Ear-pole of battery inner and electric sheet metal between batteries and processing method

A technology of conductive metal sheets and processing methods, which is applied to battery pack components, conductive materials, conductive materials, etc., and can solve problems such as copper and nickel-plated steel shells, poor spot welding performance of pure nickel, and easy to rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

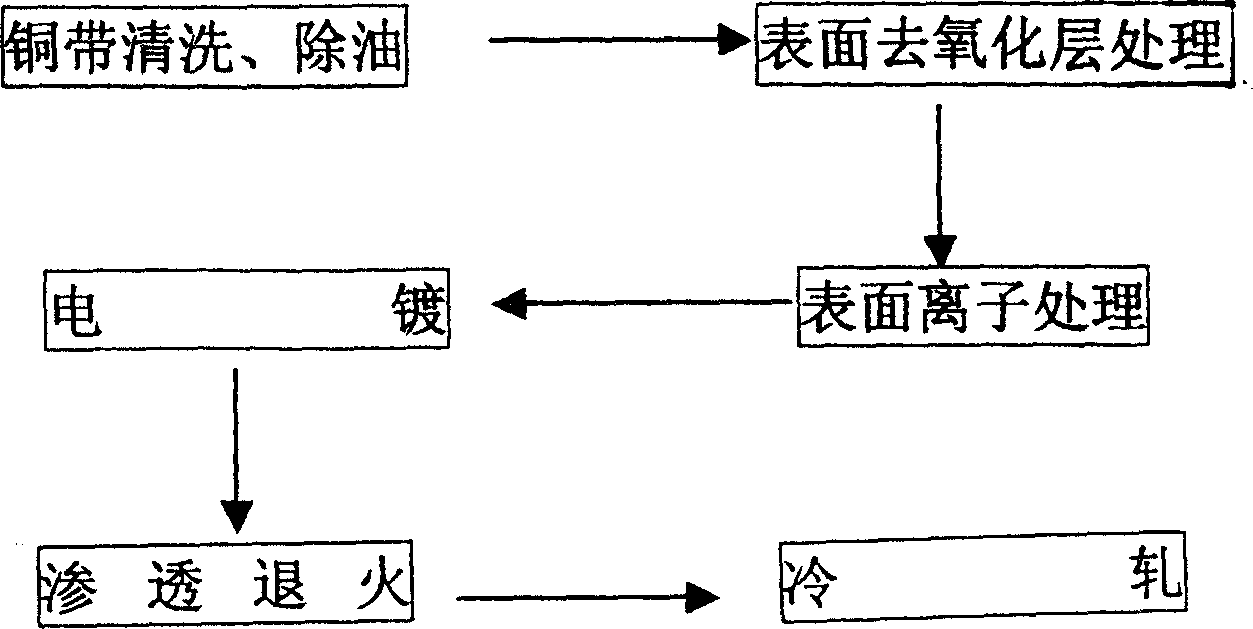

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: Select the copper strip whose grade is TP1, TP2, TU1 or TU2, clean it with detergent, then remove the oxide layer on the surface of the copper strip with a wire brush, place the copper strip in a mixture of sulfuric acid and hydrofluoric acid Immerse in the acid for 10 hours, wherein the volume ratio of sulfuric acid and hydrofluoric acid is 2: 1, take 450 parts of nickel sulfamate, 30 parts of boric acid, and 0.056 parts of wetting agent to configure the electroplating solution by weight ratio; the pH value of the electroplating solution is 4.2. Electroplating the surface of the copper strip at a temperature of 50 degrees Celsius, and the current density of the electroplating is 8A / D m 2 ; Heat the nickel-plated copper strip to 950 degrees Celsius in a vacuum furnace, keep it warm for 1.5 hours, stop heating, and cool naturally; finally, cold-roll the copper strip to the required thickness with a rolling mill, and then anneal and cold-roll again according ...

Embodiment 2

[0022] Embodiment 2, select the copper strip that the grade is TP1, TP2, TU1 or TU2, clean with detergent, then remove the oxide layer on the surface of the copper strip with a wire brush, place the copper strip in a mixture of sulfuric acid and hydrofluoric acid Soak in acid for 10 hours, wherein the volume ratio of sulfuric acid and hydrofluoric acid is 3: 1, get 290 parts of nickel sulfamate, 40 parts of boric acid, NICL 2 .6H 2 O 27 parts of configuration electroplating solution, the pH value of electroplating solution is 3.8, and temperature is carried out electroplating to the surface of copper strip under the condition of 60 degrees centigrade, the current density of electroplating is 40A / Dm 2 ;Heat the nickel-plated copper strip at 1000 degrees Celsius in a vacuum furnace, keep it warm for 1.8 hours, stop heating, and cool naturally; finally, cold-roll the copper strip to the required thickness with a rolling mill, and then anneal and cold-roll again according to the n...

Embodiment 3

[0023] Embodiment 3, select the copper strip that the trade mark is TP1, TP2, TU1 or TU2, clean with detergent, then remove the oxide layer on the surface of the copper strip with a wire brush, place the copper strip in a mixture of sulfuric acid and hydrofluoric acid Soak in acid for 10 hours, wherein the volume ratio of sulfuric acid and hydrofluoric acid is 4: 1, get 720 parts of nickel sulfamate, 42 parts of boric acid, NICL 2 .6H 2 O 12 parts of configuration electroplating solution, the pH value of electroplating solution is 4, and temperature is carried out electroplating to the surface of copper strip under the condition of 65 degrees centigrade, and the current density of electroplating is 80A / D m 2 ; Heat the nickel-plated copper strip to 1150 degrees Celsius in a vacuum furnace, keep it warm for 2 hours, stop heating, and cool naturally; finally, cold-roll the copper strip to the required thickness with a rolling mill, and then anneal and cold-roll again according t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com