A kind of high-strength wear-resistant steel plate and its production method

A technology of wear-resistant steel plates and production methods, which is applied in the field of steelmaking, can solve the problems of low hardness of wear-resistant steel plates, and achieve the effects of good welding performance, uniform strength, and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with some specific embodiments.

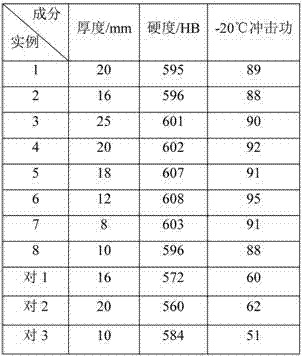

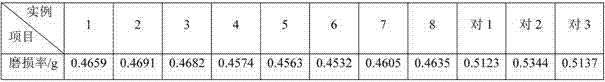

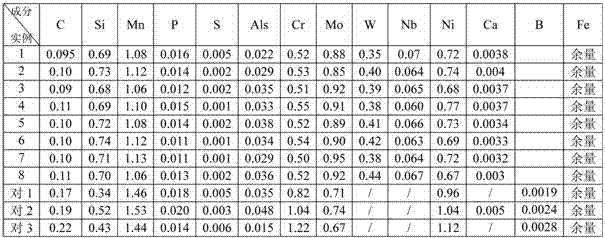

[0043] The chemical composition and weight percentage of the 550-grade high-strength wear-resistant steel plate in Examples 1-8 of the present invention are shown in Table 1 below.

[0044] Table 1 Chemical composition (wt%) of the high-strength wear-resistant steel plates of Examples 1-8 of the present invention and Comparative Examples 1-3

[0045]

[0046] The production method of the high-strength wear-resistant steel plate in the above-mentioned embodiment 1 includes the following steps: KR molten iron pretreatment, converter smelting, argon station adding aluminum line, LF furnace refining, VD refining, continuous casting, heating, controlled rolling and controlled cooling, stack cooling ;

[0047] In the KR molten iron pretreatment step: the slag before and after the slag is removed from the molten iron at the station, the thickness of the slag layer on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com