Thin-gauge X70M hot-rolled steel plate for gas transmission longitudinal welded pipe and manufacturing method

A technology of X70M and hot-rolled steel plates, which is applied in the field of high-strength X70M hot-rolled steel plates for natural gas pipelines and its manufacturing, can solve the problems of poor uniformity of steel plates, high rolling resistance, and low production costs, and achieve optimized thickness and improved The effect of starting rolling temperature and increasing reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

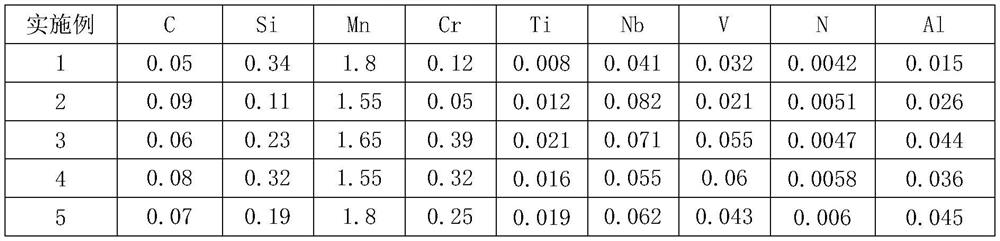

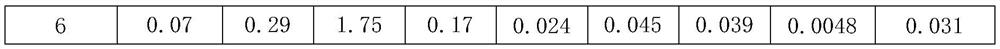

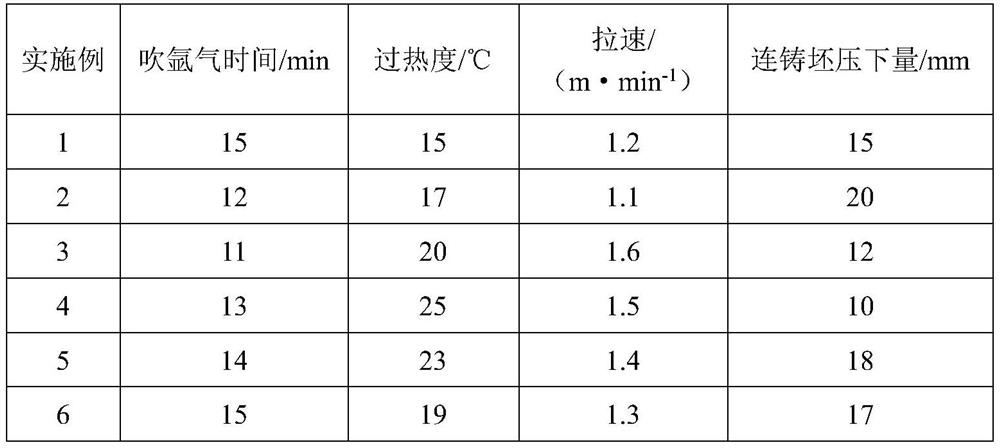

[0029] The invention provides a X70M hot-rolled steel plate for a thin gauge gas transmission straight seam welded pipe. The thickness of the steel plate is 10-18mm; the chemical composition of the steel plate is calculated by weight percentage: C 0.05%-0.09%, Si 0.10 %~0.35%, Mn1.50%~1.80%, P≤0.020%, S≤0.015%, Nb 0.04%~0.09%, Ti 0.008%~0.0250%, Al0.015%~0.045%, Cr≤0.4%, V 0.020% ~ 0.06%, N 0.0041% ~ 0.006%, the balance is Fe and unavoidable impurities; O ≤ 0.0050% in impurities, and the total amount of other impurity elements is less than 0.05%.

[0030] A method for manufacturing X70M hot-rolled steel plates for thin-gauge gas transmission straight seam welded pipes. The production process is molten steel smelting→outside furnace refining, degassing→continuous casting→slab reheating→controlled rolling→controlled cooling→air cooling to room temperature ;details as follows:

[0031] 1) Process from molten steel smelting to continuous casting:

[0032] The raw material is pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com