Method for manufacturing a high strength steel sheet

a technology of high strength steel and manufacturing method, which is applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., can solve the problems of increasing formability, reducing press formability, and deteriorating surface properties, and achieve excellent formability and surface properties, high strength, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0081]Slabs having respective chemical compositions given in Table 1 were prepared by continuous casting. They were cooled, then heated to temperatures from 1100° C. to 1300° C., and were treated by final rolling at temperatures in a range from Ar3 point to 850° C. to obtain steel sheets having thicknesses of from 1.6 to 3.2 mm. Within 1 second after completing the final rolling, cooling began on the steel sheets to conduct the primary cooling to a temperature range from 680° C. to 720° C. at cooling rates from 300 to 500° C. / s. After that, the steel sheets were held at the temperature range for 7 to 12 seconds. Then, the steel sheets were cooled at cooling rates from 25 to 30° C. / s, and were coiled at 350° C. or lower temperature to obtain the respective hot-rolled steel sheets. As for Steel No. 4, however, the temperature to stop the primary cooling was 550° C., and Steel No. 5 was coiled at 450° C., thus adjusting the micro-structure thereof given in Table 1. The percentage of po...

example 2

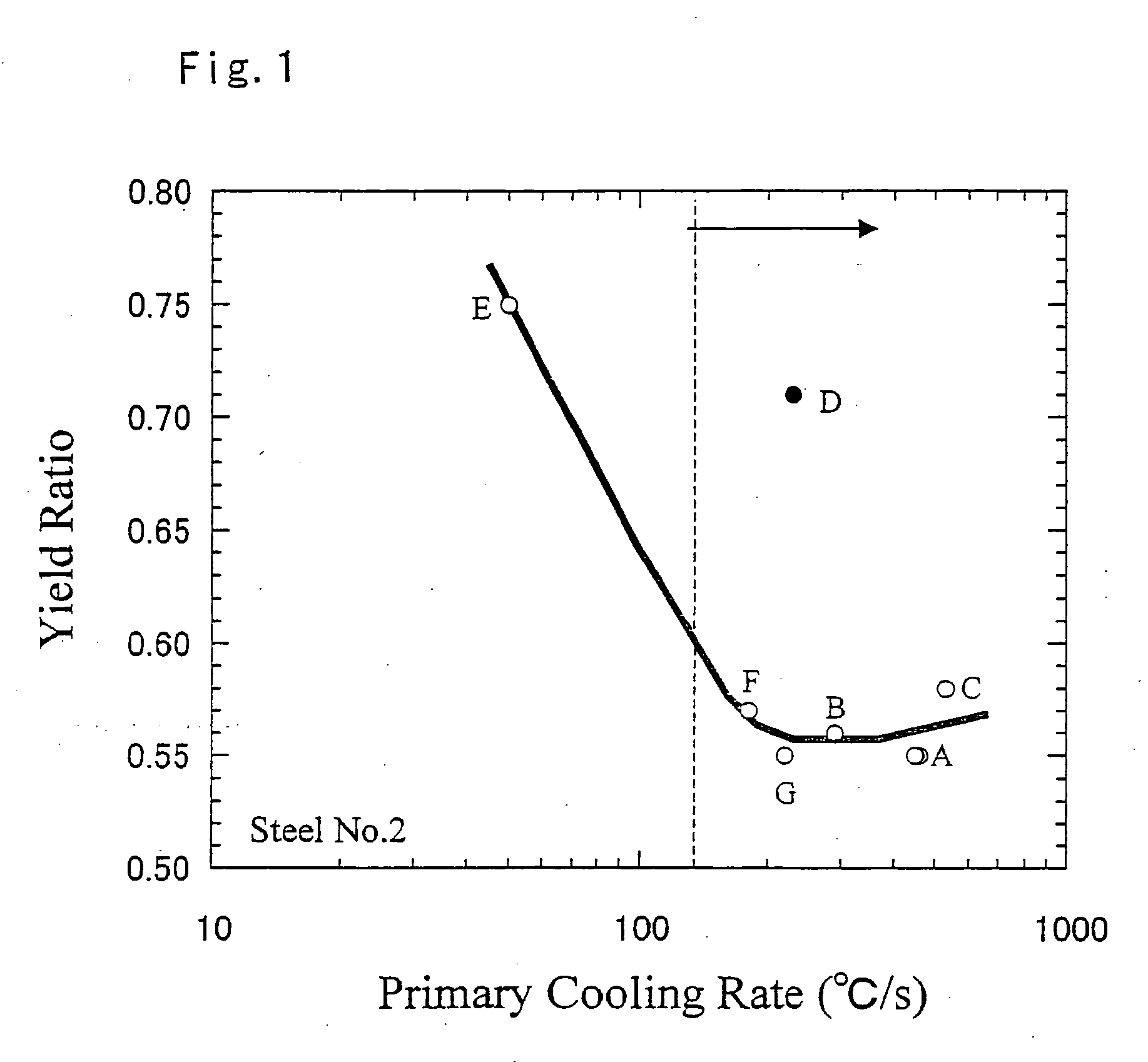

[0085]Some of the slabs having the respective chemical compositions given in Table 1 were treated by hot-rolling, cooling, and coiling under the respective manufacturing conditions given in Table 3, thus obtained the respective hot-rolled steel sheets.

TABLE 3CoolingHeatingFinishbeginningPrimaryStopSecondaryCoilingSteeltemperaturetemperatureTimecoolingtemperatureHoldingcooling ratetemperatureClassificationSymbolNo.(° C.)(° C.)(s)speed (° C. / s)(° C.)time (s)(° C. / s)(° C.)ExampleA212008500.5460738445382ExampleB212508301290738421373ExampleC2123084025306441138324ComparativeD2105082052307011242144exampleComparativeE211508301507071245136exampleExampleF212508501180717640317ExampleG212008401220686724259ExampleH211008301450698620116ComparativeI611208201340800850217exampleExampleJ6115081012807301022184ExampleK6128083015306801022181ExampleL6120083012708501330347ComparativeM6113082013903501141285exampleComparativeN611808401240634—46158exampleExampleO6Hot direct8201560682833350rollingExampleP6123...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com