Enclosed type aqueous polyurethane emulsion papermaking wet strength agent and its preparation method

A water-based polyurethane, closed-type technology, applied in the direction of reinforcing agent addition, etc., can solve problems such as restricted use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

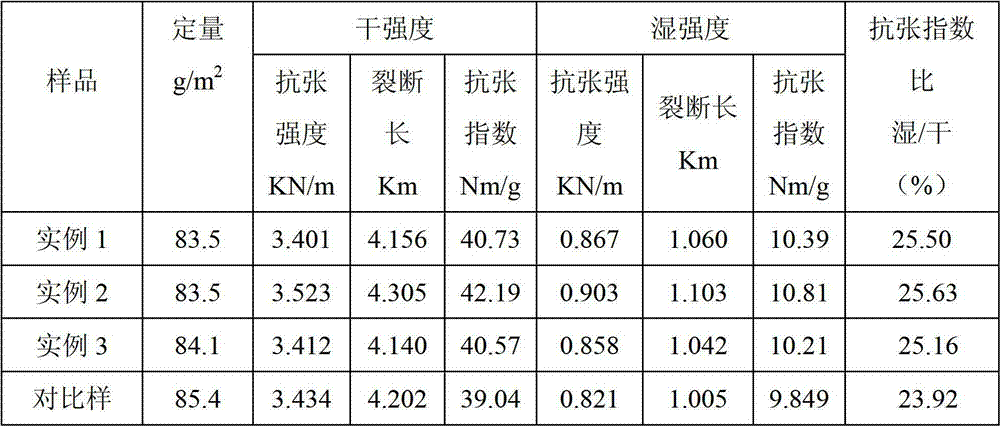

Examples

Embodiment 1

[0023] First, put 100g of polybutylene adipate diol (molecular weight: 1000) and 8g of 2,2'-dimethylol propionic acid into a four-necked flask with a stirring and heating device, and vacuum at 100°C After dehydration for 1 h, add 20 g of dry N-methylpyrrolidone and 41.8 g of toluene diisocyanate ([NCO] / [OH]=1.5) and react at 80 °C for 3 h under nitrogen protection until the NCO content reaches the theoretical value, and the terminal NCO based polyurethane prepolymers.

[0024] Then add 7g of methyl ethyl ketoxime and react at 80°C for 3h until the NCO content is zero to obtain a blocked polyurethane prepolymer;

[0025] Add 6g of triethylamine at 55°C for neutralization reaction for 1h, add 325g of deionized water to disperse to obtain the final sample, which is a bluish white emulsion with a viscosity of 9.8mPa.s at 25°C (measured by NDJ-1 rotational viscometer), weight The solid content is 32%, and the pH is 7.5.

Embodiment 2

[0027] First, put 100g of polytetrahydrofuran diol (molecular weight: 1000) and 9.4g of 2,2'-dimethylolpropionic acid into a four-necked flask with a stirring and heating device, and after vacuum dehydration at 80°C for 2 hours, add 30g Dry N-methylpyrrolidone and 55g of diphenylmethane diisocyanate ([NCO] / [OH]=1.3) were reacted at 75°C for 4h under the protection of nitrogen until the NCO content reached the theoretical value to obtain NCO-terminated polyurethane prepolymer thing. Then add 4.5g of methyl ethyl ketoxime and react at 75°C for 4h until its NCO content is zero to obtain a blocked polyurethane prepolymer, add 7g of triethylamine at 65°C for neutralization reaction for 0.5h, add 400g of deionized water, and disperse The final sample obtained was a bluish white emulsion with a viscosity of 39.8 mPa.s at 25°C (measured by NDJ-1 rotational viscometer), a weight solid content of 29%, and a pH of 7.7.

Embodiment 3

[0029] First, put 100g polyneopentyl glycol adipate diol (molecular weight: 2000) and 4.7g 2,2'-dimethylolpropionic acid into a four-necked flask with a stirring and heating device, at 100 After vacuum dehydration at ℃ for 1 h, add 15 g of N-methylpyrrolidone and 32 g of isophorone diisocyanate ([NCO] / [OH]=1.7) and react for 5 h at 85 °C under the protection of nitrogen until the NCO content reaches the theoretical value. NCO-terminated polyurethane prepolymer. Then add 5.2g of methyl ethyl ketone oxime and react at 80°C for 6h until its NCO content is zero to obtain a blocked polyurethane prepolymer, add 6g of triethylamine at 60°C for neutralization reaction for 0.5h, add 350g of deionized water for dispersion The final sample obtained was a bluish white emulsion with a viscosity of 20.5 mPa.s at 25°C (measured by NDJ-1 rotational viscometer), a weight solid content of 29.4%, and a pH of 7.4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com