Manufacturing method of high-strength hot-dip galvanized steel sheet and manufacturing method of high-strength alloyed hot-dip galvanized steel sheet

A technology of hot-dip galvanized steel sheet and manufacturing method, applied in the direction of hot-dip galvanizing process, manufacturing tools, chemical instruments and methods, etc., can solve the problems that the appearance of steel sheet plating is not improved, Cr oxide cannot be removed, etc., and achieve the goal of galvanizing Excellent coating adhesion and improved fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach >

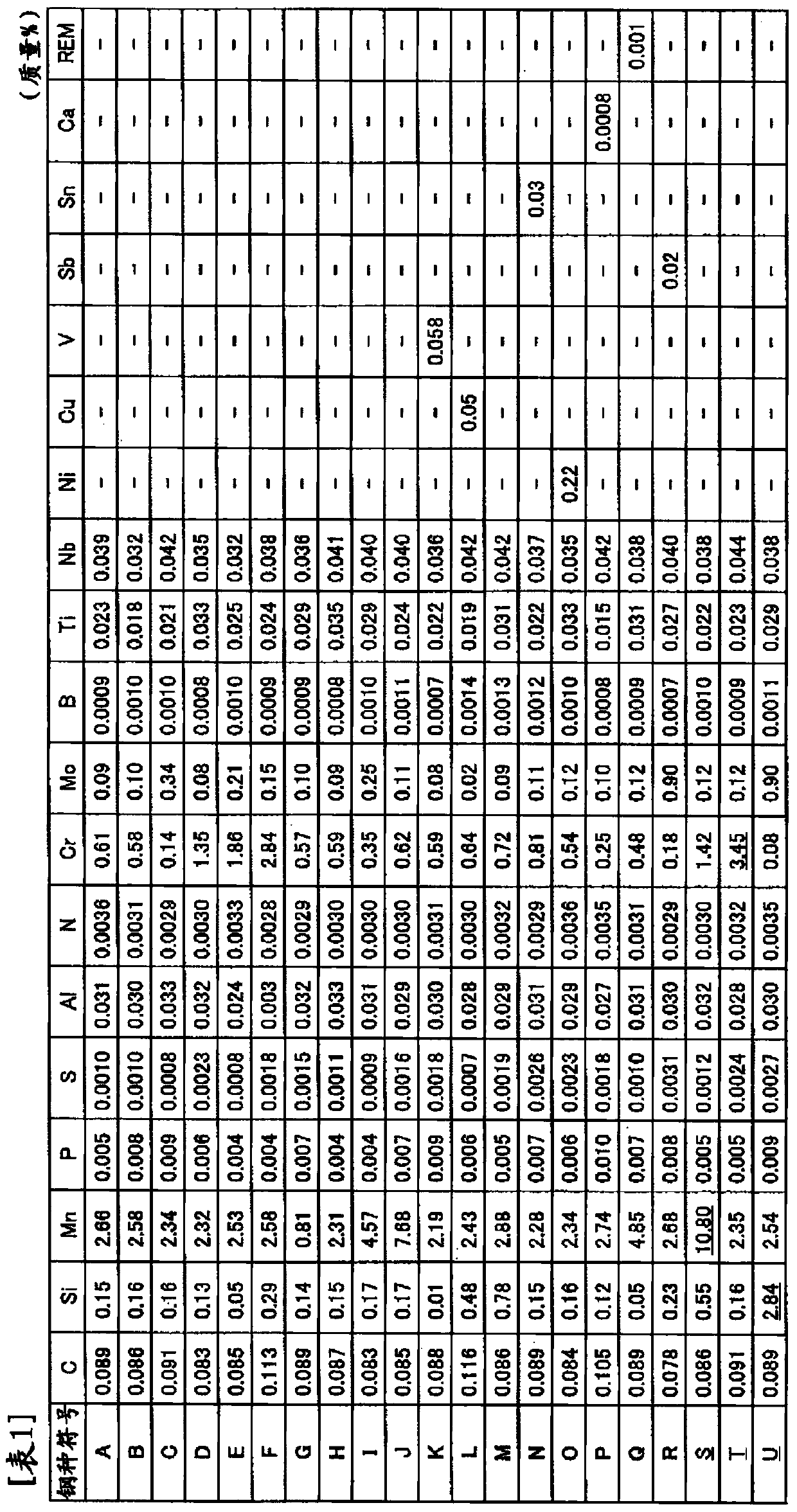

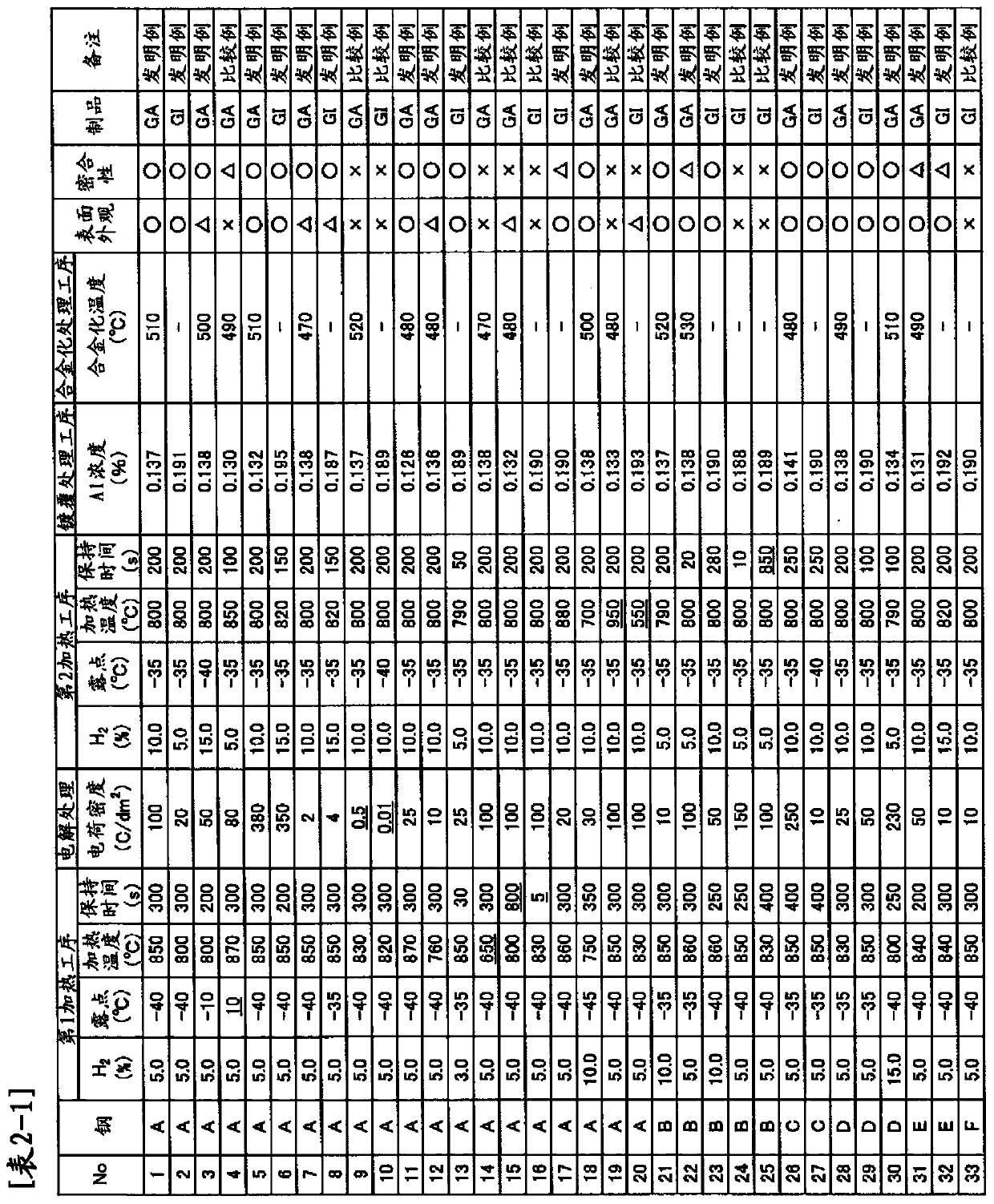

[0028] First, a steel plate as a raw material used in the production method according to the first embodiment of the present invention will be described. The steel sheet as a raw material contains C: 0.040% to 0.500%, Si: 1.00% or less, Cr: 0.10% to 2.00%, Mn: 5.00% or less, P: 0.100% or less, S: 0.0100% or less in mass % , Al: 0.100% or less, and the remainder is composed of Fe and unavoidable impurities. In addition, in addition to the above-mentioned components, in terms of mass %, it may further contain Mo: 0.01% to 0.50%, Nb: 0.010% to 0.100%, B: 0.0001% to 0.0050%, and Ti: 0.010% to 0.100%. At least 1 element. In addition, in addition to the above-mentioned components, in terms of mass%, it may further contain Cu: 1.00% or less, V: 0.500% or less, Ni: 0.50% or less, N: 0.0100% or less, Sb: 0.10% or less, Sn: 0.10% % or less, Ca: 0.0100% or less, and REM: 0.010% or less. Hereinafter, each component is demonstrated.

[0029] C: 0.040% to 0.500%

[0030] C is an elemen...

no. 2 approach >

[0090] First, a steel plate as a raw material used in the production method according to the second embodiment of the present invention will be described. The steel sheet as a raw material contains C: 0.040% to 0.500%, Si: 1.00% or less, Cr: 0.10% to 2.00%, Mn: 8.00%, P: 0.100% or less, S: 0.0100% or less, Al: 0.100% or less, and the remainder consists of Fe and unavoidable impurities. In addition, the above-mentioned steel sheet may contain at least one element selected from the group consisting of Mo: 0.01% to 0.50%, Nb: 0.010% to 0.100%, B: 0.0001% to 0.0050%, and Ti: 0.010% to 0.100% in mass % . In addition, in terms of mass%, Cu: 1.00% or less, V: 0.500% or less, Ni: 0.50% or less, N: 0.0100% or less, Sb: 0.10% or less, Sn: 0.10% or less, Ca: At least one element of 0.0100% or less and REM: 0.010% or less.

[0091] Components other than Mn are the same as those in the first embodiment, and therefore descriptions of components other than Mn are omitted. In addition, si...

no. 3 approach >

[0101] First, a steel plate as a raw material used in the manufacturing method according to the third embodiment of the present invention will be described. The raw steel sheet contains C: 0.040% to 0.500%, Si: 1.00% or less, Cr: 0.10% to 3.00%, Mn: 8.00% or less, P: 0.100% or less, S: 0.0100% or less, Al : 0.100% or less, the remainder is composed of Fe and unavoidable impurities. In addition, the above-mentioned steel sheet may contain at least one element selected from the group consisting of Mo: 0.01% to 0.50%, Nb: 0.010% to 0.100%, B: 0.0001% to 0.0050%, and Ti: 0.010% to 0.100% in mass % . In addition, in terms of mass%, Cu: 1.00% or less, V: 0.500% or less, Ni: 0.50% or less, N: 0.0100% or less, Sb: 0.10% or less, Sn: 0.10% or less, Ca: At least one element of 0.0100% or less and REM: 0.010% or less.

[0102] The above-mentioned steel sheet used in the third embodiment is almost the same as the steel sheet used as a raw material in the manufacturing method of the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com