High-intensity high-hydroscopicity medical dressing containing carboxymethyl cellulose and preparation method thereof

A technology of carboxymethyl cellulose and high water absorption, which is applied in the field of medicine, can solve the problems of complex preparation process, poor mechanical properties, and low water absorption, and achieve the effect of simple preparation process, low cost, and improved chemical adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] c Preparation of carboxymethylcellulose-containing dressings

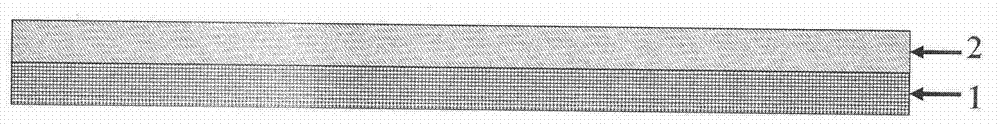

[0034] The modified cellulose non-woven fabric 1 obtained in step b and the non-woven fabric 2 are combined to form a whole by acupuncture, that is, a medical dressing containing carboxymethyl cellulose with high strength and high water absorption is produced.

[0035] The cellulose nonwoven fabric is a natural cellulose nonwoven fabric or a regenerated cellulose nonwoven fabric.

[0036] The nonwoven fabric is a natural fiber nonwoven fabric, a regenerated fiber nonwoven fabric, a synthetic fiber nonwoven fabric or a blended nonwoven fabric.

[0037] Aiming at the shortcomings of the high degree of substitution carboxymethyl cellulose fabric's mechanical properties are severely reduced, and the structural integrity of the original fabric cannot be maintained after absorbing liquid, the modified cellulose nonwoven fabric is combined with the nonwoven fabric by acupuncture. constitute a whole. On the one ha...

Embodiment 1

[0040] Embodiment 1: the preparation of the present invention's high-strength, highly water-absorbing medical dressing containing carboxymethyl cellulose

[0041] a Alkaline treatment of viscose nonwovens

[0042] First, a sodium hydroxide solution with a concentration of 1 wt% was prepared, and the viscose nonwoven fabric was immersed in the sodium hydroxide solution, and reacted at a temperature of 0° C. for 0.5 h at a bath ratio of 10:1;

[0043] b Etherification treatment of viscose nonwovens

[0044] Prepare a mixed solution of sodium hydroxide and chloroacetic acid, wherein the concentration of sodium hydroxide solution is 1wt%, and the molar ratio of chloroacetic acid to the cellulose hydroxyl group in the viscose nonwoven fabric is 0.5: 1, after the alkalization treatment obtained in step a The viscose nonwoven fabric is immersed in the mixed solution, and reacted at 0°C for 0.5h with a bath ratio of 10:1. After the reaction is completed, add 5wt% acetic acid solution...

Embodiment 2

[0047] Embodiment 2: the preparation of high-strength, high-absorbency medical dressing containing carboxymethyl cellulose of the present invention

[0048] a Alkaline treatment of viscose nonwovens

[0049] First, prepare a sodium hydroxide solution with a concentration of 20 wt%, immerse the viscose nonwoven fabric in the sodium hydroxide solution, and react at a temperature of 100° C. for 5 hours at a bath ratio of 50:1;

[0050] b Etherification treatment of viscose nonwovens

[0051] Prepare a mixed solution of sodium hydroxide and chloroacetic acid, wherein the concentration of sodium hydroxide solution is 20wt%, and the molar ratio of chloroacetic acid to the cellulose hydroxyl group in the viscose nonwoven fabric is 10: 1, after the alkalization treatment obtained in step a The viscose non-woven fabric was immersed in the mixed solution, and reacted at 100°C for 10 hours with a bath ratio of 50:1. After the reaction was completed, 30wt% acetic acid solution was added ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com