High-strength hot-dipped galvanized steel sheet having excellent plating adhesion, and method for producing same

A technology of hot-dip galvanized steel sheet and coating adhesion, which is applied in hot-dip coating technology, manufacturing tools, heat treatment furnaces, etc., can solve the problem that the effect cannot be obtained stably, and achieve excellent fatigue resistance and coating adhesion excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

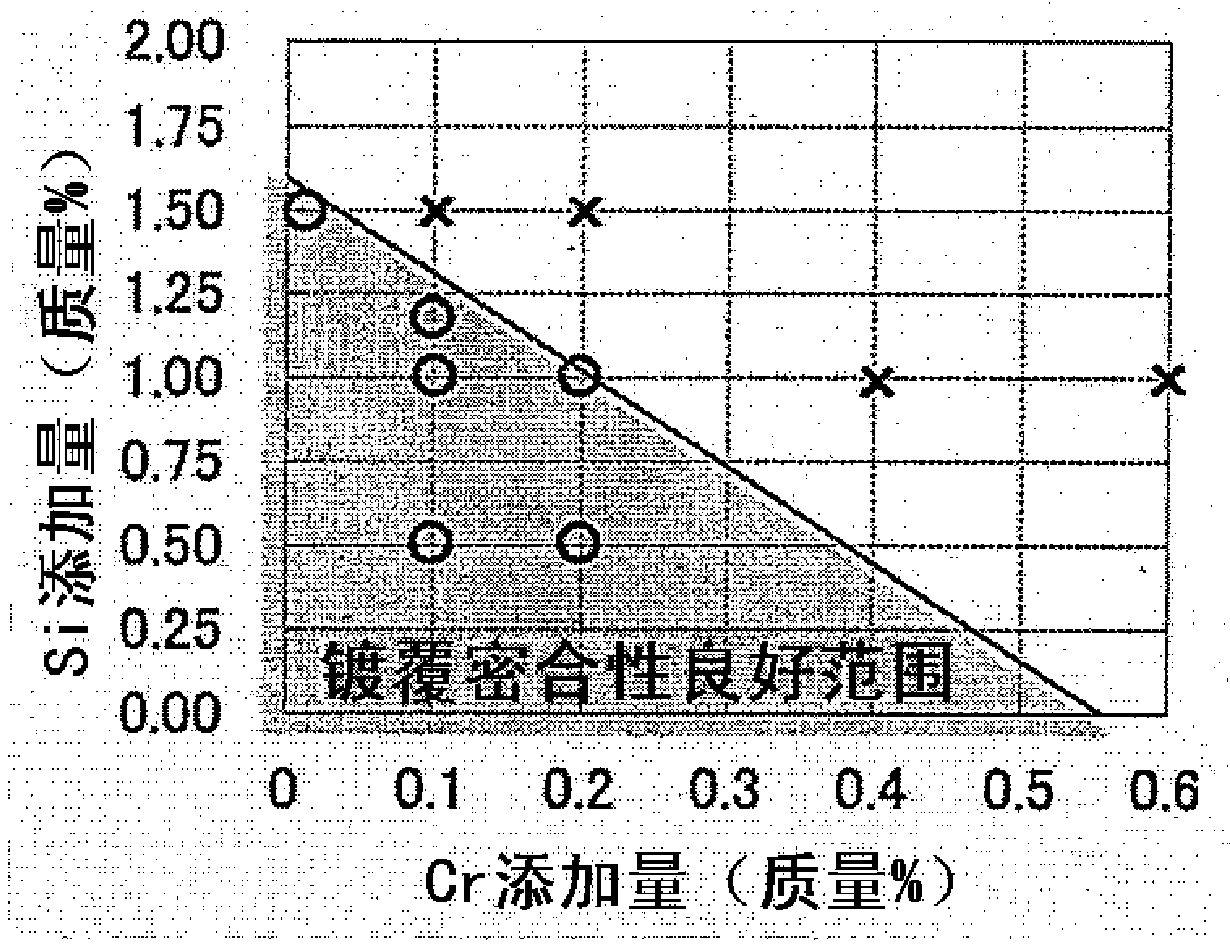

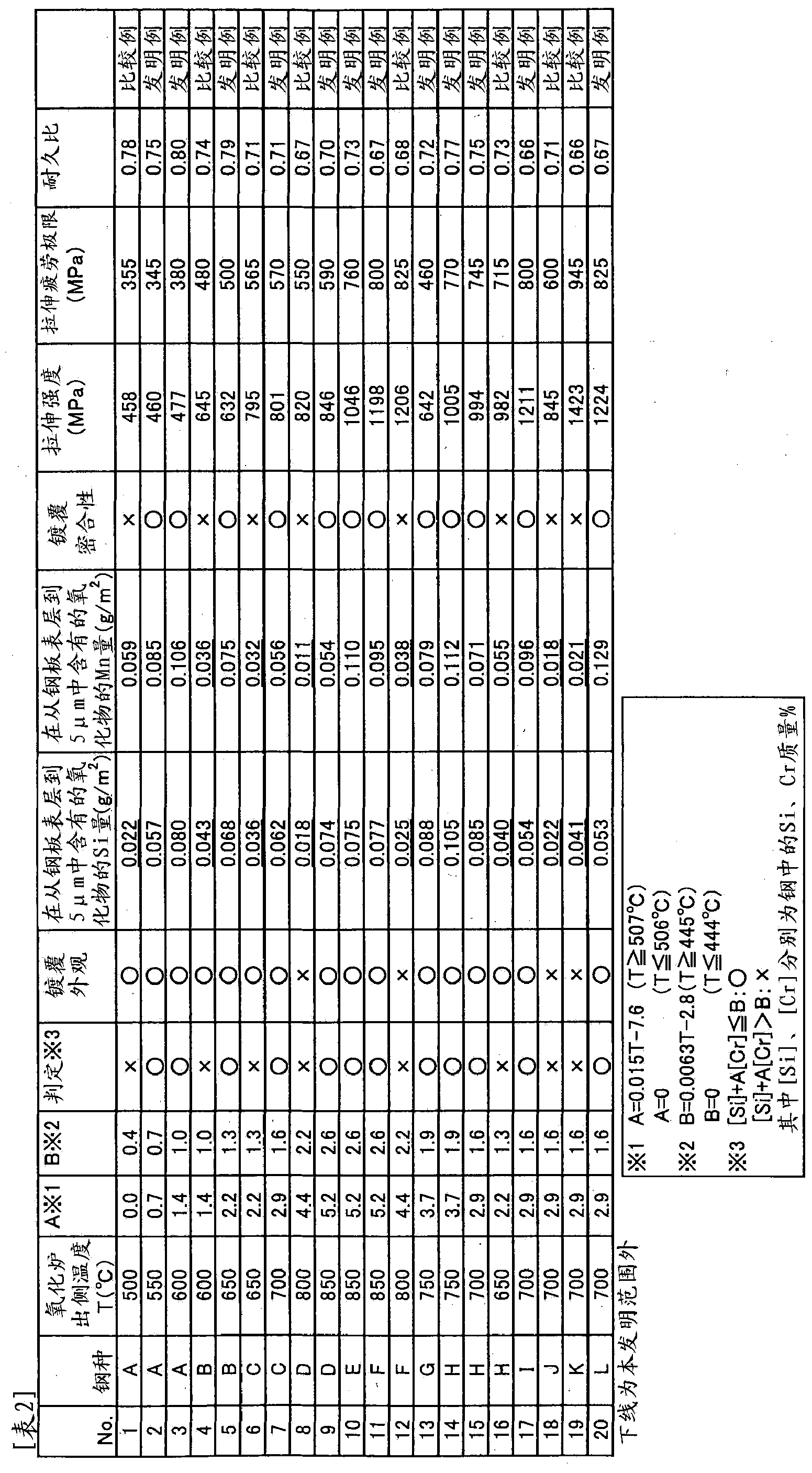

[0121] The cast slabs obtained by melting the steels having the chemical components shown in Table 1 were hot-rolled, pickled, and then cold-rolled to form cold-rolled steel sheets with a thickness of 1.2 mm.

[0122] [Table 1]

[0123] (quality%)

[0124] steel mark

C

Si

mn

Cr

P

S

A

0.03

0.5

2.0

0.1

0.01

0.001

B

0.05

1.0

2.0

0.1

0.01

0.001

C

0.07

1.2

1.9

0.1

0.01

0.001

D

0.08

1.5

1.2

0.2

0.01

0.001

E

0.09

1.5

2.3

0.2

0.01

0.001

F

0.12

1.5

2.5

0.2

0.01

0.001

G

0.09

1.5

1.4

0.02

0.01

0.001

H

0.08

1.5

2.7

0.02

0.01

0.001

I

0.11

1.5

2.7

0.02

0.01

0.001

J

0.09

1.0

1.8

0.6

0.01

0.001

K

0.11

2.3

1.9

0.2 ...

Embodiment 2

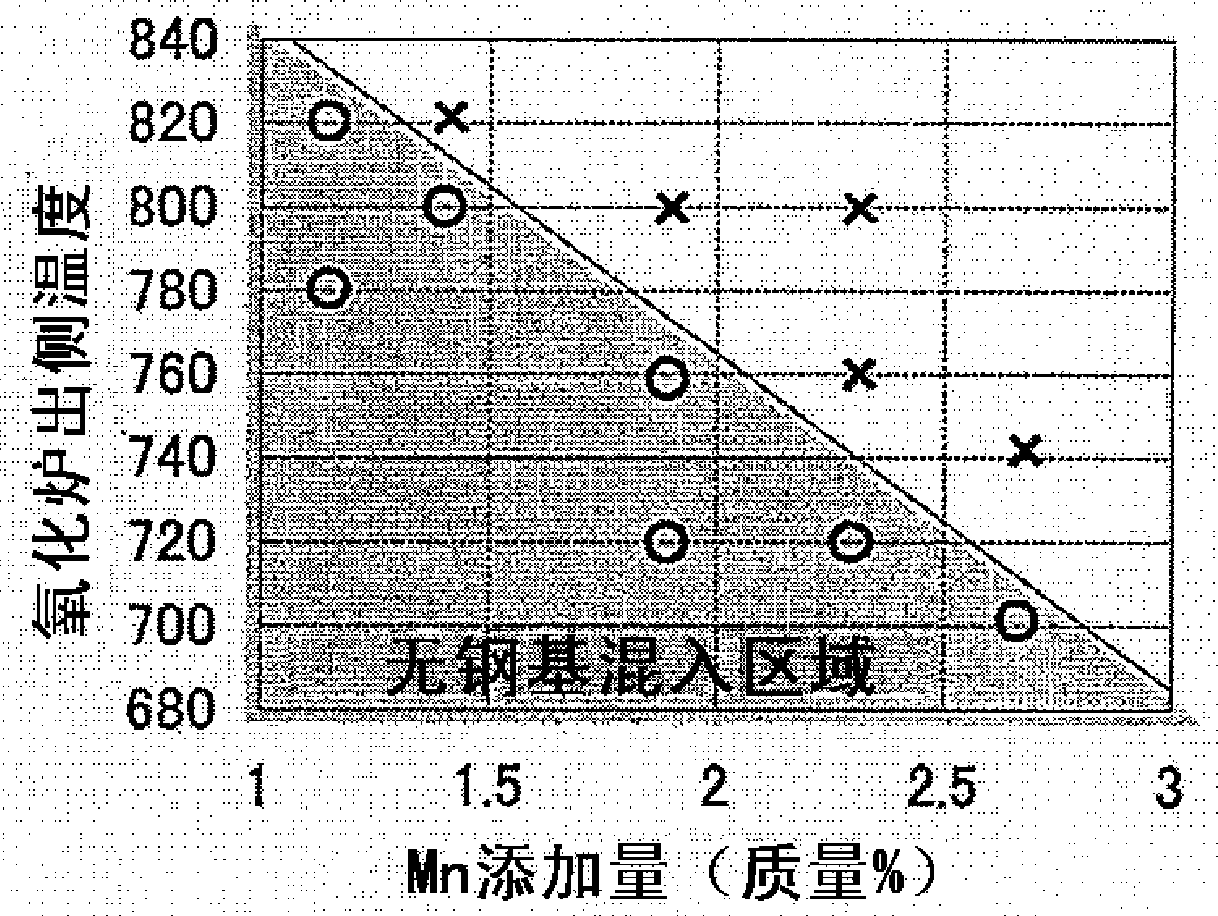

[0139] The cast slabs obtained by melting the steels having the chemical components shown in Table 1 were hot-rolled, pickled, and then cold-rolled to form cold-rolled steel sheets with a thickness of 1.2 mm.

[0140] Thereafter, oxidation treatment and reduction annealing were carried out in the same manner as in Example 1. In addition, the amount of coating was adjusted to about 50 g / m by the gas friction contact method after performing hot-dip plating in a galvanizing bath at 460°C with the added amount of Al adjusted to 0.13%. 2 , alloying treatment was carried out at the predetermined temperature shown in Table 3 for 20 to 30 seconds.

[0141] For the hot-dip galvanized steel sheet obtained as described above, the amount of plating deposition and the Fe content in the plating layer were determined. In addition, quantification of Si and Mn of oxides contained in the coating layer and from the surface layer of the steel sheet under the coating layer to the 5 μm inside of t...

Embodiment 3

[0157] The cast slabs obtained by melting the steels having the chemical components shown in Table 1 were hot-rolled, pickled, and then cold-rolled to form cold-rolled steel sheets with a thickness of 1.2 mm.

[0158] Thereafter, oxidation treatment, reduction annealing, plating, and alloying treatment were performed in the same manner as in Example 2. However, among these, the inside of the oxidation furnace is divided into three areas, and the temperature on the outlet side and the oxygen concentration in the atmosphere are adjusted by variously changing the respective combustion rates and air ratios.

[0159] For the hot-dip galvanized steel sheet obtained as described above, the plating deposition amount and the Fe content in the plating layer were determined. Furthermore, quantification of Si and Mn of oxides contained in the coating layer and from the surface layer of the steel sheet under the coating layer to the 5 μm inside of the steel sheet was carried out, and the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com