ABS material for electroplating and its preparation method and application

A technology of ABS material and ABS resin, applied in the field of ABS material for electroplating and its preparation, can solve the problems of increased internal stress, low melt index of ABS material, and reduced electroplating qualification rate of products, etc., so as to reduce internal stress and make up for insufficient heat resistance. , the effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

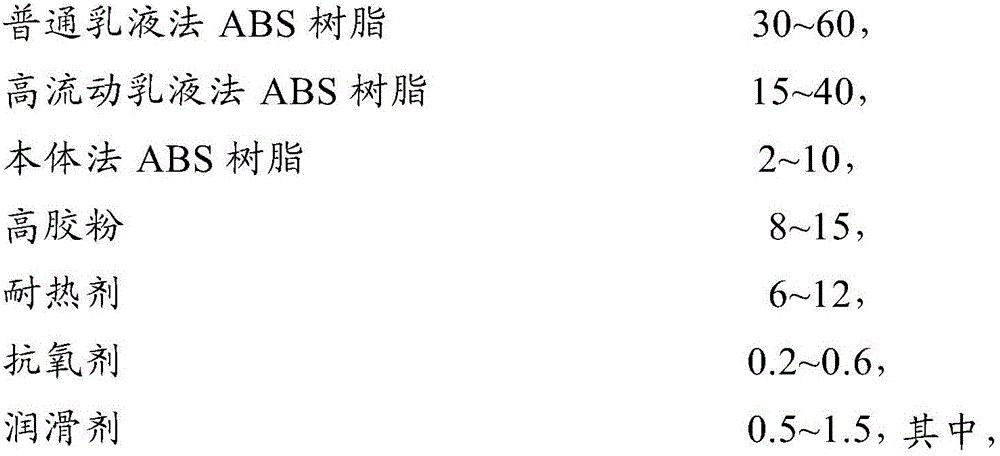

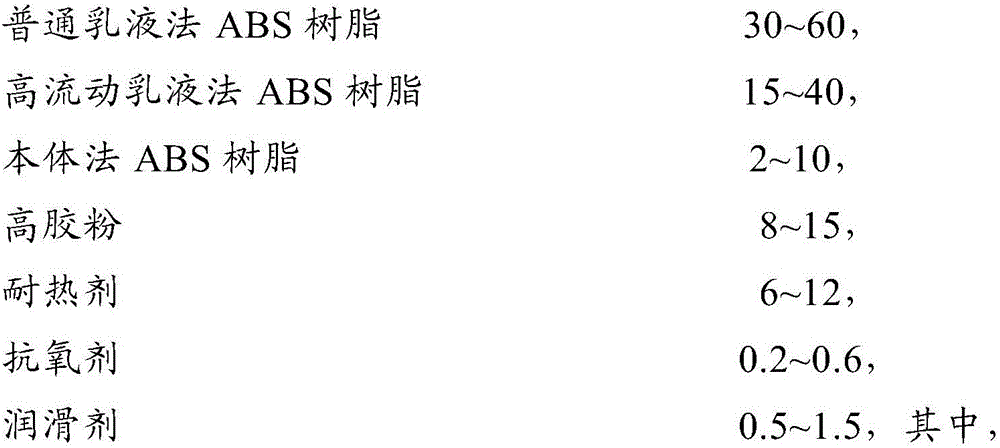

Method used

Image

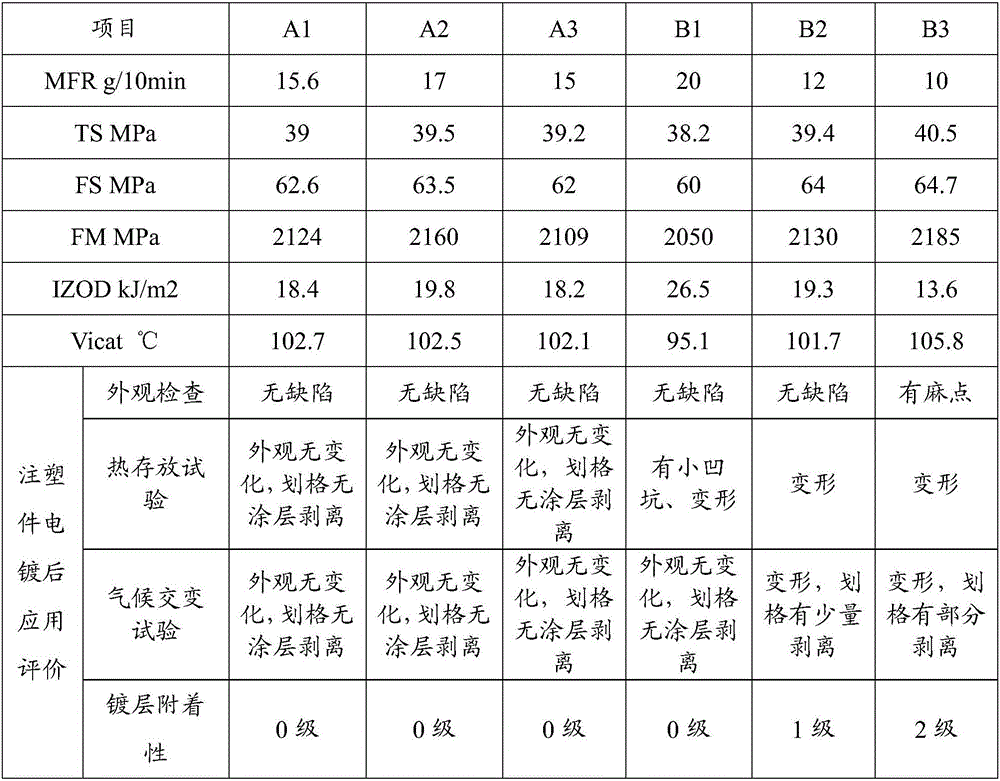

Examples

Embodiment 1

[0032] (1) In parts by weight, weigh 43 parts of ordinary emulsion method ABS resin, 35 parts of high flow emulsion method ABS resin, 2 parts of bulk method ABS resin, 12 parts of high rubber powder, 8 parts of heat-resistant agent SMI, 0.2 parts Antioxidant 1076, 0.3 part of antioxidant 168, 0.6 part of lubricant PETs;

[0033] (2) Add the raw materials weighed in the step (1) into a high-speed mixer and stir for 15 minutes to obtain a homogeneous mixture;

[0034] (3) Feed the mixture obtained in step (2) into a twin-screw extruder, and obtain the ABS material A1 for electroplating through melting, extrusion, water cooling, air-drying, and pelletizing, wherein the temperature zone of the twin-screw extruder The settings are 210°C, 225°C, 240°C, 250°C, 250°C, 260°C, 260°C, 265°C, 270°C, 260°C, and the screw speed is 300 rpm.

Embodiment 2

[0036] (1) In parts by weight, weigh 35 parts of ordinary emulsion method ABS resin, 40 parts of high flow emulsion method ABS resin, 5 parts of bulk method ABS resin, 12 parts of high rubber powder, 8 parts of heat-resistant agent SMI, 0.2 parts Antioxidant 1076, 0.3 part of antioxidant 168, 0.6 part of lubricant PETs;

[0037] (2) Add the raw materials weighed in the step (1) into a high-speed mixer and stir for 15 minutes to obtain a homogeneous mixture;

[0038] (3) The mixture obtained in the step (2) is fed into a twin-screw extruder, and obtained through melting, extruding, water cooling, air-drying, and pelletizing, the ABS material A2 for electroplating, wherein the temperature of the twin-screw extruder is set Set at 210°C, 225°C, 240°C, 250°C, 250°C, 260°C, 260°C, 265°C, 270°C, 260°C, and the screw speed is 300rpm.

Embodiment 3

[0040] (1) In parts by weight, weigh 54 parts of ordinary emulsion method ABS resin, 20 parts of high flow emulsion method ABS resin, 7 parts of bulk method ABS resin, 11 parts of high rubber powder, 8 parts of heat-resistant agent SMI, 0.2 parts Antioxidant 1076, 0.3 part of antioxidant 168, 0.6 part of lubricant PETs;

[0041] (2) Add the raw materials weighed in the step (1) into a high-speed mixer and stir for 15 minutes to obtain a homogeneous mixture;

[0042] (3) The mixture obtained in step (2) is sent into a twin-screw extruder, and obtained through melting, extruding, water cooling, air-drying, and pelletizing, the ABS material A3 for electroplating is obtained, wherein the temperature setting of the twin-screw extruder 210°C, 225°C, 240°C, 250°C, 250°C, 260°C, 260°C, 265°C, 270°C, 260°C, and the screw speed is 300rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com