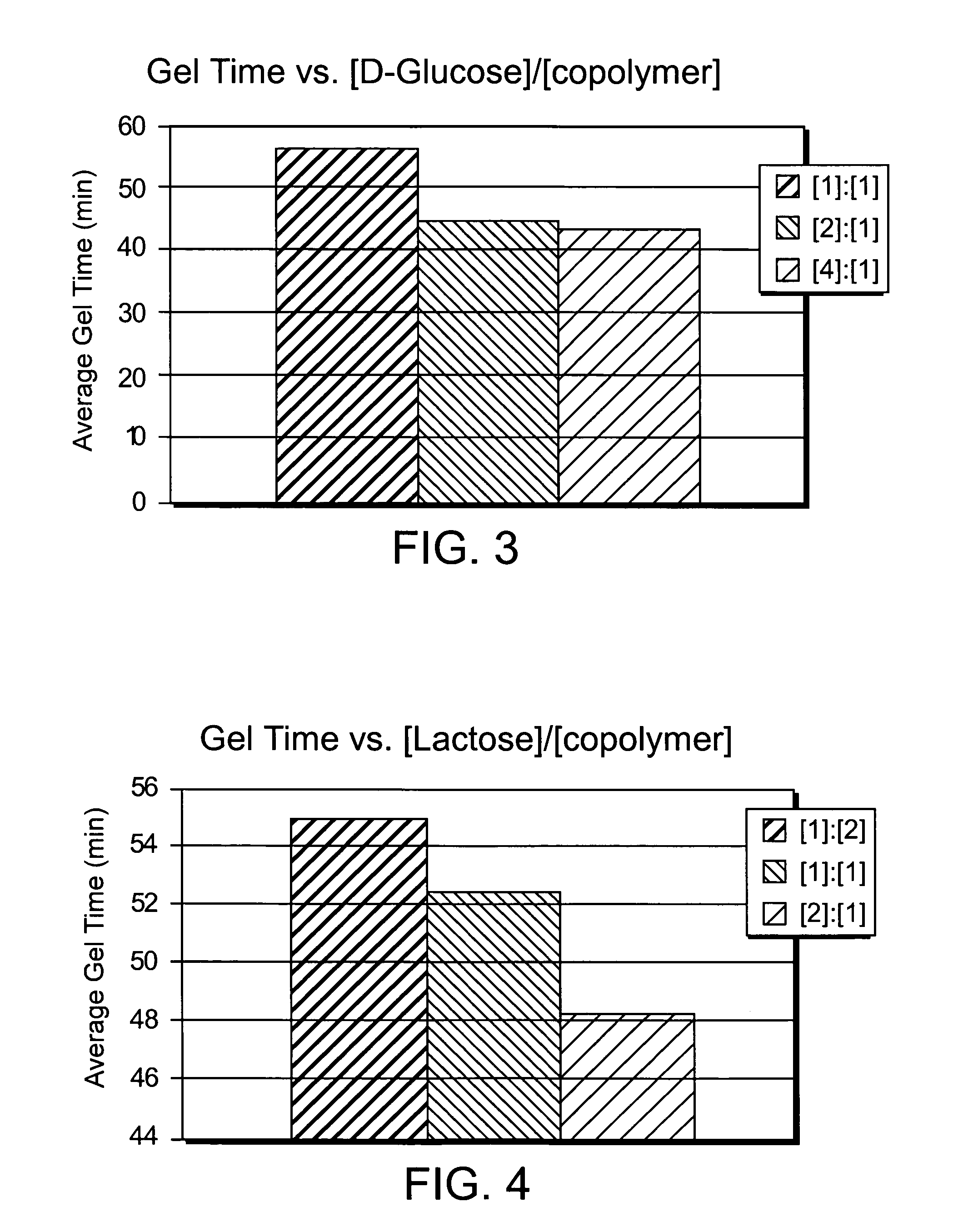

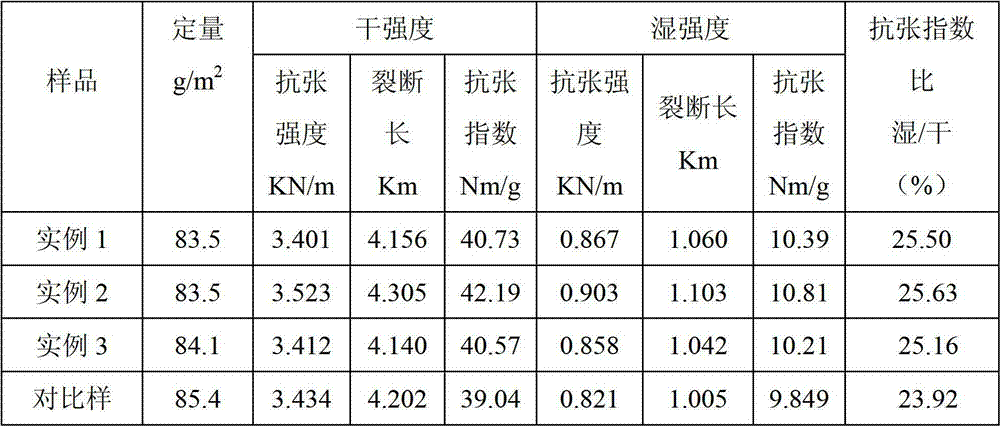

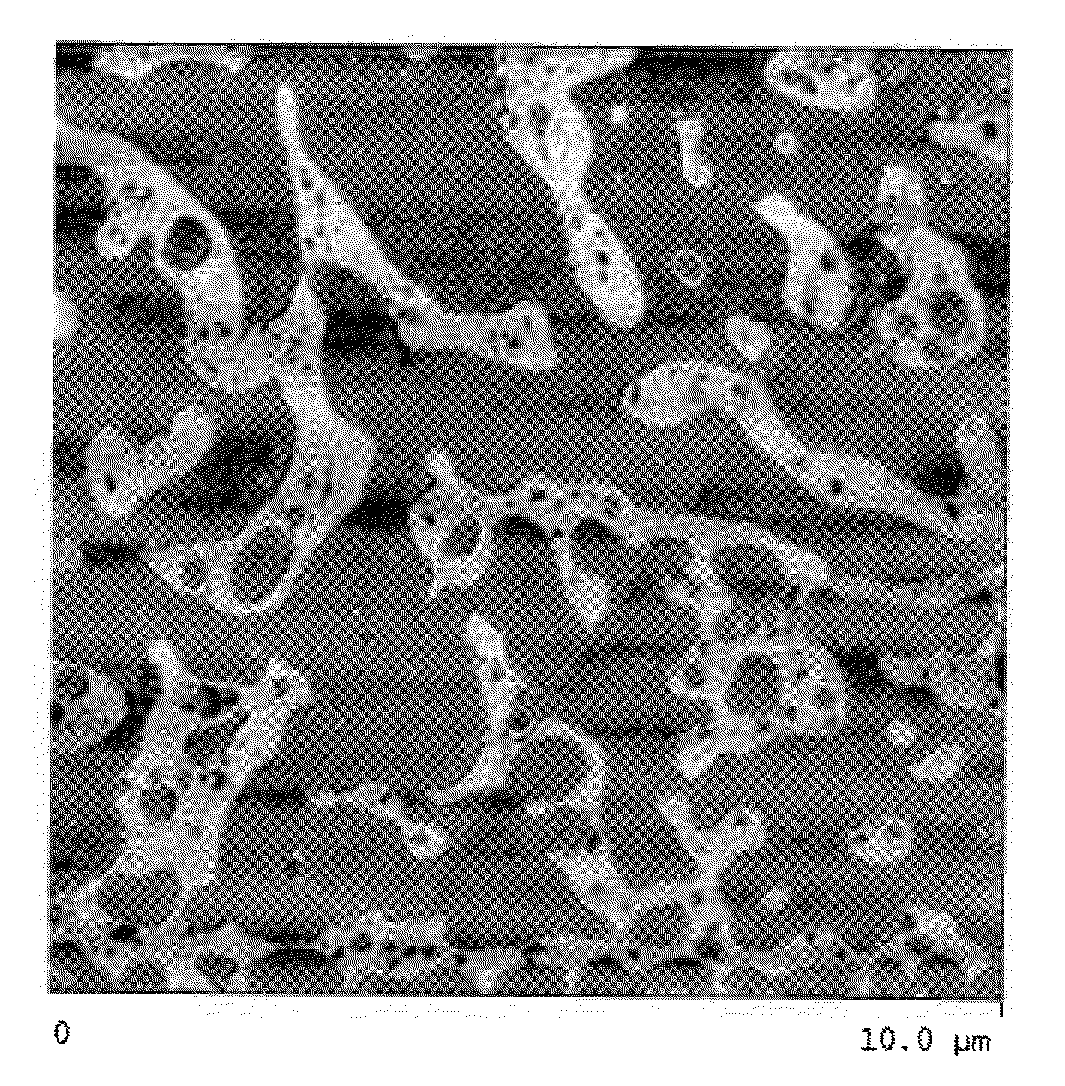

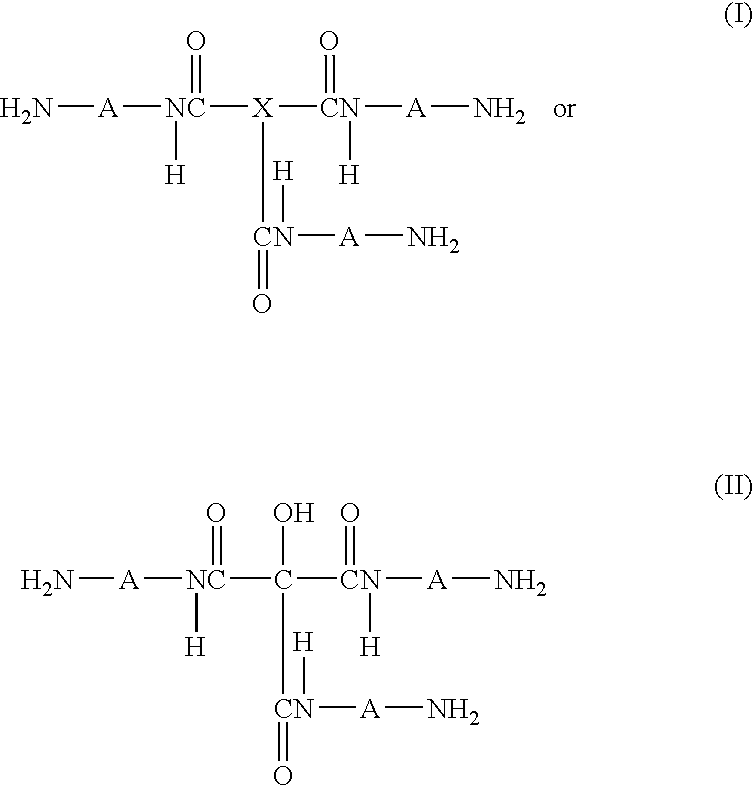

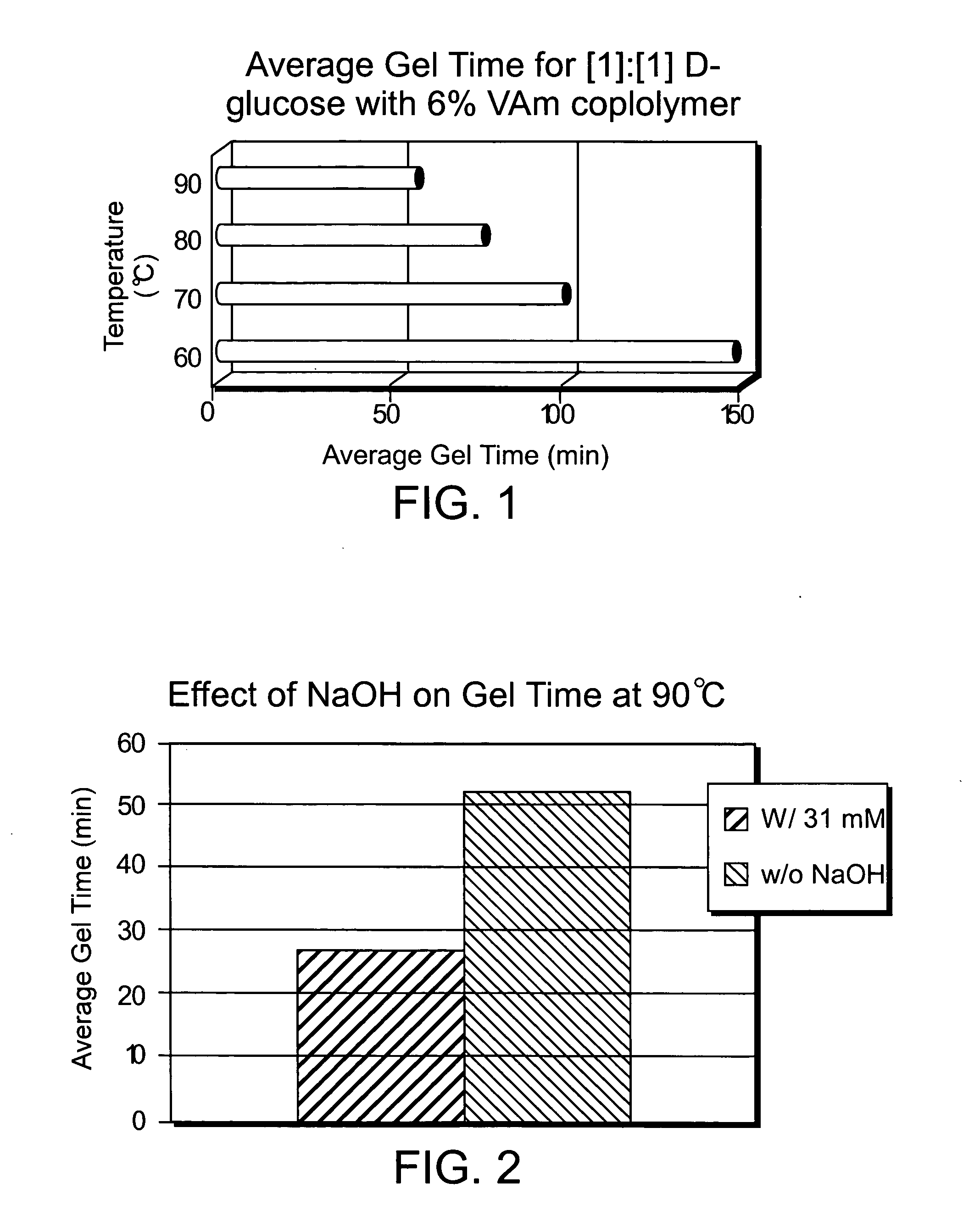

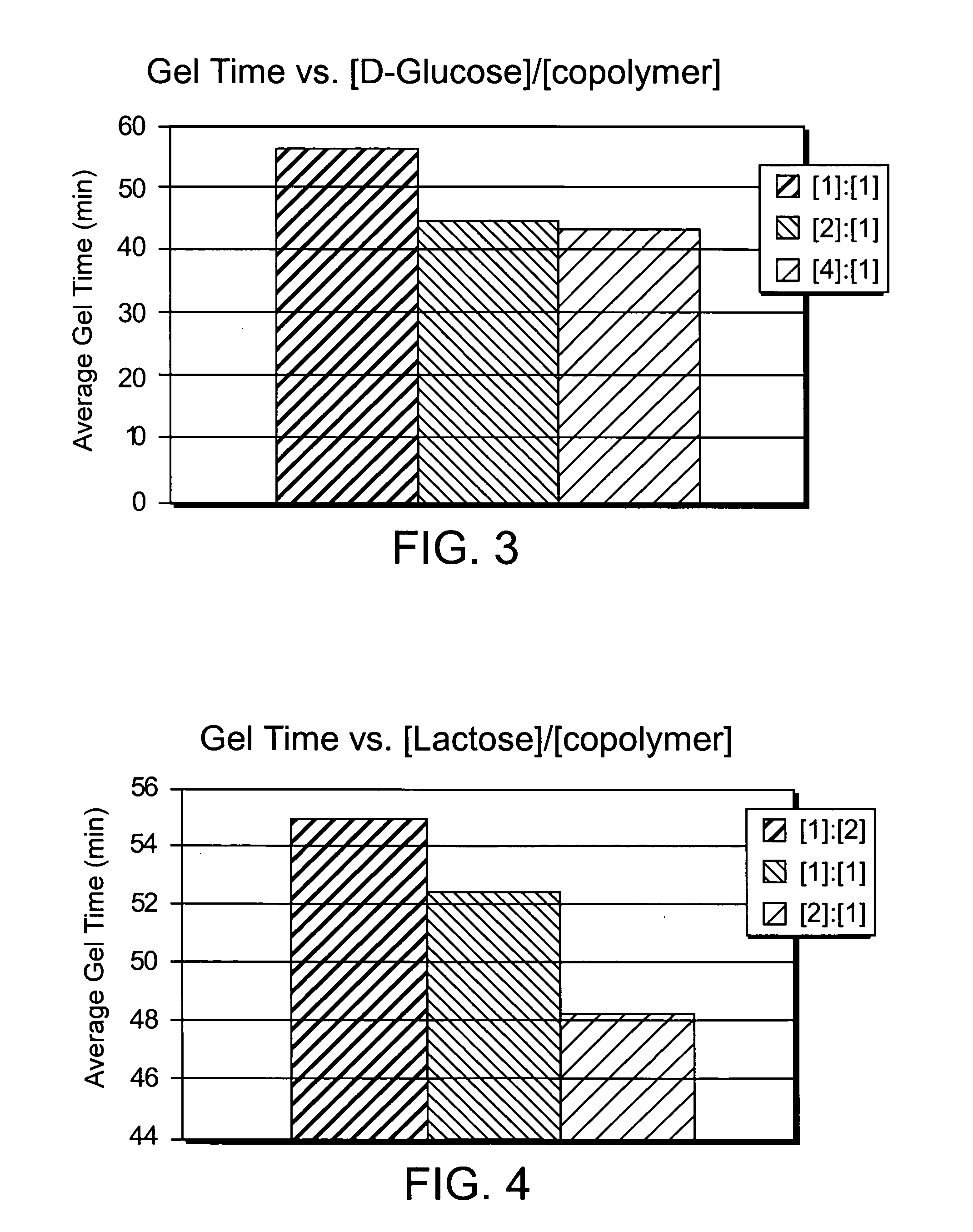

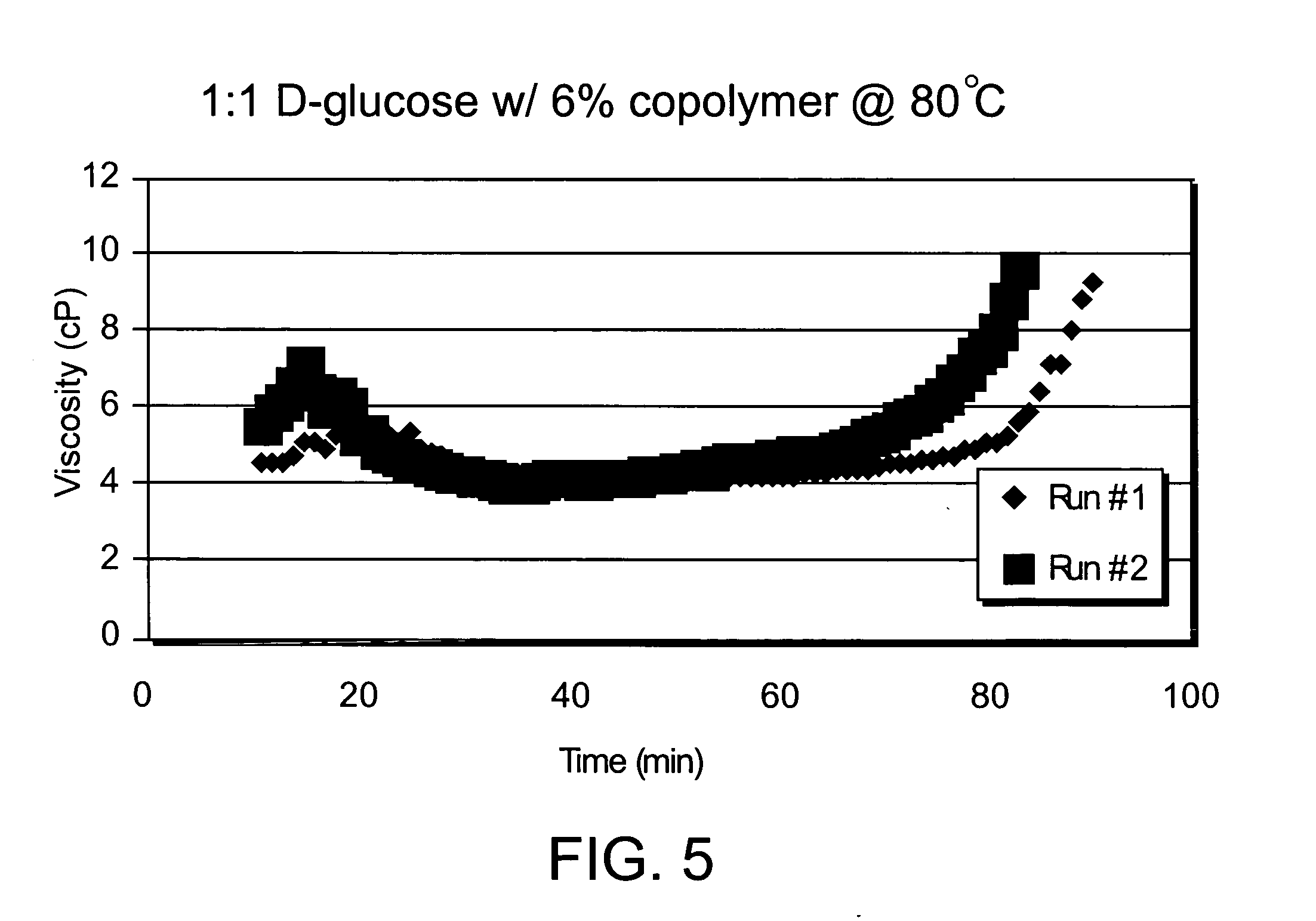

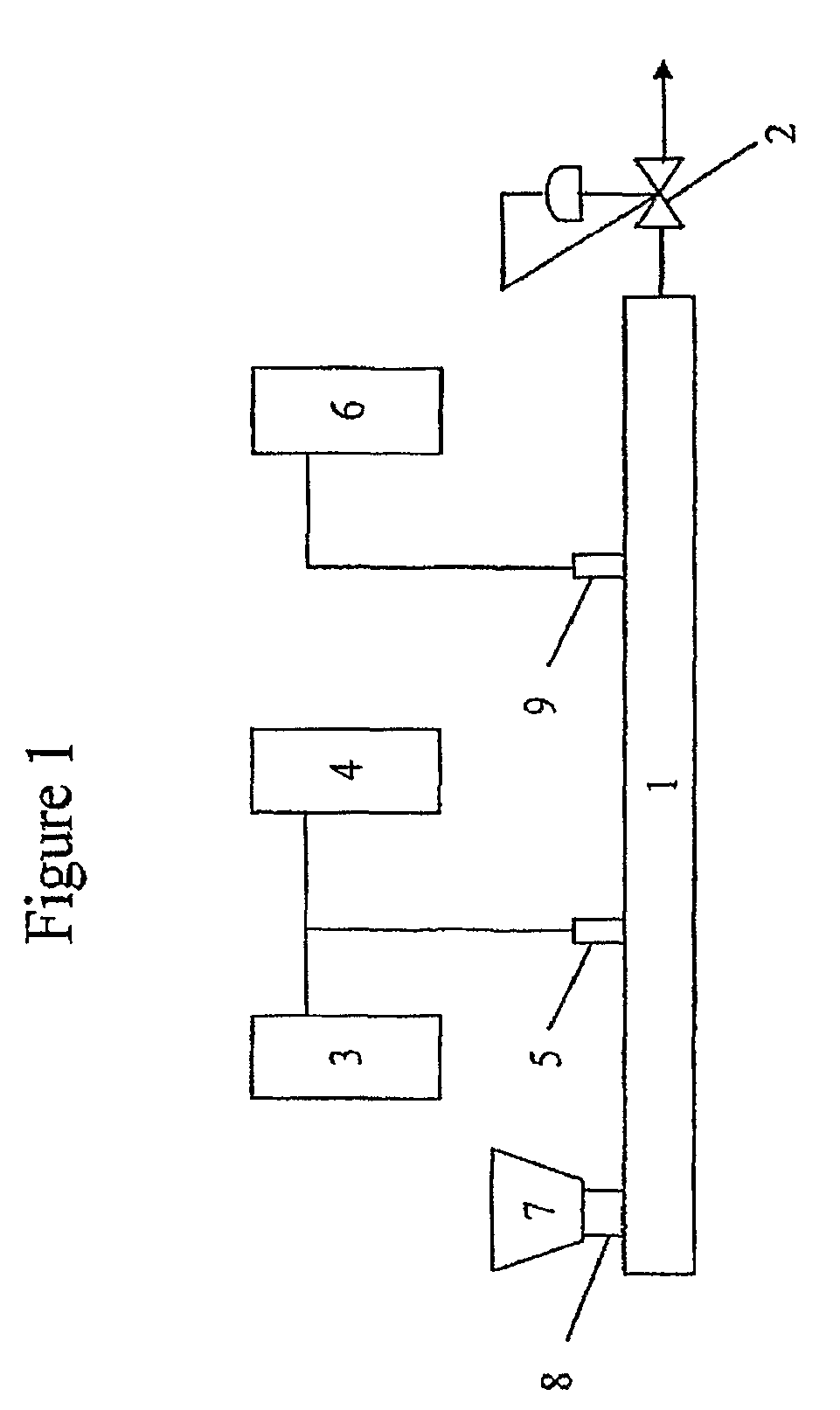

A composition includes at least one hydrophilic polymer containing primary (—NH2) and / or secondary (—NHR) amine groups and at least one saccharide containing a reducible function. A method of increasing the strength of paper includes the step of contacting the paper with a composition comprising (i) at least one hydrophilic polymer containing at least two groups which are independently the same or different a primary amine group or a secondary amine group and at least one saccharide containing a reducible function. A hydrogel composition is formed from a mixture of at least one hydrophilic polymer containing at least two groups which are independently the same or different a primary amine group or a secondary amine group and at least one saccharide containing a reducible function.

Owner:UNIVERSITY OF PITTSBURGH +1

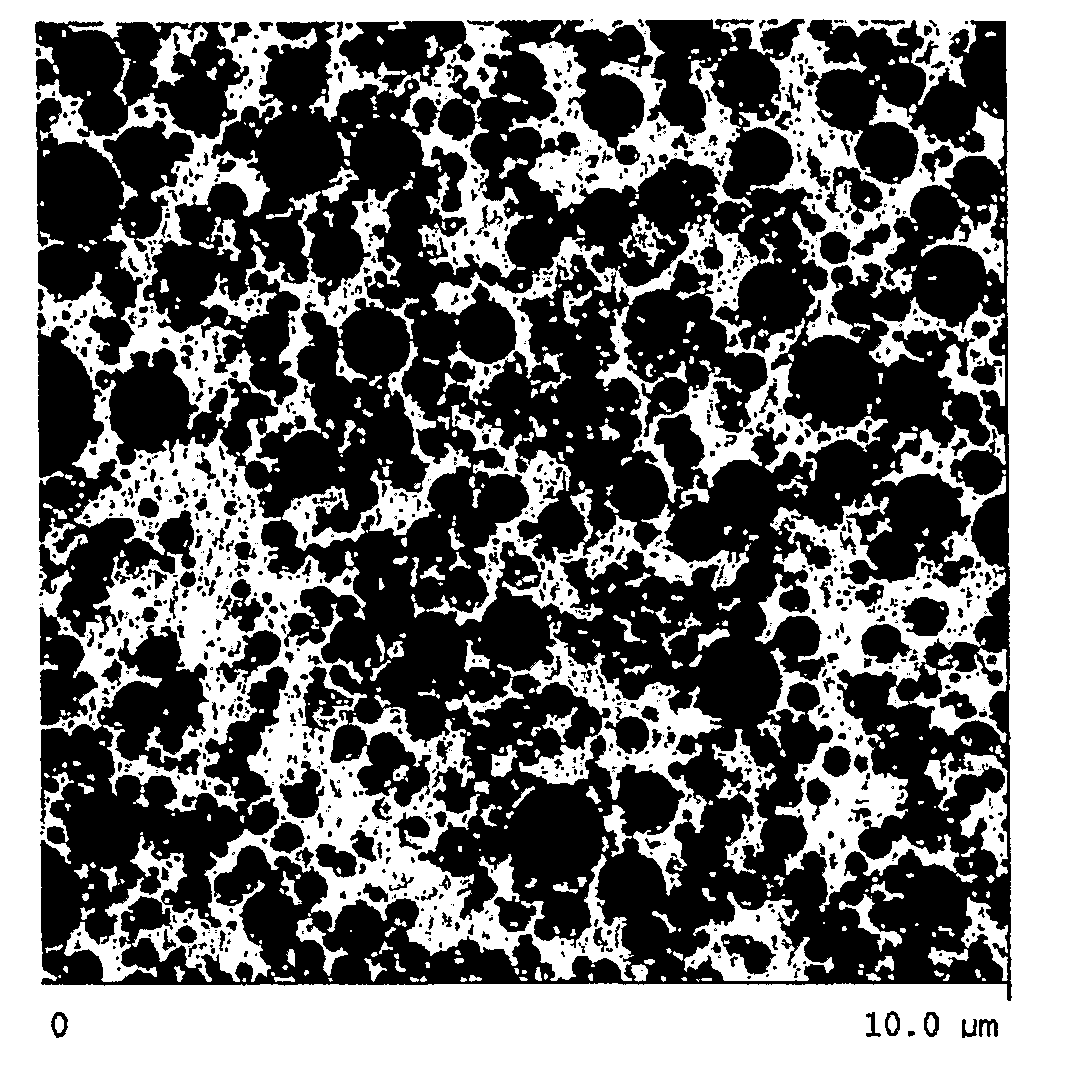

Dispersible nonwoven wipe material

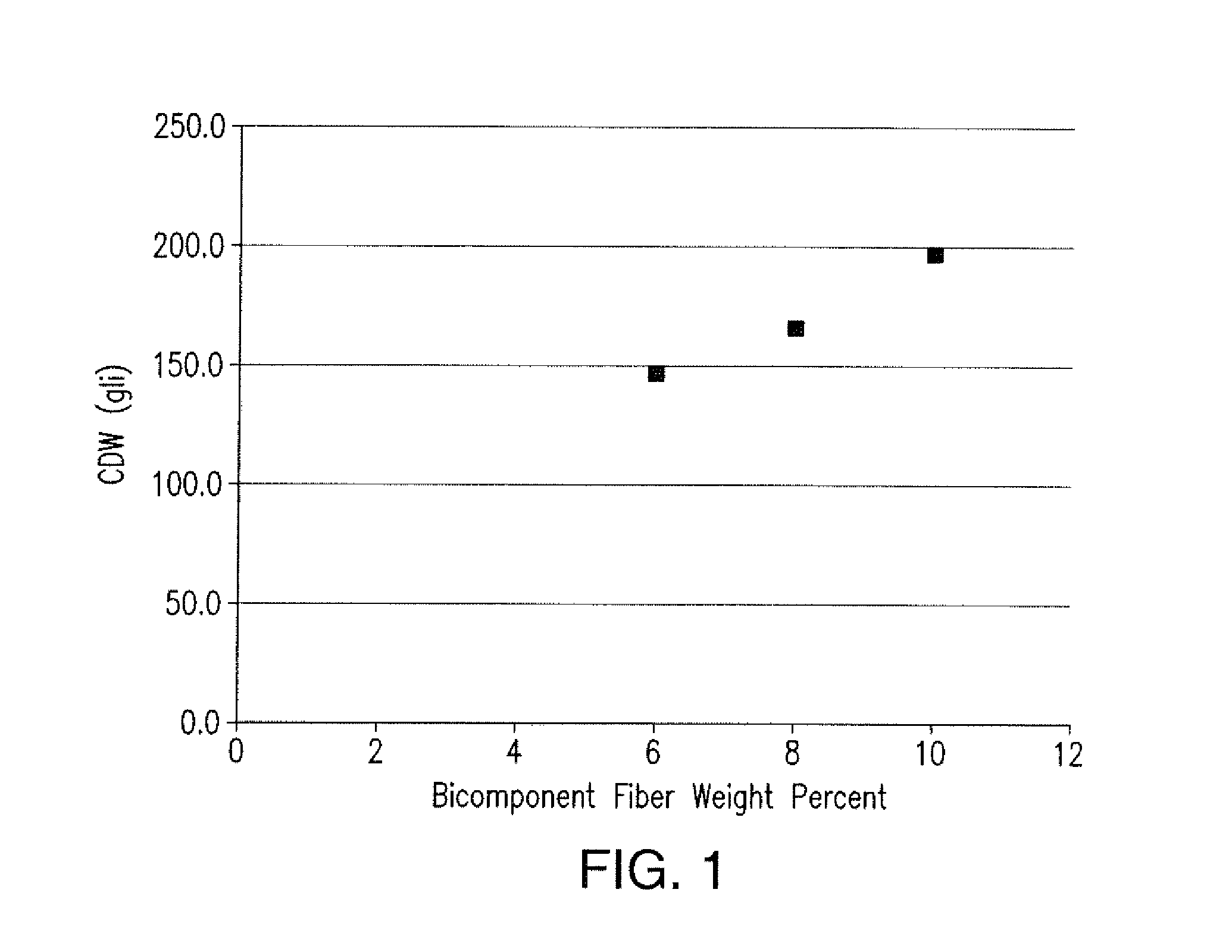

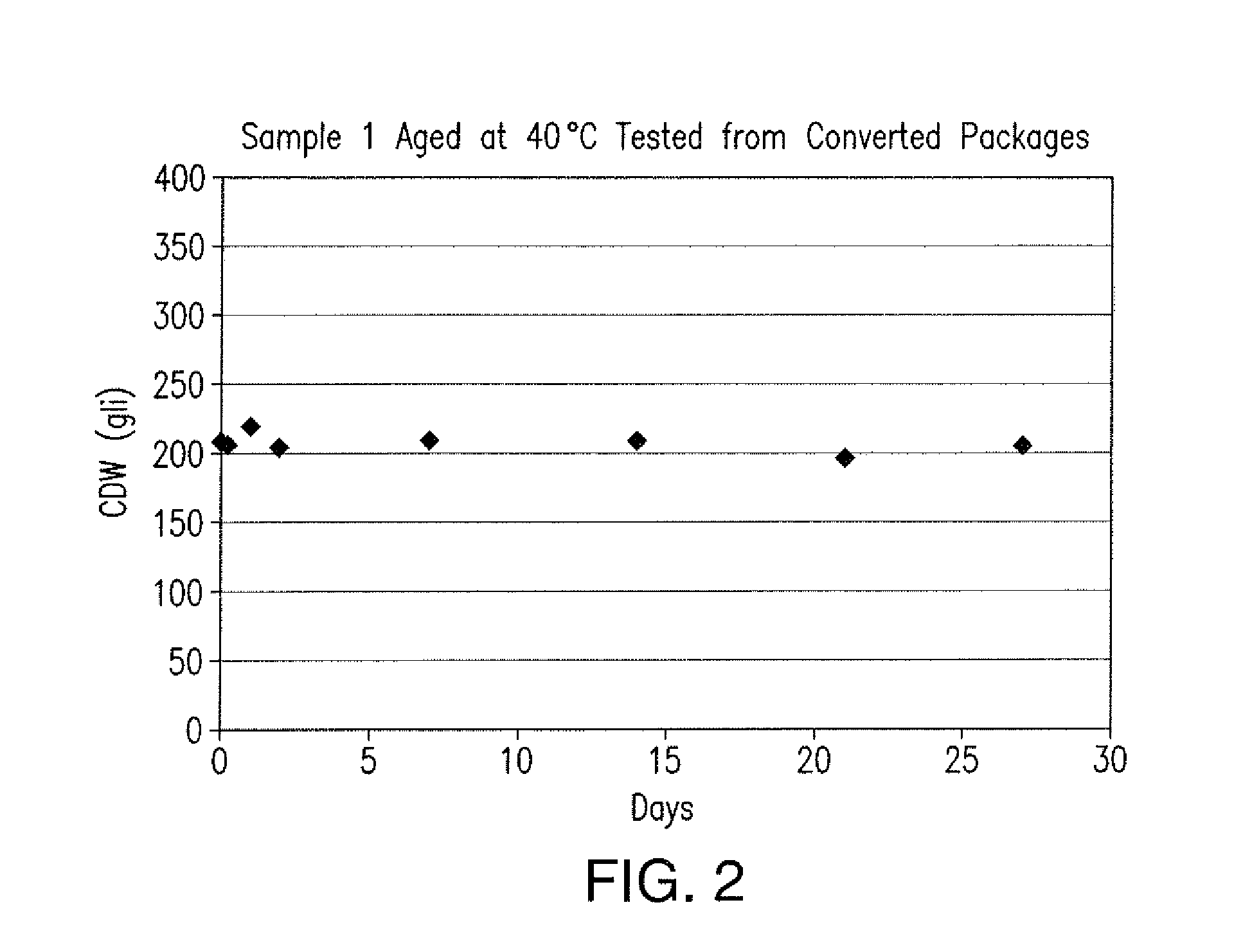

ActiveUS20120144611A1High wet and dry strengthGood dispersionBoard cleaning devicesSpecial paperMedicineSubject matter

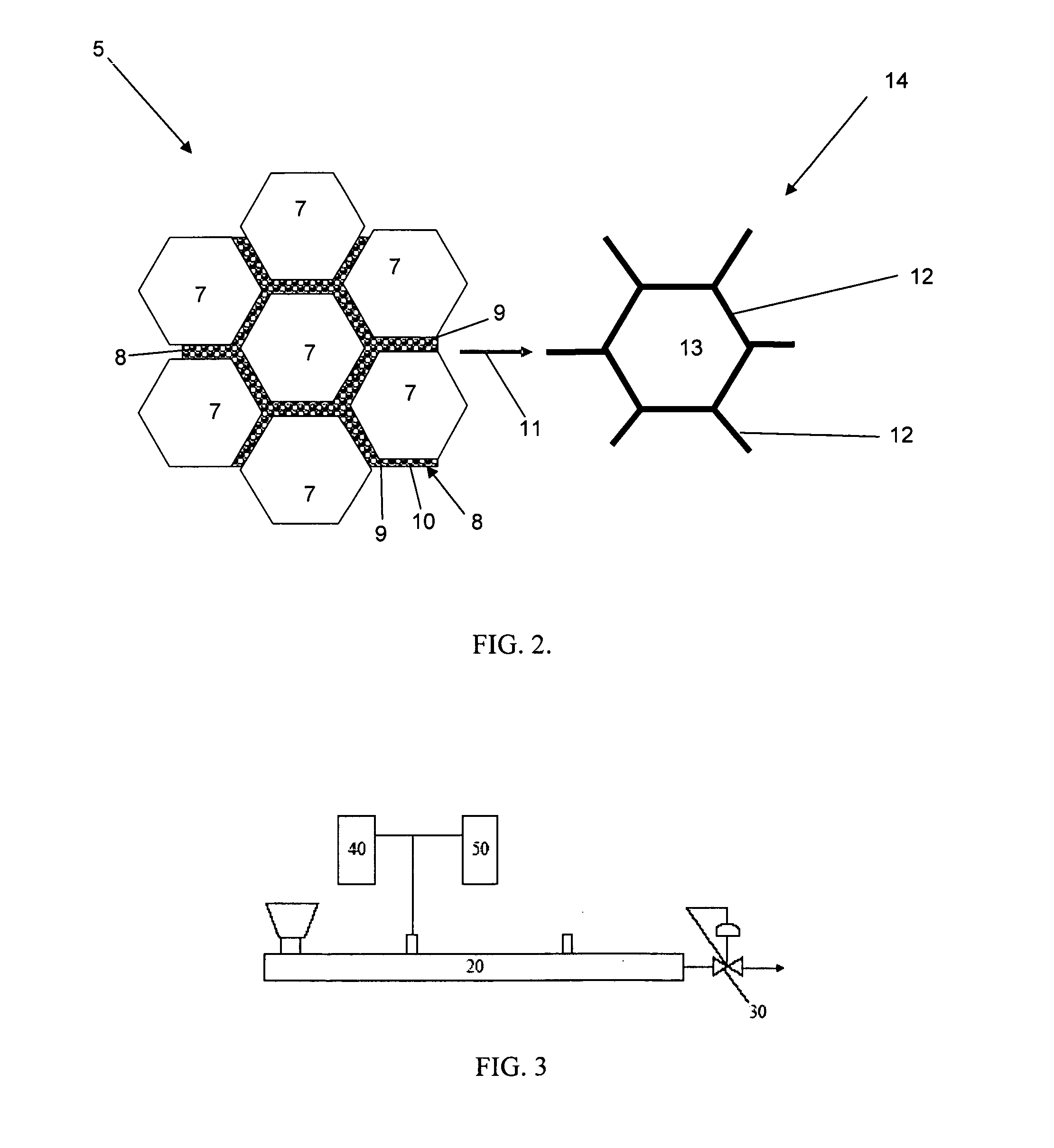

The presently disclosed subject matter relates to a dispersible, nonwoven multistrata wipe material that is stable in a wetting liquid and flushable in use. More particularly, the presently disclosed subject matter relates to multilayered structures including, but not limited to, two, three, or four layers to form the dispersible nonwoven wipe material. The layers contain combinations of cellulosic and noncellulosic fibers, and optionally a binder or additive.

Owner:GLATFELTER CORP

Disposable scrubbing product

InactiveUS20050129897A1Resists effect of waterMaintain stiffnessStampsWrappersEngineeringFibrous layer

The present invention discloses a disposable scrubbing product for use in household cleaning or personal care applications. The scrubbing product of the invention is a multi-layer laminate product and generally includes at least two distinct layers, an abrasive layer and an absorbent fibrous layer such as a layer tissue made from papermaking fibers, a layer of coform, an airlaid web, or combinations thereof. The abrasive layer is formed primarily of polymeric fibers in a disordered or random distribution as is typical of fibers deposited in meltblown or spunbond processes so as to form an open, porous structure. In one embodiment, multiple layers of an abrasive structure are releasably attached together. In this manner, the top or outermost layer may be removed after being used in order to expose an unused abrasive structure located below the discarded layer.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Composite cleaning products having shape resilient layer

InactiveUS20060135026A1Resists effect of waterMaintain stiffnessCarpet cleanersLayered productsPersonal careEngineering

The present invention discloses a disposable cleaning product for use in household cleaning or personal care applications. The cleaning product of the invention is a multi-layer laminate product and may include at least two distinct layers, an abrasive layer and an absorbent layer. The absorbent layer contains a sponge-like member optionally in combination with a plurality of cellulosic fibrous webs. The sponge-like member can be made from various materials. For example, in one embodiment, the sponge-like member comprises one or more layers of a spunbond web containing crimped, bicomponent filaments.

Owner:KIMBERLY-CLARK WORLDWIDE INC

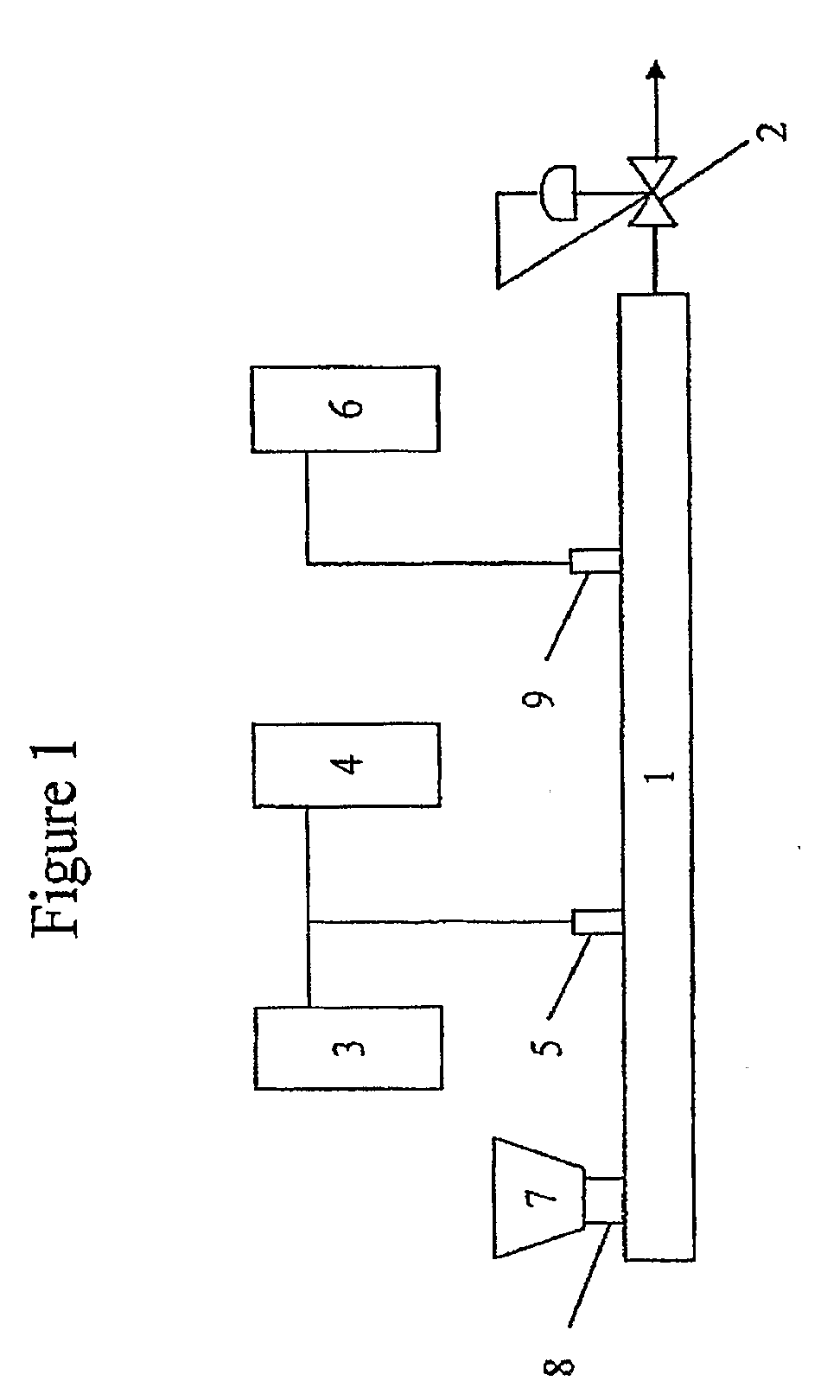

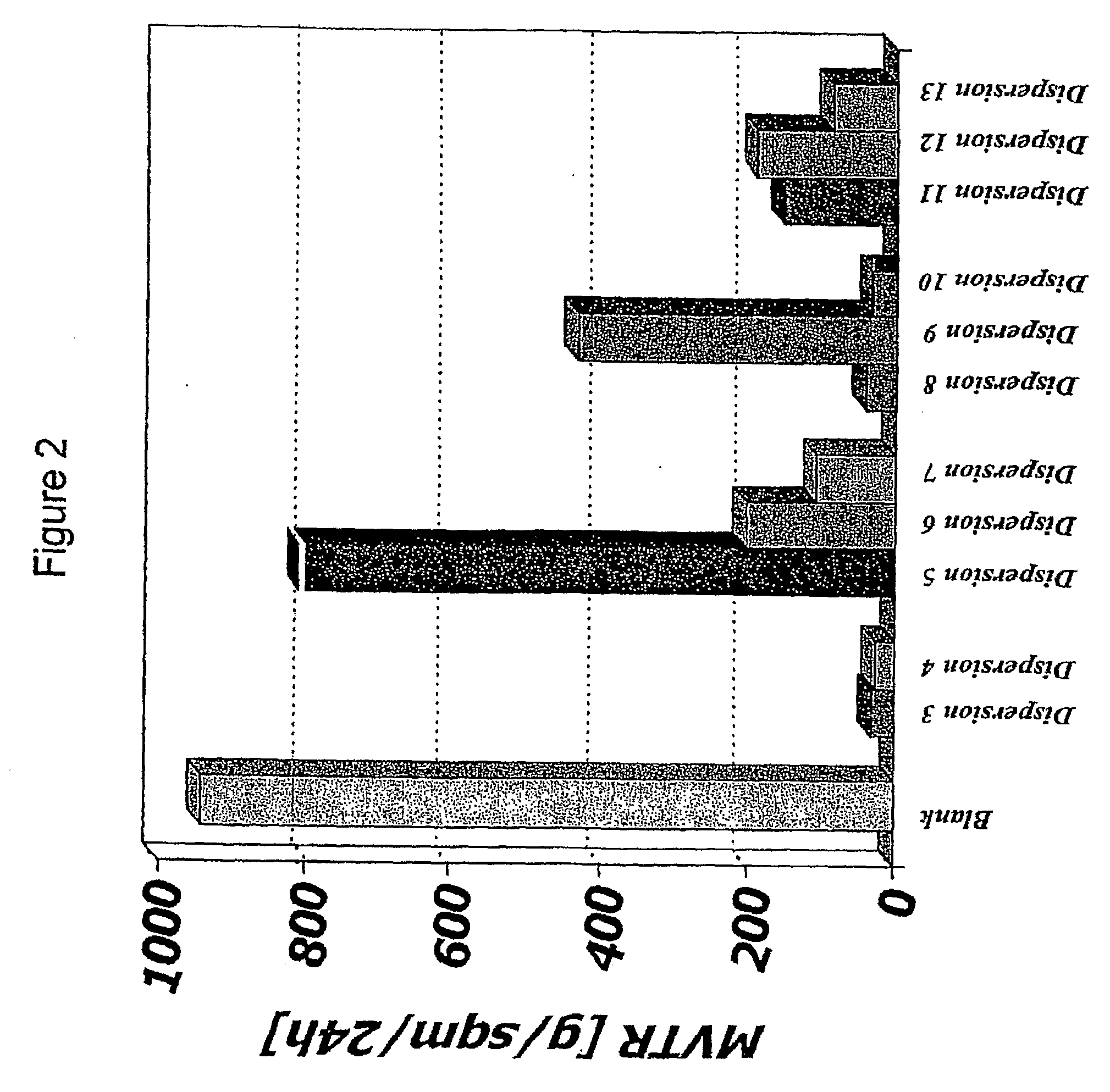

Fibrillated polyolefin foam

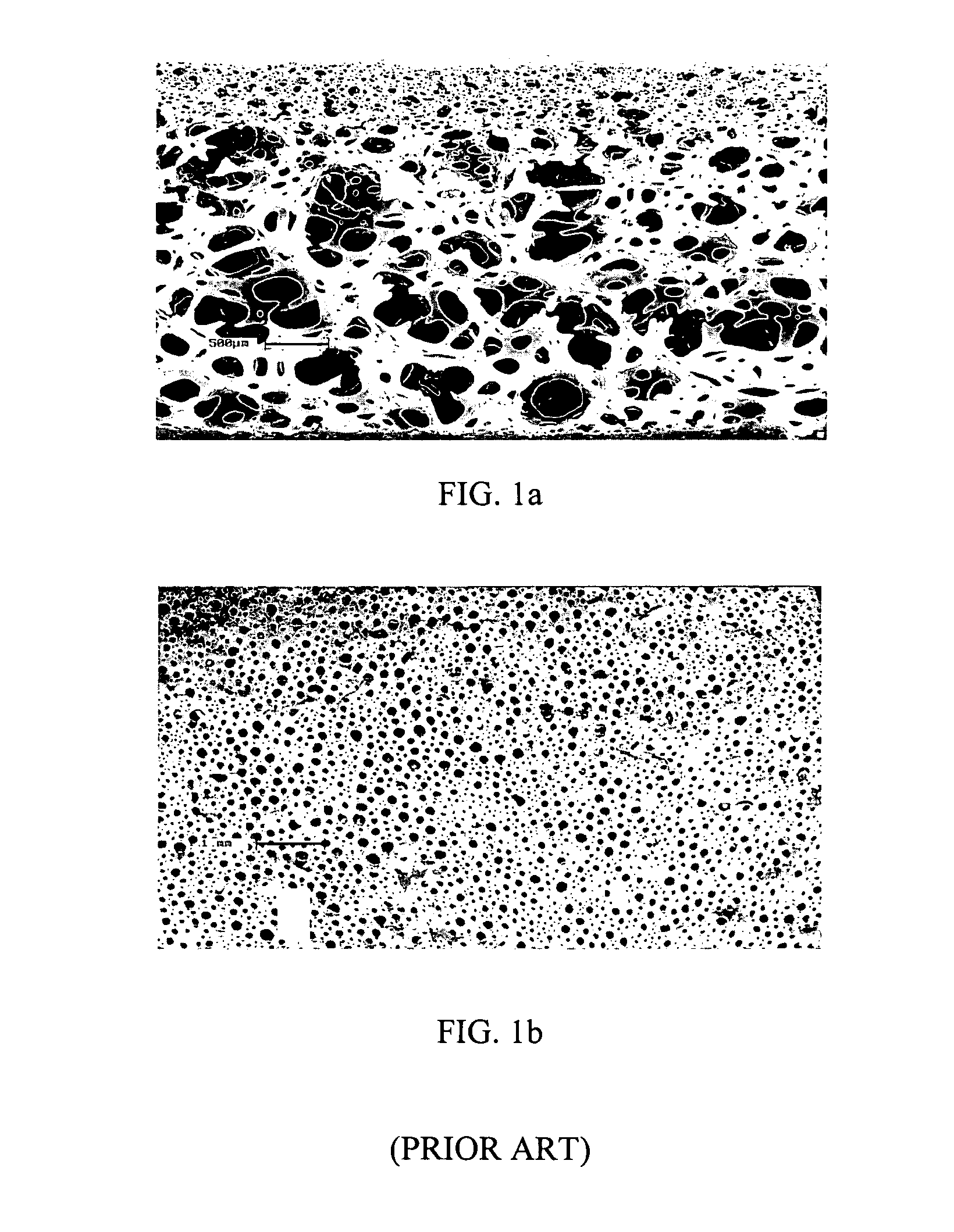

ActiveUS20080076844A1Improve heat resistanceLow compression setAbsorbent padsBandagesThermoplasticFiber

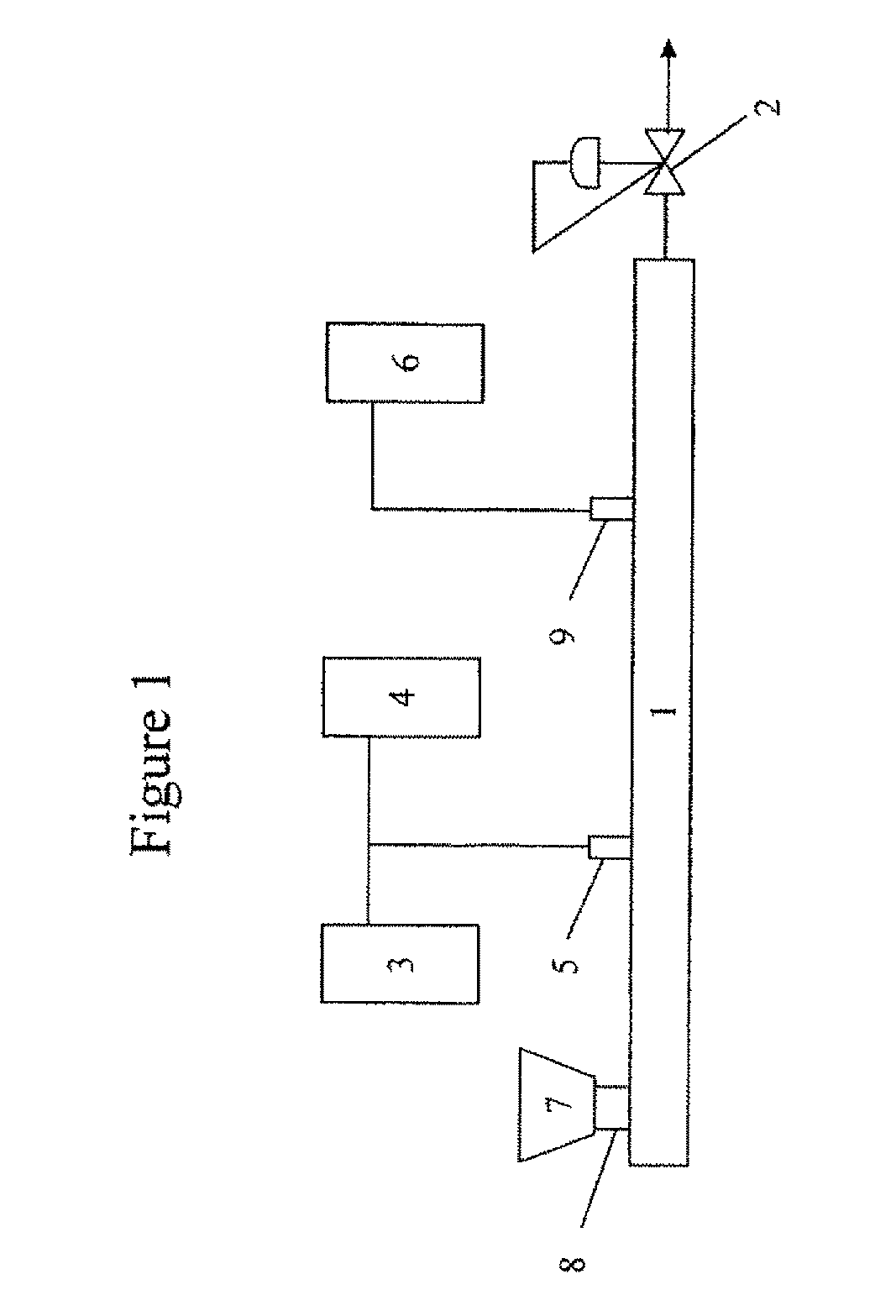

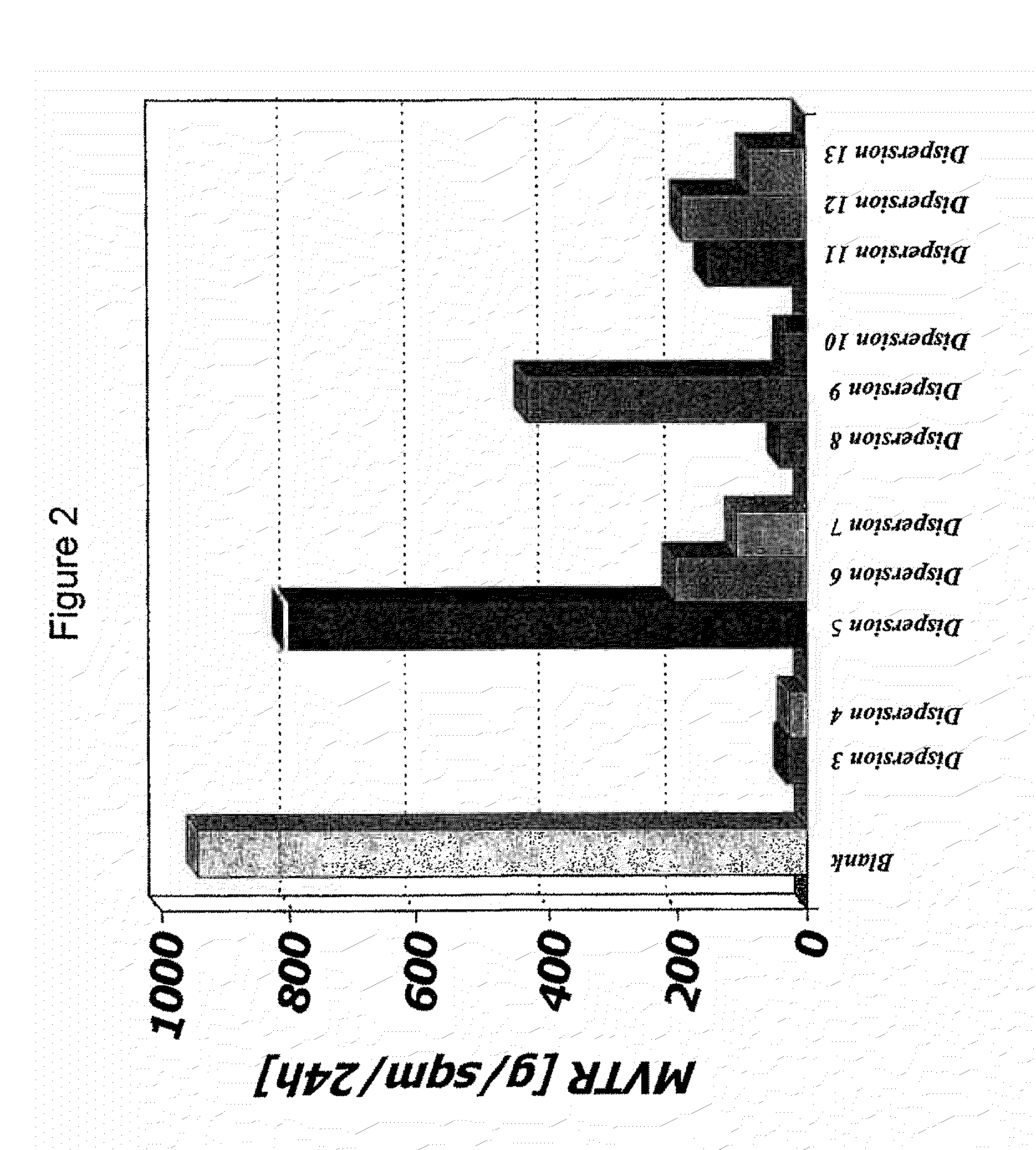

A method for generating a thermoplastic foam from an aqueous dispersion, the aqueous dispersion comprising a thermoplastic resin, water, and a dispersion stabilizing agent, the method including: adding at least one froth stabilizing surfactant to the aqueous dispersion to form a mixture; adding a fiber to the mixture; and frothing the mixture to create a froth, removing at least a portion of the water in the froth to create a foam, wherein the foam generated has a non-cellular fibrillated morphology. In another aspect, embodiments disclosed herein relate to a foam having a thermoplastic-based, fibrillated, non-cellular structure, wherein the foam has an average density of about 0.02 g / cm3 to about 0.07 g / cm3. In certain embodiments, the foam may be used in an absorbent article.

Owner:DOW GLOBAL TECH LLC

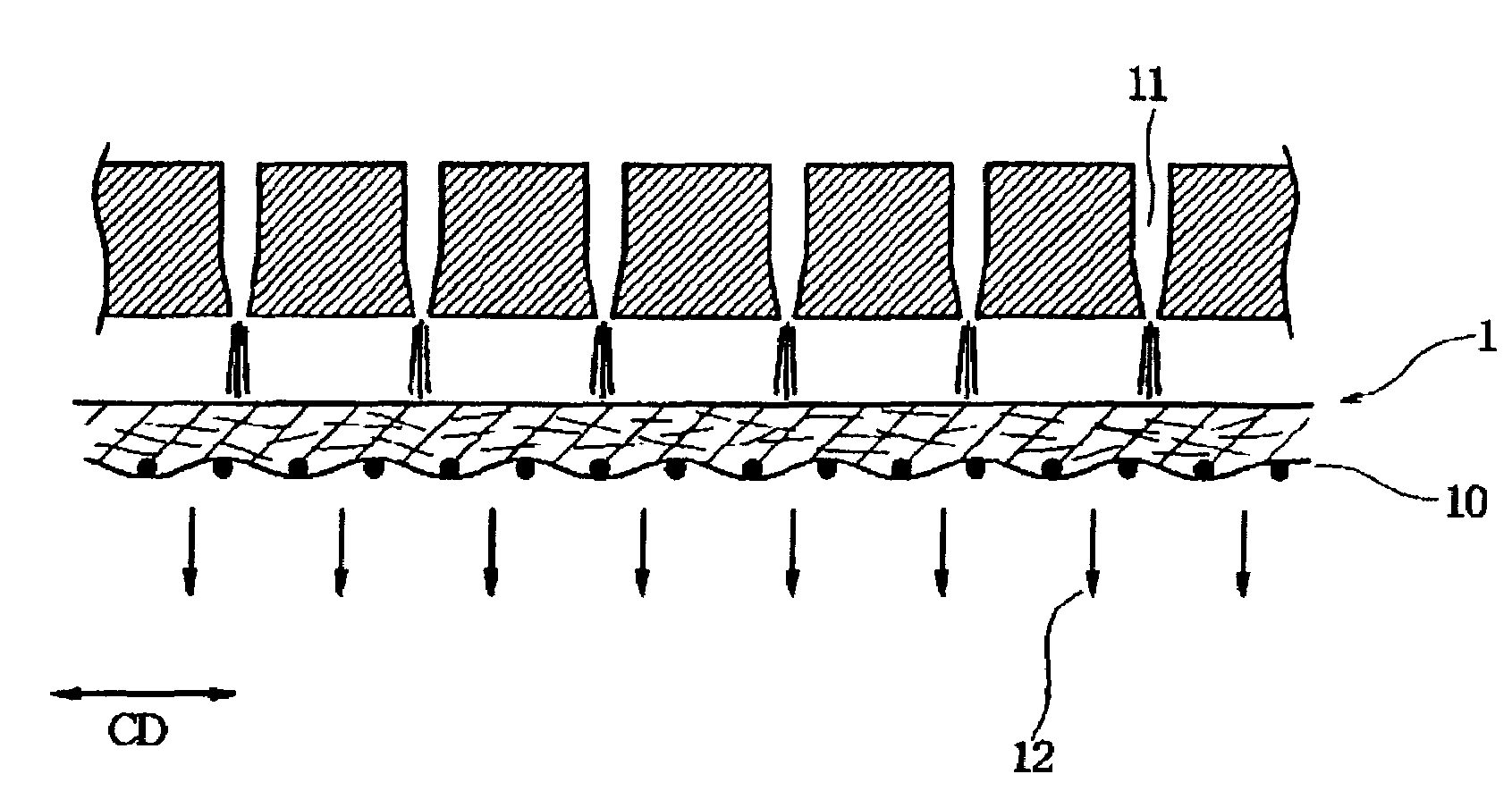

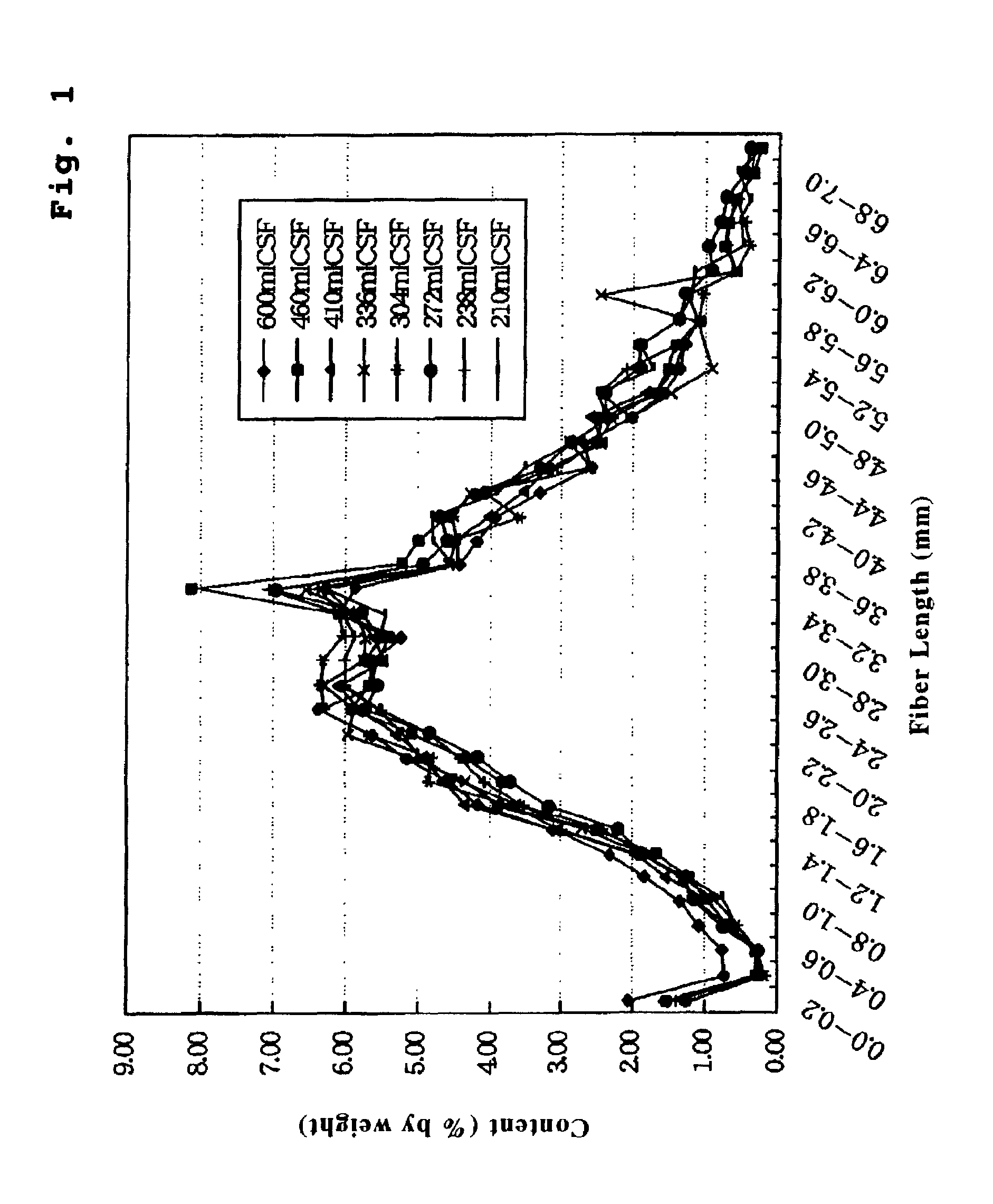

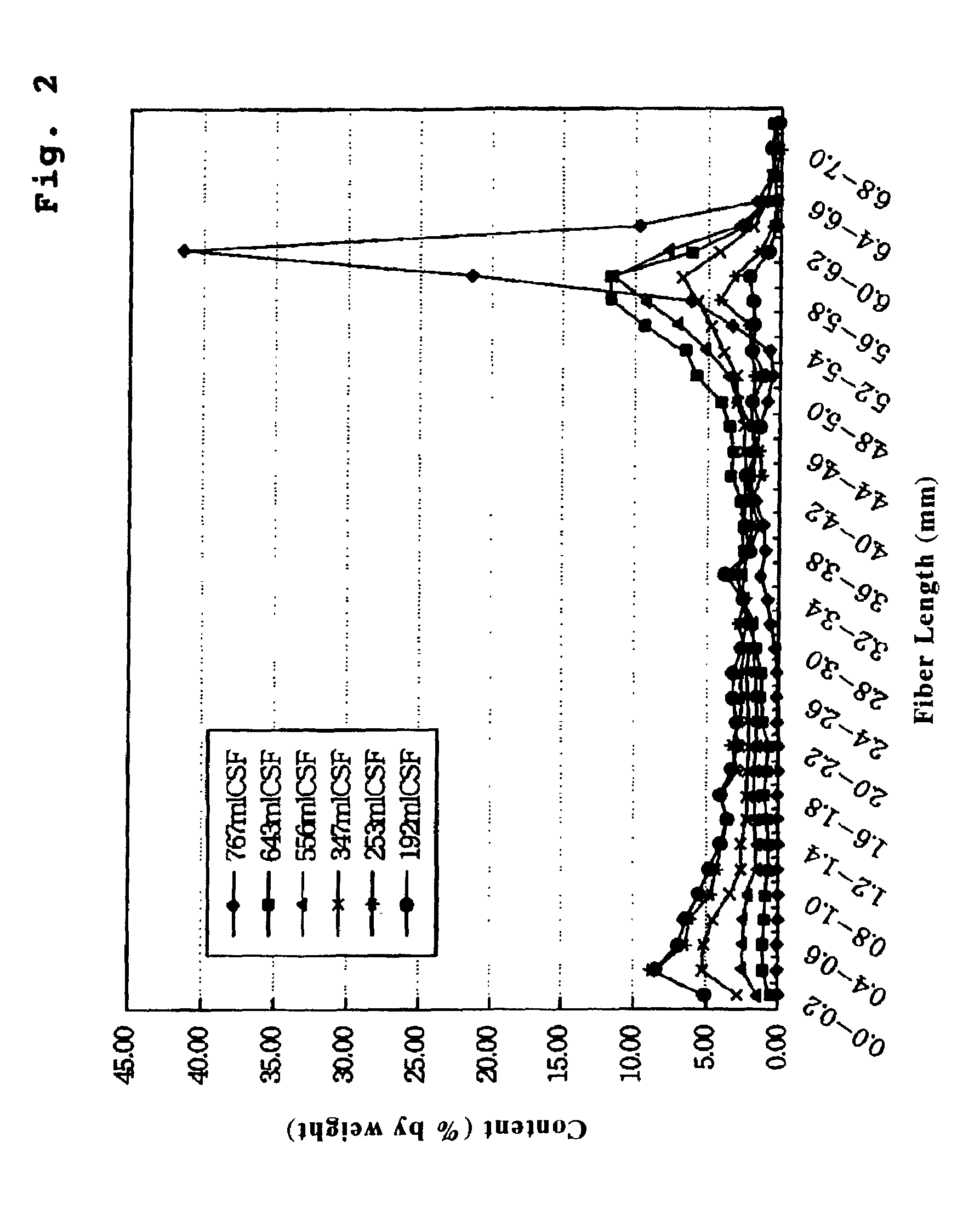

Water-disintegratable sheet and manufacturing method thereof

InactiveUS7241711B2Good wettingImprove dry strengthNon-fibrous pulp additionNatural cellulose pulp/paperFiberPolymer science

Disclosed is a water disintegratable sheet of which fibers are hydroentangled about each other. The water disintegratable sheet includes: at least one kind of primary fibers having a fiber length of at most 10 millimeter; and bast / leaf fibers having a Canadian Standard freeness value of at most 600 milliliter and a fiber length of at most 10 millimeter.

Owner:UNI CHARM CORP

Cellulose Articles Containing an Additve Composition

ActiveUS20080295985A1Improve propertiesImproved grease resistanceNatural cellulose pulp/paperSpecial paperSpecific volumeCellulose fiber

In one embodiment, the present invention provides a method of forming a cellulose article having a specific volume of less than 3 cc / gm. The method includes the step of incorporating cellulose fibers with a compound, wherein the compound includes an aqueous dispersion. The aqueous dispersion may have at least one polymer selected from the group consisting of an ethylene-based thermoplastic polymer, a propylene-based thermoplastic polymer, and mixtures thereof; at least one polymeric stabilizing agent; and water. In certain embodiments, a combined amount of the at least one polymer and the at least one stabilizing agent comprises about 25 to about 74 volume percent of the aqueous dispersion.

Owner:DOW GLOBAL TECH LLC

Meltblown scrubbing product

InactiveUS7994079B2Effective diameterEffective and abrasionAbrasion apparatusLaminationFiberPersonal care

The present invention discloses a disposable meltblown scrubbing product for use in household cleaning or personal care applications and an abrasive aggregate fiber which may be utilized in the scrubbing product. The meltblown web is formed primarily of polymeric fibers in a disordered or random distribution as is typical of fibers deposited in meltblown processes so as to form an open, porous structure. The aggregate fibers of the present invention generally are formed of two or more separate abrasive polymer fibers or strands which are adhered together along at least about 5 mm of the fiber length. The abrasive fibers of the meltblown web are generally greater than about 15 microns in diameter.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Loofah viscose fibers and preparation method thereof

ActiveCN102162150ARetention of antibacterial propertiesImprove use valueArtificial filaments from viscoseWet spinning methodsMaterials preparationFiltration

The invention discloses loofah viscose fibers and a preparation method thereof. Loofah sponge, loofah leftovers or seeded loofah is used as a raw material; and the viscose fibers with excellent performance and natural antibacterial performance are produced by the processes of material preparation, digestion, alkali refining, bleaching, washing, concentration, pulping, impregnation, squeezing, ageing, yellowing, grinding, dissolution, mixing, filtration, deaeration, filtration, spinning, drafting and post treatment. The quality index of the loofah sponge pulp fully accords with the quality requirement of pulp for the viscose fibers, the antibacterial performance of the loofah sponge is reserved, the use value of the loofah sponge is improved, the problem of raw material shortage of the conventional viscose fibers is solved, agricultural wastes can be fully utilized for producing the biomass fibers, and environmental pollution and excessive dependency on the petroleum resource are reduced.

Owner:潍坊欣龙生物材料有限公司

High-intensity high-hydroscopicity medical dressing containing carboxymethyl cellulose and preparation method thereof

InactiveCN103041437AReplace controllableThe degree of substitution is controllableFibre treatmentAbsorbent padsCarboxymethyl celluloseChemical adsorption

The invention provides high-intensity high-hydroscopicity medical dressing containing carboxymethyl cellulose and a preparation method thereof. The method comprises the following specific steps: preparing carboxymethyl cellulose non-woven fabric through two steps of alkali added aqueous medium process; combining the obtained carboxymethyl cellulose non-woven fabric with a non-woven fabric to form a unit through needling, so as to prepare the high-intensity high-water absorbability medical dressing containing carboxymethyl cellulose. The dressing has the advantages that the substituted ratio of the prepared carboxymethyl cellulose non-woven fabric is controlled among 0.1-.05, and the substitution is uniform; the space physical adsorption property of the carboxymethyl cellulose non-woven fabric is kept, and meanwhile, the chemical adsorption performance is improved; the obtained carboxymethyl cellulose non-woven fabric and the non-woven fabric are compounded to a unit, which improves the dryness strength of the dressing prepared by the invention, beautifies the appearance, and improves the hand feeling. Besides, the method is simple and convenient in preparation technology and lower in cost.

Owner:WUHAN TEXTILE UNIV

Lightweight fireproof foaming cement door inner filling material and preparation method thereof

InactiveCN101143777AIncrease gas productionWith thermal insulationSolid waste managementCeramicwareReducing agentWeight light

The invention discloses a lightweight flame retardant and foamy filling material of cement doors and manufacturing method thereof, comprising magnesium oxide, magnesium sulphate, fly ash, high alumina refractory cement, calcium chloride, water proofing agent, water reducing agent and foaming agent, with bulk density ranging between 200 kg / m3 and 500kg / m3; the ingredients are formulated by weight at a rate of: magnesium oxide (40 percent -55 percent), magnesium sulfate (15 percent-40 percent), fly ash (5 percent-20 percent), high alumina refractory cement (5 percent-20 percent), calcium chloride (2 percent-6 percent), water proofing agent (2 percent5 percent), water reducing agent (0.2 percent1.5 percent) and foaming agent (0.1 percent-0.5 percent). With the technical solution, the product has the advantages of high strength, light weight, flame retardancy, sound insulation, weather resistance, thermal resistance, energy efficient, freedom from toxicity, harm and irradiation, low manufacturing cost, simple process, etc, which can be widely employed for fire / theft proof metal interior door, building material and like sectors.

Owner:ZHEJIANG MEIXIN IND CO LTD

Composition for increasing cellulosic product strength and method of increasing cellulosic product strength

InactiveUS7494566B2Improve paper strengthEffective combinationNatural cellulose pulp/paperSpecial paperCellulose pulpViscosity

A composition includes water; at least one hydrophilic polymer containing at least two groups which are independently the same or different a primary amine group or a secondary amine group and at least one saccharide containing a reducible function as described above. The hydrophilic polymer and the saccharide are mixed to form a reaction mixture and reacted to increase the viscosity of the reaction mixture. The reaction is then substantially terminated by reducing the pH of the composition. A method of increasing the strength of a cellulosic pulp product includes the steps of: contacting wet cellulosic pulp with a composition comprising (i) at least one hydrophilic polymer containing at least two groups which are independently the same or different a primary amine group or a secondary amine group and at least one saccharide containing a reducible function, the hydrophilic polymer and the saccharide of the composition having been reacted in a crosslinking reaction prior to contacting the composition with the cellulosic pulp product to increase the viscosity the composition; and, after contacting the cellulosic pulp with the composition, causing the crosslinking reaction between the hydrophilic polymer and the saccharide of the composition to proceed further.

Owner:UNIVERSITY OF PITTSBURGH +1

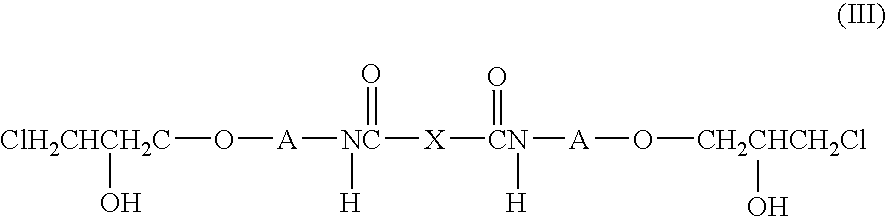

Enclosed type aqueous polyurethane emulsion papermaking wet strength agent and its preparation method

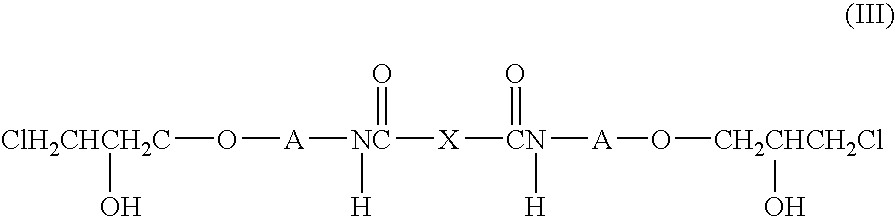

InactiveCN102731746AImprove performanceHigh wet and dry strengthReinforcing agents additionFiberCarboxylic acid

The invention discloses an enclosed type aqueous polyurethane emulsion papermaking wet strength agent and its preparation method. The preparation method comprises the following steps of: (1) dehydrating polyol and a carboxylic acid type chain extender; (2)adding an organic solvent and polyisocyanates, reacting in a nitrogen atmosphere at 70-100 DEG C until the content of NCO in the solution reaches a theoretical value, so as to obtain a -NCO-terminated polyurethane prepolymer; (3) adding a blocking agent and reacting at 75-85 DEG C until the NCO content is zero, so as to obtain an enclosed type polyurethane prepolymer. and (4) adding triethylamine at 55-65 DEG C to conduct a neutralization reaction for 0.5-1h, adding water, and stirring to disperse to obtain the enclosed type aqueous polyurethane emulsion papermaking wet strength agent. According to the invention, deblocking can be realized at high temperature, and wet and dry strength of paper can be raised by the utilization of reactions between isocyanate and hydroxyl, amino and the like in fiber.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Cotton-like lining cloth and production process thereof

The invention relates to cotton-like lining cloth which is formed by blending viscose fibre / polyester staple fiber blended yarn serving as warp yarn and functional polyester filament serving as weft yarn, wherein the functional polyester filament can absorb and discharge moisture. In addition, a production process of the cotton-like lining cloth is further related. The production process includes the following steps: 1, warp yarn selection; 2 weft yarn selection; 3, weaving; 4, overflow desizing and bleaching processing or overflow desizing and bath dyeing processing; 5, dehydration; 6, scotching; 7, sizing; 8, coating calendaring; 9, perching volume classification; and 10, laboratory sample detection.

Owner:CPL NEW MATERIAL TECH CO LTD

Diaphragm paper for mercury-free alkaline zinc-manganese dioxide cell, and preparation method of diaphragm paper

ActiveCN104631198AImprove densification performanceHigh strengthWater-repelling agents additionPaper coatingPapermakingManganese

The invention discloses diaphragm paper for a mercury-free alkaline zinc-manganese dioxide cell, and a preparation method of the diaphragm paper, and belongs to the technical field of fiber-containing paper and a preparation method thereof. A sizing agent comprises the following raw materials in parts by weight: 40-55 parts of superfine nylon fibers, 25-35 parts of tencel fibers and 20-30 parts of pulp fibers; the sizing agent is prepared by dispersing a dispersing agent by adopting a papermaking machine wet-process papermaking technology. The three types of fibers are mixed to prepare an alkaline zinc-manganese dioxide cell diaphragm, so that not only can the physical strength performance of the diaphragm paper be improved and the relatively good alkaline absorption performance can be guaranteed; due to the improvement of the strength of the diaphragm paper, the usage amount of the sizing agent can be properly reduced, so that the quantitation and the thickness fluctuation of the diaphragm paper can be favorably stabilized, and thus guarantee for meeting the use of the mercury-free alkaline zinc-manganese dioxide cell can be provided.

Owner:浙江鹏辰造纸研究所有限公司

Cellulose articles containing an additive composition

ActiveUS20110308751A1Improved propertyIncrease resistanceNatural cellulose pulp/paperSpecial paperCellulose fiberThermosetting polymer

In one embodiment, the present invention provides a method of forming a cellulose article having a specific volume of less than 3 cc / gm. The method includes the step of incorporating cellulose fibers with a compound, wherein the compound includes an aqueous dispersion. The aqueous dispersion may have at least one polymer selected from the group consisting of an ethylene-based thermoplastic polymer, a propylene-based thermoplastic polymer, and mixtures thereof; at least one polymeric stabilizing agent; and water. In certain embodiments, a combined amount of the at least one polymer and the at least one stabilizing agent comprises about 25 to about 74 volume percent of the aqueous dispersion.

Owner:DOW GLOBAL TECH LLC

Dry Strength System for the Production of Paper and Board

InactiveUS20090107644A1Maintain good propertiesHigh molecular weightNatural cellulose pulp/paperSpecial paperCross-linkCardboard

The instant invention relates to certain cross-linked polyamides and their use in the paper and board industry for improving dry strength. The polyamide from the reaction of a di- or tri-primary amine with a di- or tri- or tetra carboxylic acid is further reacted with a di- or tri-functional cross-linking compound to give a cationic or anionic product with no reactive groups.

Owner:CLARIANT FIANCE (BVI) LTD

Method for increasing paper strength

ActiveUS20150144282A1Improve dry strengthImprove wet strengthNatural cellulose pulp/paperSpecial paperPulp and paper industryUltimate tensile strength

The present invention provides a method for increasing paper strength in papermaking process comprising adding to a pulp a composition comprising an anionic polyacrylamide (APAM) and a high charge cationic glyoxylated polyacrylamide (GPAM). The present invention also provides paper obtained with said method.

Owner:KEMIRA OY

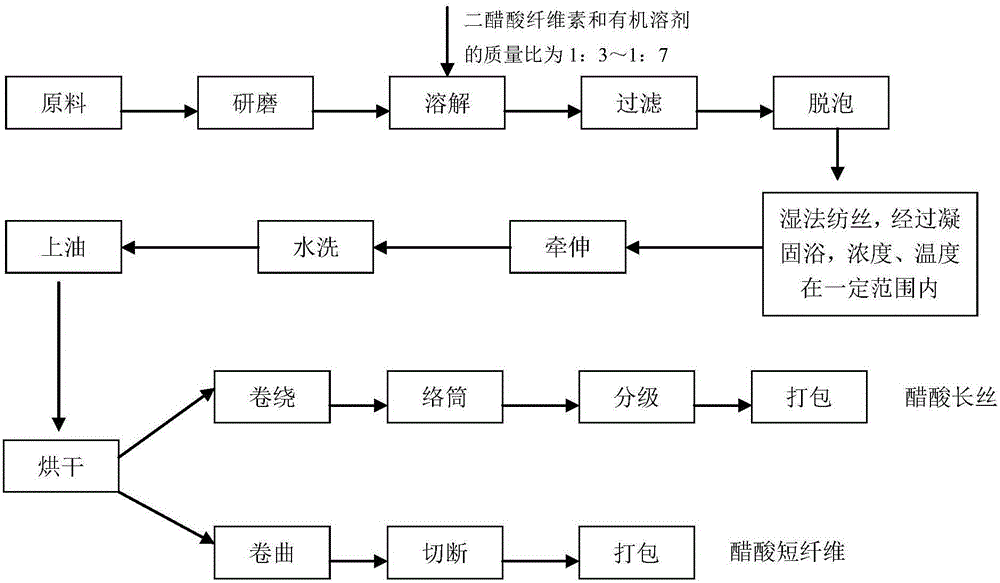

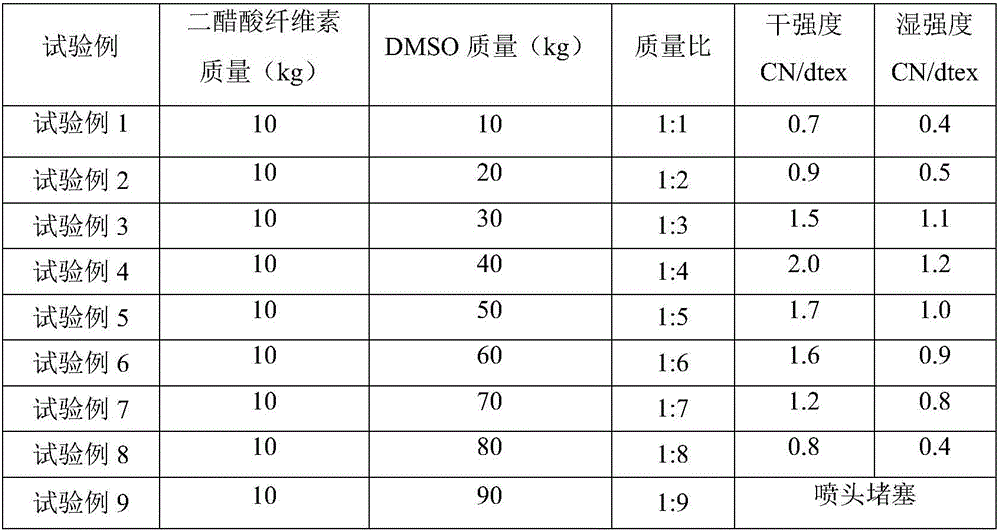

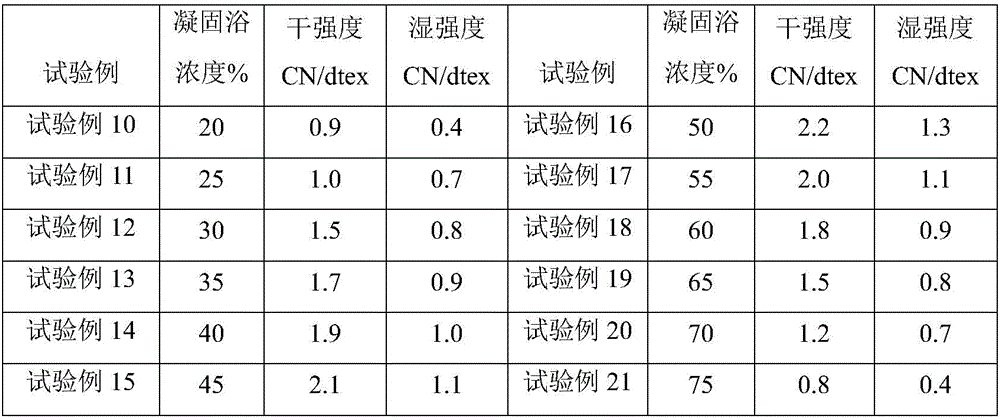

Wet spinning method for preparing cellulose acetate fiber

ActiveCN106012076AReduce pollutionImprove production environmentArtificial filaments from cellulose derivativesFiberCellulose diacetate

The invention discloses a wet spinning method for preparing cellulose acetate fiber. The wet spinning method comprises the following steps: grinding solid cellulose diacetate, of which the degree of acetylation is 2.1 to 2.8 and the water content is 1 to 7 percent, into powder; adding the cellulose diacetate powder and an organic solvent into a dissolving tank, and carrying out sufficient stirring for mixing, and raising the temperature for dissolution, wherein the mass ratio of the cellulose diacetate powder to the organic solvent ranges from 1:3 to 1:7, the dissolving time is 0.5 to 8 hours, and the dissolving temperature is 35 to 120 DEG C; filtering and deforming a dope obtained after dissolution to obtain a spinning dope; after the spinning dope passes through a metering pump and a filter, spraying the filtered spinning dope from spinneret orifices to enter a coagulation bath to obtain nascent fiber, wherein the concentration of the coagulation bath is 25 to 70%, and the temperature is 20 to 90 DEG C; preparing a finished acetate fiber product from the nascent fiber through drafting, washing, oiling and drying. The cellulose acetate fiber prepared according to the method disclosed by the invention has excellent indexes, good mechanical properties, and remarkably improved dry strength and wet strength; the preparation process is simple, feasible, and easy to control; the solvent cost is low.

Owner:吉林富博纤维研究院有限公司

Method for producing hot-melting artistic anti-fake paper

ActiveCN101250838AGood compatibility and binding forceGood mix distribution characteristicsWater-repelling agents additionPulp beating methodsFiberHot melt

The invention relates to a method for preparing hot melt art antifalsification paper, which comprises the following steps: firstly, selecting wood fiber to do fluff and one-time beating, selecting RRXW commodity fiber and fluorescent fiber to process and beat, mixing wood fiber pulp, RRXW fiber pulp and fluorescent fiber pulp according to the proportion of 82: 15: 3, doing blending and beating, charging chemical findings and assistant to blend, dehydrating, modeling, decorating, adopting hot wind dry, far infrared dry and seal dry to do polybasic modeling dry, gluing paper to do non-contact dry, and improving the gluing effect. The multiple fiber allocation of the invention enables pulp to be provided with good compatibility connection and even blend distribution property, higher dry-wet strength, physics, appearance property and the polybasic modeling drying ensures the paper dry effect and the RRXW fiber against damaging. The method for preparing hot melt art antifalsification paper is simple in preparation, reliable in preparation technique, strong in operation and superior in hot melt property and antifalsification property.

Owner:SHANDONG KAILI SPECIAL PAPER

Method for producing 30-count siro spinningslubby yarn through mono-tencel fiber spinning

The invention relates to a method for producing a 30-count siro spinningslubby yarnthrough mono-tencel fiber spinning. The 30-count siro spinningslubby yarn is produced through procedures that cotton is cleaned and combed, tencel fiber is pre-combined, the heads are combined, the tails are combined, and the yarn is roughed, refined, and spooled. In the cotton cleaning procedure, the cotton is finely grasped, is combed for multiple times and hit slightly, is uniformly mixed and pressed laterally, the hitting speed is reduced, and the cotton is slowly loosened; in the cotton combing procedure, the combing quality is improved, and the fiber damage is reduced; in the combination procedures, rear-area traction is intensified in the head combination procedure, the rear-area traction is reduced in the tail combination procedure, the quantity is slightly fixed, the pressure is boosted, the speed is slow, the cotton is uniformly fixed, the extension parallelism degree of fiber is increased, and bent fiber is reduced; in the yarn roughing procedure, the quantity is slightly fixed, the pressure is boosted, the speed is slow, and the twisting degree is large; in the yarn refining procedure, a siro spinning and intelligent slubby yarn device is additionally mounted on a yarn refining machine; in the spooling procedure, a pressurizing device is additionally mounted on an automatic spooling machine idle pressing line, and knots can be well tied. The slubby yarn provided by the invention is soft, smooth and comfortable, high in dry and wet resistance, good in air permeability and damp absorption property, good in water washing stability and rich in concave and convex three-dimensional feeling.

Owner:JIHUA 3509 TEXTILE

Lightweight fireproof filling material for metal door produced by expansion perlite and preparation method thereof

InactiveCN101215179AAct as waterproof and water-blockingWith thermal insulationThermal insulationAdhesive

The invention discloses a lightening fireproof filling material for producing metal door by expanded perlite and a process for preparation. The material comprises expanded perlite, magnesium oxide, magnesium sulfate, calcium hydroxide, aqueous adhesive and water proofing agent, the volume weight is between 200-300kg / m3, the proportionings of each component according to weight percentage respectively are that the expanded perlite takes 45-65, the magnesium oxide takes 15-25, the magnesium sulfate takes 5-15, the calcium hydroxide takes 0.5-4 and the aqueous adhesive takes 2-5. Employing the technical scheme, the product has the advantages of high mechanical strength, light weight, high grade of fire resistance, good effect of sound absorption and acoustic insulation, strong anti-weatherability, heat insulation, heat preservation and energy conservation, easy production and no poison, on hazard and no radiation and the like. The product can be widely used in metal door industry, architectural materials industry and the related industries.

Owner:ZHEJIANG MEIXIN IND CO LTD

Composition for increasing cellulosic product strength and method of increasing cellulosic product strength

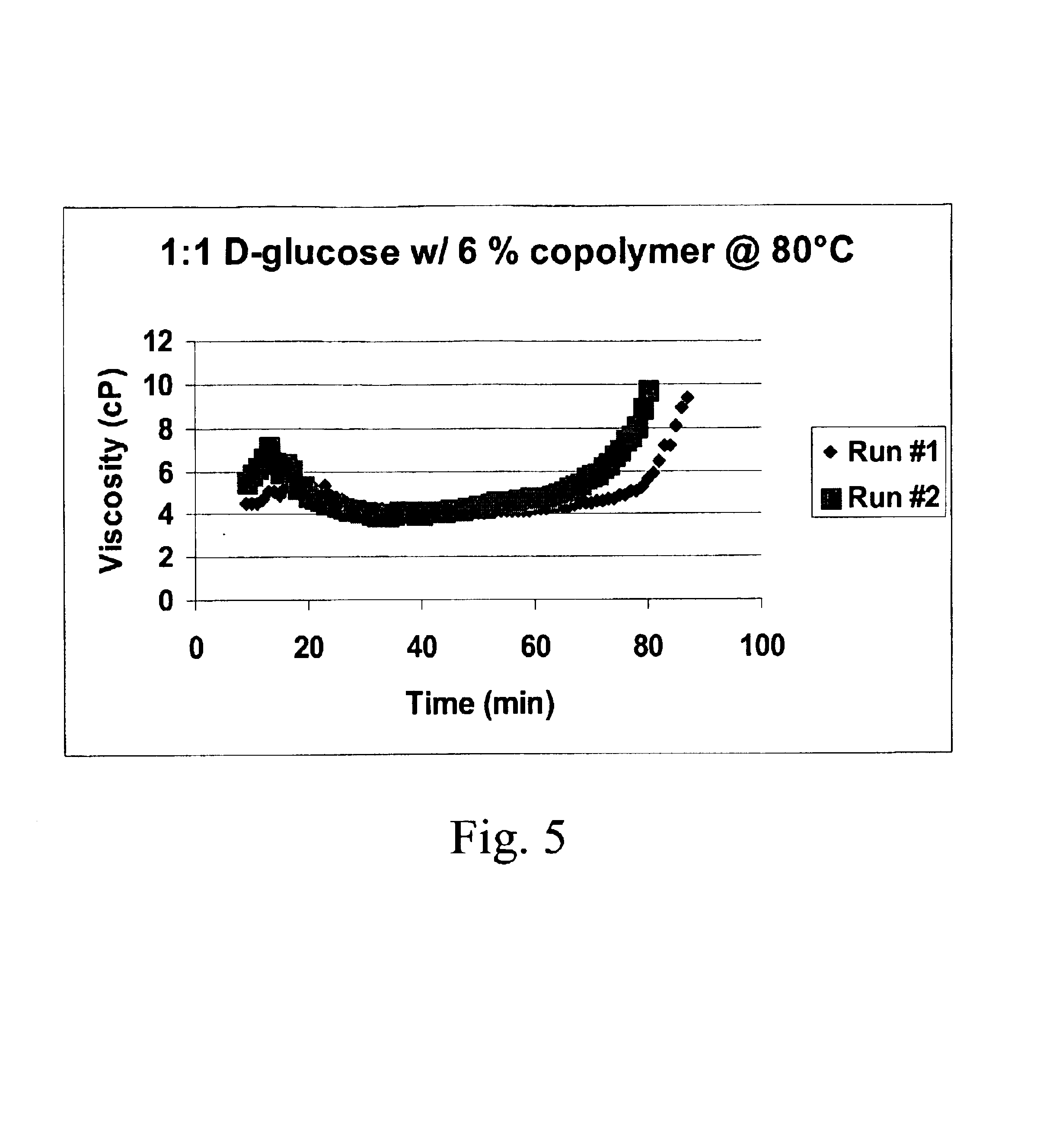

InactiveUS20050082025A1Improve paper strengthEffective combinationNatural cellulose pulp/paperSpecial paperCelluloseViscosity

A composition includes water; at least one hydrophilic polymer containing at least two groups which are independently the same or different a primary amine group or a secondary amine group and at least one saccharide containing a reducible function as described above. The hydrophilic polymer and the saccharide are mixed to form a reaction mixture and reacted to increase the viscosity of the reaction mixture. The reaction is then substantially terminated by reducing the pH of the composition. A method of increasing the strength of a cellulosic pulp product includes the steps of: contacting wet cellulosic pulp with a composition comprising (i) at least one hydrophilic polymer containing at least two groups which are independently the same or different a primary amine group or a secondary amine group and at least one saccharide containing a reducible function, the hydrophilic polymer and the saccharide of the composition having been reacted in a crosslinking reaction prior to contacting the composition with the cellulosic pulp product to increase the viscosity the composition; and, after contacting the cellulosic pulp with the composition, causing the crosslinking reaction between the hydrophilic polymer and the saccharide of the composition to proceed further.

Owner:UNIVERSITY OF PITTSBURGH +1

Wool/crotalaria sp./mulberry silk/cotton/polyester fiber blended fabric and preparation method thereof

The invention relates to a wool / crotalaria sp. / mulberry silk / cotton / polyester fiber blended fabric. The fabric comprises the following material components in percentage by weight: 28% of wool fiber, 35% of crotalaria sp. fiber, 17% of polyester fiber, 18% of cotton fiber and 3% of mulberry silk. The method includes the steps of: 1, top dying process of the cotton fiber and the crotalaria sp. Fiber; 2, dying and re-combing process of the wool fiber, the polyester fiber and the mulberry silk fiber; 3, spinning process; 4 weaving process; 5, dying and finishing process; the spinning process includes: mixing and performing primary gilling, secondary gilling, third gilling and fourth gilling on products prepared by the dying and re-combing process of the wool fiber, the polyester fiber and the mulberry silk fiber, then being subjected to primary roving, secondary roving and spinning processes together with yarn prepared by the top dying process of the cotton fiber and the crotalaria sp. Fiber, when a double-steel wire hook is adopted in the spinning process. The fabric achieves the purpose of being breathable, antibacterial and health-care, and meanwhile meets the requirements on various technical indexes of spring and summer fabrics.

Owner:江苏华西村纺织服装有限公司

Method for increasing paper strength

ActiveUS9347181B2High wet and dry strengthLow costNatural cellulose pulp/paperReinforcing agents additionPulp and paper industryPolyacrylamide

The present invention provides a method for increasing paper strength in papermaking process comprising adding to a pulp a composition comprising an anionic polyacrylamide (APAM) and a high charge cationic glyoxylated polyacrylamide (GPAM). The present invention also provides paper obtained with said method.

Owner:KEMIRA OY

Medical bactericidal paper and its production methods

InactiveCN1431365AHigh wet and dry strengthGood uniform air permeabilityReinforcing agents additionBiochemical engineeringEthylene oxide

A sterilized medical paper sued for packing bags of medical tools is made up through proportioning raw materials, breaking in water, beating, adding melamine-formaldehyde resin or cationic thermosetting synthetic resin strengthening agent PAE, shaping, and winding. Its advantages are high dry or wet strength and air permeability and automatic degradation after used.

Owner:四川环龙生活用品有限公司

Cellulose articles containing an additive composition

ActiveUS8029646B2Improved propertyIncrease resistanceNatural cellulose pulp/paperSpecial paperSpecific volumeCellulose fiber

Owner:DOW GLOBAL TECH LLC

Filtration paper, preparation method and application thereof

InactiveCN103132394AUniform paperImproved pore size distributionFiltration separationFilter paperFiberFiltration

The present invention discloses filtration paper, a preparation method and an application thereof. The method comprises the following steps: uniformly mixing 10-35% by mass of plant fibers and 65-90% by mass of man-made fibers to obtain a fiber raw material pulp, wherein the plant fibers are sequentially subject to ease for 10-20 min and pulping for 20-40 min, the man-made fibers are subject to ease for 30-40 min, a fiber length of the man-made fibers is 3-15 mm, and a size is 3-10 dtex; uniformly mixing the fiber raw material pulp, a dispersant and water to obtain a pulp; conveying the pulp to a papermaking machine to prepare base paper; and applying an adhesive on the base paper, drying and rolling to obtain the finished product. The prevent invention further discloses the filtration paper prepared by the method, and applications of the filtration paper as edible oil filtration paper. The filtration paper has characteristics of uniform texture, good pore size distribution, high dry and wet strength, no toxicity, no odor, safety, health, rapid edible oil filtration, and good effect.

Owner:上海科梦投资集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com