A kind of method utilizing bamboo pulp to prepare hydroxyethyl cellulose

A technology of hydroxyethyl cellulose and bamboo pulp, which is applied in the field of preparation of hydroxyethyl cellulose, can solve the problems of large differences in cellulose energy, achieve good solubility, easy post-processing, and stable solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

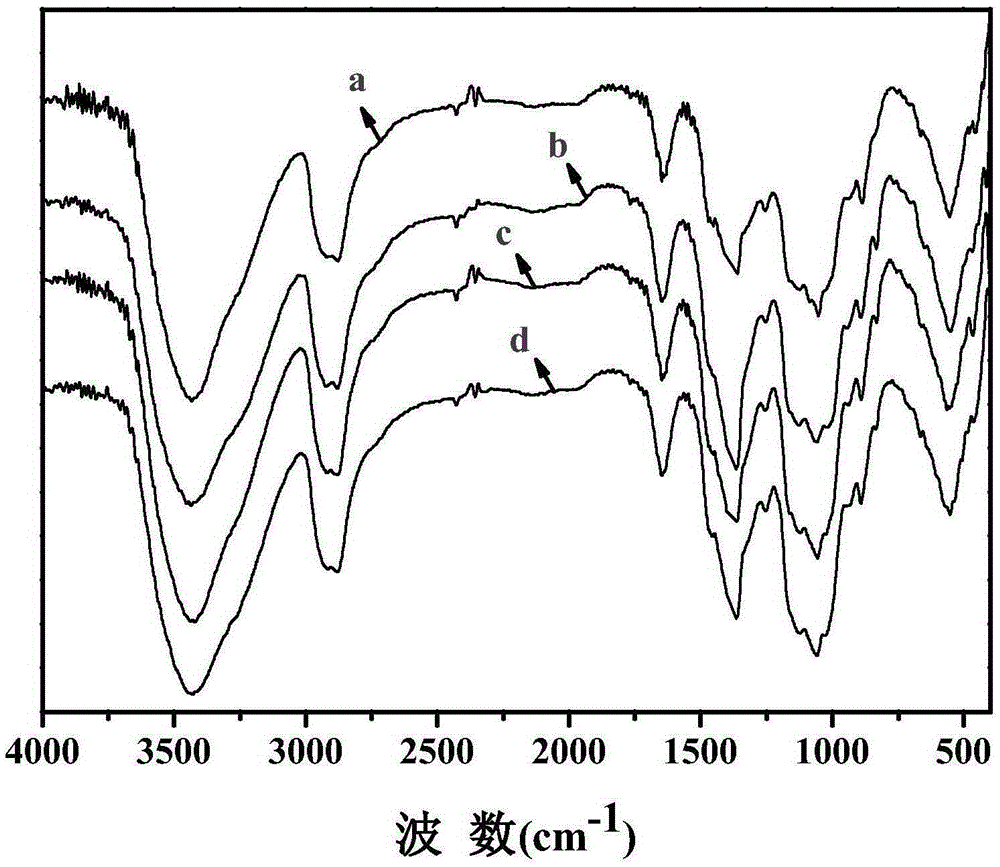

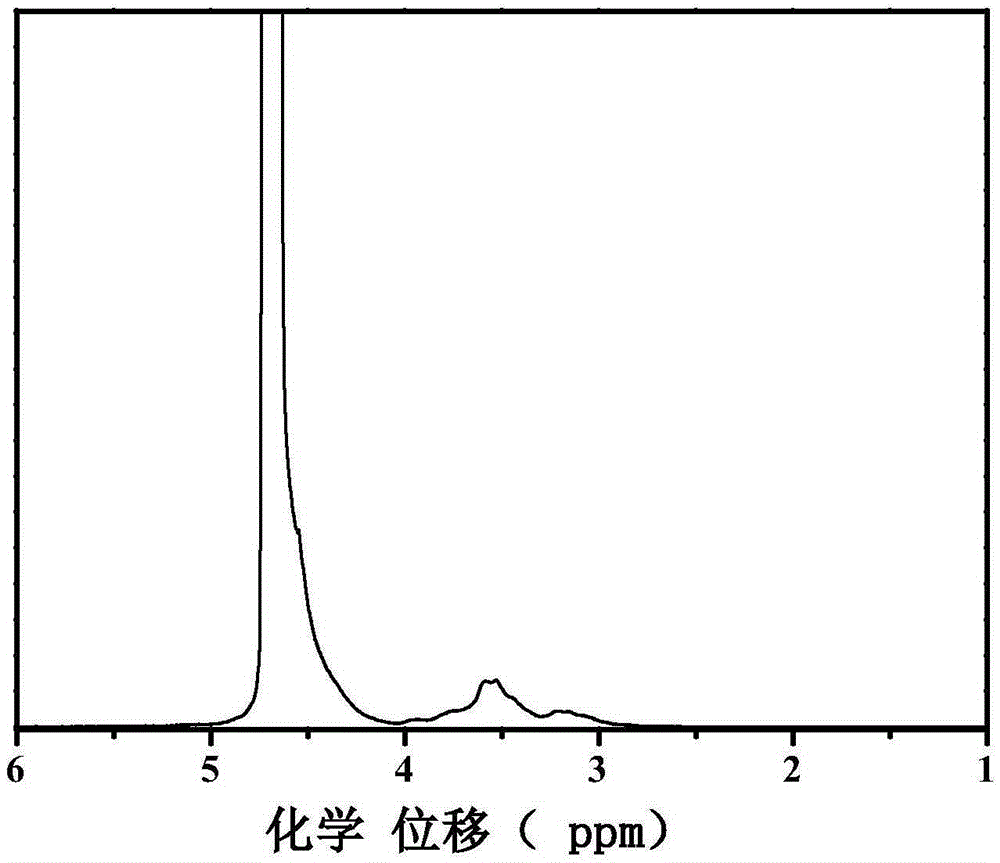

[0031] Weigh 200g of urea and 100g of monoethanolamine and mix them uniformly in a reaction vessel, heat to 110°C for 3 hours; add 3000g of sodium hydroxide solution with a concentration of 7.6%, mix well, freeze to -7°C to obtain a solvent; Adding the content of 75g alpha cellulose in 2925g solvent is 95%, and the bamboo pulp of degree of polymerization is 800 and stirs rapidly at room temperature 10 minutes, obtains the bamboo pulp solution that mass concentration is 2.5%; Chlorohydrin (chlorohydrin and bamboo The molar ratio of the glucose units in the pulp is 6) into the bamboo pulp solution, react at room temperature for 3 hours, then raise the temperature to 55°C and react for 2 hours; neutralize with hydrochloric acid until the solution is neutral to stop the reaction, and separate, that is 91.3 g of hydroxyethylcellulose were obtained. figure 1 A in is the infrared spectrogram of hydroxyethyl cellulose; figure 2 It is the proton magnetic resonance spectrum of hydroxy...

Embodiment 2

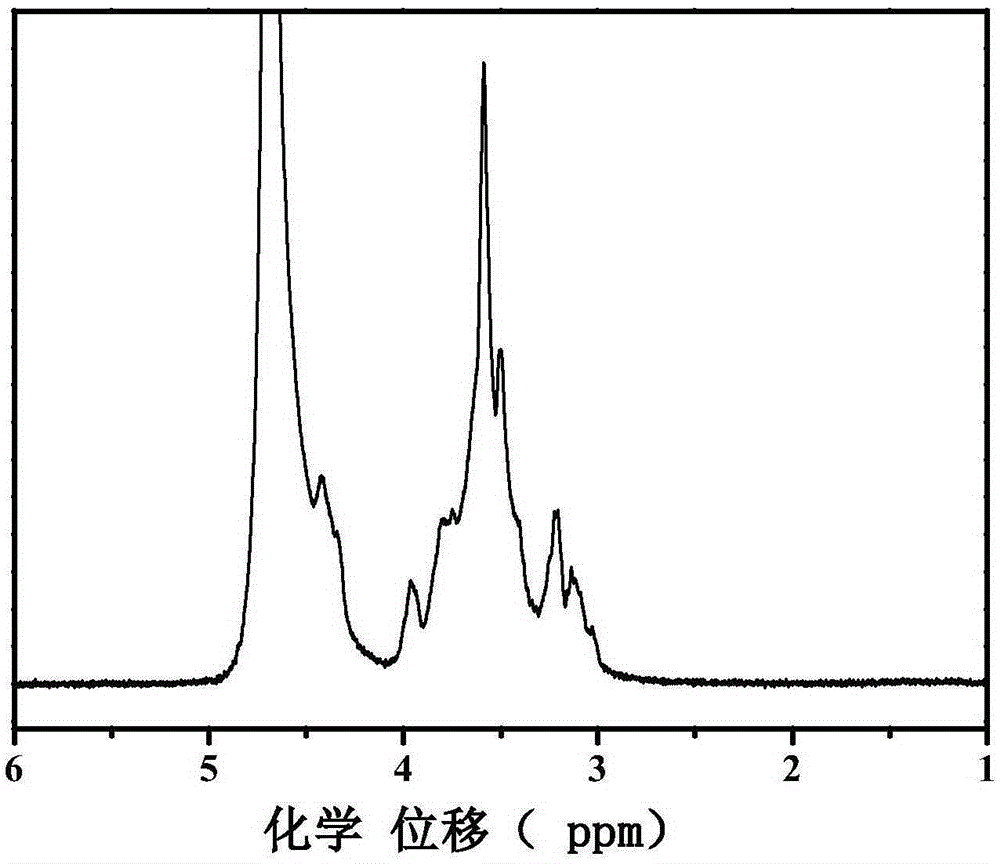

[0033] Weigh 200g of urea and 100g of monoethanolamine and mix them uniformly in a reaction vessel, heat to 110°C for 3 hours; add 3000g of sodium hydroxide solution with a concentration of 7.6%, mix well, freeze to -7°C to obtain a solvent; Adding the content of 90g alpha cellulose in 2910g solvent is 95%, and the bamboo pulp of degree of polymerization is 800 and stirs rapidly at room temperature 10 minutes, obtains the bamboo pulp solution that mass concentration is 3%; Chlorohydrin (chlorohydrin and glucose The molar ratio of the unit is 6) adding it to the bamboo pulp solution, reacting at room temperature for 3 hours, raising the temperature to 55°C and reacting for 2 hours; neutralizing with hydrochloric acid until neutral to stop the reaction, and separating to obtain 110.3g of hydroxyethyl cellulose white. figure 1 b in is the infrared spectrogram of hydroxyethyl cellulose; image 3 It is the proton magnetic resonance spectrum of hydroxyethyl cellulose; Figure 7 It...

Embodiment 3

[0035] Weigh 200g of urea and 100g of monoethanolamine and mix them uniformly in a reaction vessel, heat to 110°C for 3 hours; add 3000g of sodium hydroxide solution with a concentration of 7.6%, mix well, freeze to -7°C to obtain a solvent; Adding the content of 105g alpha cellulose in 2895g solvent is 95%, and the bamboo pulp of polymerization degree is 800 and stirs rapidly at room temperature 10 minutes, obtains the bamboo pulp solution that mass concentration is 3.5%; Chlorohydrin (chlorohydrin and glucose The molar ratio of the unit is 6) adding it to the bamboo pulp solution, reacting at room temperature for 3 hours, raising the temperature to 55°C and reacting for 2 hours; neutralizing with hydrochloric acid until neutral to stop the reaction, and separating to obtain 127.6g of hydroxyethyl cellulose white.

[0036] figure 1 C in is the infrared spectrogram of hydroxyethyl cellulose; Figure 4 It is the proton magnetic resonance spectrum of hydroxyethyl cellulose; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com