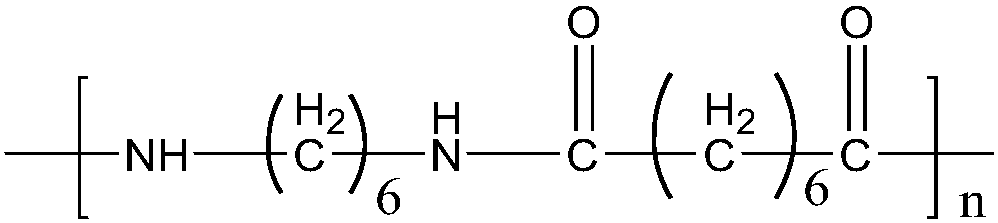

Electrospun nylon 66/pva/boric acid nanofiber and preparation method thereof

A technology of composite nanofiber and nylon, which is applied in the direction of spinning solution preparation, fiber treatment, fiber chemical characteristics, etc., can solve the problems of strong taste and toxicity of formic acid, and achieve the effect of good filterability, high strength and small fiber diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Another aspect of the present invention provides a method for preparing electrospun nylon 66 / PVA / boric acid composite nanofibers, comprising the following steps:

[0037] (1) Nylon 66 salt is dissolved in water to form a precursor solution;

[0038] (2) In the precursor solution described in step (1), add PVA and boric acid to form a spinning mixed solution, and obtain nylon 66 / PVA / boric acid precursors by electrospinning;

[0039] (3) The nylon 66 / PVA / boric acid precursor described in step (2) is dried, and after heat treatment, nylon 66 / PVA / boric acid composite nanofibers are obtained.

[0040] Electrospinning:

[0041] The electrospinning described in step (2) is a special fiber manufacturing process, and the polymer solution or melt is jet-spun in a strong electric field. Under the action of the electric field, the droplet at the needle will change from a spherical shape to a conical shape (that is, "Taylor cone"), and extend from the tip of the cone to obtain a...

Embodiment 1

[0055] At room temperature, weigh 4g of nylon 66 salt, dissolve nylon 66 salt in water, and stir magnetically for 2 hours to form a precursor solution, which is labeled as A solution;

[0056] Add 1g of PVA and 0.25g of boric acid in solution A to form a spinning mixed solution with a solution concentration of 10%, which is marked as solution B, and the absolute viscosity of the spinning mixed solution is 2.5Pa·S;

[0057] The preparation B solution is placed in the spinning device, the curing distance is adjusted to 15cm and the voltage is 20kV, the wire mesh is connected to the negative electrode, and the nylon 66 / PVA / boric acid precursor is collected on the wire mesh as the negative electrode.

[0058] The obtained nylon 66 / PVA / boric acid precursors were dried and heated at 220° C. for 2 hours under nitrogen gas to prepare nylon 66 / PVA / boric acid composite nanofibers.

[0059] The mass ratio of each component in the prepared nylon 66 / PVA / boric acid composite nanofiber is: ...

Embodiment 2

[0063] At room temperature, weigh 4g of nylon 66 salt, dissolve nylon 66 salt in water, and stir magnetically for 2 hours to form a precursor solution, which is labeled as A solution;

[0064] Add 6g of PVA and 1.5g of boric acid in solution A to form a spinning mixed solution with a solution concentration of 15%, marked as solution B, and the absolute viscosity of the spinning mixed solution is 3.0Pa·S;

[0065] The preparation B solution is placed in the spinning device, the solidification distance is adjusted to 16cm and the voltage is 22kV, the wire mesh is connected to the negative electrode, and the nylon 66 / PVA / boric acid precursor is collected on the wire mesh as the negative electrode.

[0066] The obtained nylon 66 / PVA / boric acid precursors were dried and heated at 230° C. for 2 hours under nitrogen to prepare nylon 66 / PVA / boric acid composite nanofibers.

[0067] The mass ratio of each component in the prepared nylon 66 / PVA / boric acid composite nanofiber is:

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com