Zn alloy plated steel sheet having excellent phosphatability and spot weldability and method for manufacturing same

一种制造方法、合金钢板的技术,应用在热浸镀工艺、金属材料涂层工艺、涂层等方向,能够解决熔点低、熔融镀覆钢板点焊性、变差等问题,达到磷酸盐处理性优异、点焊性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Prepare a base steel sheet as a test piece for coating. The base steel sheet is a low-carbon cold-rolled steel sheet with a thickness of 0.8 mm, a width of 100 mm and a length of 200 mm. The base steel sheet is then immersed in acetone and ultrasonically cleaned to remove surface presence Impurities such as rolling oil. After that, plasma treatment was performed on the surface of the test piece for plating to control the centerline average roughness (Ra) in the range of 1.0 to 1.1 μm. After that, after performing a 750°C reduction atmosphere heat treatment in order to ensure the mechanical properties of the steel sheet in an ordinary hot-dip coating operation, it was immersed in a plating solution having the composition of Table 1 below to produce a galvanized alloy steel sheet. At this time, for all the examples, the plating solution temperature was 450°C, and the surface temperature of the base steel sheet into which the plating solution was introduced was fixed at 460...

Embodiment 2

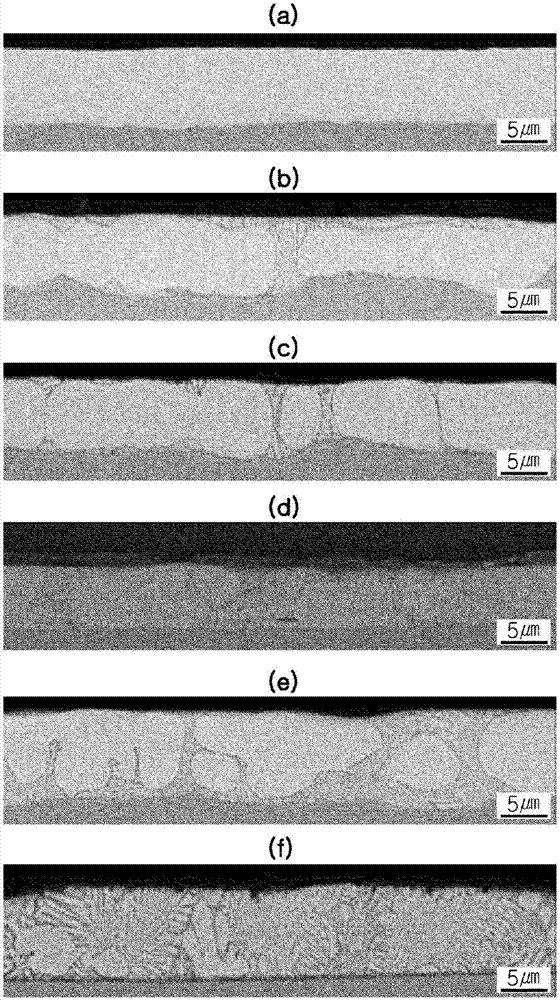

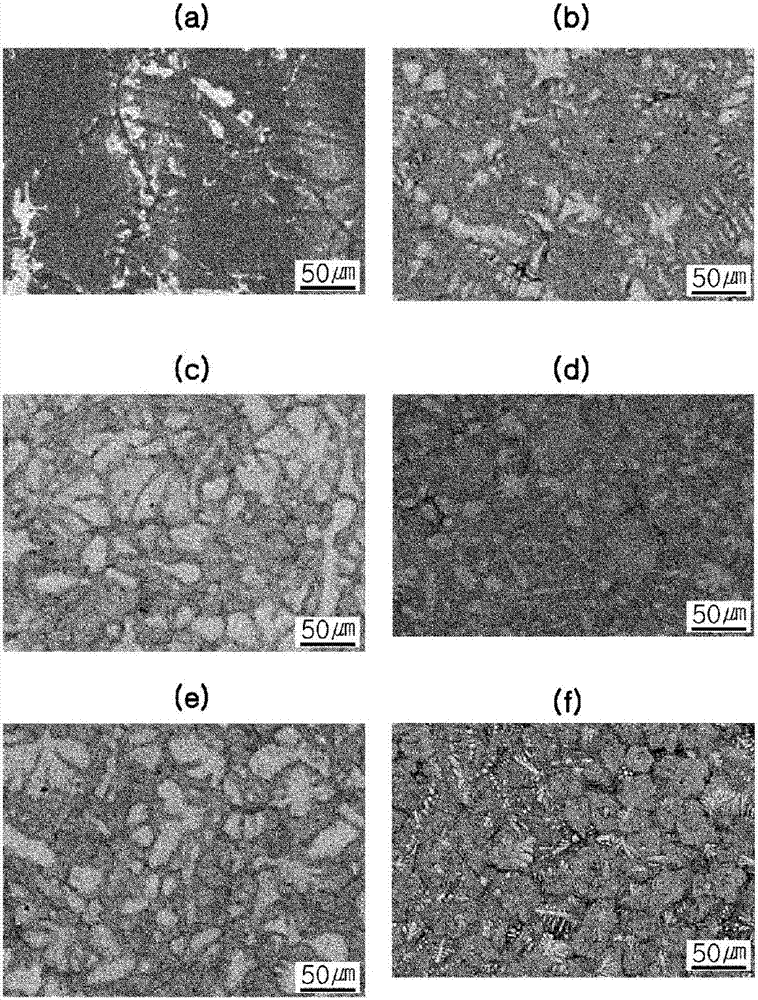

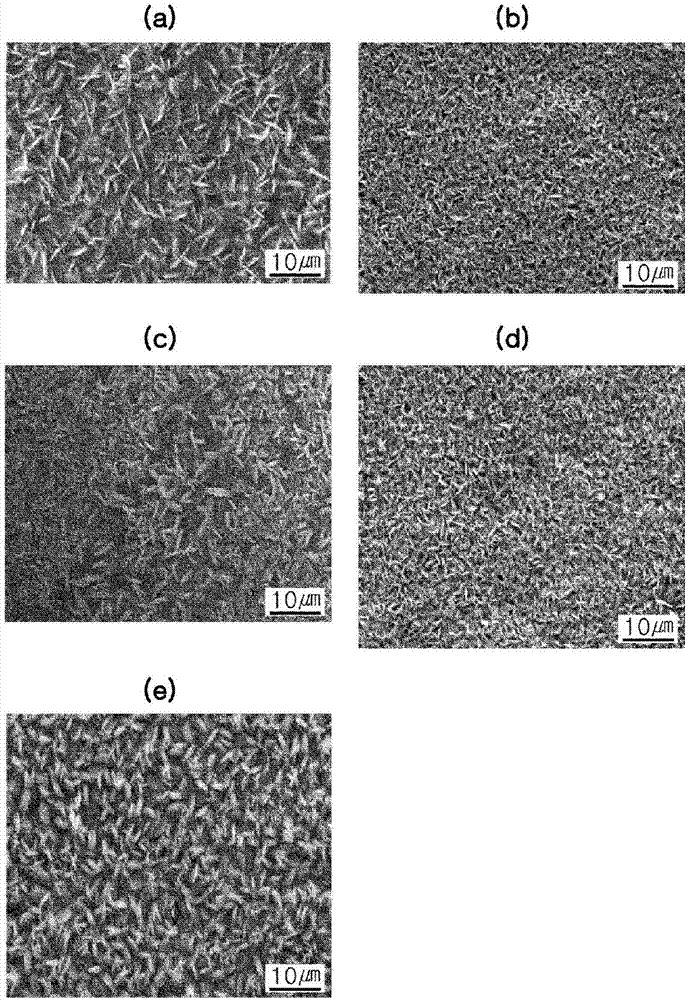

[0080] The following Table 3 shows the content of each alloy element contained in the Zn single-phase structure of the galvanized alloy steel sheet of Example 1 and the corrosion resistance evaluation results.

[0081] At this time, for the content of each alloy contained in the Zn unidirectional structure, after cutting the galvanized alloy steel sheet vertically, the cross-sectional photograph was taken with a Field Emission Scanning Electron Microscope (FE-SEM, Field Emission Scanning Electron Microscope) at 3000 times, and EDS (Energy Dispersive Spectroscopy) was used to analyze the Zn single-phase structure to measure the content of each alloy element.

[0082] In addition, in the evaluation of corrosion resistance, after each galvanized alloy steel sheet was loaded into a salt spray test machine, the time for red rust to occur was measured in accordance with the international standard (ASTM B117-11). At this time, 5% salt water (temperature 35℃, pH6.8) was used, and 2ml / 80cm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com