A kind of wet spinning preparation method of acetate fiber

An acetate fiber and wet spinning technology, applied in the spinning field, can solve the problems of expensive ionic solvent, incapable of large-scale production and application, and high energy consumption, achieve excellent indicators, improve production environment, and good mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

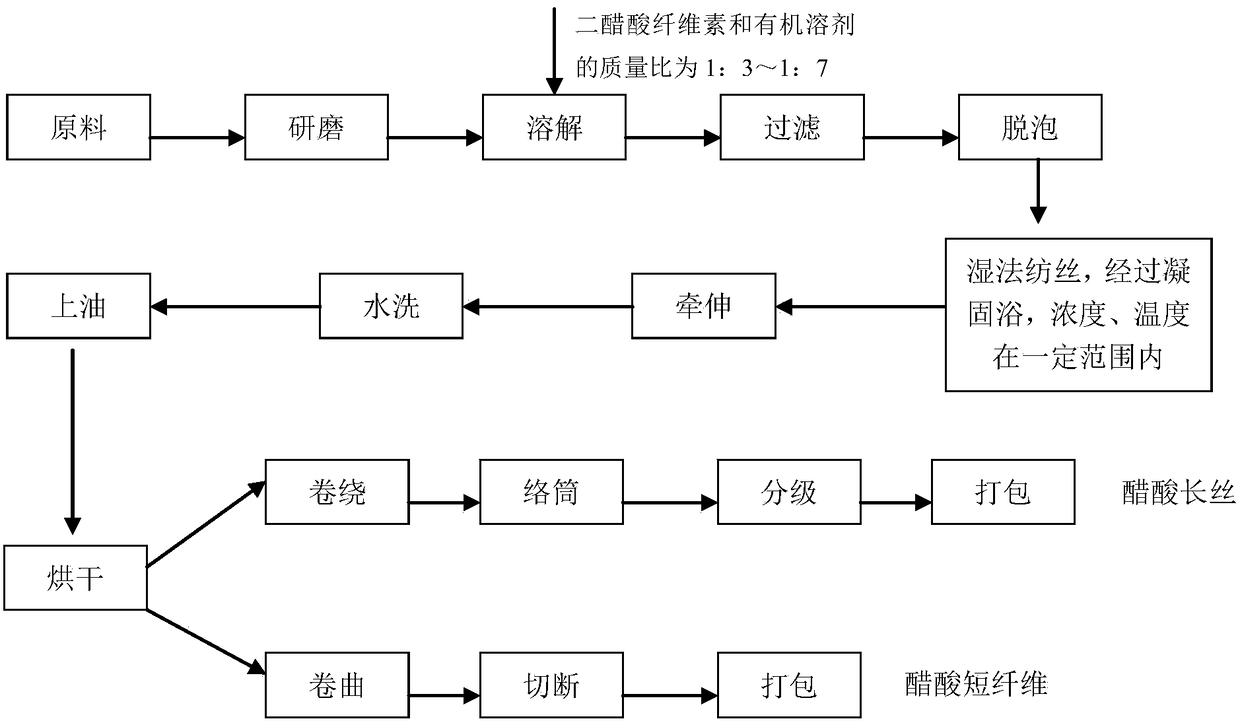

Method used

Image

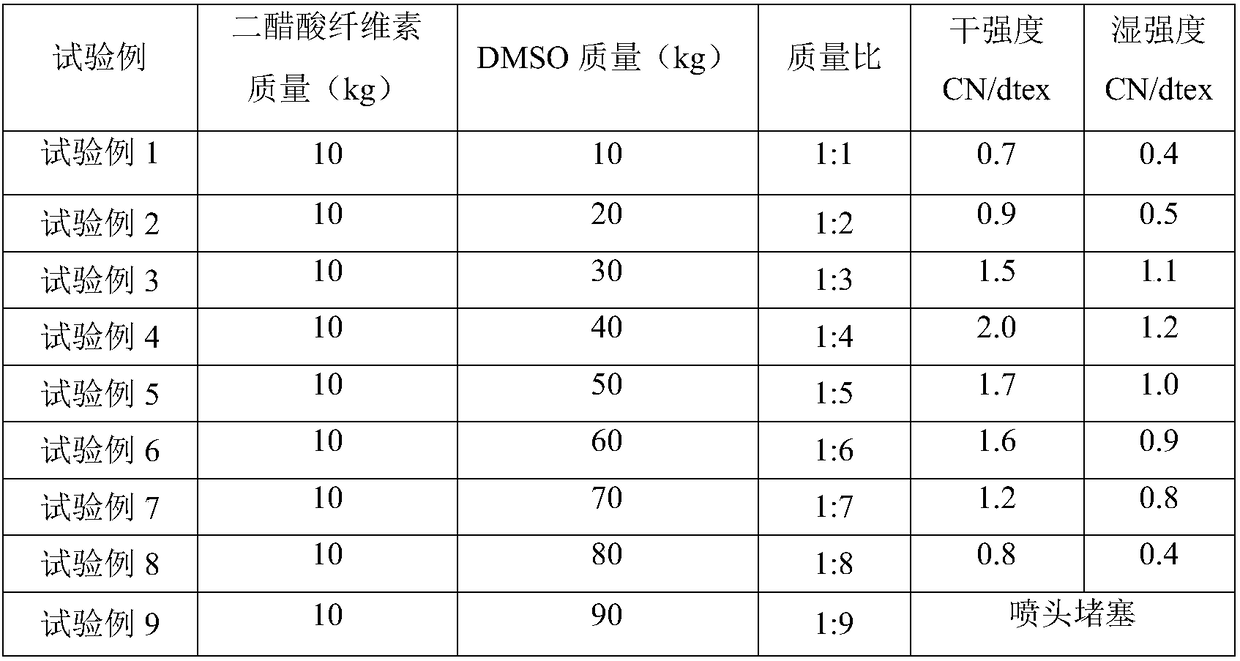

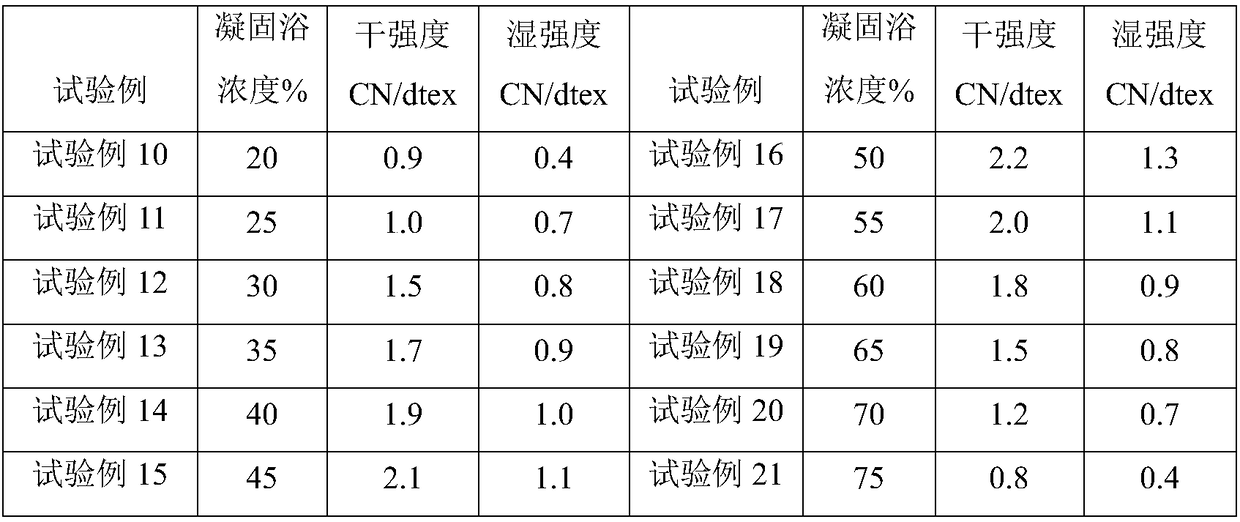

Examples

Embodiment 1

[0037] (1) the degree of esterification of 5kg granular blocks is 2.1, and the cellulose diacetate with a water content of 1% is ground into powder;

[0038] (2) Add cellulose diacetate powder and 30kg of DMAC solvent into the dissolution tank, stir and mix thoroughly, heat up and dissolve, the dissolution temperature is 35°C, and the dissolution time is 8 hours;

[0039] (3) After degassing and filtering, the spinning stock solution is formed;

[0040] (4) The spinning stock solution at 15°C is sprayed out from the spinneret hole after being passed through a metering pump and a filter, and enters a coagulation bath, which is a DMAC aqueous solution with a concentration of 25% and a temperature of 20°C to form nascent fibers;

[0041] (5) As-spun fibers are drawn, washed, oiled, dried, wound, and graded to form acetate fiber finished products, and the total draft ratio of the drafting process is 0.5.

[0042] The index of the obtained acetate fiber finished product: the dry str...

Embodiment 2

[0044] (1) the degree of esterification of 5kg grains is 2.8, and the cellulose diacetate with a water content of 7% is ground into powder;

[0045] (2) Add cellulose diacetate powder and 35kg of DMAC solvent into the dissolution tank, stir and mix thoroughly, heat up and dissolve, the dissolution temperature is 100°C, and the dissolution time is 0.5 hours;

[0046] (3) After degassing and filtering, the spinning stock solution is formed;

[0047] (4) The spinning stock solution at 100°C is sprayed out from the spinneret hole after being passed through a metering pump and a filter, and enters a coagulation bath, which is a DMAC aqueous solution with a concentration of 70% and a temperature of 90°C to form primary fibers;

[0048] (5) As-spun fibers are drawn, washed, oiled, dried, wound, and graded to form acetate fiber finished products, and the total draft ratio of the drafting process is 7.

[0049] The index of the obtained acetate fiber finished product: the dry strength...

Embodiment 3

[0051] (1) the degree of esterification of 10kg grains is 2.5, and the cellulose diacetate with a water content of 4% is ground into powder;

[0052] (2) Add cellulose diacetate powder and 35kg DMF solvent into the dissolving tank, fully stir and mix, heat up and dissolve, the dissolving temperature is 40°C, and the dissolving time is 3 hours;

[0053] (3) After degassing and filtering, the spinning stock solution is formed;

[0054] (4) The spinning dope at 40°C is sprayed out from the spinneret hole after being passed through a metering pump and a filter, and enters a coagulation bath, which is a DMF aqueous solution with a concentration of 30% and a temperature of 25°C to form primary fibers;

[0055] (5) As-spun fibers are drawn, washed, oiled, dried, wound, and graded to form acetate fiber finished products, and the total draft ratio of the drafting process is 1.

[0056] The index of the obtained acetate fiber finished product: the dry strength is 2.0CN / dtex, the wet st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com