Resin composition, resin sheet, multilayer printed circuit board, and semiconductor device

A resin composition and resin technology, applied in the directions of printed circuits, printed circuit components, circuit substrate materials, etc., can solve the problems of long processing time, and achieve the effects of excellent heat resistance and excellent developability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0228] Hereinafter, although an Example demonstrates this invention more concretely, this invention is not limited at all by these Examples.

Synthetic example 1

[0230] (Synthesis of Cyanate Compounds)

[0231] Dissolve 1-naphthol aralkyl resin (manufactured by Nippon Steel & Sumikin Chemical Co., Ltd.) 300 g (1.28 mol in terms of OH groups) and 194.6 g (1.92 mol) of triethylamine (1.5 mol per 1 mol of hydroxyl group) This was made into solution 1 in 1800 g of dichloromethane.

[0232] Under the condition of stirring, 125.9g (2.05mol) of cyanogen chloride (1.6mol relative to 1mol of hydroxyl), 293.8g of dichloromethane, 194.5g (1.92mol) of 36% hydrochloric acid (1.5mol of relative to 1mol of hydroxyl) 1. Water 1205.9g was kept at a liquid temperature of -2 to -0.5°C, and the solution 1 was injected for 30 minutes. After solution 1 was injected, it was stirred at this temperature for 30 minutes, and then a solution obtained by dissolving 65 g (0.64 mol) of triethylamine (0.5 mol per 1 mol of hydroxyl) in 65 g of dichloromethane was injected over 10 minutes (solution 2 ). After the injection of solution 2 was completed, the reaction w...

Embodiment 1

[0236] (Manufacture of resin composition and resin sheet)

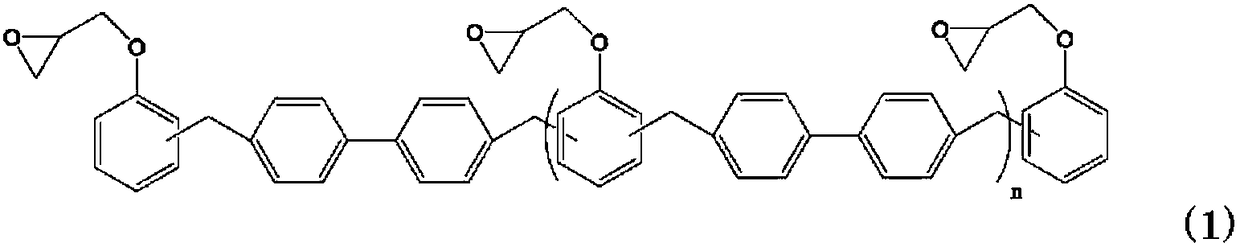

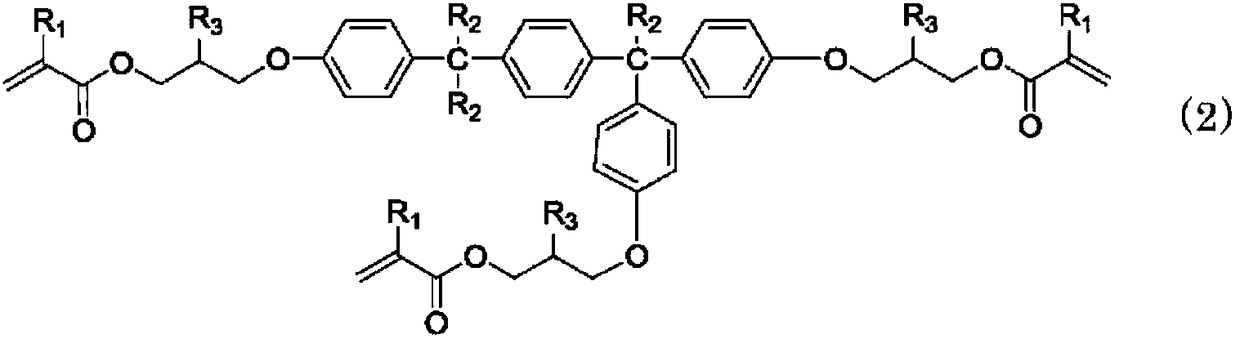

[0237] The biphenyl aralkyl type epoxy resin (n in the formula (1) is 1-3 as the biphenyl aralkyl type epoxy resin (A) represented by formula (1). NC3000L (trade name), Nippon Kayaku Co., Ltd.) 22.4 parts by mass, 2-benzyl-2-dimethylamino-1-(4-morpholinophenyl)-butanone-1 (Irgacure (registered trademark) 369, manufactured by BASFJAPAN LTD.) 6.5 parts by mass, propylene glycol monomethyl ether acetate (hereinafter sometimes abbreviated as PGMEA.) solution of TrisP-PA epoxy acrylate compound as compound (C) (KAYARAD (registered Trademark) ZCR-6007H, non-volatile content 65% by mass, acid value: 70 mgKOH / g, manufactured by Nippon Kayaku Co., Ltd.) 77.5 parts by mass (50.4 parts by mass in terms of non-volatile content), as components other than (C) 17.4 parts by mass of dipentaerythritol hexaacrylate (KAYARAD (registered trademark) DPHA, manufactured by Nippon Kayaku Co., Ltd.) of the compound (D) having an ethylenicall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com