Acidic corrosion resistant X60MS pipeline steel and preparation method thereof

A pipeline steel, acid resistance technology, applied in the field of iron and steel metallurgy, can solve the problem of pipeline steel weldability, HIC resistance performance, steel plate strength, yield ratio, elongation and other parameters fluctuated greatly, and the inclusion grain size is not provided. level, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

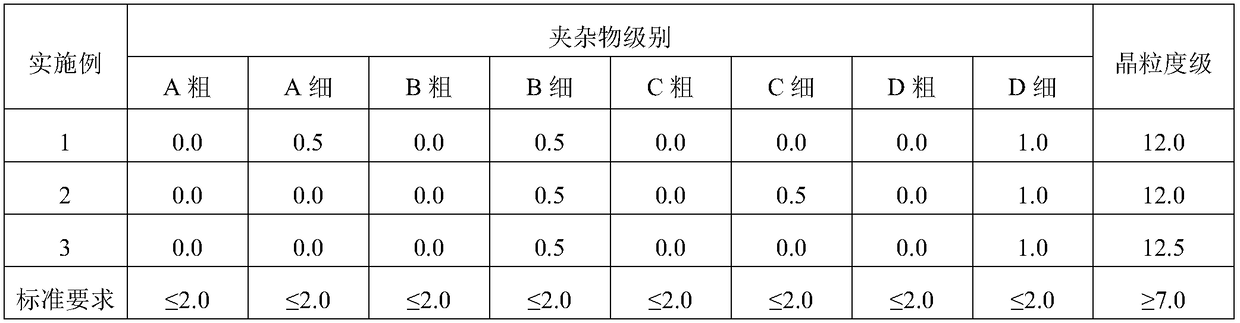

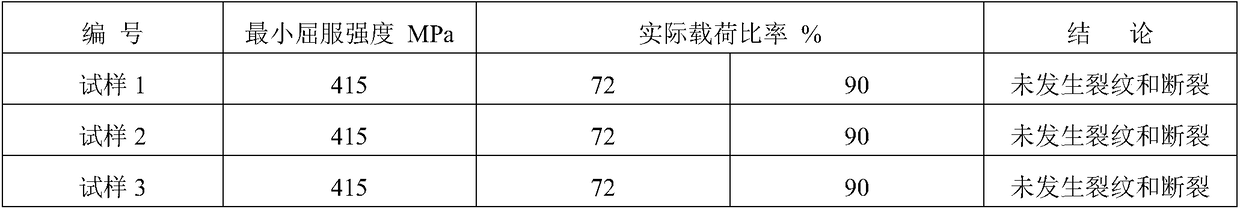

Embodiment 1

[0078] Embodiment 1, preparation of acid corrosion resistant X60MS pipeline steel

[0079] Adopt KR method to desulfurize molten iron and high-quality steel scrap, LF refining and RH vacuum treatment to ensure the cleanliness of molten steel, LF refining uses a large amount of slag to make slag, RH vacuum treatment ensures the deep vacuum cycle time of molten steel, calcium treatment after vacuum treatment, Ar gas softening The blowing time is longer than 10 minutes, and the slab is continuously cast in the whole process of protection pouring, and the dynamic soft reduction technology is adopted to reduce the center segregation of the continuous casting slab to obtain the slab;

[0080] The slab is heated to a heating temperature of 1172°C, and the total time in the furnace is 185 minutes, and then the first-stage rolling is carried out, that is, the rolling in the austenite recrystallization zone, the starting rolling temperature is 1160°C, and the reduction ratio of the first...

Embodiment 2

[0081] Embodiment 2, preparation of acid corrosion resistant X60MS pipeline steel

[0082] Adopt KR method to desulfurize molten iron and high-quality steel scrap, LF refining and RH vacuum treatment to ensure the cleanliness of molten steel, LF refining uses a large amount of slag to make slag, RH vacuum treatment ensures the deep vacuum cycle time of molten steel, calcium treatment after vacuum treatment, Ar gas softening The blowing time is longer than 10 minutes, and the slab is continuously cast in the whole process of protection pouring, and the dynamic soft reduction technology is adopted to reduce the center segregation of the continuous casting slab to obtain the slab;

[0083] The slab is heated to a heating temperature of 1170°C, and the total time in the furnace is 190 minutes, and then the first-stage rolling is carried out, that is, the rolling in the austenite recrystallization zone, the starting rolling temperature is 1158°C, and the reduction ratio of the first...

Embodiment 3

[0084] Embodiment 3, preparation of acid corrosion resistant X60MS pipeline steel

[0085] Adopt KR method to desulfurize molten iron and high-quality steel scrap, LF refining and RH vacuum treatment to ensure the cleanliness of molten steel, LF refining uses a large amount of slag to make slag, RH vacuum treatment ensures the deep vacuum cycle time of molten steel, calcium treatment after vacuum treatment, Ar gas softening The blowing time is longer than 10 minutes, and the slab is continuously cast in the whole process of protection pouring, and the dynamic soft reduction technology is adopted to reduce the center segregation of the continuous casting slab to obtain the slab;

[0086] The slab is heated to a heating temperature of 1176°C, and the total time in the furnace is 188 minutes, and then the first stage of rolling is carried out, that is, the rolling in the austenite recrystallization zone, the starting rolling temperature is 1165°C, and the reduction ratio of the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield ratio | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com