Hot-dip-galvanized steel sheet

A hot-dip galvanized steel sheet, hot-dip galvanized technology, applied in hot-dip galvanizing process, heat treatment furnace, heat treatment equipment, etc., can solve the problems of insufficient consideration of coating adhesion, corrosion resistance, durability, etc., and achieve excellent Effects of corrosion resistance after painting, excellent appearance after painting, and excellent spot weldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0074] Hereinafter, the present invention will be specifically described based on examples. It should be noted that the present invention is not limited to the following examples.

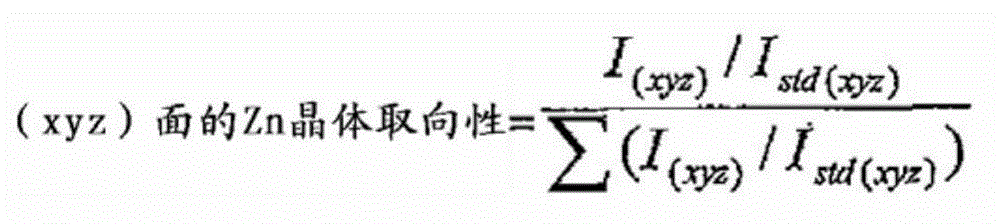

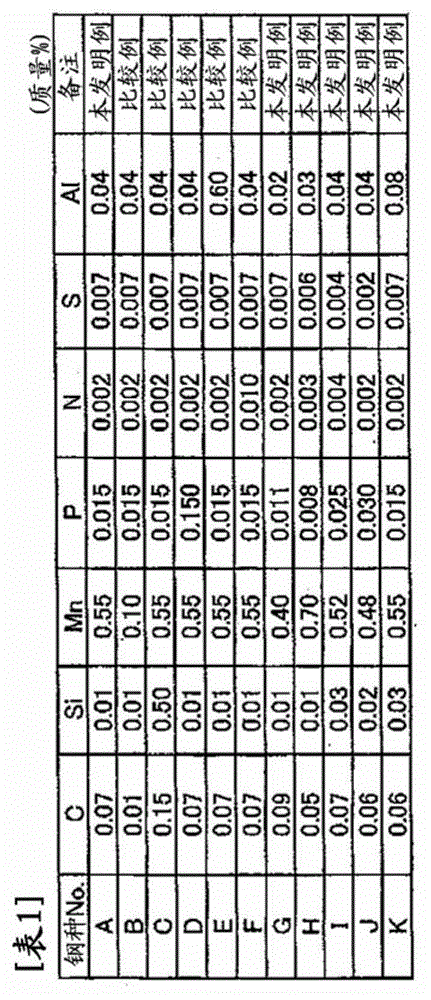

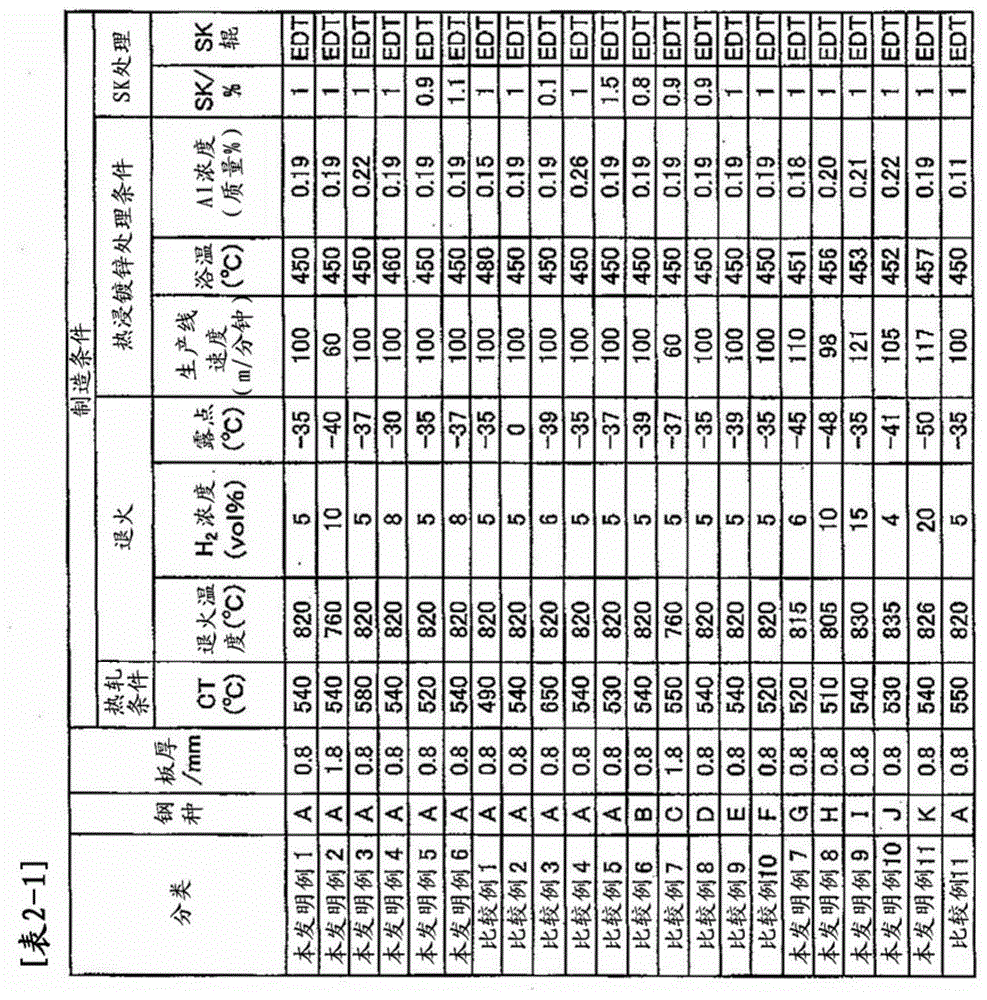

[0075] After removing the black scale of the hot-rolled steel sheet by pickling, cold rolling is carried out with a reduction ratio of 65%, so that the plate thickness is 0.8mm and 1.8mm. This hot-rolled steel sheet has the steel composition shown in Table 1, and is shown in Table 2 ( The table consisting of Table 2-1 and Table 2-2 was coiled at a finish rolling temperature and a coiling temperature of 650° C. or less shown in Table 2). Thereafter, the surface was degreased on the input side of the CGL (continuous galvanizing line), annealed and galvanized under the conditions shown in Table 2 to manufacture galvanized steel sheets. The bath temperature and the Al concentration in the bath were appropriately changed. EDT processed rolls were used for the rolls, and the rolling reduction was appro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield stress | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com