Patents

Literature

64results about How to "Good spot weldability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength cold-rolled hot-galvanized precipitation reinforced steel and manufacturing method thereof

ActiveCN102199723AGood welding performancePremium surface qualityTemperature control deviceMetal rolling arrangementsSheet steelImpurity

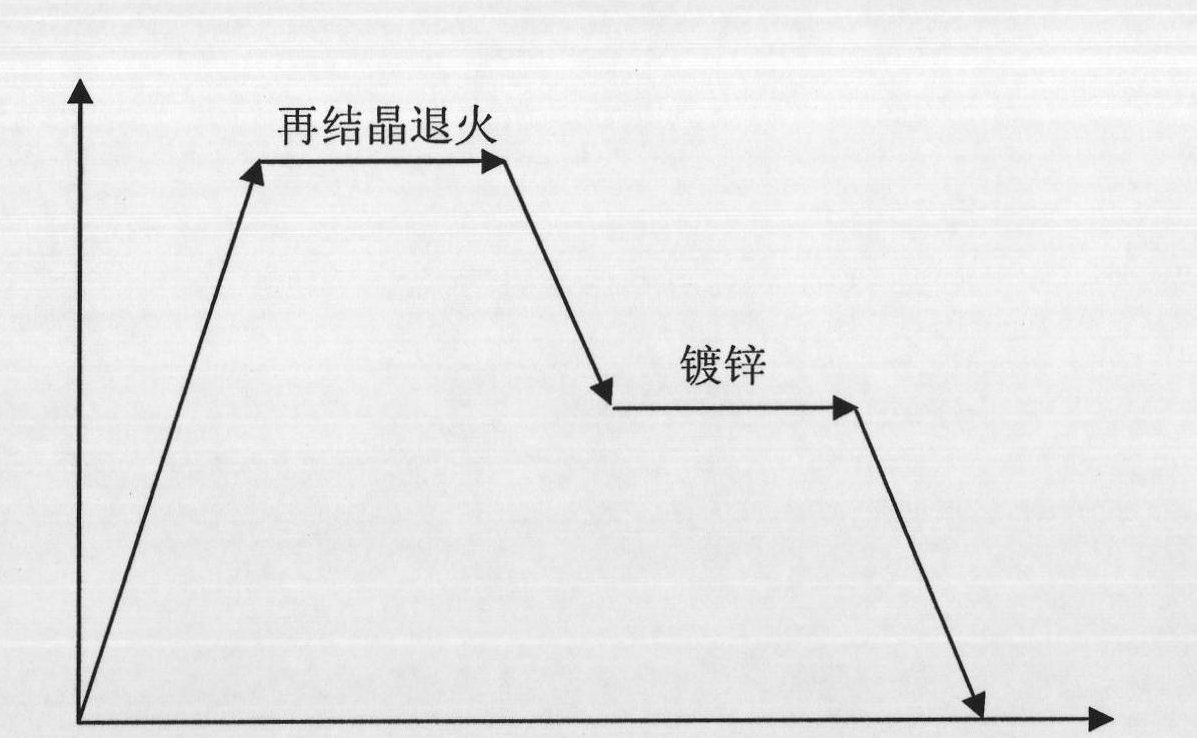

The invention discloses a high-strength cold-rolled hot-galvanized precipitation reinforced steel plate and a manufacturing method thereof. The steel plate comprises the following components: 0.09 to 0.12 weight percent of C, less than or equal to 0.05 weight percent of Si, 0.8 to 1.8 weight percent of Mn, less than or equal to 0.02 weight percent of P, less than or equal to 0.01 weight percent of S, less than or equal to 0.008 weight percent of N, 0.02 to 0.06 weight percent of Al, 0.05 to 0.08 weight percent of Nb and Ti and the balance of Fe and inevitable impurities. The microstructure ofthe steel plate is ferrite and second phase particles, wherein the diameter of the second phase particles is about less than 6 mu m, the yield strength is 500 to 600MPa, the tensile strength is 570 to 710MPa, and the total coefficient of elongation is over 14 percent (80 gauge length and transverse stretching). The hot-galvanized steel plate has high welding performance and surface quality and can be widely used in automotive structural membranes.

Owner:BAOSHAN IRON & STEEL CO LTD

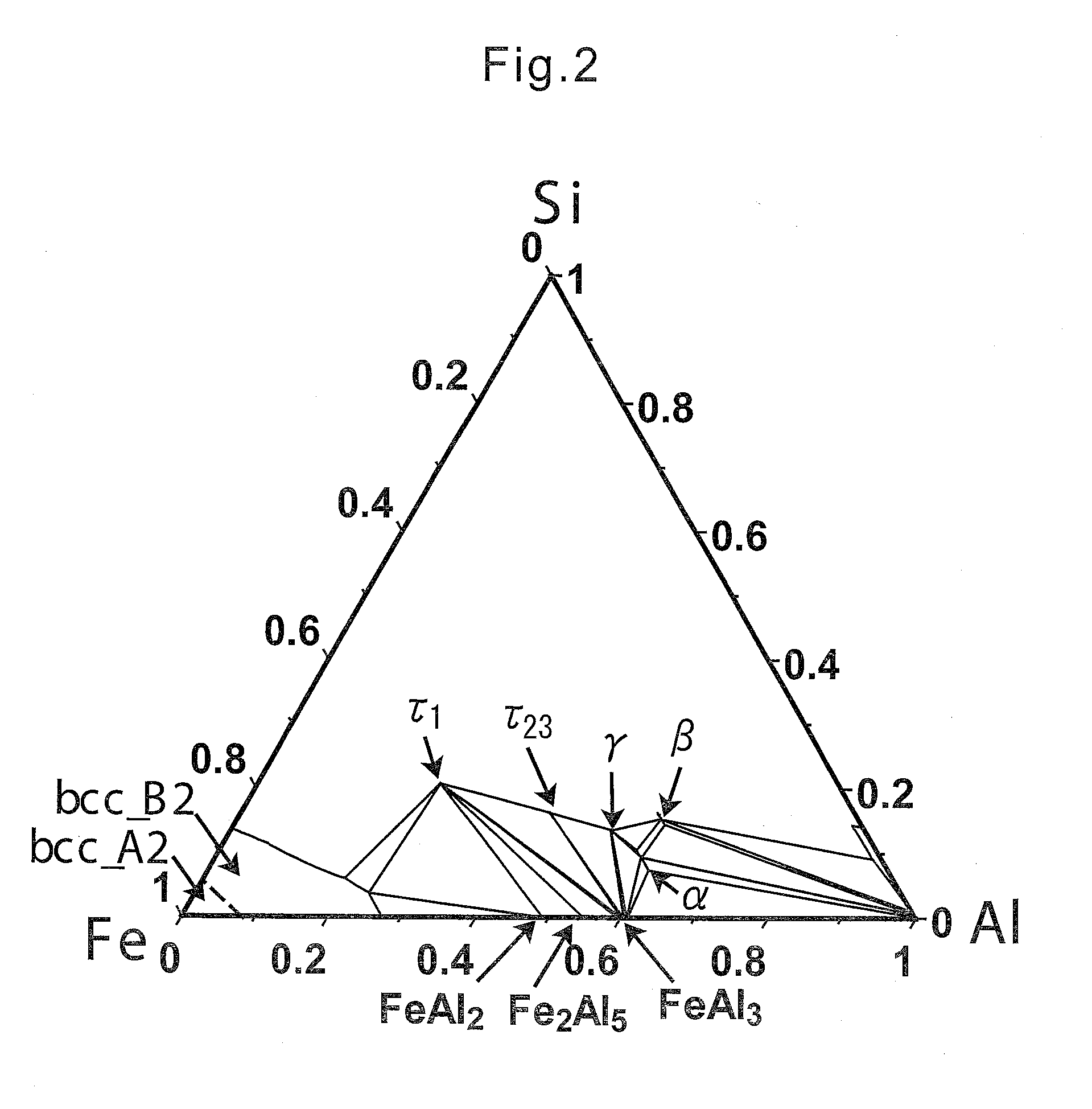

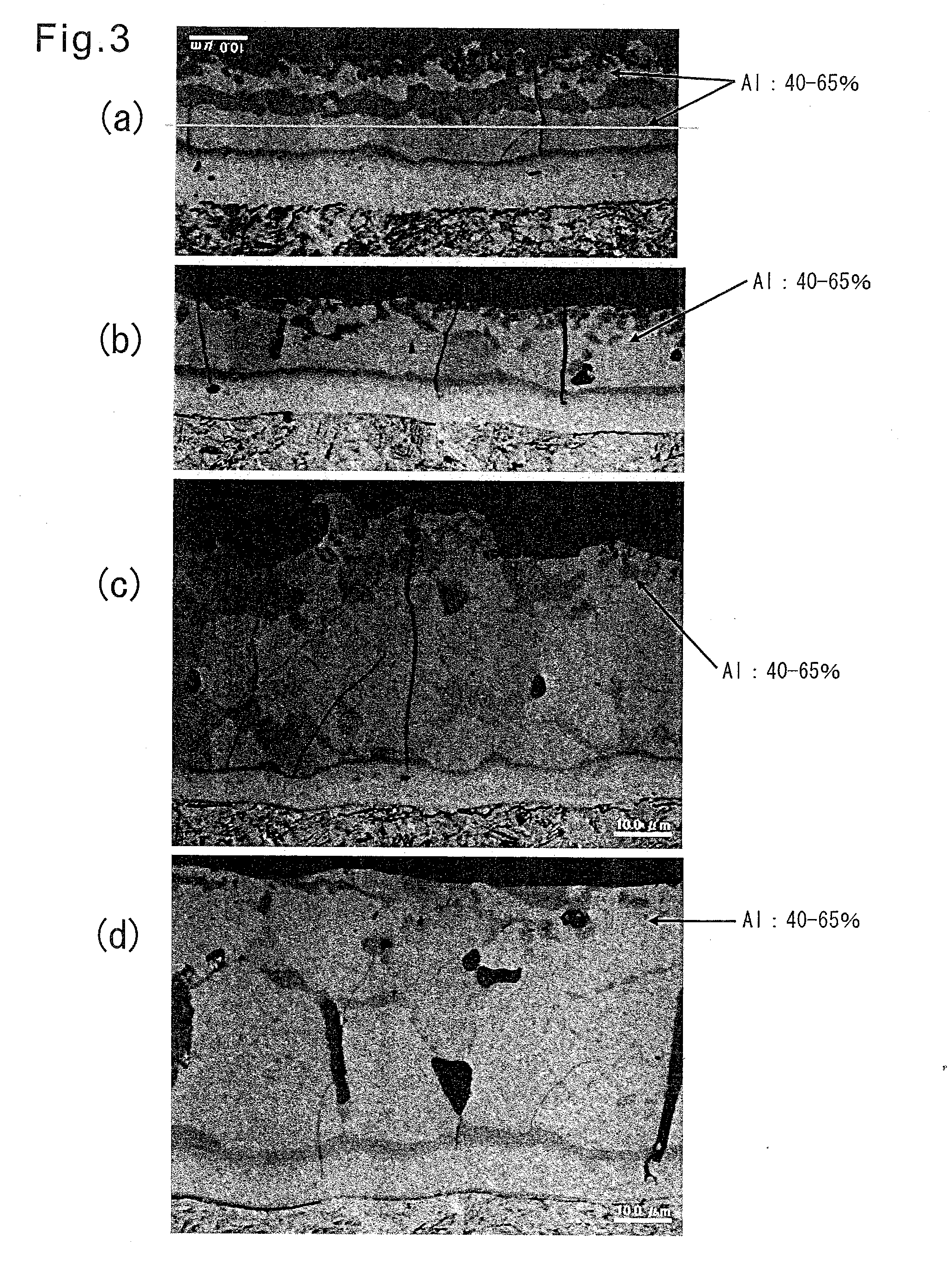

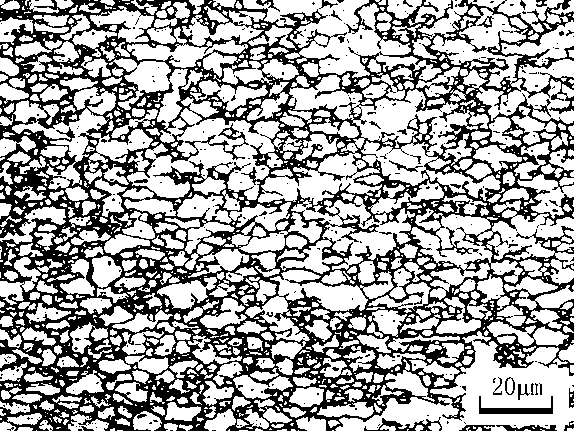

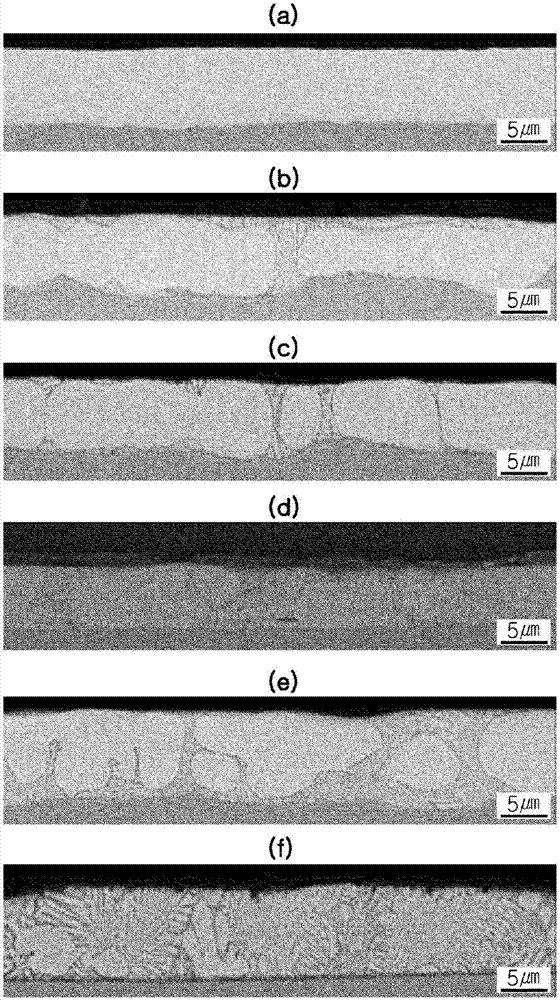

Hot stamped high strength part excellent in post painting anticorrosion property and method of production of same

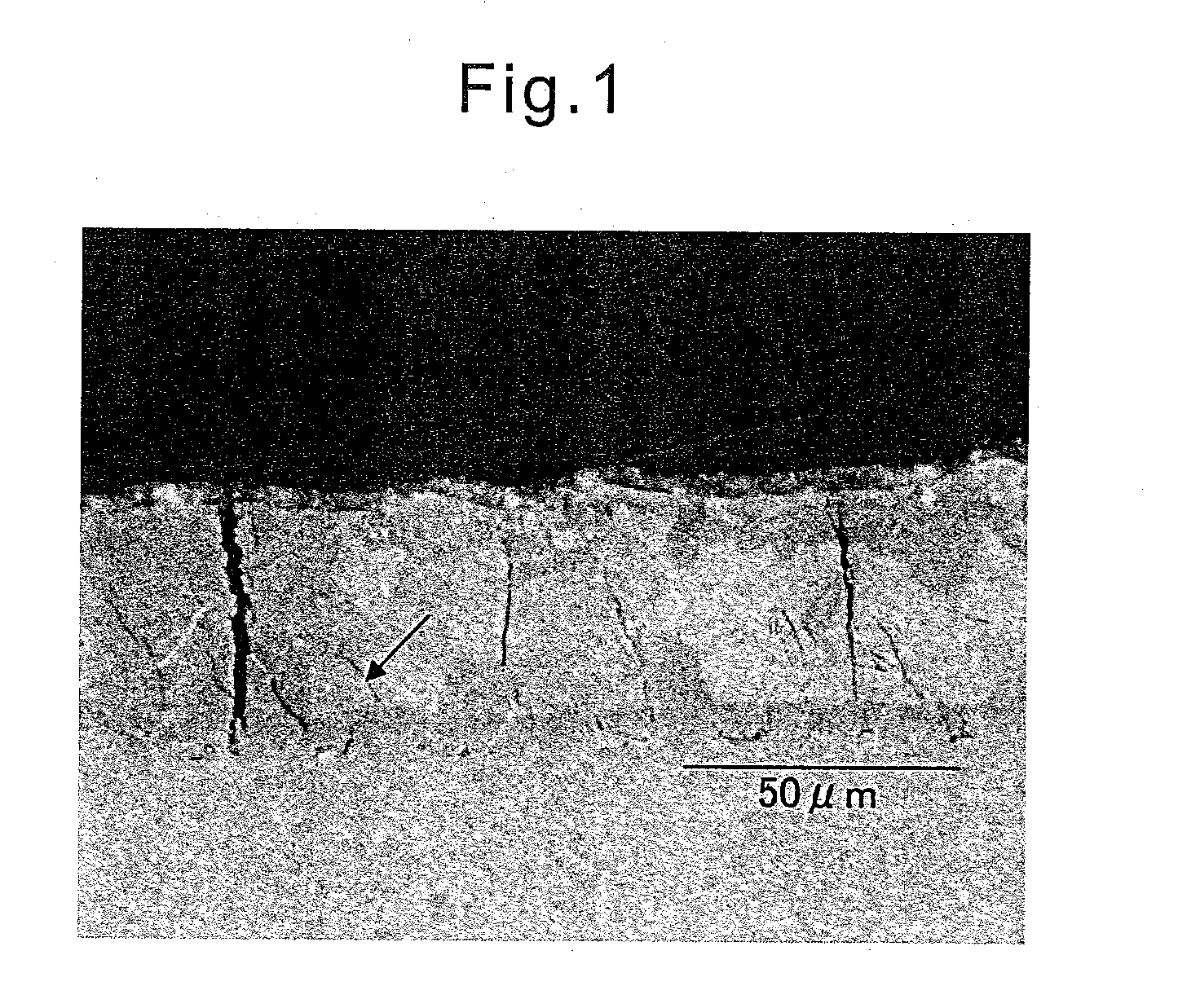

ActiveUS20140030544A1Inhibits the formation of cracksHigh strengthHot-dipping/immersion processesFurnace typesHot stampingCrazing

A hot stamped high strength part in which the propagation of cracks which form at the plating layer at the time of hot stamping when hot stamping aluminum plated steel sheet is suppressed and the post painting anticorrosion property is excellent even without adding special ingredient elements which suppress formation of cracks in an aluminum plating layer is provided.A hot stamped high strength part which is excellent in post painting anticorrosion property, which hot stamped high strength part has an alloy plating layer which includes an Al—Fe intermetallic compound phase on the surface of the steel sheet, wherein the alloy plating layer is comprised from phases of a plurality of intermetallic compounds, a mean linear intercept length of crystal grains of a phase containing Al: 40 to 65 mass % among the phases of the plurality of intermetallic compounds is 3 to 20 μm, an average value of thickness of the Al—Fe alloy plating layer is 10 to 50 μm, and a ratio of the average value of thickness to the standard deviation of thickness of the Al—Fe alloy plating layer satisfies the following relationship:0<standard deviation of thickness / average value of thickness≦0.15.

Owner:NIPPON STEEL CORP

Steel for 300MPa-grade automobile structural part and production method for steel

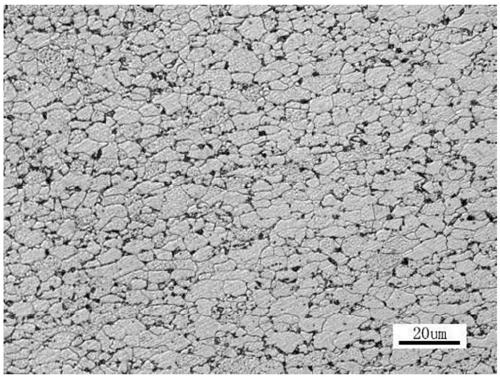

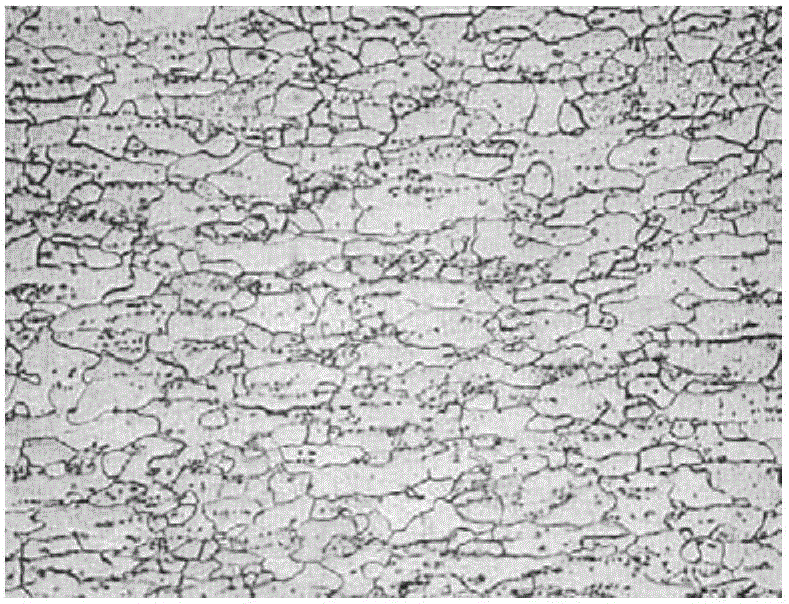

The invention relates to steel for a 300MPa-grade automobile structural part and a production method for the steel. The steel comprises the following main components in percentage by weight: 0.06-0.08 percent of C, 0.05-0.09 percent of Si, 0.30-0.45 percent of Mn, 0.025-0.055 percent of Al, 0.015-0.025 percent of P, less than or equal to 0.006 percent of S, 0.010-0.019 percent of Nb, less than or equal to 0.006 percent of N and the balance of Fe and impurities. The production method comprises the production steps of molten iron desulfurization, converter smelting, ladle argon blowing, continuous casting, heating of a casting blank, hot rolling, winding, conventional pickling, cold rolling, continuous operation and flattening for later use. The production method disclosed by the invention has the advantages of short process flow, lower energy consumption and stable mechanical property; and in addition, on the premise that the yield strength of 300-340MPa and the tensile strength of 390-445MPa are met, the elongation percentage is not lower than 31 percent, the plastic strain ratio r is 1.45-1.80, a strain hardening index n is 0.16-0.20, a wide-cold test bending is 180 degrees and a bending diameter d is equal to 0; and in a metallographic structure, an equiaxed ferrite is 85-90 percent and a granular pearlite is 10-15 percent.

Owner:武汉钢铁有限公司

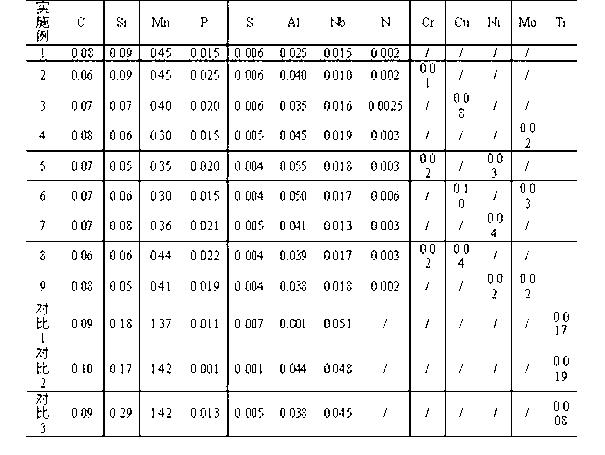

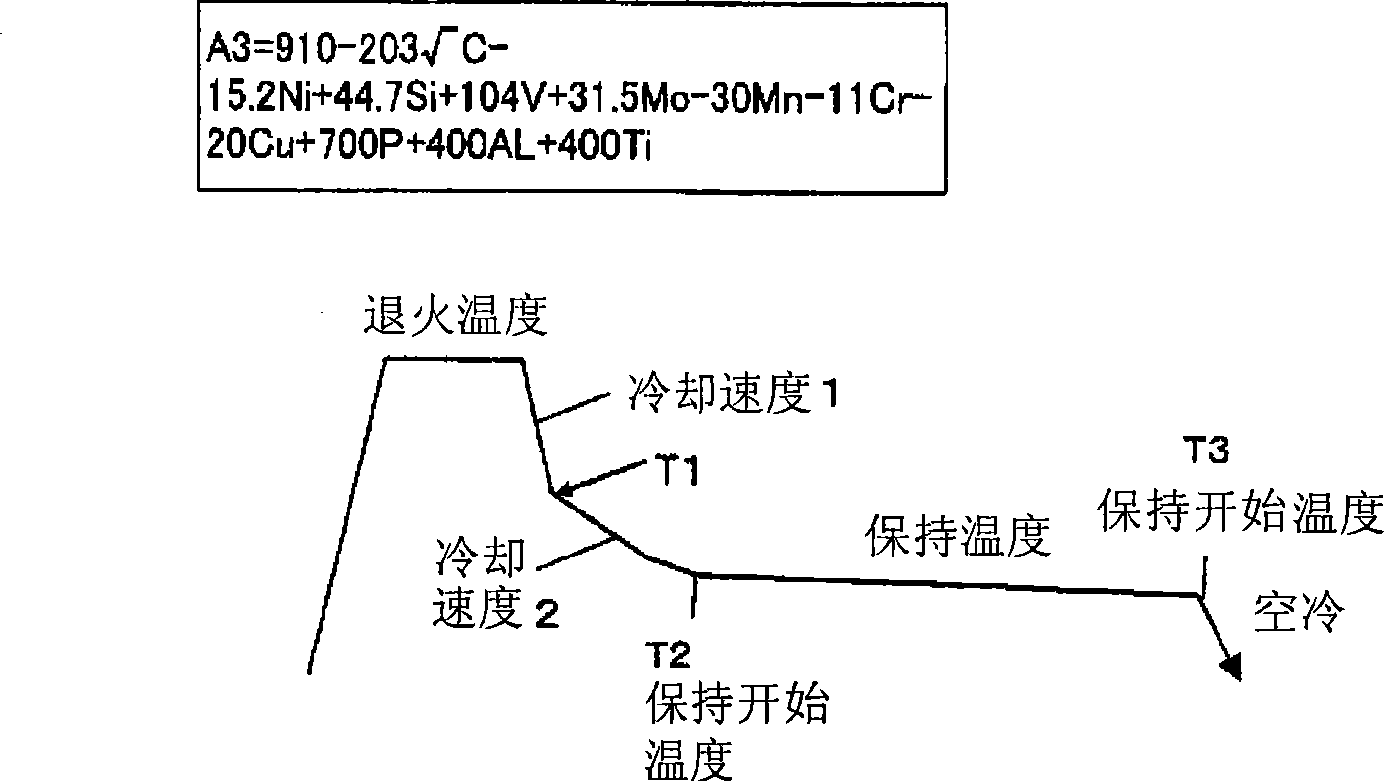

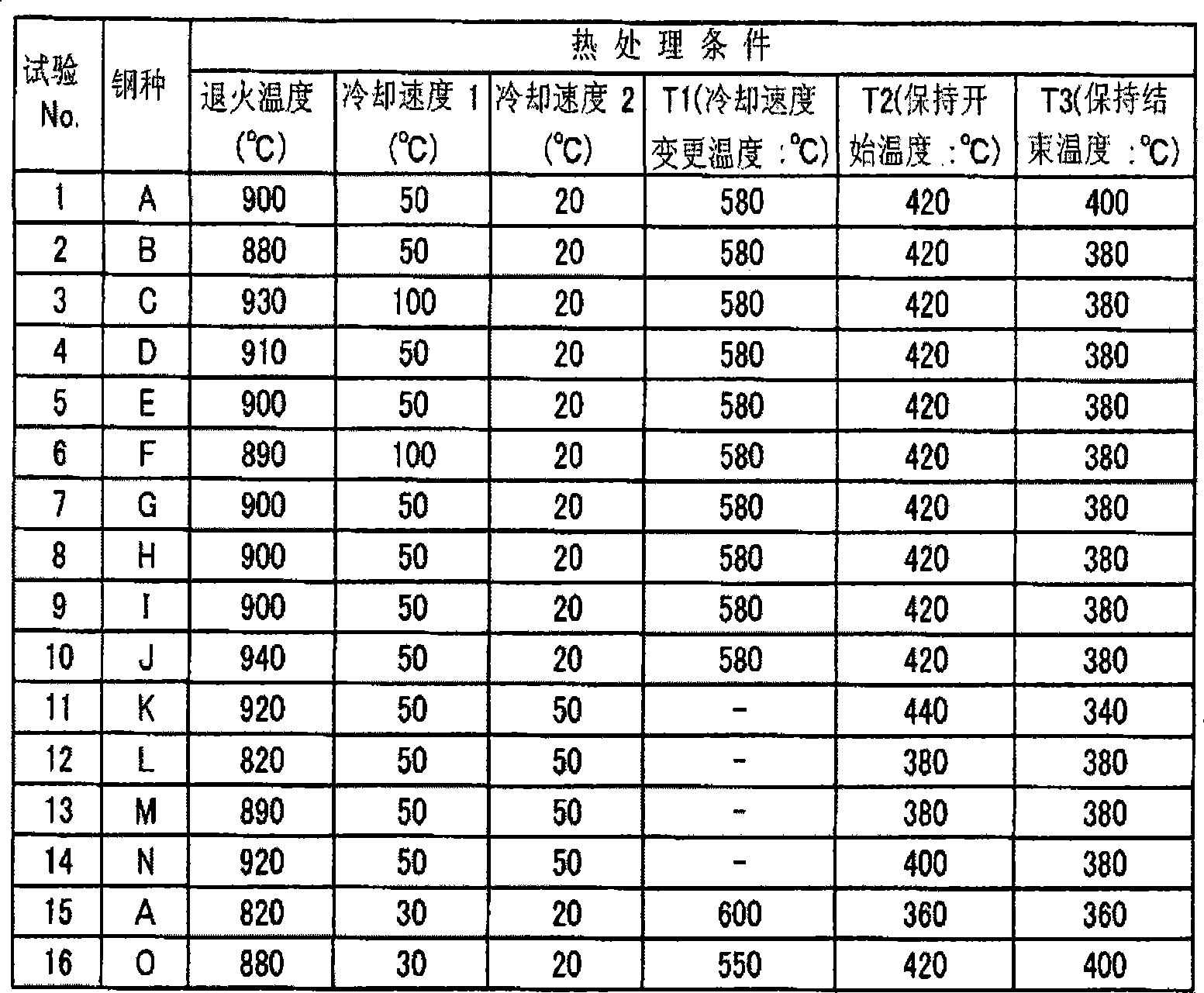

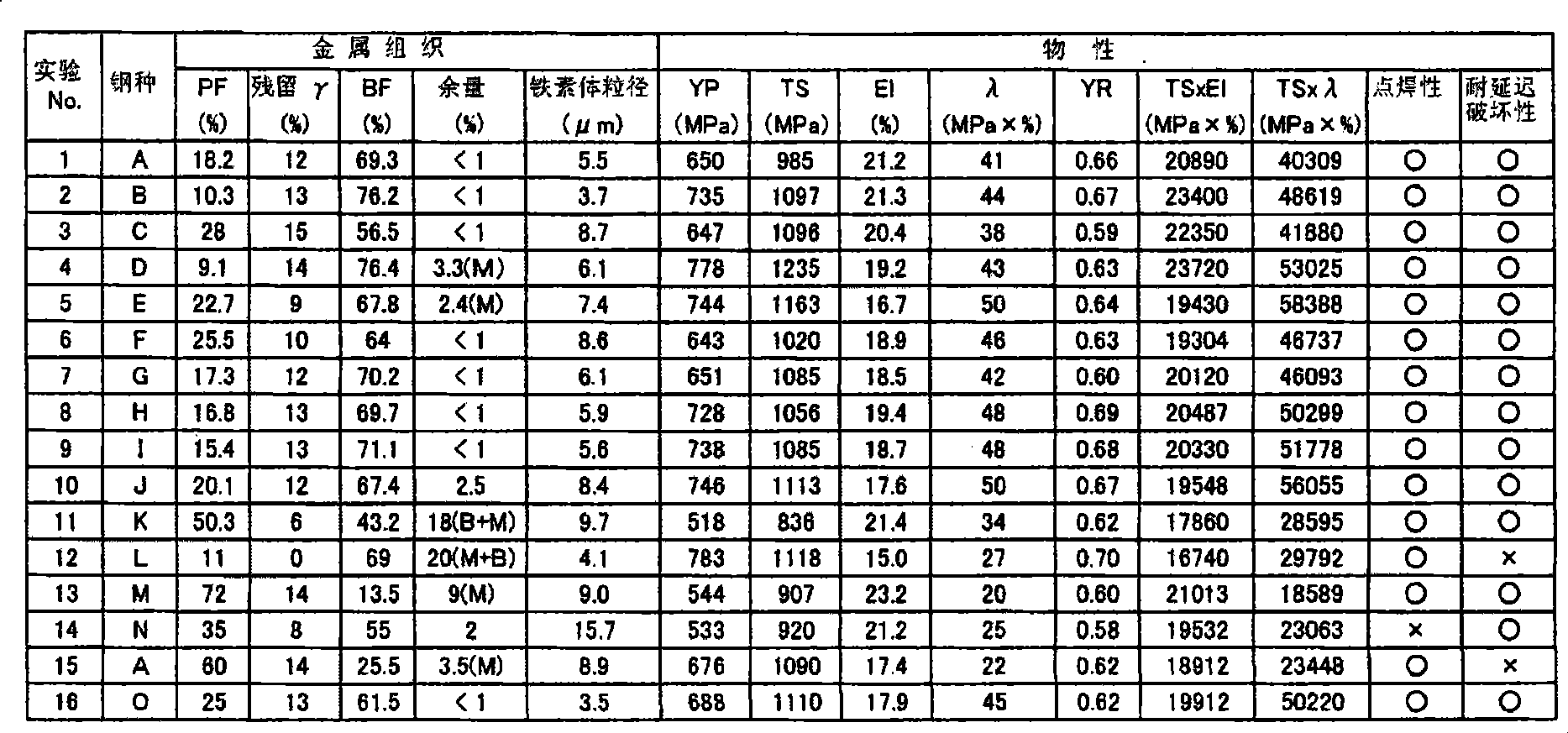

High-strength composite steel sheet having excellent moldability and delayed fracture resistance

InactiveCN101460646AGuaranteed tensile strengthGood formabilityFurnace typesHeat treatment furnacesChemical compositionHigh intensity

Disclosed is a high-strength composite steel sheet having a tensile strength of 980 MPa or greater and excellent in moldability, delayed fracture resistance and spot weldability. The steel sheet comprises a steel having the following chemical composition: C: 0.12-0.25%, Si: 1.0-3.0%, Mn: 1.5-3.0%, P: 0.15% or less, S: 0.02% or less, Al: 0.4% or less, and Cr: 1.0% or less, with the remainder being iron and unavoidable impurities, wherein the contents of Si, Al, Mn and Cr satisfy the relationship expressed by the following formula: (Si+Al) / Mn or (Si+Al) / (Mn+Cr)=0.74-1.26 and the steel sheet has a specified microstructure.

Owner:KOBE STEEL LTD

Ear-pole of battery inner and electric sheet metal between batteries and processing method

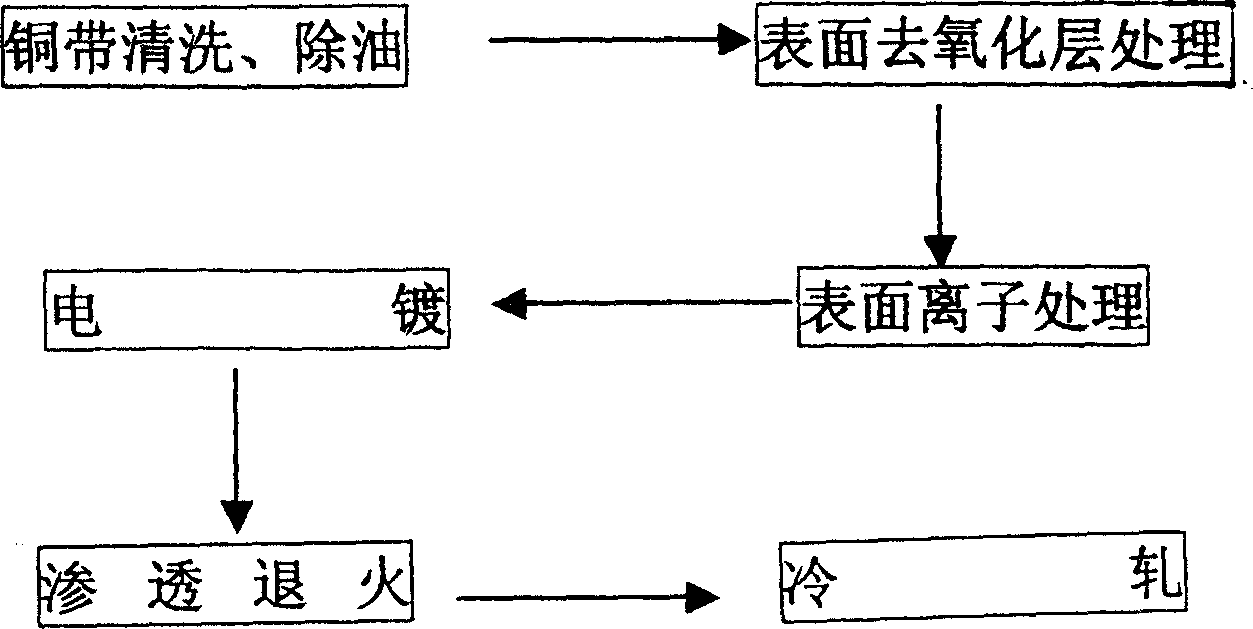

InactiveCN1722493AGood spot weldabilityImprove performanceConductive materialCell component detailsMetal sheetElectroplating

This invention relates to electrode ear in the cell and conductive metal sheet among the cells and their processing method, with the advantages of low price, good weldability, conductivity and comprehensive property better than pure nickel and nickel-plating steel. The invention comprises base plate in copper material, characterized in that the base plate surface is nickel-copper alloy layer, and comprising the following steps: cleaning the copper belt, eliminating oil, dealing deoxidation and ion treatment to the copper belt surface, then electroplating, percolation annealing and at last cold rolling.

Owner:YIXING HUIHUA COMPOSITE MATERIAL CO LTD

Steel sheet and plated steel sheet, method for producing hot-rolled steel sheet, method for producing cold-rolled full-hard steel sheet, method for producing heat-treated sheet, method for producing steel sheet, and method for producing plated steel sheet

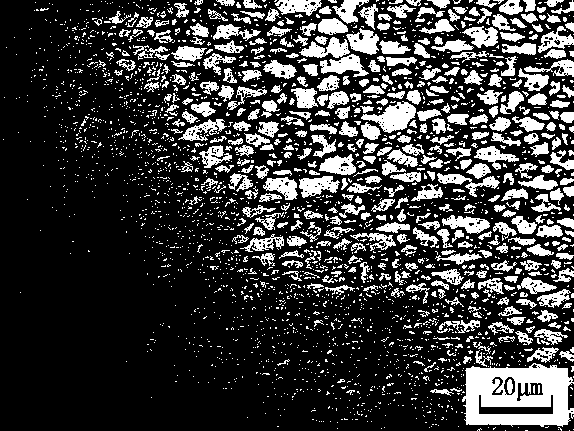

ActiveUS20190085427A1Low yield ratioHigh tensile strengthHot-dipping/immersion processesFurnace typesMicro structureSheet steel

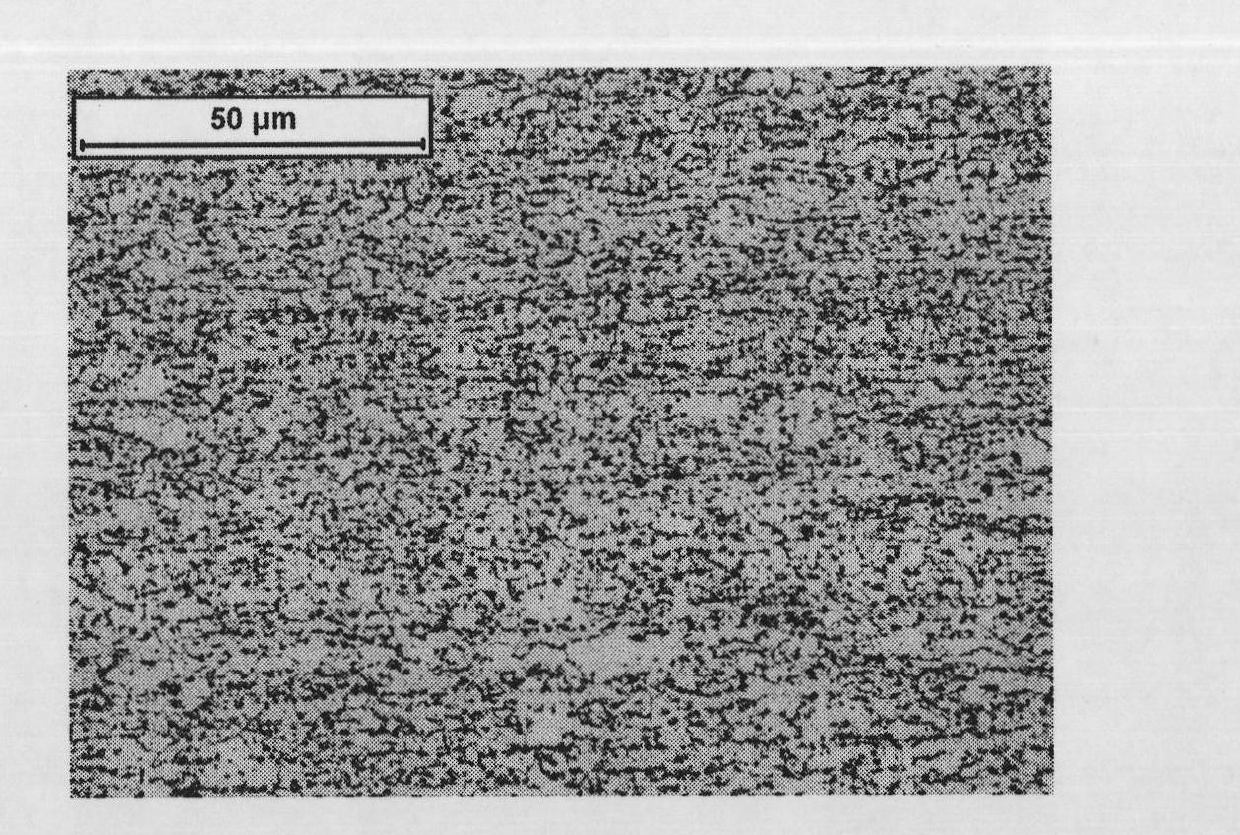

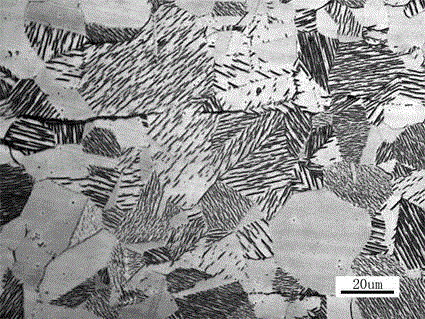

Provided herein is a plated steel sheet having a yield ratio, strength (tensile strength), elongation, hole expansibility, and CTS. A method for producing the plated steel sheet is also provided, among others. A steel sheet of a specific composition is provided that has a micro structure containing 70 to 90% of ferrite, 5 to 20% of martensite, 5% or less of retained austenite, 10% or less of bainite, and 5% or less of perlite by volume. The ferrite has an average crystal grain diameter of 20 μm or less. The martensite has an average crystal grain diameter of 5 μm or less. The retained austenite has an average crystal grain diameter of 5 μm or less. The bainite has an average crystal grain diameter of 7 μm or less. The steel sheet has a tensile strength of 590 MPa or more.

Owner:JFE STEEL CORP

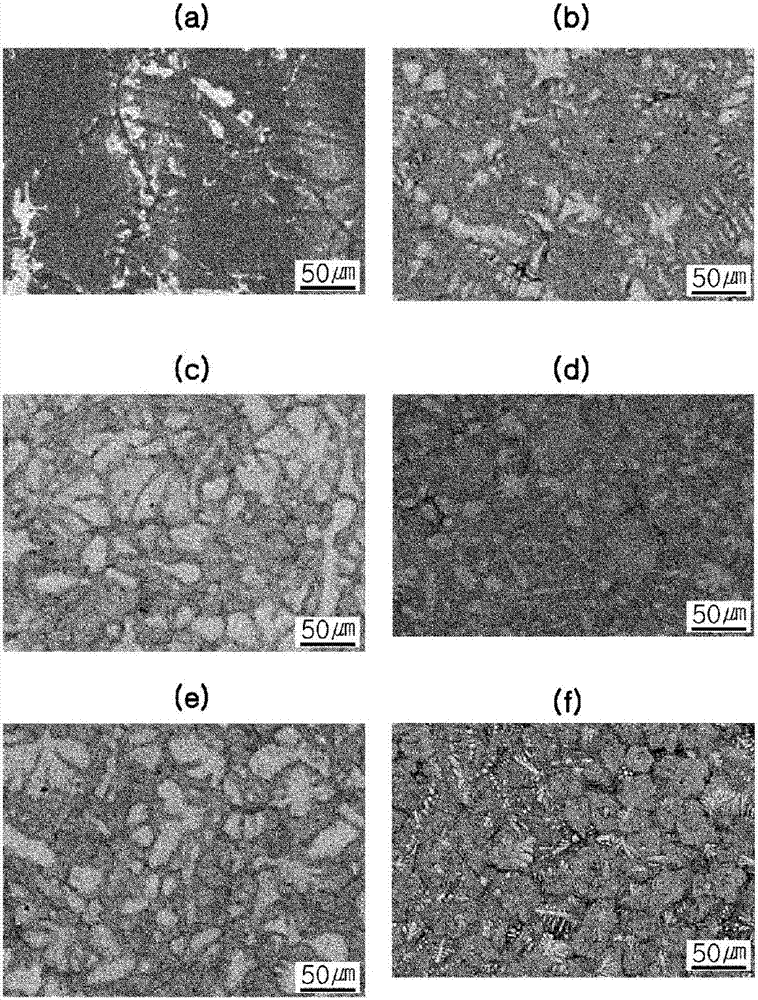

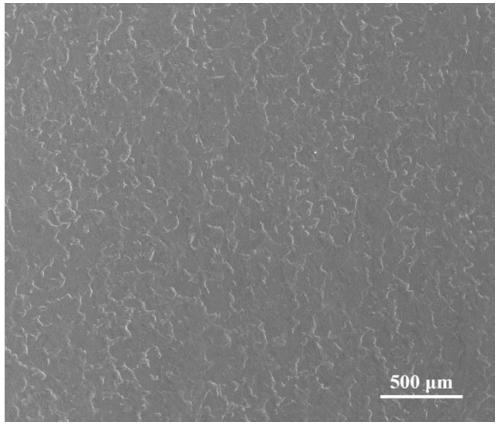

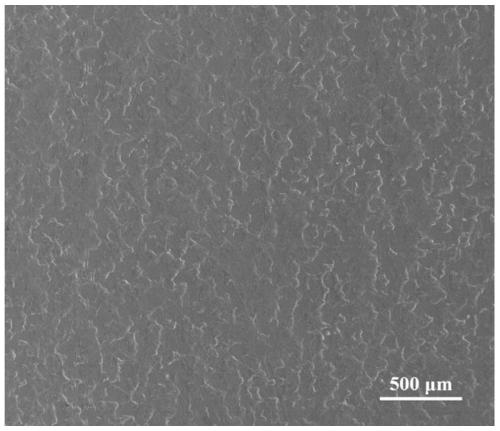

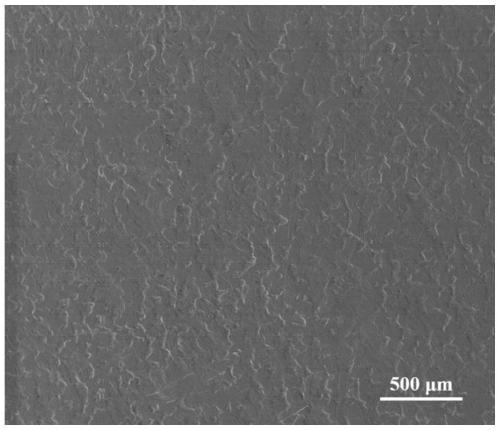

Zn alloy plated steel sheet having excellent phosphatability and spot weldability and method for manufacturing same

ActiveCN107109608AGood spot weldabilityEasy to handleHot-dipping/immersion processesIntermetallicSurface structure

A Zn alloy plated steel sheet having excellent phosphatability and spot weldability and a method for manufacturing the same are provided. In the Zn alloy plated steel sheet including a base steel sheet and a Zn alloy plating layer, the Zn alloy plating layer includes, by wt%, Al: 0.5-2.8%, Mg: 0.5-2.8%, and a remainder of Zn and inevitable impurities, and a cross-sectional structure of the Zn alloy plating layer includes, by area percentage, more than 50% of a Zn single phase structure and less than 50% of a Zn-Al-Mg-based intermetallic compound. A surface structure of the Zn alloy plating layer includes, by area percentage, 40% or less of a Zn single phase structure and 60% or more of a Zn-Al-Mg-based intermetallic compound.

Owner:POSCO CO LTD

Hot-dip-galvanized steel sheet

ActiveCN104838035AExcellent plating adhesionGood spot weldabilityHot-dipping/immersion processesFurnace typesSpot weldingImpurity

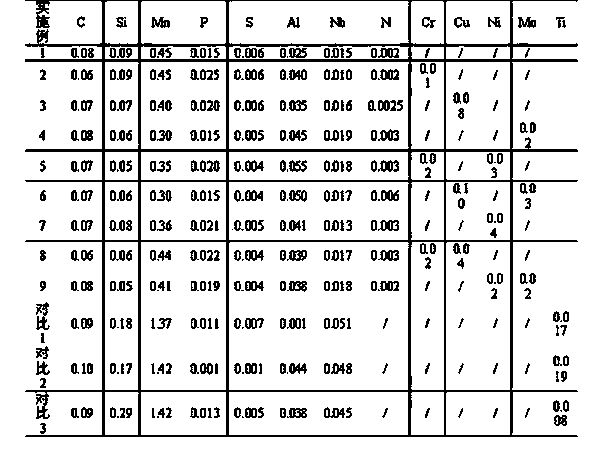

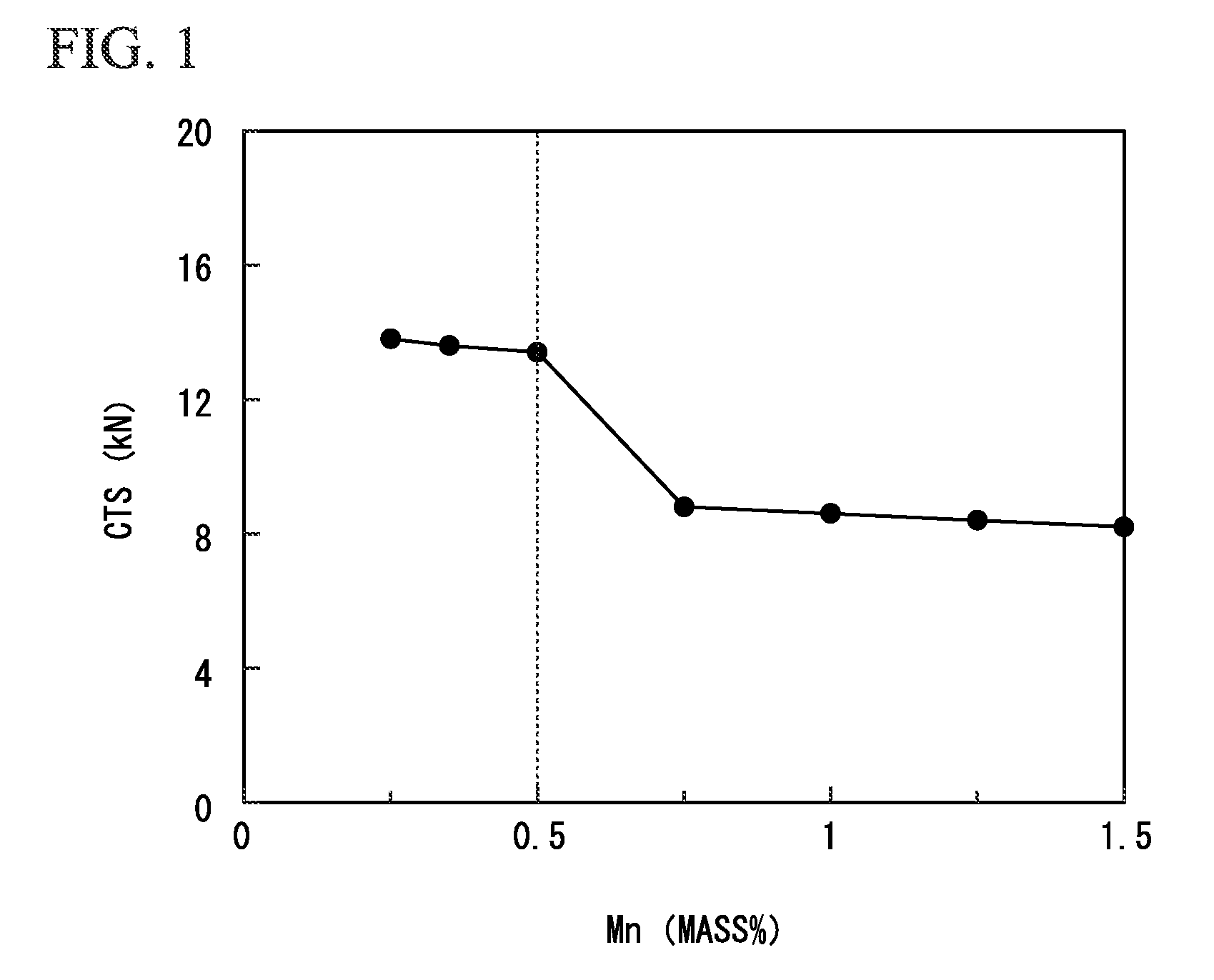

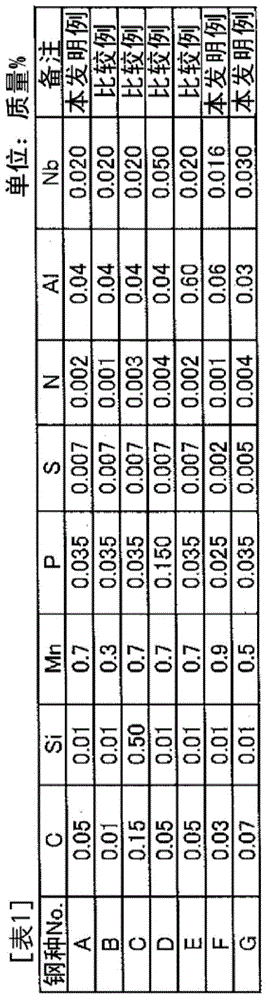

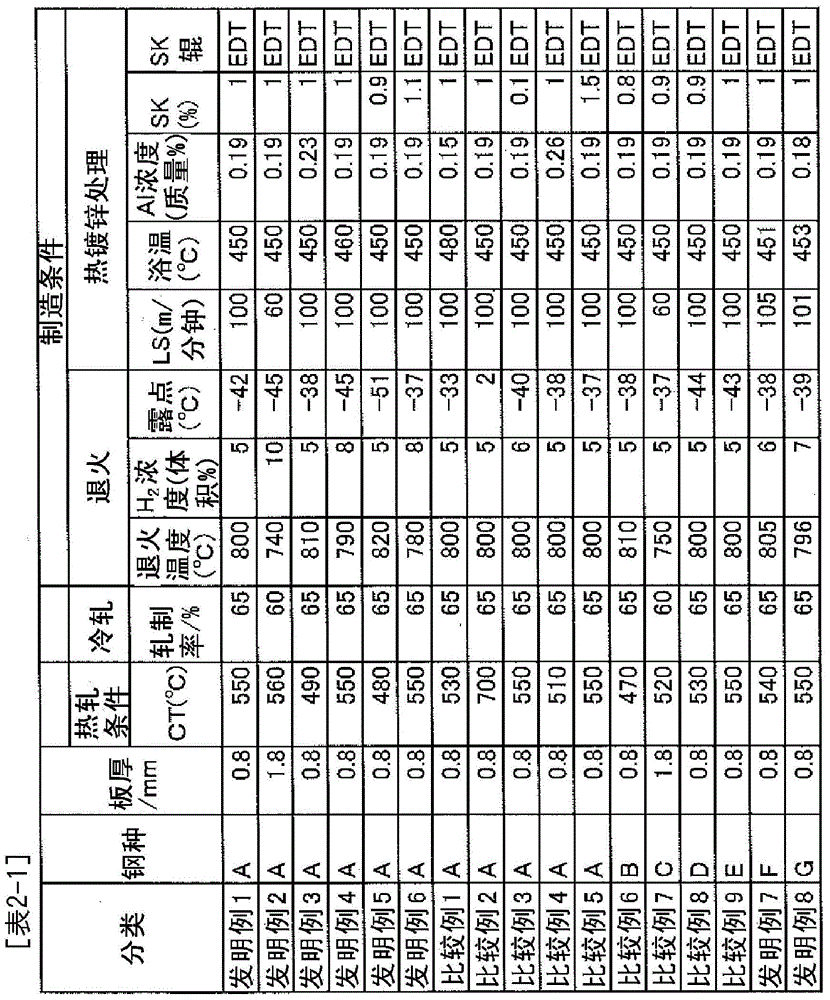

Provided is a hot-dip-galvanized steel sheet which exhibits excellent appearance, post-pressing plating adhesion, spot-welding properties, and post-pressing / post-coating corrosion resistance. This hot-dip-galvanized steel sheet has a yield stress (YS) of 260-350MPa, inclusive, and has: a steel sheet comprising a composition containing, in mass%, C in the amount of 0.05-0.1%, inclusive, Si in the amount of 0.10% or less, Mn in the amount of 0.30-0.70%, inclusive, P in the amount of 0.040% or less, S in the amount of 0.010% or less, N in the amount of 0.005% or less, and Al in the amount of 0.10% or less, with Fe and inevitable impurities constituting the remainder; a hot-dip galvanized layer containing Al in the amount of 0.3-0.6 mass%, inclusive, and formed on at least part of the surface of the steel sheet; and an intermetallic compound present between the steel sheet and the hot-dip galvanized layer, and containing Al in the amount of 0.12gm-2 to 0.22gm-2, inclusive, and Fe2Al5 having an average particle diameter of 1μm or less.

Owner:JFE STEEL CORP

Al-plated steel sheet for hot pressing and process for manufacturing al-plated steel sheet for hot pressing

ActiveCN105814228AExcellent thermal lubricityImprove corrosion resistanceHot-dipping/immersion processesThin material handlingZinc compoundsSquare Millimeter

The invention relates to an Al-plated steel sheet which is to be subjected to hot pressing and which exhibits excellent hot lubricity, excellent corrosion resistance after coating and excellent spot weldability. This Al-plated steel sheet for hot pressing comprises a steel sheet, an Al deposit layer formed on one or both surfaces of the steel sheet, and a surface film layer formed on the Al deposit layer, wherein: the surface film layer contains a zinc compound, the zinc compound adheres to the Al-plated steel sheet in an amount of 0.3 to 1.5g / m<2> per surface in terms of metallic zinc, and the amount of zinc adhering to an arbitrary continuous area of one square millimeter is 1.5g / m2 or less.

Owner:NIPPON STEEL CORP

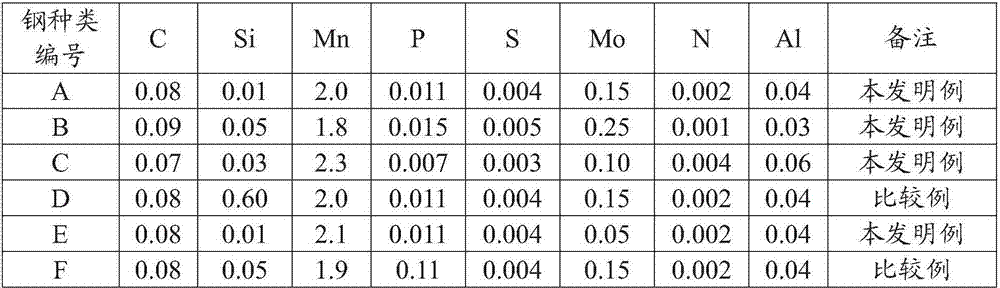

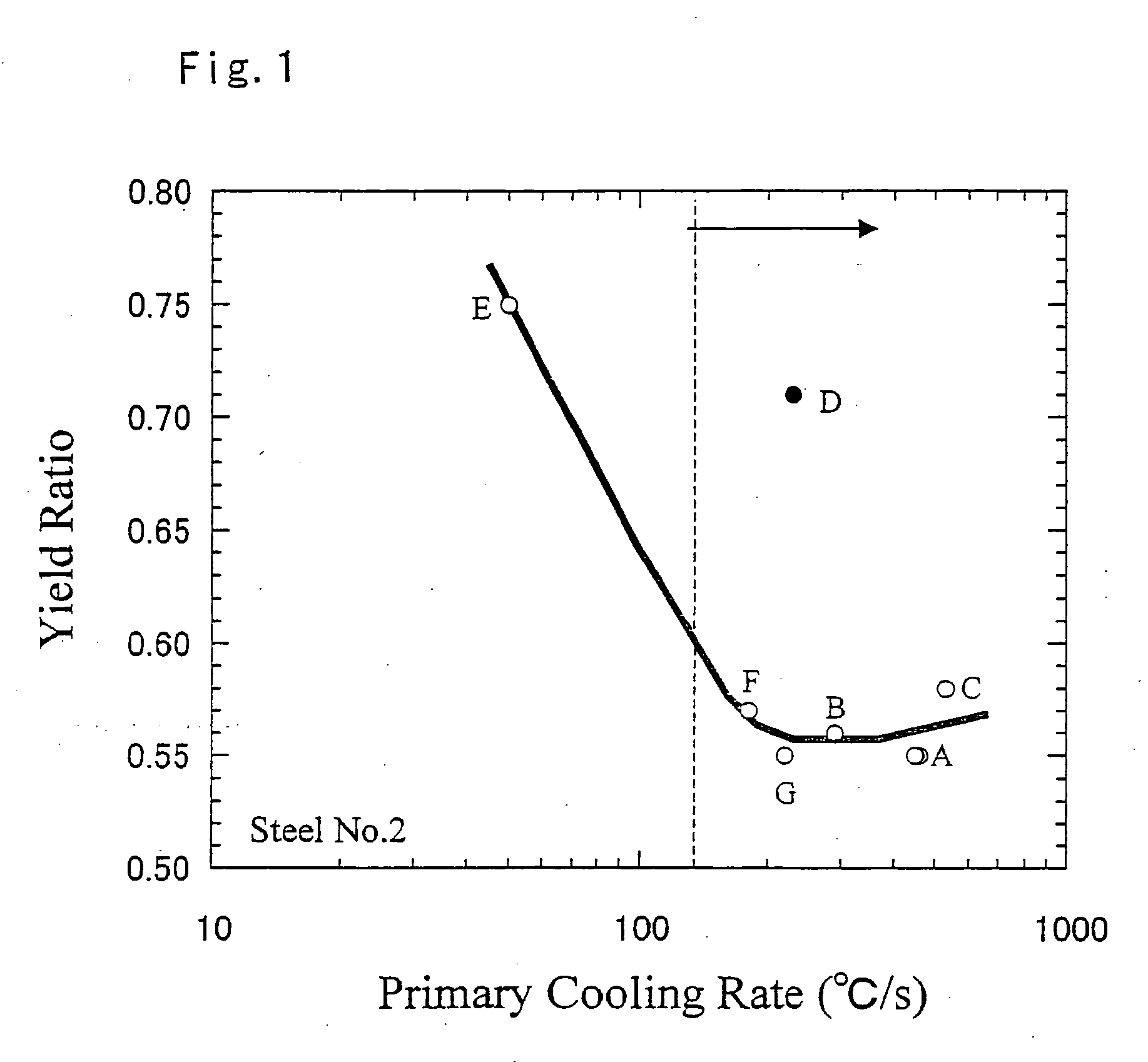

High-strength hot-dip galvanized steel sheet with excellent spot weldability and stability of material properties

InactiveCN1858286AGood spot weldabilityHigh tensile strengthHot-dipping/immersion processesContaminated soil reclamationMartensiteUltimate tensile strength

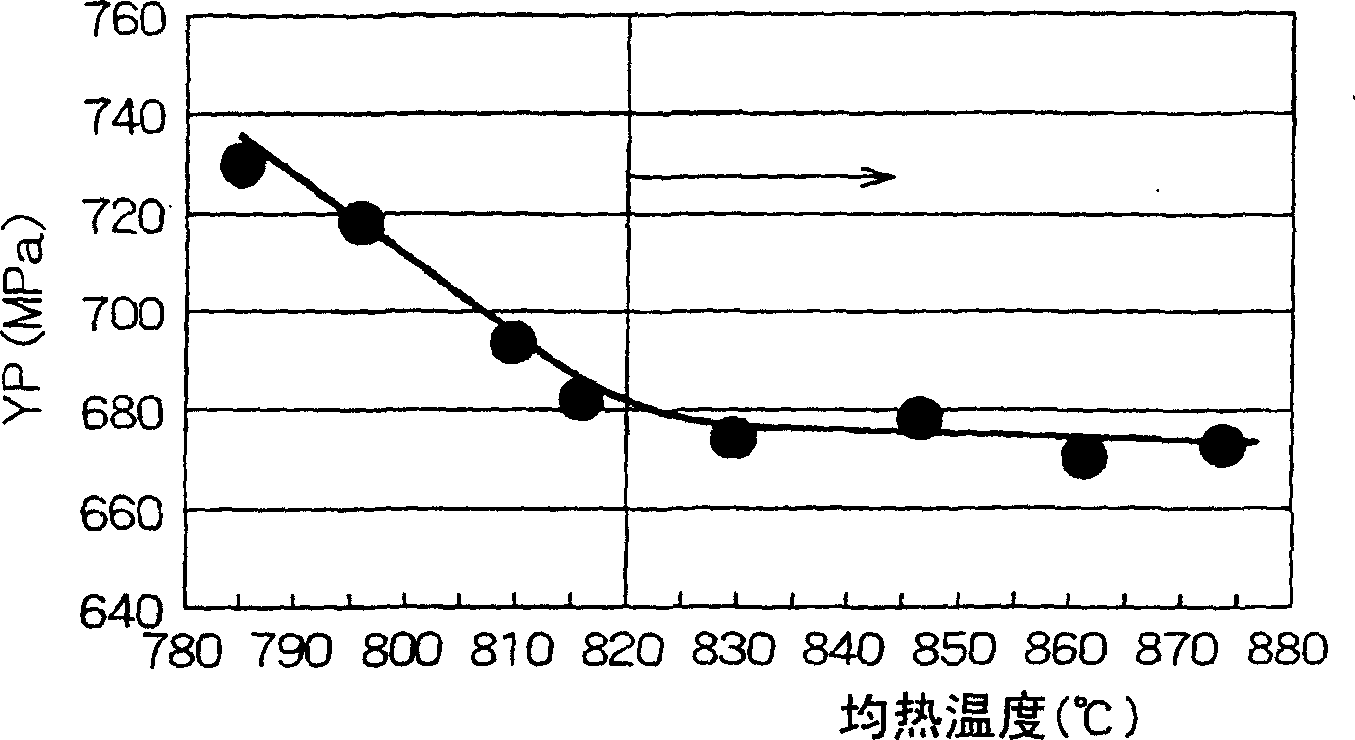

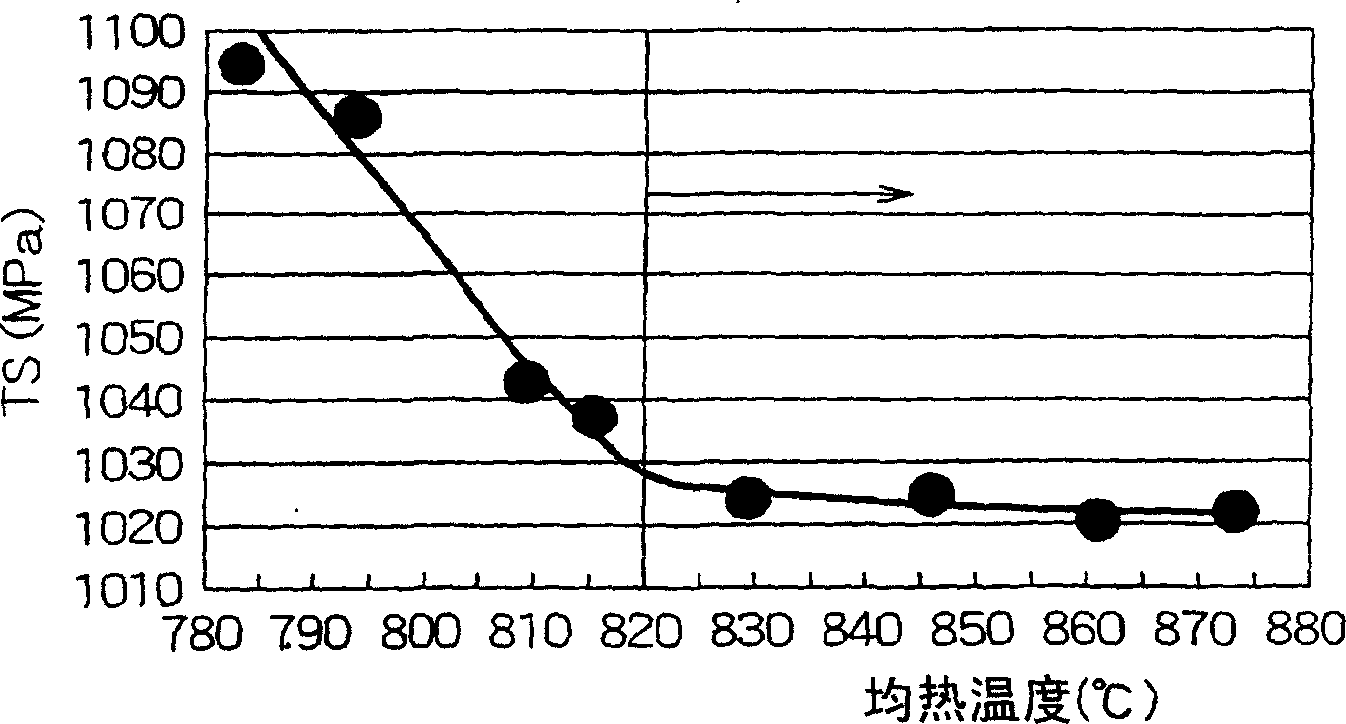

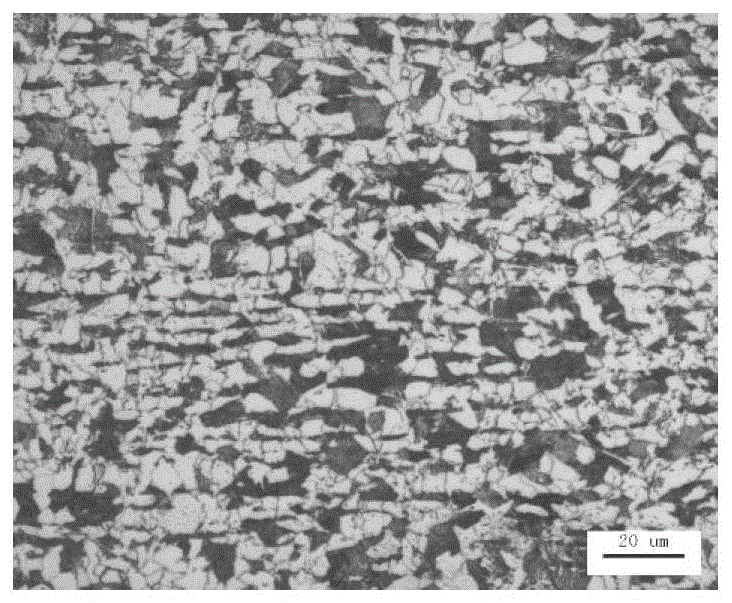

A high-strength hot-dip galvanized steel sheet is provided which comprises a composite structure consisting essentially of ferrite and martensite. The steel comprises, by mass %, C: 0.05 to 0.12%, Si: not more than 0.05%, Mn: 2.7 to 3.5%, Cr: 0.2 to 0.5%, Mo: 0.2 to 0.5%, Al: not more than 0.10%, P: not more than 0.03%, and S: not more than 0.03%. The high-strength hot-dip galvanized steel sheet has not only excellent spot weldability, but also excellent 'stability of material properties', including tensile strength, total elongation, and yield strength, in a high range of strengths from 780 to 1180 MPa, even if the manufacturing condition (especially, the condition of the cooling process after annealing the steel sheet) is changed.

Owner:KOBE STEEL LTD

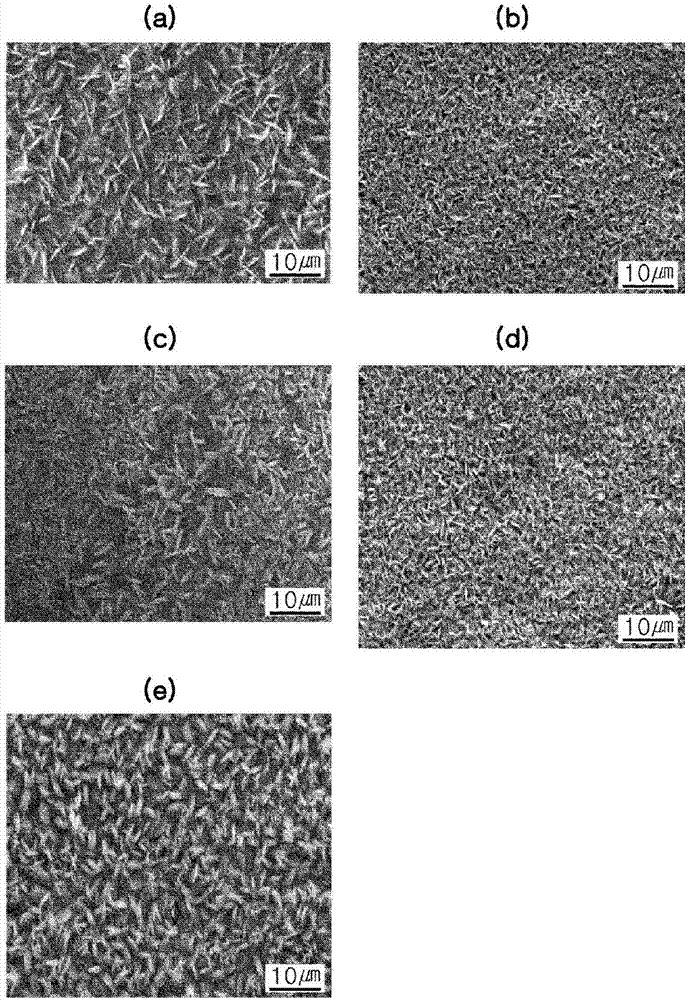

High-strength hot-dip-galvanized steel sheet

ActiveCN107075653AExcellent plating qualityGood lookingHot-dipping/immersion processesFurnace typesSurface layerSurface roughness

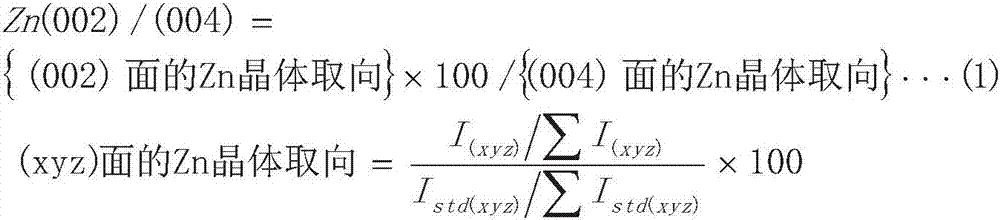

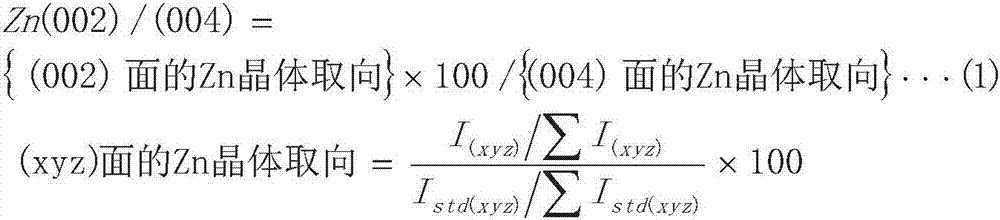

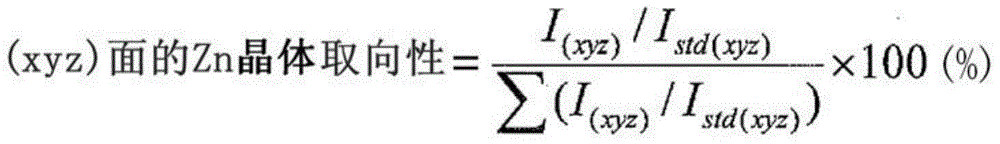

Provided is a high-strength hot-dip-galvanized steel sheet exhibiting excellent plating adhesion in worked sections, excellent plating appearance, and excellent spot weldability. The present invention is provided with: a cold-rolled steel sheet which comprises a specific composition, is provided with a structure having a martensite area ratio of at least 7% but less than 25%, and a ferrite area ratio of at least 50%, and has an internal oxidation amount in a ferrite surface layer section of not more than 0.05 g / m2 per surface; an intermetallic compound which is formed on the cold-rolled steel sheet, includes at least 0.03 g / m2 but not more than 0.12 g / m2 of Al, and includes Fe2Al5 having an average grain size of less than 0.7 [mu]m; and a hot-dip-galvanized layer which is formed on the intermetallic compound, satisfies 0.15%<=Al%<=0.30% (Al% indicates the content (mass%) of Al in the hot-dip-galvanized layer), and has a surface roughness (Ra) of 0.8-1.6 [mu]m inclusive, a glossiness (G value) of 750-850 inclusive, and a zinc-basal-plane orientation ratio (Zn(002) / (004)) of 30-60% inclusive.

Owner:JFE STEEL CORP

High strength cold-rolled steel sheet excellent in ductility, hole-forming property and surface treatment property, molten galvanized steel sheet, and method for manufacturing same

ActiveCN108431268AImprove stamping formabilityImprove ductilityHot-dipping/immersion processesSolid state diffusion coatingManganeseSilicon

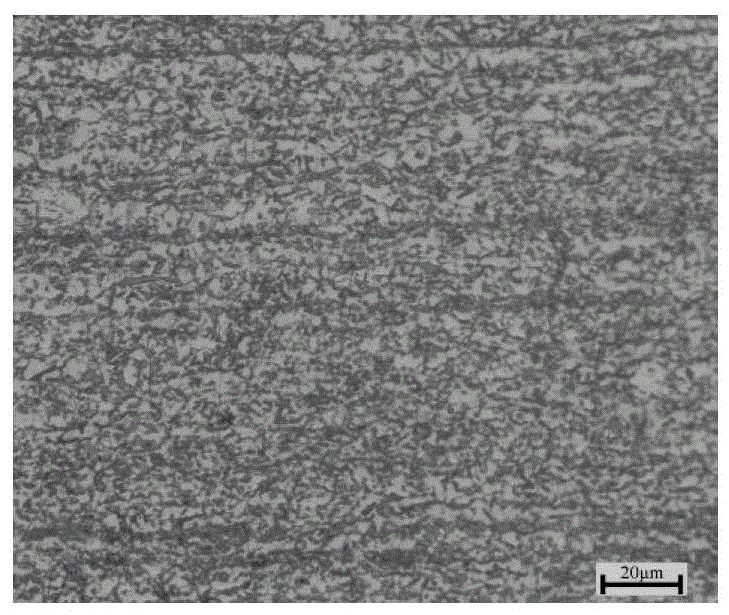

Provided are a high-strength cold-rolled steel sheet excellent in ductility, boring workability and surface treatment characteristics, a molten galvanized steel sheet, and a method for manufacturing the same. The cold-rolled steel sheet of the present invention comprises in % by weight: 0.05 to 0.3% of carbon (C); 0.6 to 2.5% of silicon (Si); 0.01 to 0.5% of aluminum (Al); 1.5 to 3.0% of manganese(Mn); and the remainder being Fe and unavoidable impurities, wherein the steel microstructure contains, in an area fraction, ferrite of 60% or less, acicular bainite of 25% or more, martensite of 5%or more, and acicular retained austenite of 5%, wherein the ferrite has an average diameter of 2 [mu]m or less and the ferrite satisfies that Fn2 defined by relational expression 1 is 89% or more andFa5 defined by relational expression 2 is 70% or less.

Owner:POSCO CO LTD

Surface treatment liquid for plated steel sheet to be hot-pressed

ActiveCN107636200AImprove corrosion resistanceGood spot weldabilityHot-dipping/immersion processesSuperimposed coating processEmulsionWater dispersible

The invention relates to a surface treatment liquid for a plated steel sheet to be hot-processed. The present invention is a surface treatment liquid with excellent storage stability and is able to provide a surface-treated steel sheet for which the treatment coating formed has excellent water resistance, solvent resistance, adhesion to plated steel sheets, and hot lubricity as well as chemical conversion treatability after hot-pressing, corrosion resistance after coating, and spot weldability. The surface treatment liquid for a plated steel sheet that is to be hot-pressed comprises an aqueousZnO dispersion (A) and a water-dispersible organic resin (B). The aqueous ZnO dispersion (A) comprises water and ZnO particles, the particle diameter of which is 50-300 nm. The water-dispersible organic resin (B) has an acid value of 5-45 mg KOH / g and 5-300 nm emulsion particle diameter. The mass ratio (WA / WB) of the mass (WA) of ZnO particles in the aqueous ZnO dispersion to the mass (WB) of solids of the water-dispersible organic resin is 30 / 70 to 95 / 5.

Owner:NIPPON STEEL CORP +1

Steel sheet and plated steel sheet, method for producing hot-rolled steel sheet, method for producing cold-rolled full-hard steel sheet, method for producing heat-treated sheet, method for producing steel sheet, and method for producing plated steel sheet

ActiveUS20190078173A1Improve the plating effectHigh elongationHot-dipping/immersion processesFurnace typesMicro structureUltimate tensile strength

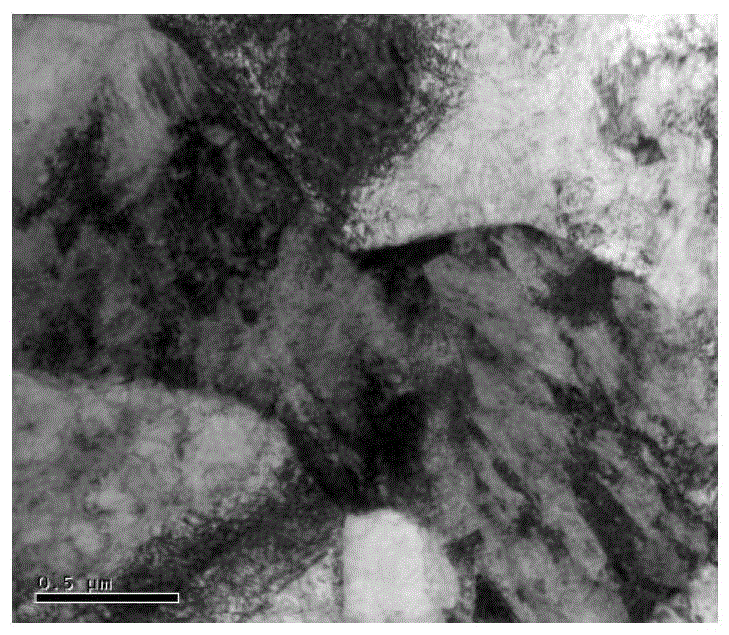

Provided herein is a steel sheet of a specific composition that has a micro structure containing, by volume, 75 to 95% of ferrite, 3 to 15% of martensite, 0.5 to 10% of perlite, 10% or less of unrecrystallized ferrite, and 21.5% or less of a low-temperature occurring phase representing the remainder, and in which the ferrite has an average crystal grain diameter of 6 μm or less, and the martensite has an average crystal grain diameter of 3 μm or less, and an average aspect ratio of 4.0 or less, and in which a Nb base precipitate having an average grain diameter of 0.10 μm or less is contained. The steel sheet has a tensile strength of 590 MPa or more.

Owner:JFE STEEL CORP

High-strength low-specific-gravity steel sheet having superior spot weldability

InactiveUS20160040273A1Good spot weldabilityImprove productivityFurnace typesHeat treatment furnacesAl contentWeldability

A steel sheet including, by mass %, C: more than 0.100% and 0.500% or less, Si: 0.0001% or more and less than 0.20%, Mn: more than 0.20% and 0.50% or less, Al: 3.0% or more and 10.0% or less, N: 0.0030% or more and 0.0100% or less, Ti: more than 0.100% and 1.000% or less, P: 0.00001% or more and 0.0200% or less, S: 0.00001% or more and 0.0100% or less, and a remainder including Fe and impurities, in which a sum of a C content and a Ti content satisfies 0.200<C+Ti≦1.500 by mass %, a product of an Al content and an Si content satisfies Al×Si≦0.8 by mass %, and a specific gravity is 5.5 to less than 7.5.

Owner:NIPPON STEEL CORP

Aluminum alloys suitable for automotive wheels

An aluminum alloy suitable for automobile wheels, characterized in that it contains the following components in mass percentage: 0.1-0.2% iron, 5-7% silicon, 3-10% copper, 1-2% magnesium, 0.1% cobalt -2.0%, lead 0.01-0.05%, zirconium 0.001-0.005%, manganese 0.01-0.05%, vanadium 0.01-0.05%, and the balance aluminum. The aluminum alloy obtained by the invention has good forgeability, spot weldability, fusion weldability, corrosion resistance and Lüders line-free at room temperature, and meets the requirements of the automobile industry.

Owner:WUJIANG SHI FINE WORKMANSHIP & ALUMINUM WORD MANUFACTORY

460MPa grade cold-rolled microalloy high strength steel, and manufacturing method thereof

ActiveCN108929987AImprove mechanical propertiesHigh strengthFurnace typesHeat treatment furnacesSocial benefitsManufacturing technology

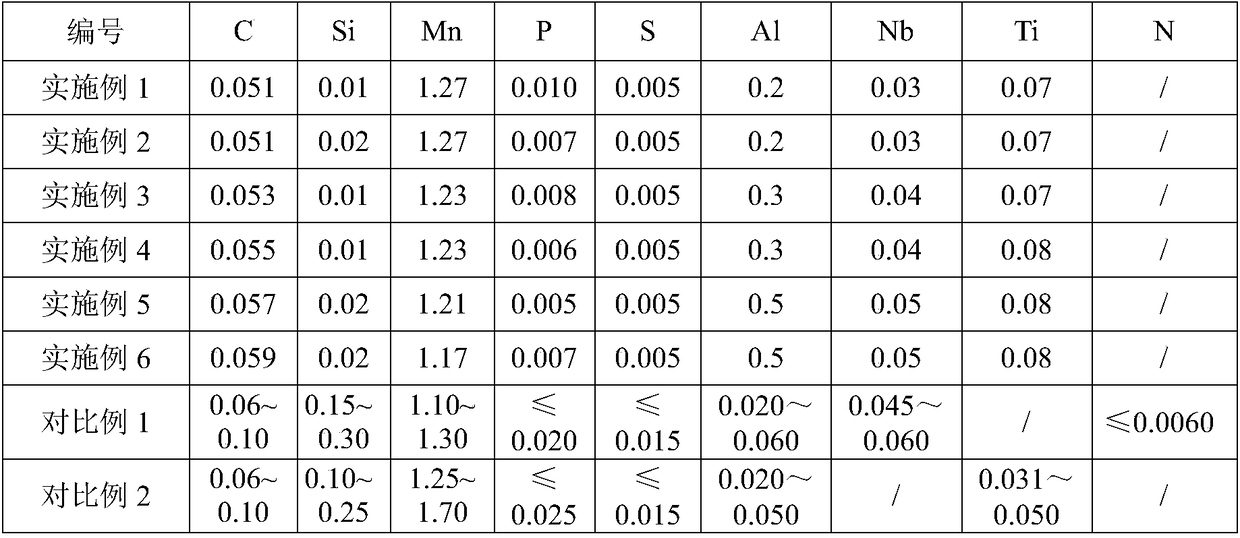

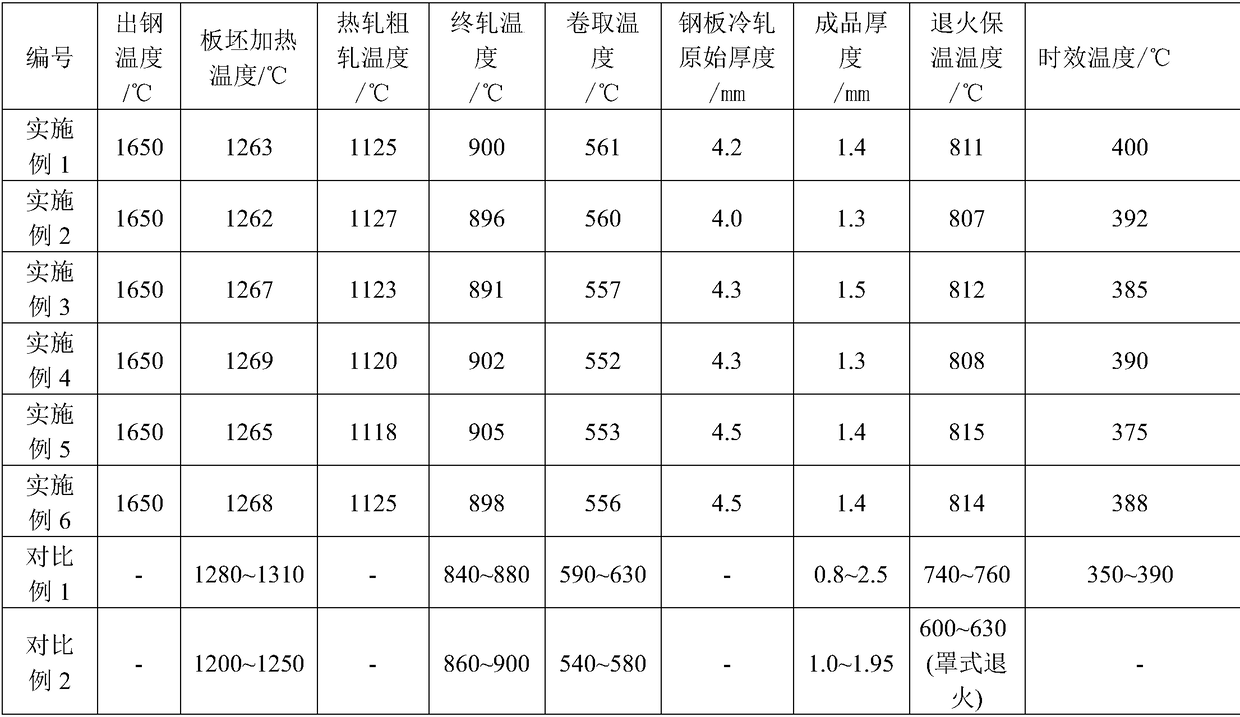

The invention discloses 460MPa grade cold-rolled microalloy high strength steel. The 460MPa grade cold-rolled microalloy high strength steel comprises, by mass, 0.051 to 0.059% of C, 0.01 to 0.02% ofSi, 1.17 to 1.27% of Mn, 0.2 to 0.5% of Al, P<=0.010, S<=0.006, 0.03 to 0.05% of Nb, 0.07 to 0.08% of Ti, and the balance Fe and unavoidable impurities. A manufacturing method is combined with component design and manufacturing technology improvement, so that the obtained steel products are high in strength, percentage elongation, spot welding performance, and moulding performance, excellent platability is achieved, rebound deformation performance is small, problems in the prior art such as poor formation performance, weldability, and rebound performance of high strength steel of the same grade are solved, and obvious social benefit and economic benefit are achieved.

Owner:武汉钢铁有限公司

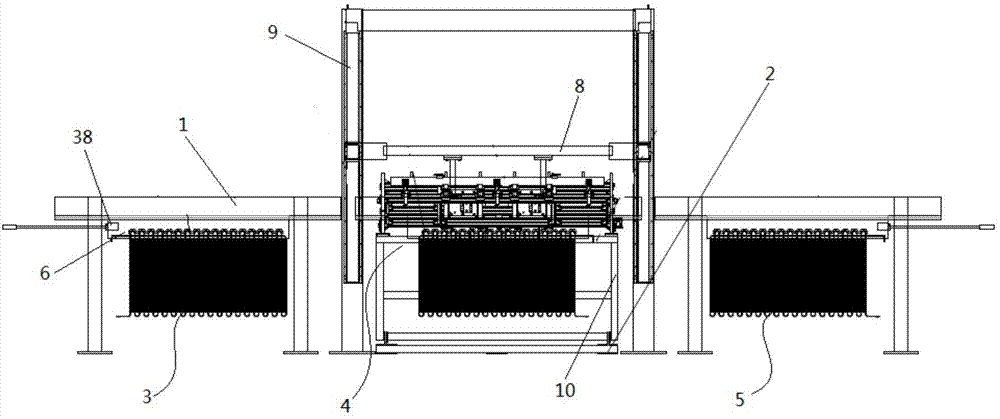

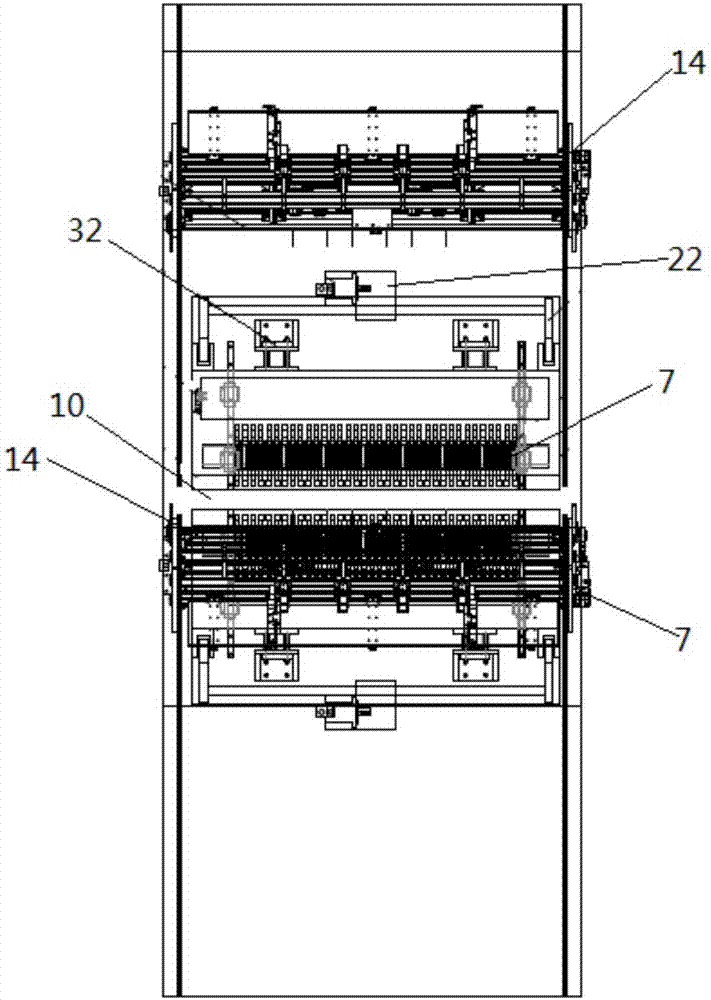

Condenser pipe arrangement spot welding machine with hanging rack

ActiveCN107498165AWon't slideFirmly connectedWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSpot welding

The invention discloses a condenser pipe arrangement spot welding machine with a hanging rack. The condenser pipe arrangement spot welding machine comprises a hanging rack structure arranged on an X-axis track. A material hanging mechanism, a spot welding mechanism and a discharging mechanism are sequentially arranged on the movable hanging rack mechanism in the direction of the X-axis track. The material hanging mechanism comprises the hanging rack. Spot welding devices are correspondingly arranged on the spot welding mechanism along the two sides of the X-axis track. A Y-axis lifting device is arranged on the upper portion of the spot welding mechanism in the Y-axis direction. The Y-axis lifting device can move along a Y-axis track. The Y-axis lifting device can be automatically connected with the hanging rack moving to the portion below the Y-axis lifting device. A spot welding clamping station is arranged below the Y-axis lifting device. The hanging rack can move into the spot welding clamping station. Multiple U-shaped clamping grooves are uniformly formed in the spot welding clamping station. Multiple L-shaped steel wire limiting pieces are arranged on one sides of the U-shaped clamping grooves. A push air cylinder is connected to each steel wire limiting piece. Discharging machines are arranged on the two sides of the spot welding mechanism.

Owner:CHANGZHOU CHANGFA REFRIGERATION TECH CO LTD

Hot-dip galvanized steel sheet

ActiveCN104968824AExcellent adhesionGood spot weldabilityHot-dipping/immersion processesFurnace typesMetallurgySpot welding

The purpose of the present invention is to provide a hot-dip galvanized steel sheet that, after press work, has excellent plating adhesion, excellent spot-welding properties, and excellent corrosion resistance after coating, and has an excellent external appearance after coating. The hot-dip galvanized steel sheet has a steel sheet, a hot-dip galvanized layer, and an intermetallic compound. The steel sheet has, in mass%, 0.03%-0.70% C, no more than 0.10% Si, 0.5%-0.9% Mn, 0.020%-0.050% P, no more than 0.010% S, 0.010%-0.035% Nb, no more than 0.005% N, and no more than 0.10% Al, with the remainder being Fe and unavoidable impurities. The hot-dip galvanized layer includes 0.3%-0.6% Al. The intermetallic compound includes 0.12-0.22 gm-2 Al and includes Fe2Al5 having an average particle diameter of no more than 1 µm.

Owner:JFE STEEL CORP

High-strength cold-rolled steel sheet excellent in stretch-flangeability and spot weldability and manufacturing method thereof

The invention provides a high-strength cold-rolled steel sheet having excellent stretch flangeability and spot welding property and a manufacturing method of the steel sheet. The steel sheet comprises 0.03-0.15% of C, 0.30-0.10% of Si, 1.20-2.20% of Mn, not more than 0.015% of P, not more than 0.010% of S, 0.02-0.15% of Al, not more than 0.005% of N, 0.20-0.60% of Cr, 0.010-0.060% of Nb, 0.030-0.100% of V and 0.0007-0.0050% of Ca, with the balance being Fe and unavoidable impurities, and with the (Mn+2Nb+V) being not more than 2.3% and not less than 1.6%. In the manufacturing method, the start rolling temperature of hot continuous rolling precision rolling is 1000-1100 DEG C, the finish rolling temperature is 890-950 DEG C, the acid-washing cold rolling rate is 60-80%, and two-stage cooling, namely slow cooling firstly and rapid cooling secondly, are adopted after annealing and temperature maintaining steps. The tensile strength of the finally obtained steel sheet is higher than 800 MPa. The obtained steel sheet is good in strength ductility matching, and excellent in stretch flangeability and spot welding property.

Owner:ANGANG STEEL CO LTD

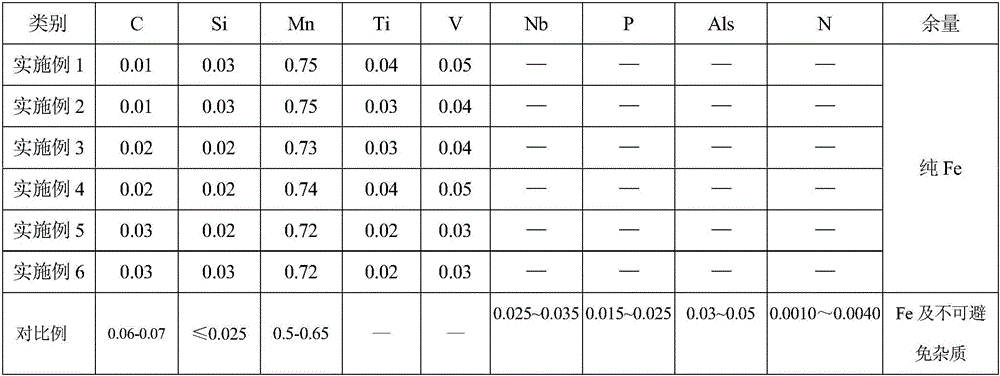

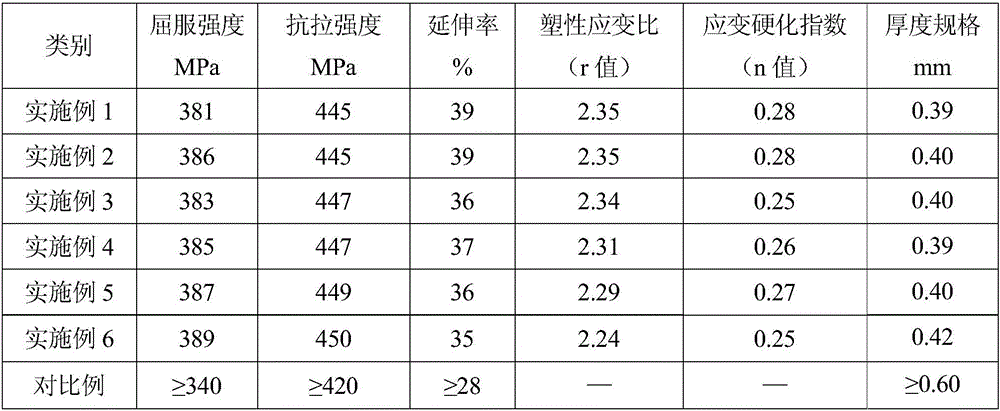

Novel ultra-thin microalloy high-strength steel and preparation method thereof

InactiveCN105734407AHigh strengthHigh elongationAdditive manufacturing apparatusIncreasing energy efficiencyChemical compositionParameter control

The invention discloses novel ultra-thin microalloy high-strength steel and a preparation method thereof.The novel ultra-thin microalloy high-strength steel is prepared from, by weight, 0.01%-0.03% of C, 0.02%-0.03% of Si, 0.72%-0.75% of Mn, 0.02%-0.04% of Ti, 0.03%-0.05% of V and the balance Fe and unavoidable impurities.In addition, the invention further provides the preparation method of the novel ultra-thin microalloy high-strength steel.According to the novel ultra-thin microalloy high-strength steel and the preparation method thereof, the technical problem that the thickness specification of a same-class high-strength steel plate produced through the prior art cannot meet the ultra-thin requirement is solved through component design by cooperating with technological parameter control.

Owner:武汉钢铁有限公司

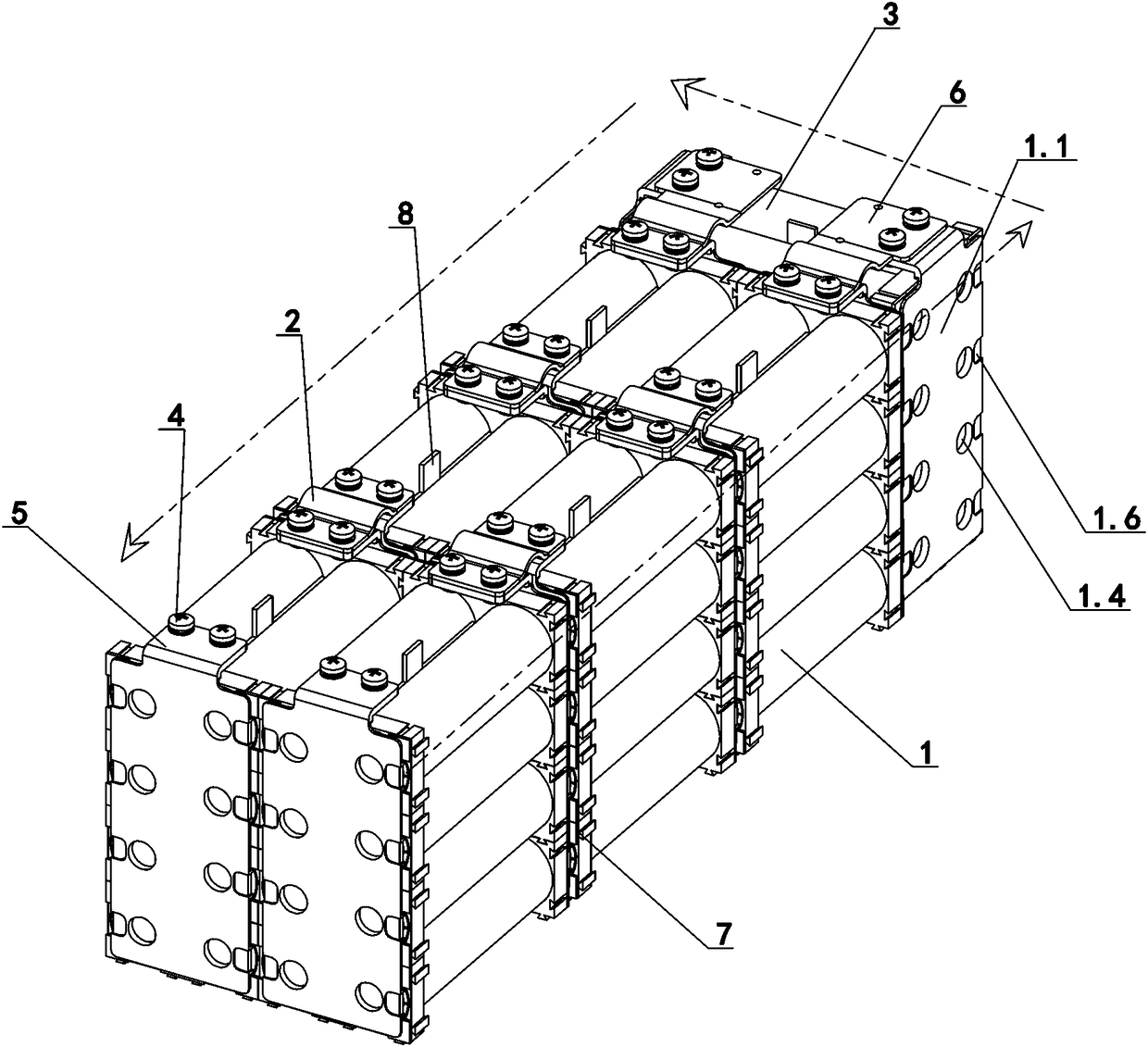

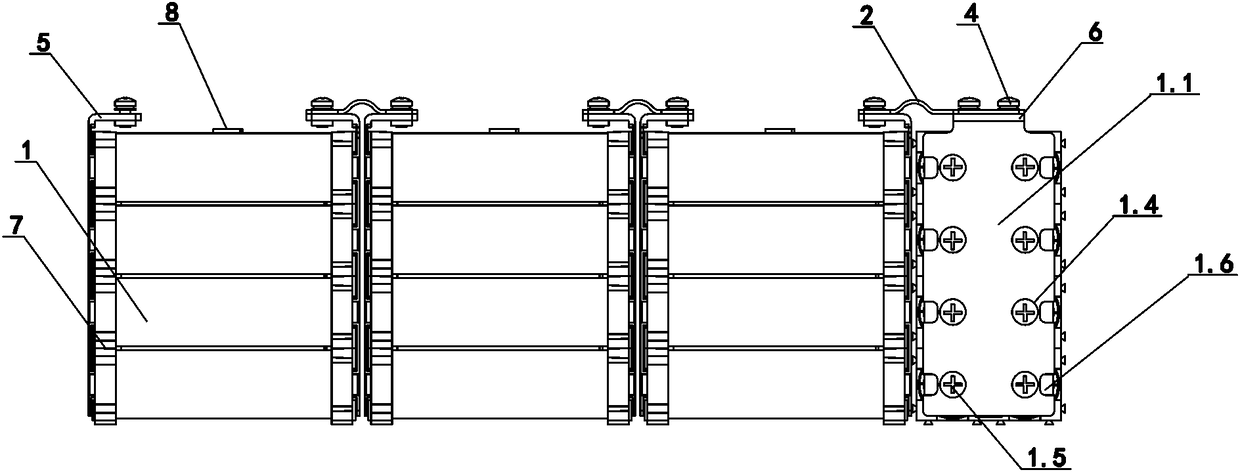

Cylindrical cell battery pack packaging structure suitable for bearing large current

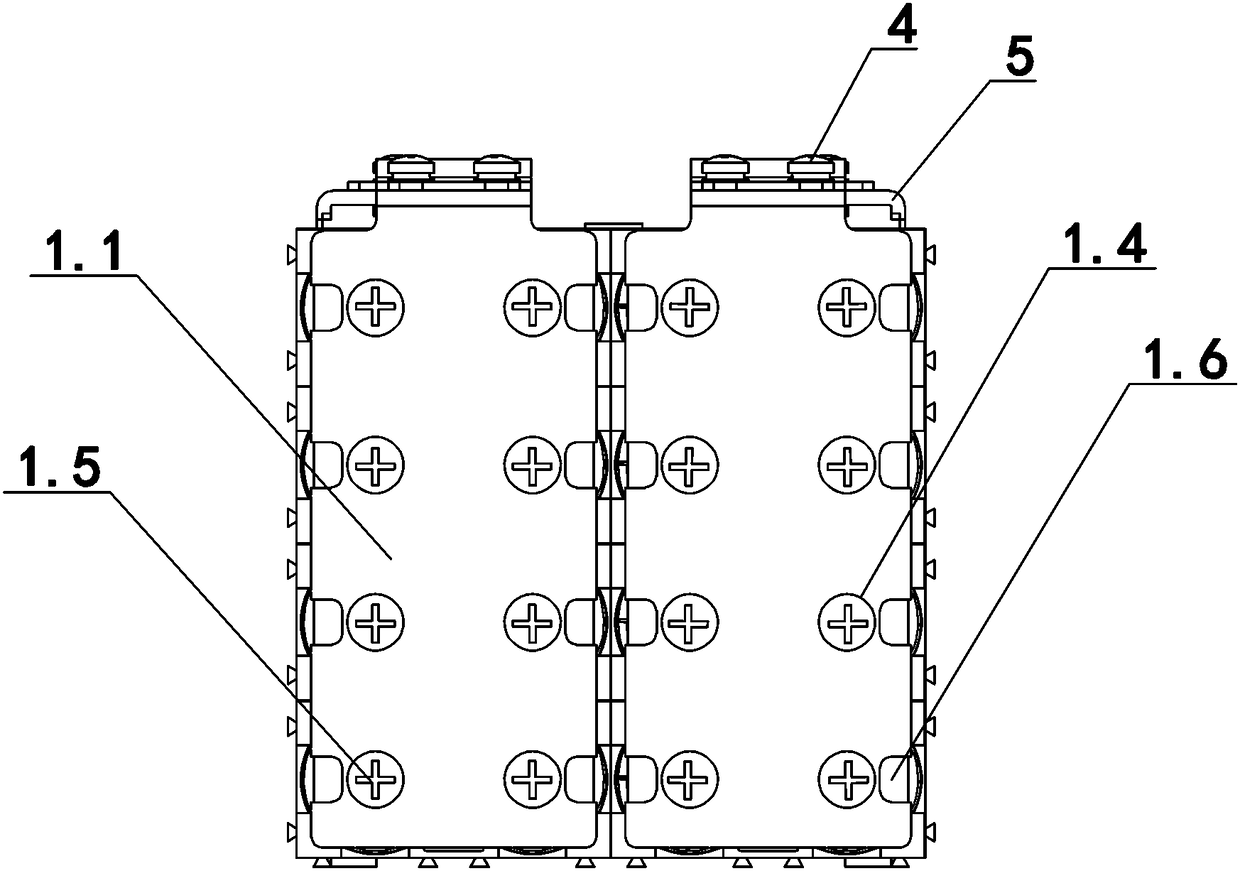

PendingCN108539114ACompact structureEasy to installFinal product manufactureCylindrical casing cells/batteryElectrical batteryEngineering

The invention discloses a cylindrical cell battery pack packaging structure suitable for bearing a large current. The cylindrical cell battery pack packaging structure suitable for bearing the large current comprises multiple longitudinal cylindrical cell battery monomers (1) of which negative and positive electrodes are connected end to end through connecting components (2), and horizontal cylindrical cell battery monomers (3) which are installed at the end parts of the longitudinal cylindrical cell battery monomers (1) and form U-type arrangement with the longitudinal cylindrical cell battery monomers (1). The cylindrical cell battery monomer comprises a copper current-carrying plate (1.1), a nickel sheet (1.2) and multiple cylindrical cells (1.3). The copper current-carrying plate (1.1)is installed at two negative and positive ends of the cylindrical cells (1.3). The nickel sheet (1.2) is installed between the copper current-carrying plate (1.1) and the cylindrical cells (1.3). Thenickel sheet (1.2) is connected with electrodes of the cylindrical cells (1.3) and the copper current-carrying plate (1.1). The cylindrical cell battery pack packaging structure is capable of bendinglugs at two sides of the nickel sheet to a groove in the front face of the copper current-carrying plate, the structure is simple, and a battery monomer parallelly-connected structure is capable of increasing a thickness of the copper current-carrying plate according to the need, so a design requirement of the oversize current is satisfied.

Owner:四川众联航泰科技有限公司

Automatic online tin paste dispensing equipment and working method thereof

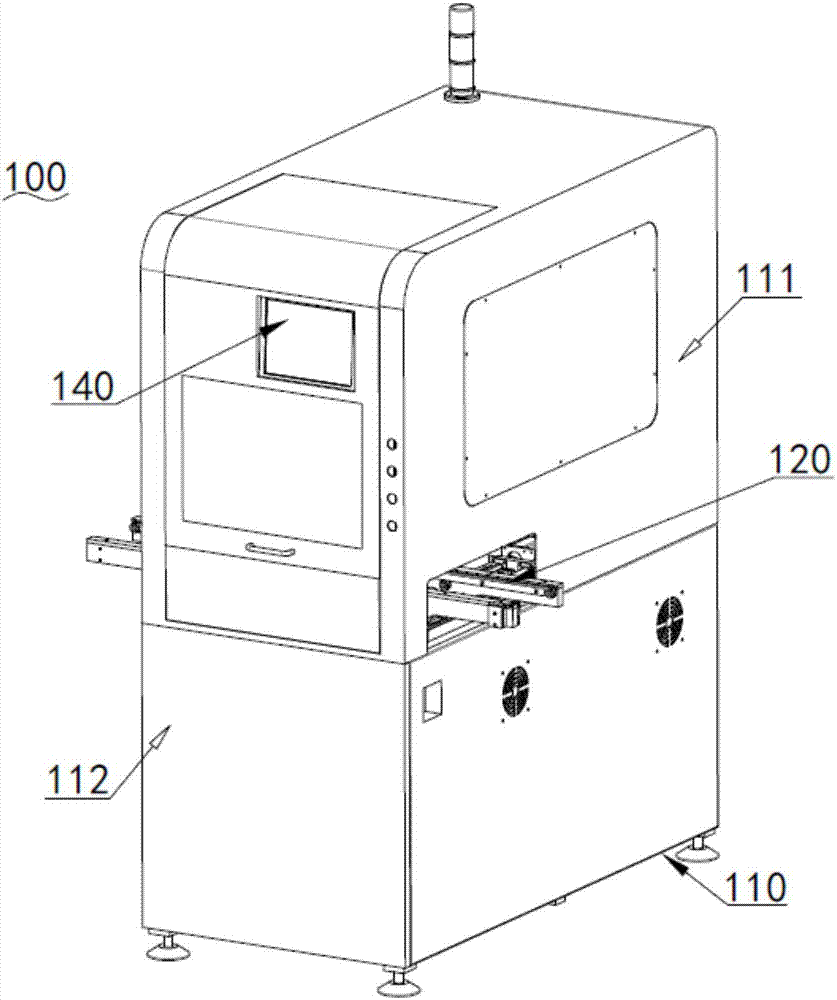

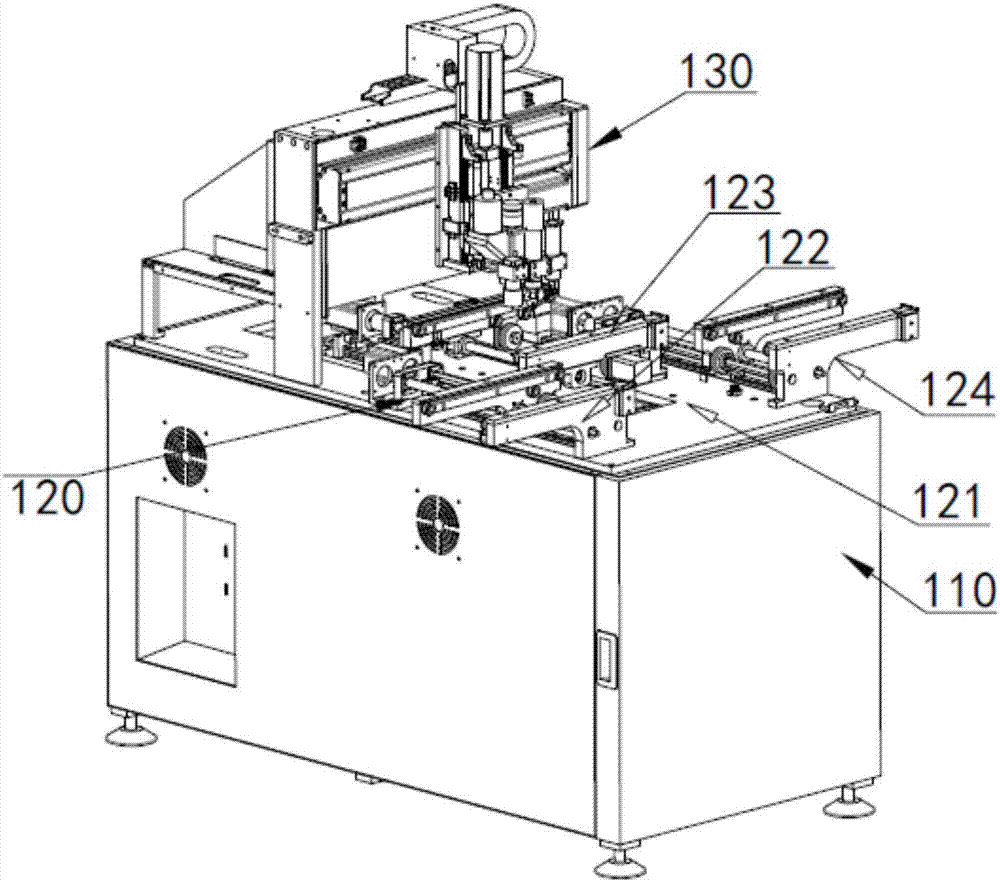

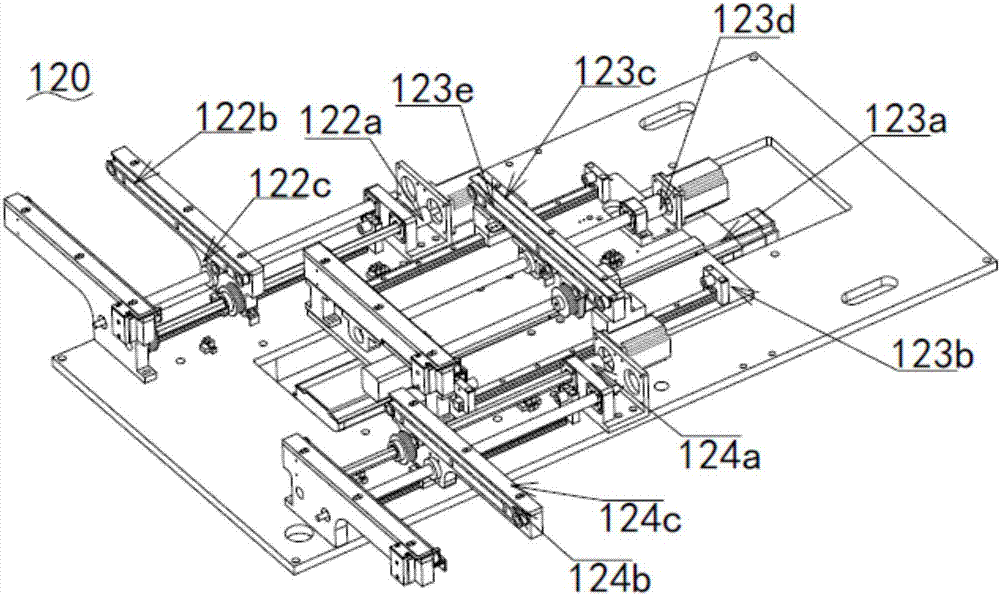

PendingCN107088689AEasy to transportPlay a dynamic effectMetal working apparatusSoldering auxillary devicesEngineeringSpot welding

The invention relates to the technical field of tin dispensing equipment, in particular to automatic online tin paste dispensing equipment and a working method thereof. The automatic online tin paste dispensing equipment comprises a rack, a workbench, a tin dispensing device and a control device. The rack comprises an upper rack body and a lower rack body. The upper rack body is installed on the lower rack body and covers the workbench and the tin dispensing device. The control device is electrically connected to the workbench and the tin dispensing device. The workbench comprises an installation plate, a feeding assembly, a fixing assembly and a discharging assembly. The tin dispensing device comprises a supporting frame, a driving sliding platform, a detection assembly, a tin smearing assembly and a tin welding assembly. The automatic online tin paste dispensing equipment is high in working efficiency and automation degree and good in spot welding effect. The working method of the automatic online tin paste dispensing equipment comprises the steps that a program is written in the control device at first; a plate is fixed to the workbench, detected through the detection assembly, and smeared with tin paste through the tin smearing assembly; spot welding is conducted in the position where the tin paste is smeared through the tin welding assembly; and after spot welding is completed, the plate is detected again through the detection assembly. The working method is high in tin dispensing quality, automation degree and working efficiency.

Owner:VECTRON TECH ELECTRONICS EQUIP

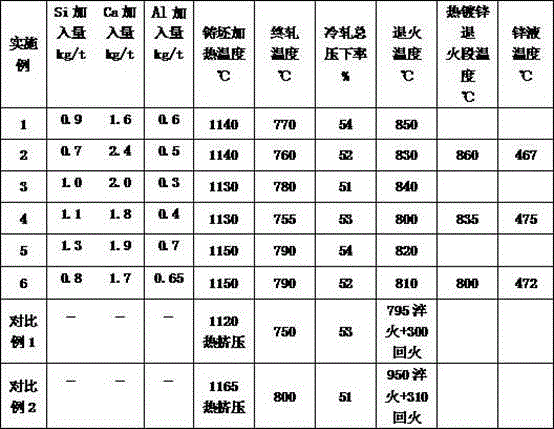

High-strength steel with resistance to delayed fracture with yield ratio ≤ 0.5 and production method

InactiveCN103667893BHigh elongationHigh strain hardening exponentHot-dipping/immersion processesEnergy absorptionYield ratio

The invention provides high-strength anti-delayed fracture steel with a yield ratio of no more than 0.5. The steel comprises, by weight, 0.11 to 0.25% of C, 15.5 to 17.5% of Mn, 0.030 to 0.050% of Mo, 0.005 to 0.02% of Co, 0.005 to 0.009% of B, 0.009 to 0.011% of N and 0.011 to 0.025% of La+Ce+Nd. A production method for the steel comprises the following steps: desulphurization of molten iron; converter smelting; RH vacuum treatment; continuous casting; hot rolling, wherein finish rolling temperature is in a range of 755 to 790 DEG C; cold rolling, wherein a reduction rate is 51 to 54%; and continuous annealing. According to the invention, the problems of low elongation percentage, a high yield ratio and poor welding performance of high-strength steel of a same grade are overcome, and the phenomenon of delayed fracture is avoided; an automobile crash-proof part manufactured from the steel has better formability, welding performance and energy absorption performance compared with other cold-rolled high-strength steel, and use security, weight reduction performance and energy saving performance of a product are substantially improved; B, Mo, Co and N are employed, so refined crystalline strengthening and precipitation strengthening are realized, and a low yield ratio, heat resistance and corrosion resistance are guaranteed; a steel plate has double effects and a low yield ratio, and good forming capability, good bearing performance and anti-fracture performance of a material are guaranteed.

Owner:武汉钢铁有限公司

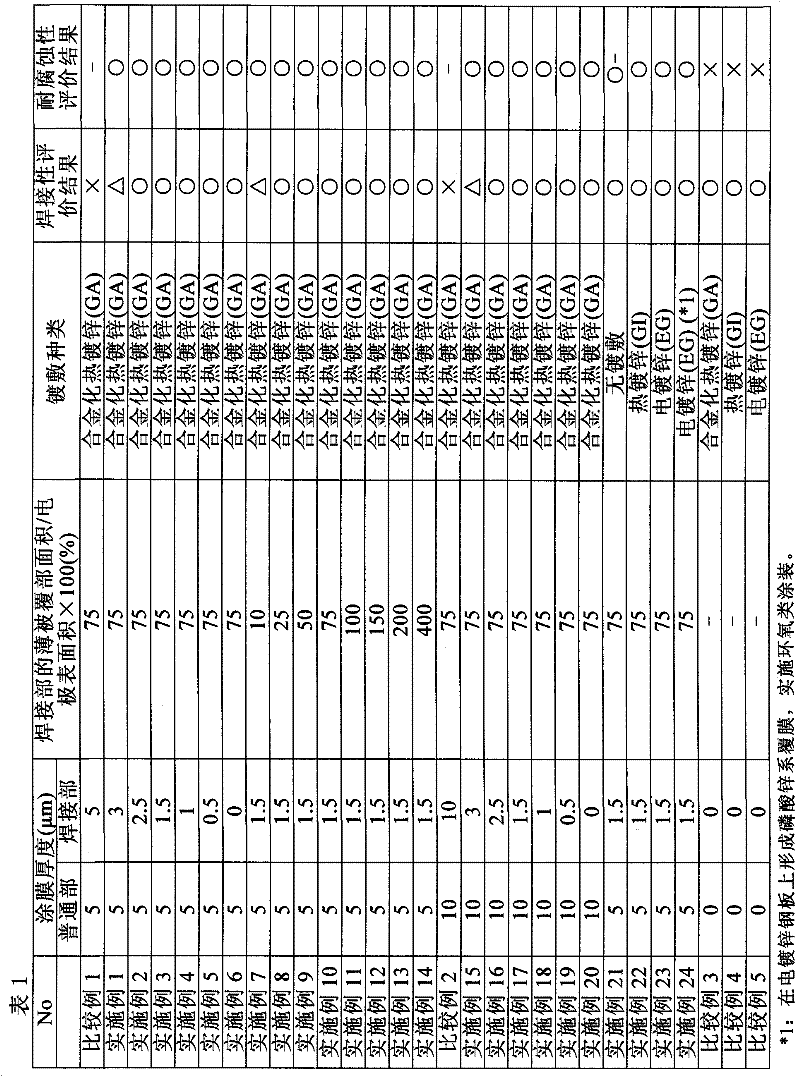

Rust-proof steel sheet and method for producing the same

InactiveCN102164742AGood spot weldabilityAccelerated corrosionLiquid surface applicatorsAnti-corrosive paintsMaterials scienceRust

Provided is a rust-proof steel sheet having on at least one side an organic and / or inorganic coating layer, wherein the coating layer of the portion to be spot welded is thinner than the coating layer of the portion not to be spot welded. Also provided is a method for producing the rust-proof steel sheet. The rust-proof steel sheet has sufficiently low electrical resistivity at the welded parts that sound welded parts can be formed, and has both spot weldability and corrosion resistance.

Owner:JFE STEEL CORP

Thick-specification galvanized steel plate for elevator and manufacturing method thereof

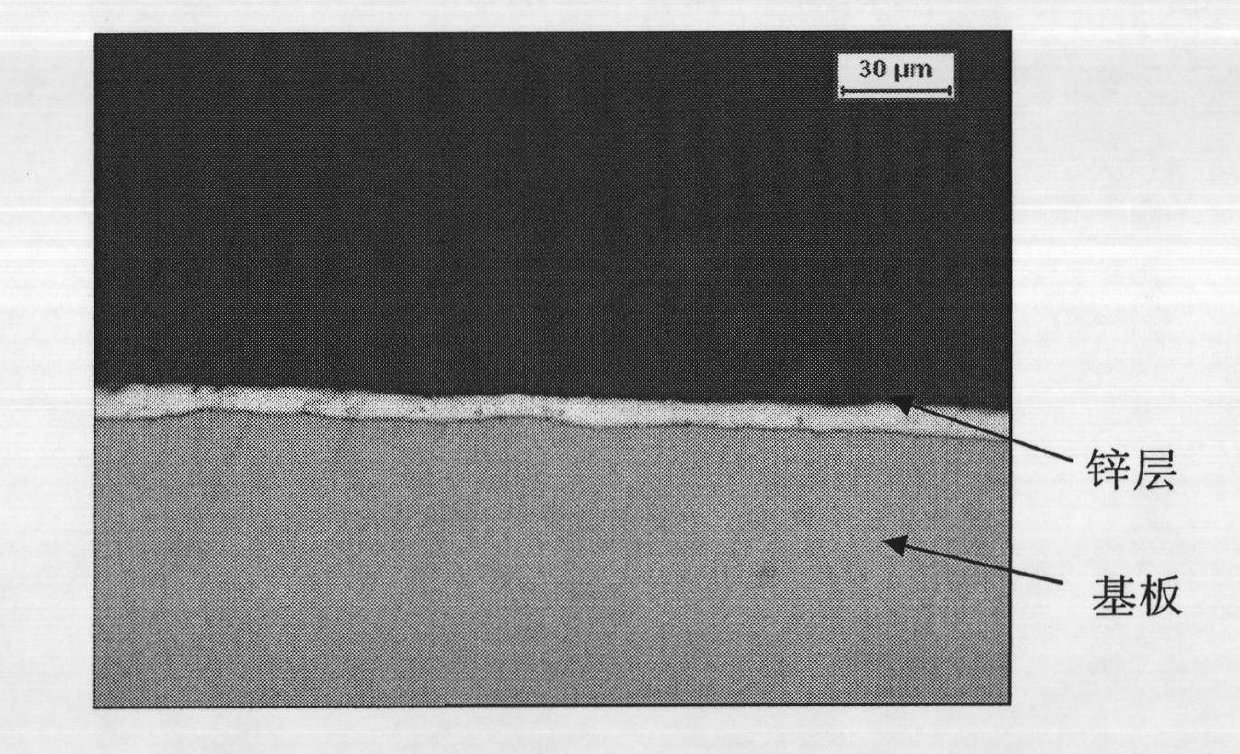

ActiveCN110004369AStrong adhesionImprove surface qualityHot-dipping/immersion processesSheet steelImpurity

The invention discloses a thick-specification galvanized steel plate for an elevator and a manufacturing method thereof and belongs to the technical field of hot-dip galvanized steel plates. The thick-specification galvanized steel plate comprises a base plate and is composed of following components which include, by mass percentage, maximum 0.060% of C, maximum 0.040% of Si, 0.10-0.25% of Mn, maximum 0.015% of P, maximum 0.010% of S, maximum 0.035% of Als, and the balance Fe and inevitable impurities. A hot-dip galvanized layer is formed on the surface of the base plate and comprises 0.10-0.30% of Al by mass percentage. The base plate comprises 0.035% of Als by mass percentage. The thickness of the base plate is 1.4-2.0 mm. The weight of the hot-dip galvanized layer is 160-275 g / m2. According to the thick-specification galvanized steel plate, by improving the components of the galvanized steel plate and the base plate hot-dip galvanizing technology, after the base plate is subjected to hot-dip galvanizing with the thickness larger than or equal to 1.4 mm, adhesive force of a plated layer is strong, the surface and the edge are smooth and free of cloud patterns, it is ensured thatthe galvanized steel plate is high in surface quality after being coated in a coloring manner. The thick-specification galvanized steel plate for the elevator is reasonable in design, low in manufacturing cost and applicable to industrialized production.

Owner:MAANSHAN IRON & STEEL CO LTD

Method for manufacturing a high strength steel sheet

InactiveUS20090223607A1High strengthGood molding effectFurnace typesMetal rolling arrangementsSheet steelHigh intensity

Owner:JFE STEEL CORP

Preparation method of connecting conductor material for energy storage system

PendingCN114012358AReduce weight and costLight in massMolten spray coatingFurnace typesAluminum compositesElectrical battery

The invention discloses a preparation method of a connecting conductor material for an energy storage system, which comprises the following steps of: fusing and welding a prepared pure nickel foil and a pretreated aluminum material into a nickel-aluminum composite material through a polymer diffusion welding technology in the preparation process, and treating the nickel-aluminum composite material by adopting a linear cutting technology or a blanking technology, and finally, preparing the connecting conductor material for the energy storage system through local polishing and insulating material spraying processes. According to the method, the preparation cost of the material is effectively reduced, the pollution to the environment is reduced, the safety performance of the battery is effectively improved, the service life of the battery is effectively prolonged, and the problems that the sleeve is not attached, the process is complex, and the sleeve is easy to crack are solved. In addition, according to the method, single-face, double-face or local single-face and double-face compounding can be carried out according to needs, the cost is controlled to the minimum under the condition that the using performance is not affected, and the material effectiveness is maximized.

Owner:JIANGSU K TECH PRECISION TECH +1

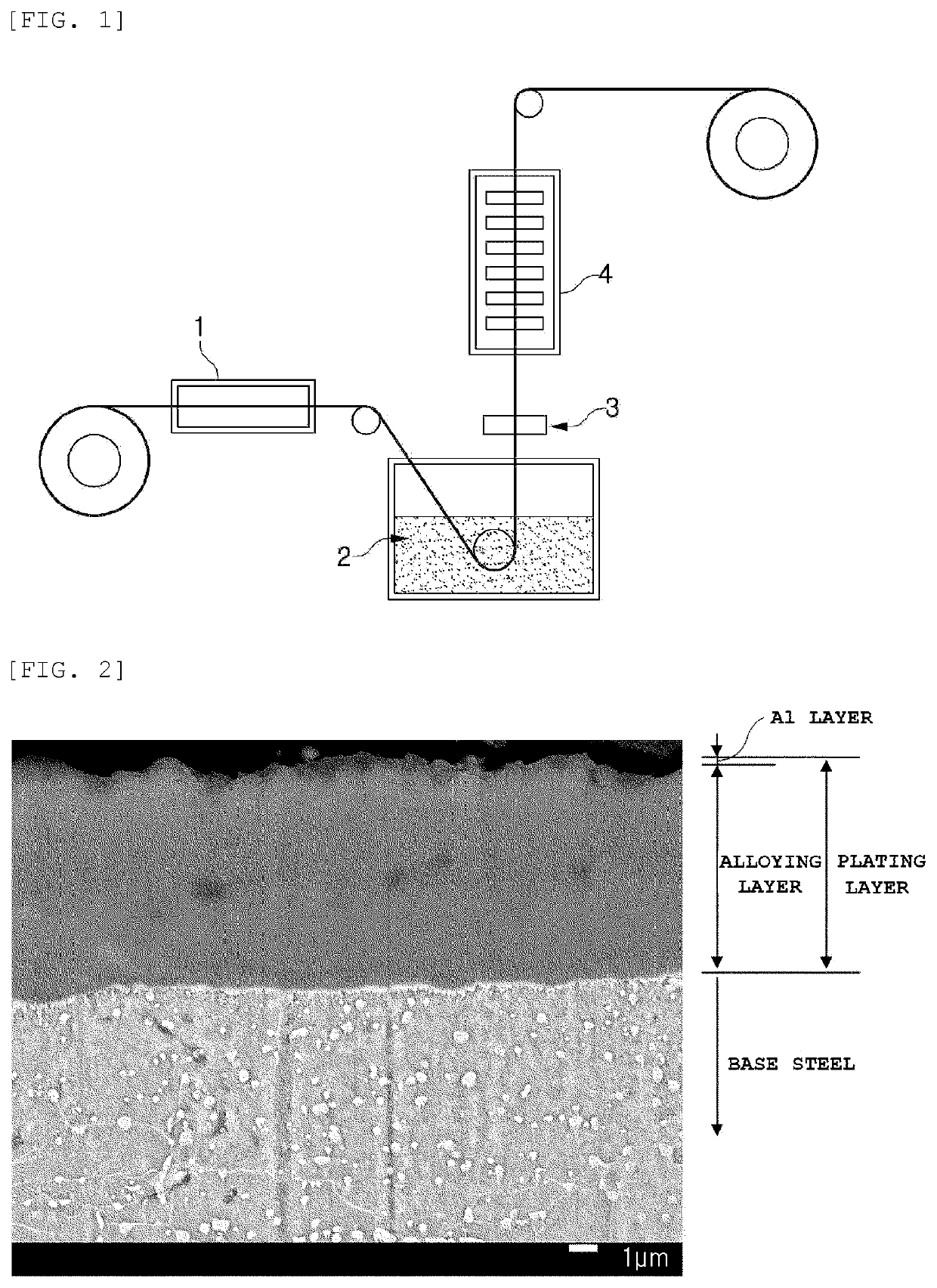

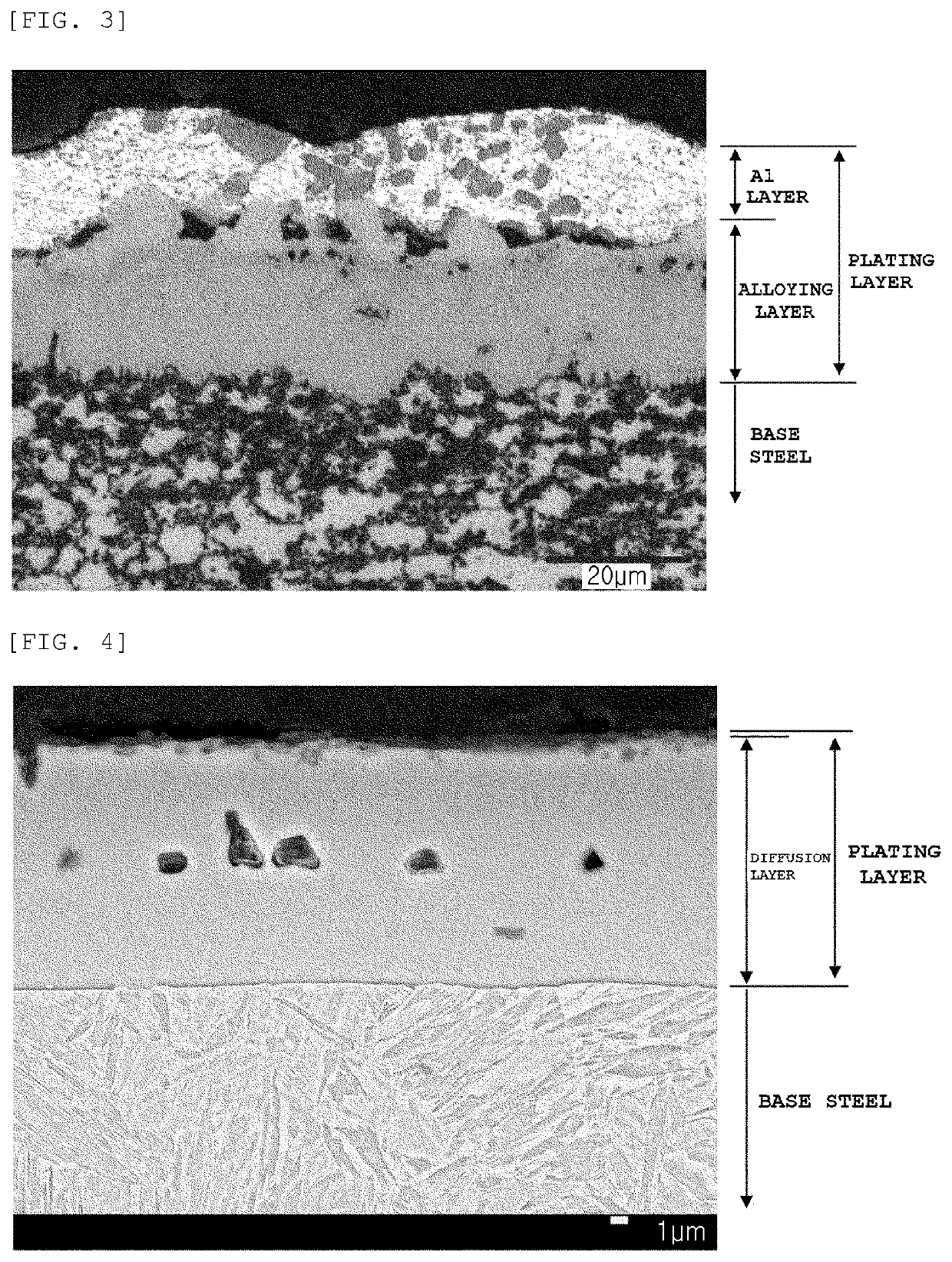

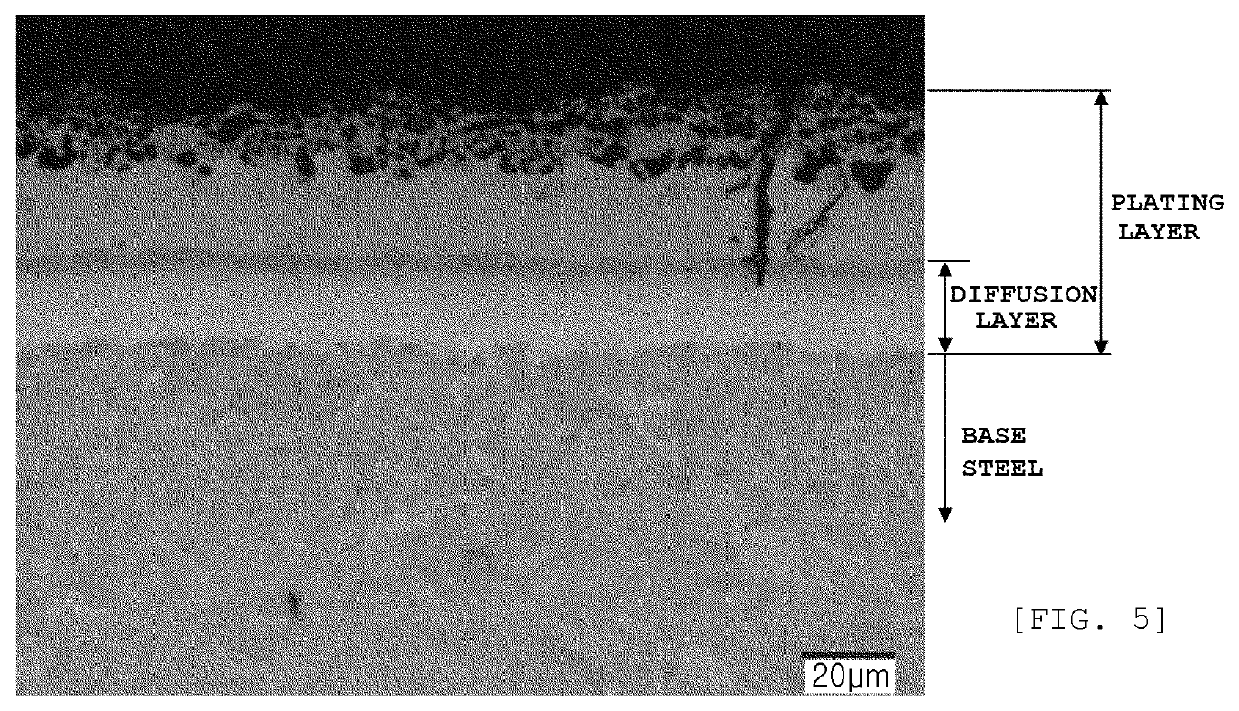

Aluminum-based plated steel plate for hot press having excellent resistance against hydrogen delayed fracture and spot weldability, and method for manufacturing same

PendingUS20220049338A1Improve hydrogen resistanceGood spot weldabilityHot-dipping/immersion processesFurnace typesAlcladSpot welding

The present invention provides an aluminum-based plated steel plate used in hot-press forming, the steel plate comprising: a base steel plate; and a plating layer formed on the base steel plate, wherein the plating layer comprises: an alloying layer formed on the surface of the base steel plate and including one or more of Fe 3Al, FeAl(Si), Fe 2Al 5, and FeAl 3; and an aluminum layer formed on the alloying layer and having a thickness less than 10% of the thickness of the plating layer, and the plating layer has a thickness of 5-20 μm and an oxygen content of 10 weight % or less, as measured by GDS, at a depth of 0.1 μm from the surface of the plating layer.

Owner:POHANG IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com