Preparation method for acetate fiber through dry-wet process

A technology for cellulose acetate and cellulose acetate, which is applied in the field of dry and wet preparation of cellulose acetate, can solve the problems of poor mechanical properties of cellulose acetate fibers, environmental pollution, and high production costs, and achieves improvements in plant area environmental protection indicators, and increases in application fields, The effect of low product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

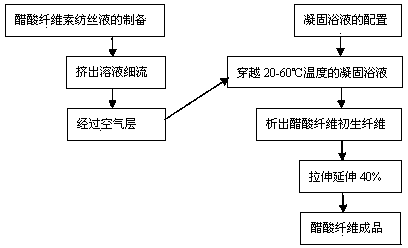

[0024] As shown in the attached figure, use glacial acetic acid containing 10% water as a solvent, prepare a solution with a concentration of 18% from cellulose acetate sheets with a degree of substitution of 2.0 and a degree of polymerization of 500, and add it to a dissolution kettle with a stirrer and a thermometer , dissolved at room temperature for 4 hours, vacuum defoaming; through the filter device and metering pump, extruded from the spinneret hole, the distance between the spinneret surface and the coagulation bath was set at 100mm; the solution extruded from the spinneret was fine After flowing through a section of air layer with a distance of 100mm, it passes through the coagulation bath. The content of glacial acetic acid in the coagulation bath is 10%, and the temperature of the coagulation bath is 40°C. The solvent in the solution trickle diffuses to the coagulation bath, and the coagulant in the bath diffuses to the inside of the trickle, so the polymer is precip...

Embodiment 2

[0026] Use glacial acetic acid containing 5% water as solvent, prepare a solution with a concentration of 22% from cellulose acetate sheets with a degree of substitution of 2.5 and a degree of polymerization of 550, add it to a dissolution kettle with a stirrer and a thermometer, and dissolve it at 20°C 3h, vacuum defoaming; through the filter device and metering pump, extrude from the spinneret hole, the distance between the spinneret surface and the coagulation bath is set at 130mm; the solution squeezed out from the spinneret passes through this section After the air layer enters and passes through the coagulation bath for 2 seconds, the content of glacial acetic acid in the coagulation bath is 15%, the temperature of the coagulation bath is 50°C, and the polymer is precipitated in the coagulation bath to form acetate fiber; then stretching is carried out at an elongation rate of 40%. The monofilament linear density of the obtained acetate filament is 7.0dtex, the breaking s...

Embodiment 3

[0028] As shown in the attached figure, use glacial acetic acid with a water content of 15% as a solvent, prepare a solution with a concentration of 12% from cellulose acetate particles with a degree of substitution of 2.9 and a degree of polymerization of 600, and add it to a dissolution kettle with a stirrer and a thermometer , dissolved at 30°C for 6 hours, vacuum defoaming; through the filter device and metering pump, extruded from the spinneret hole, the solution extruded from the spinneret passed through a section of air layer with a distance of 200mm, and then immersed in the coagulation bath 5 seconds (5s). The content of glacial acetic acid in the coagulation bath is 20%, and the temperature of the coagulation bath is 20°C. The solvent in the solution trickle diffuses to the coagulation bath, and the coagulant in the bath diffuses to the inside of the trickle, so the polymer is precipitated in the coagulation bath to form acetate fiber. Then stretching treatment is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Monofilament linear density | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Monofilament linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com