Patents

Literature

265results about How to "Reduce grain size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

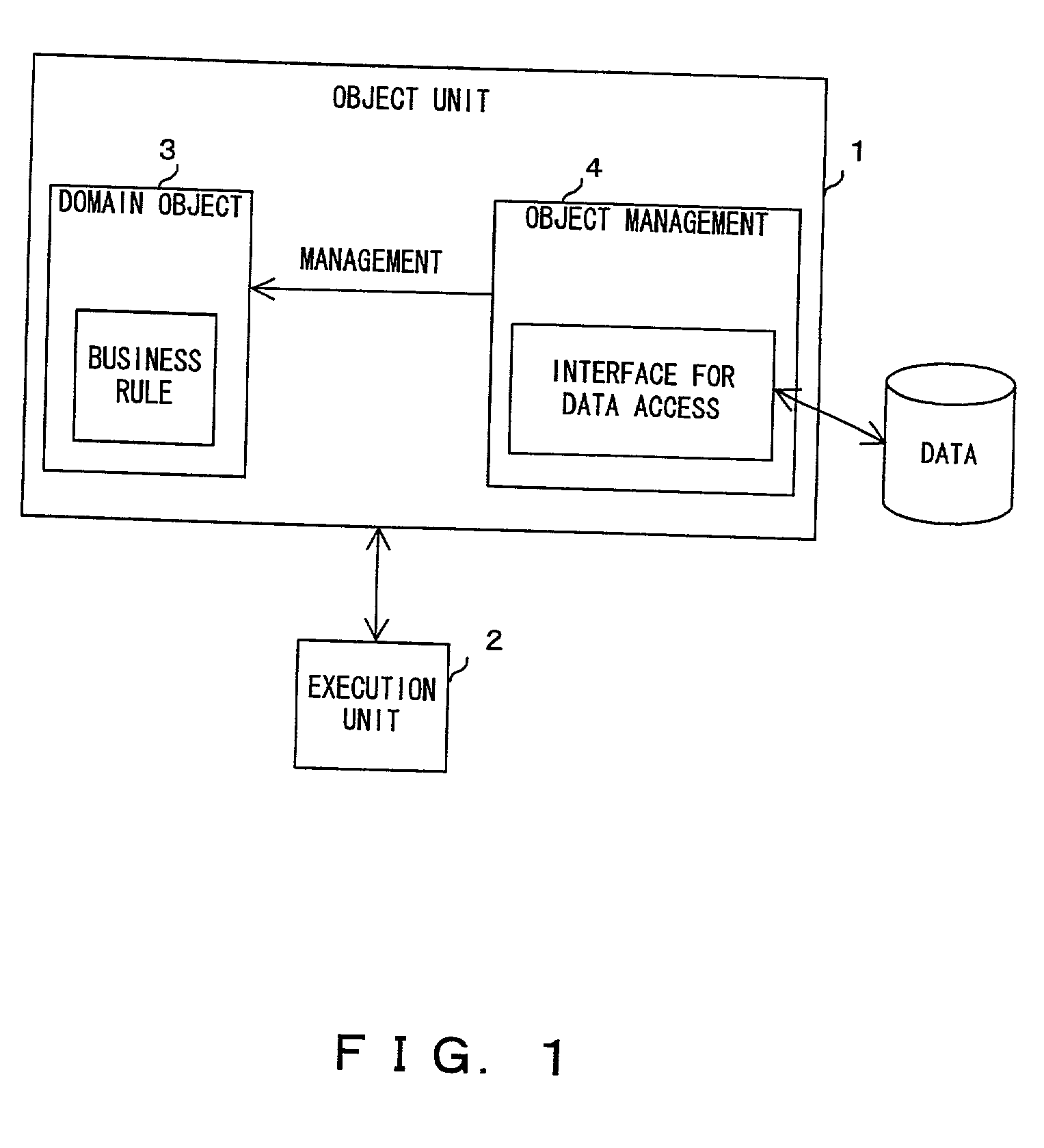

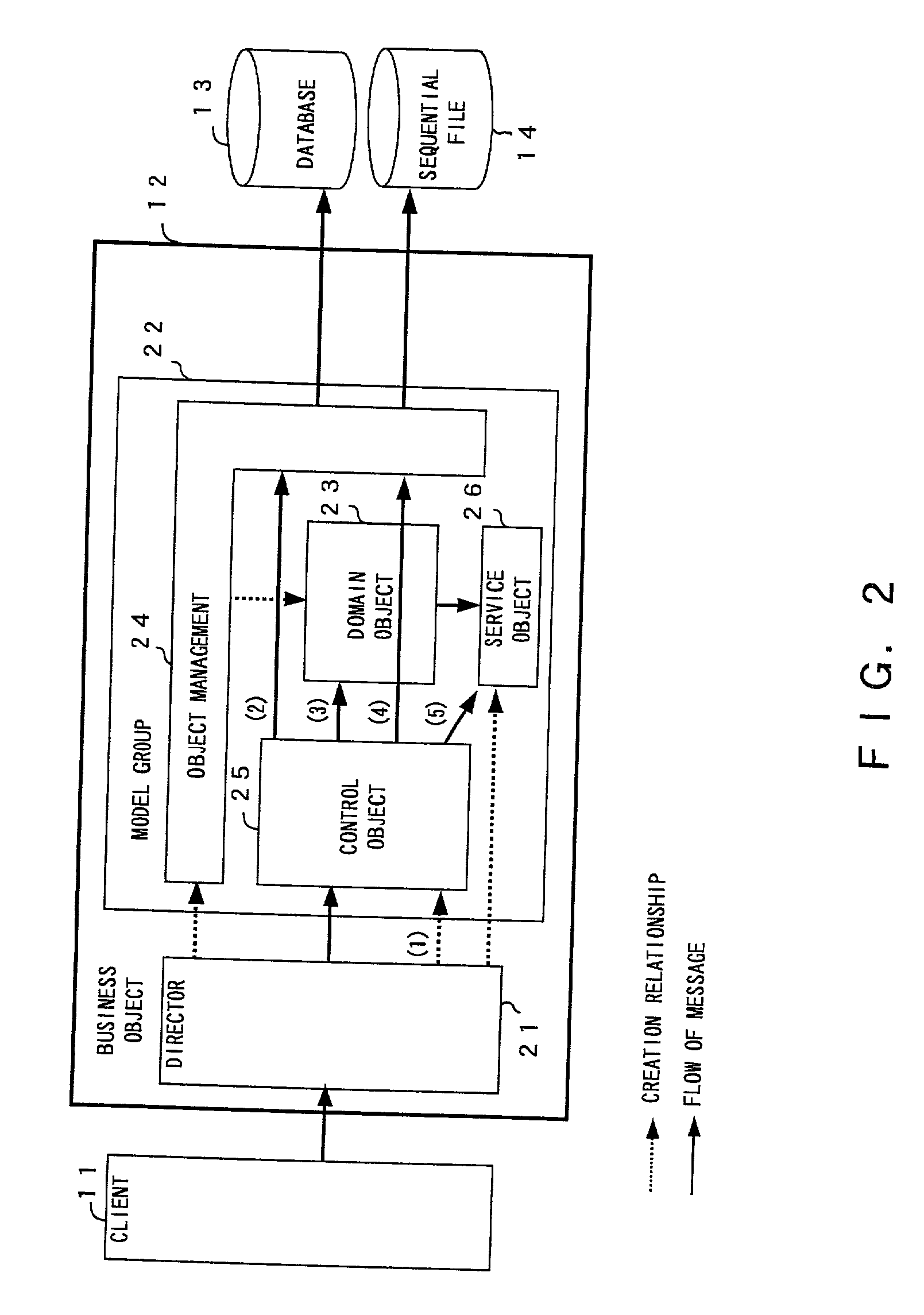

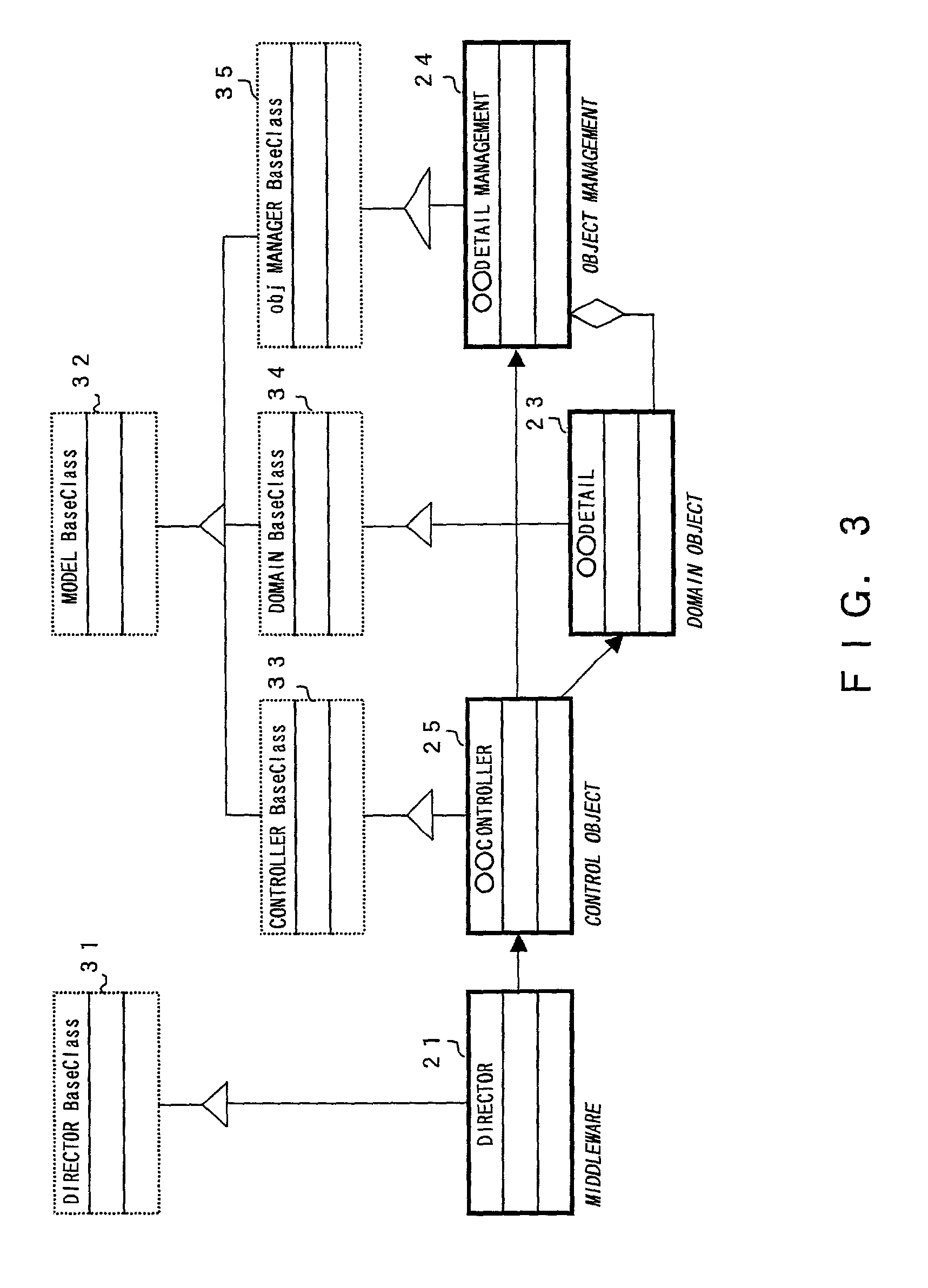

Object-oriented business system and method

InactiveUS20010009033A1Degree of improvementReduce grain sizeProgram control using stored programsOffice automationData accessObject store

A domain object stores a business rule, and an object management is provided with an interface for data access. A service object executes a service requested by other objects. A control object controls the collaboration relationship among these objects according to the process request from a client, and notifies the client of the process result.

Owner:FUJITSU LTD

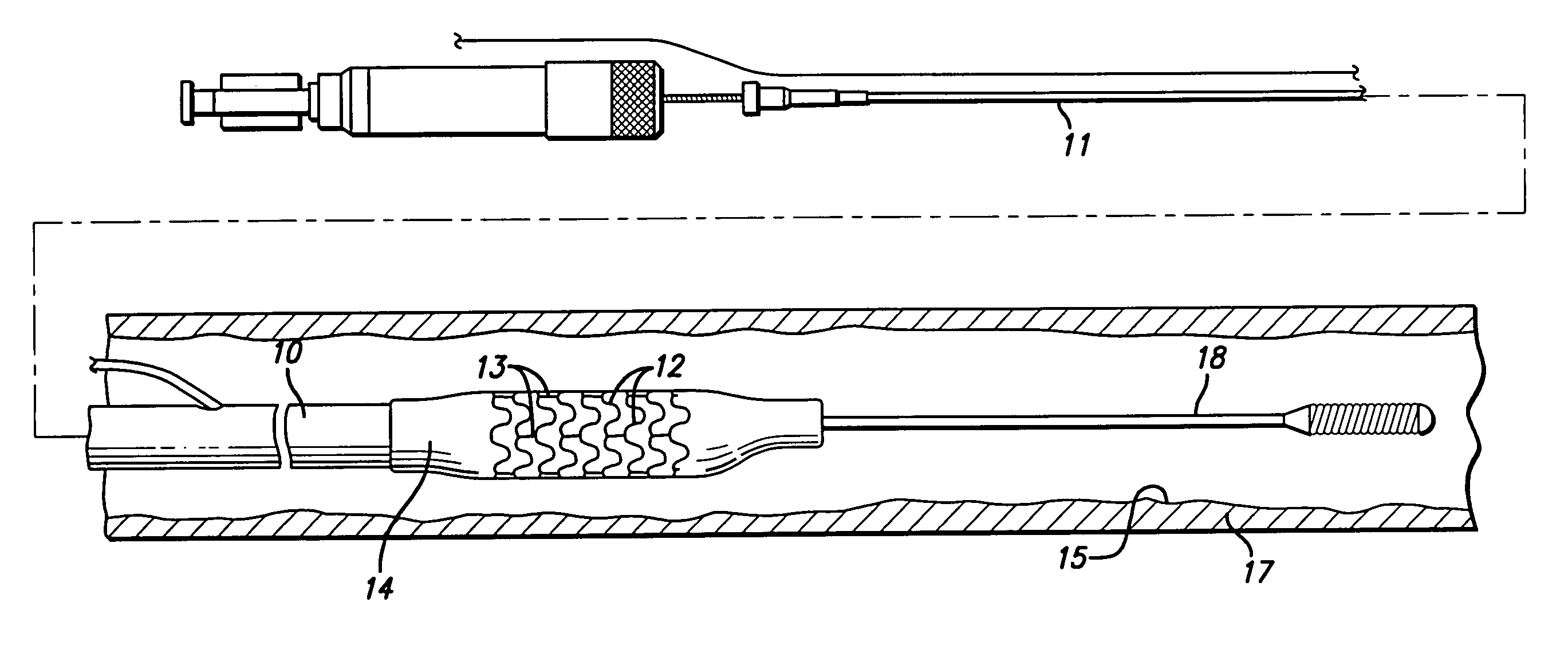

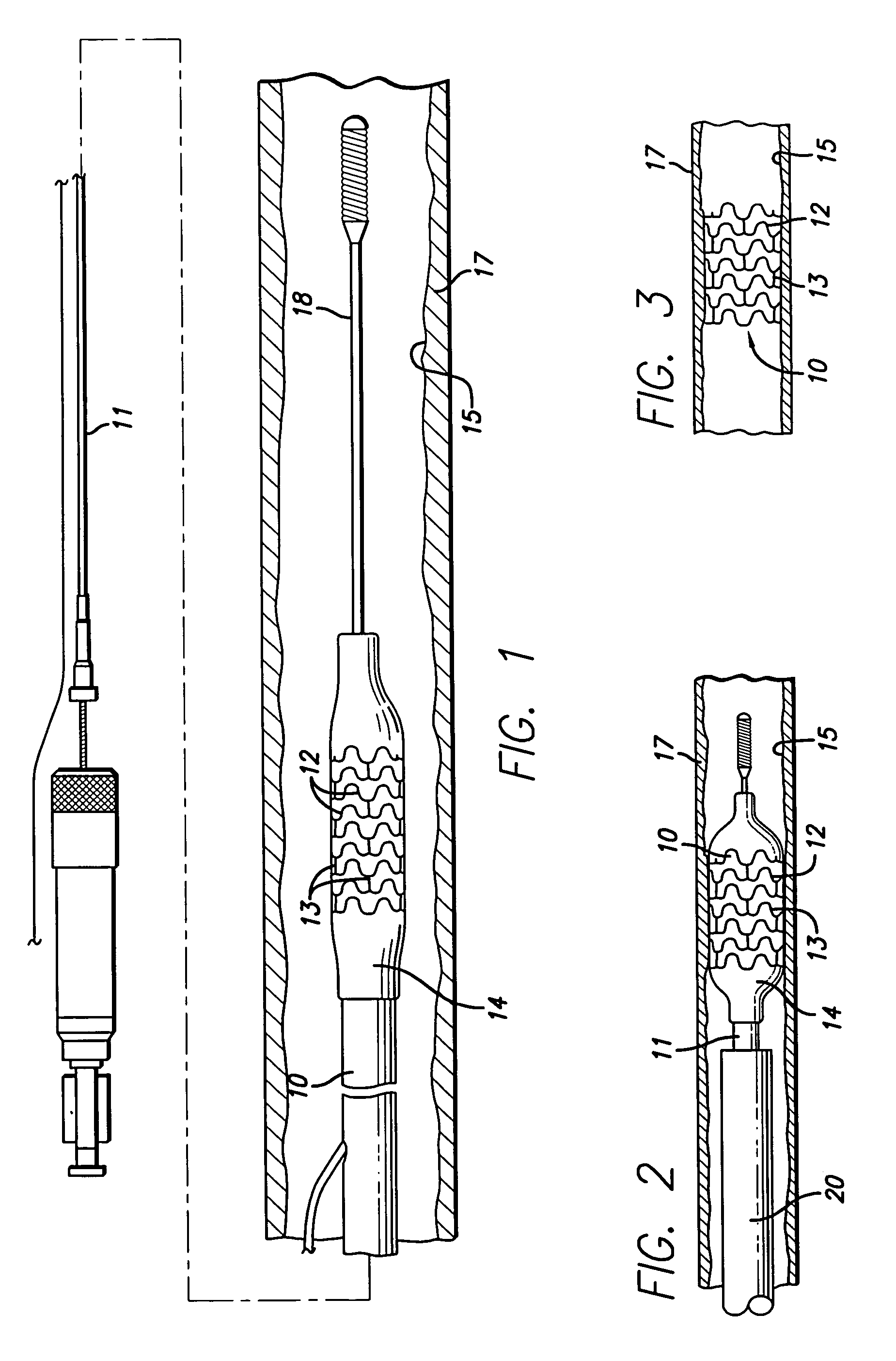

Method and apparatus for thermal spray processing of medical devices

InactiveUS7201940B1Reduce grain sizeReduce in quantityMolten spray coatingSurgeryArterial prosthesisThermal spraying

Owner:ABBOTT CARDIOVASCULAR

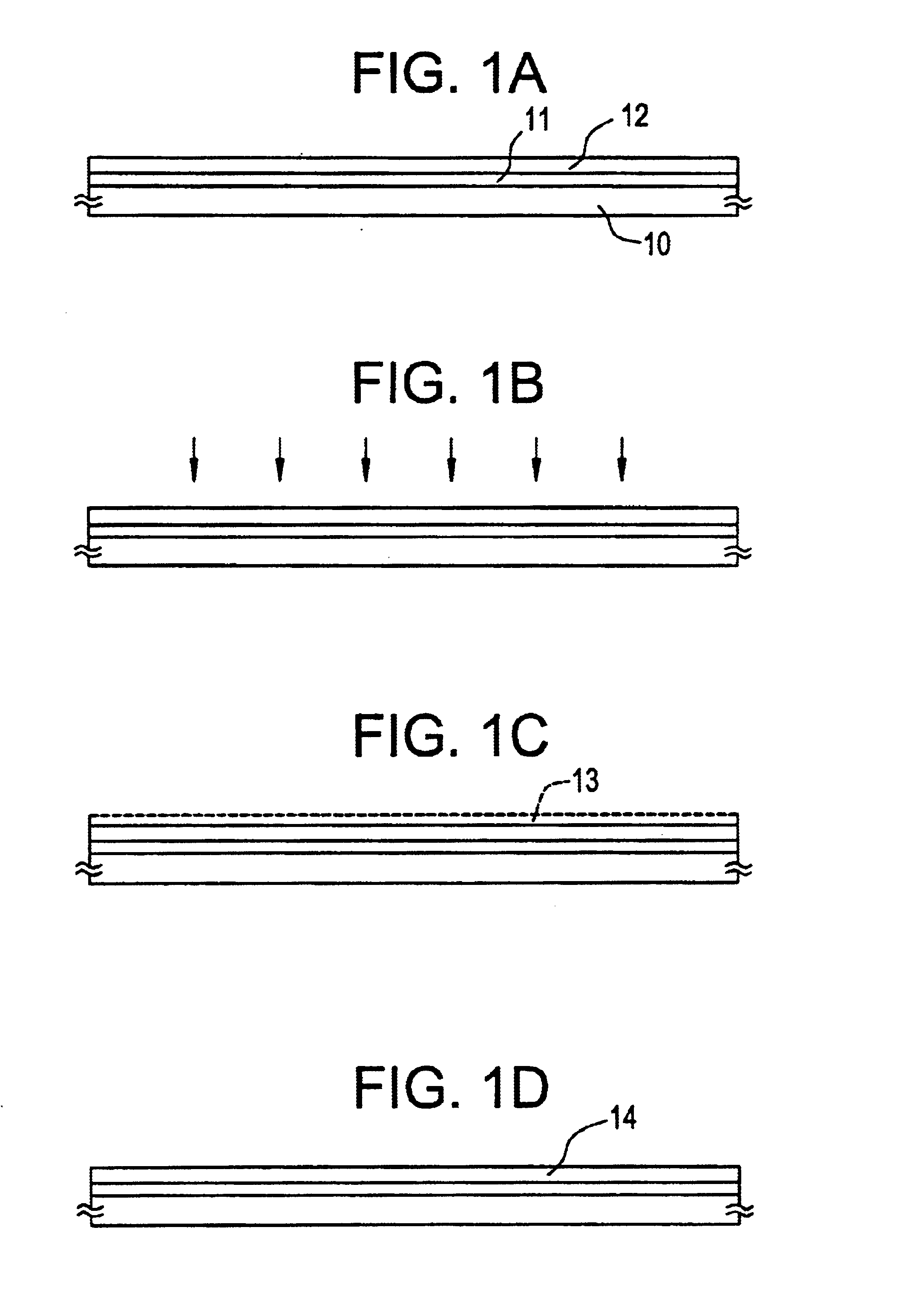

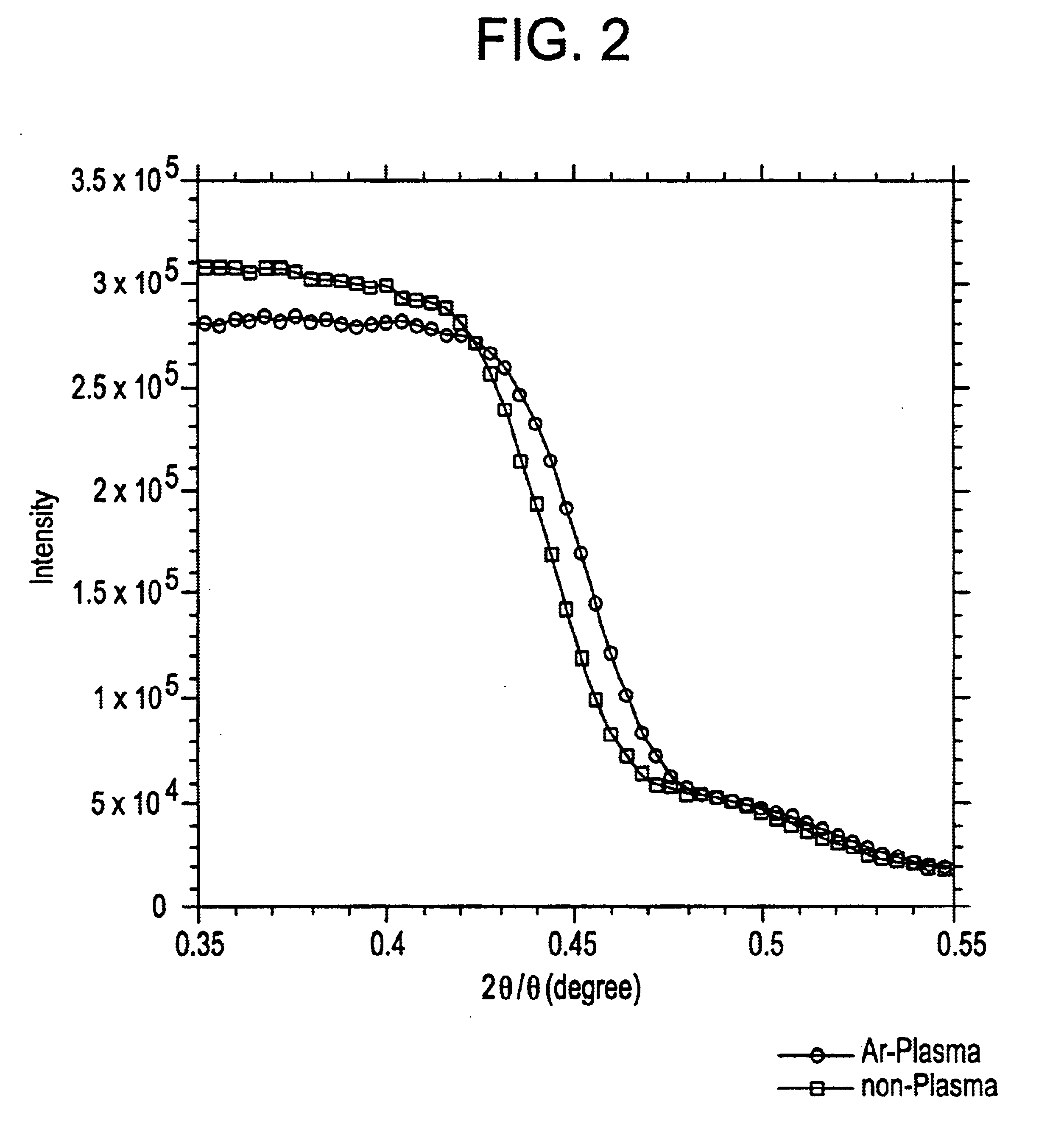

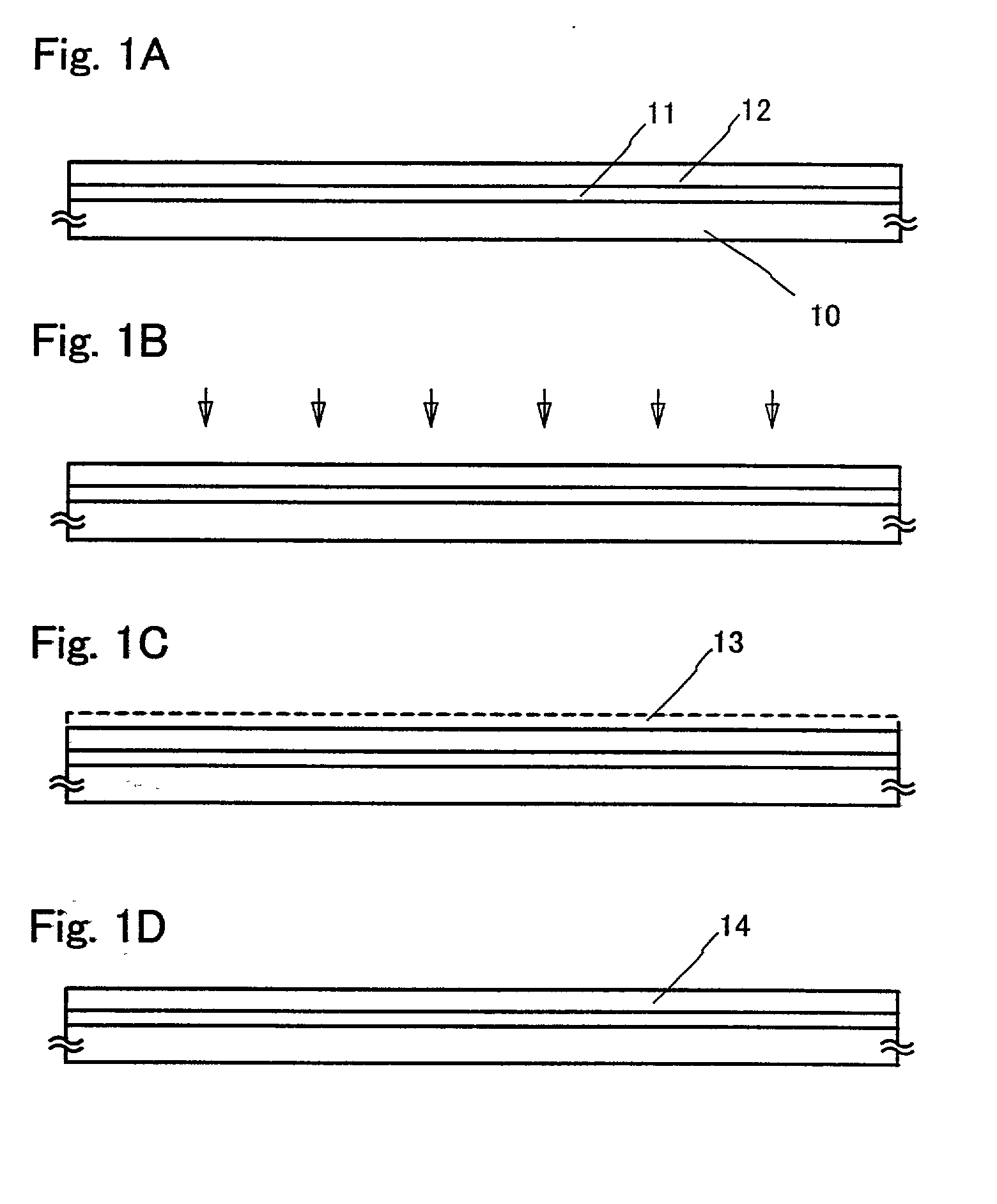

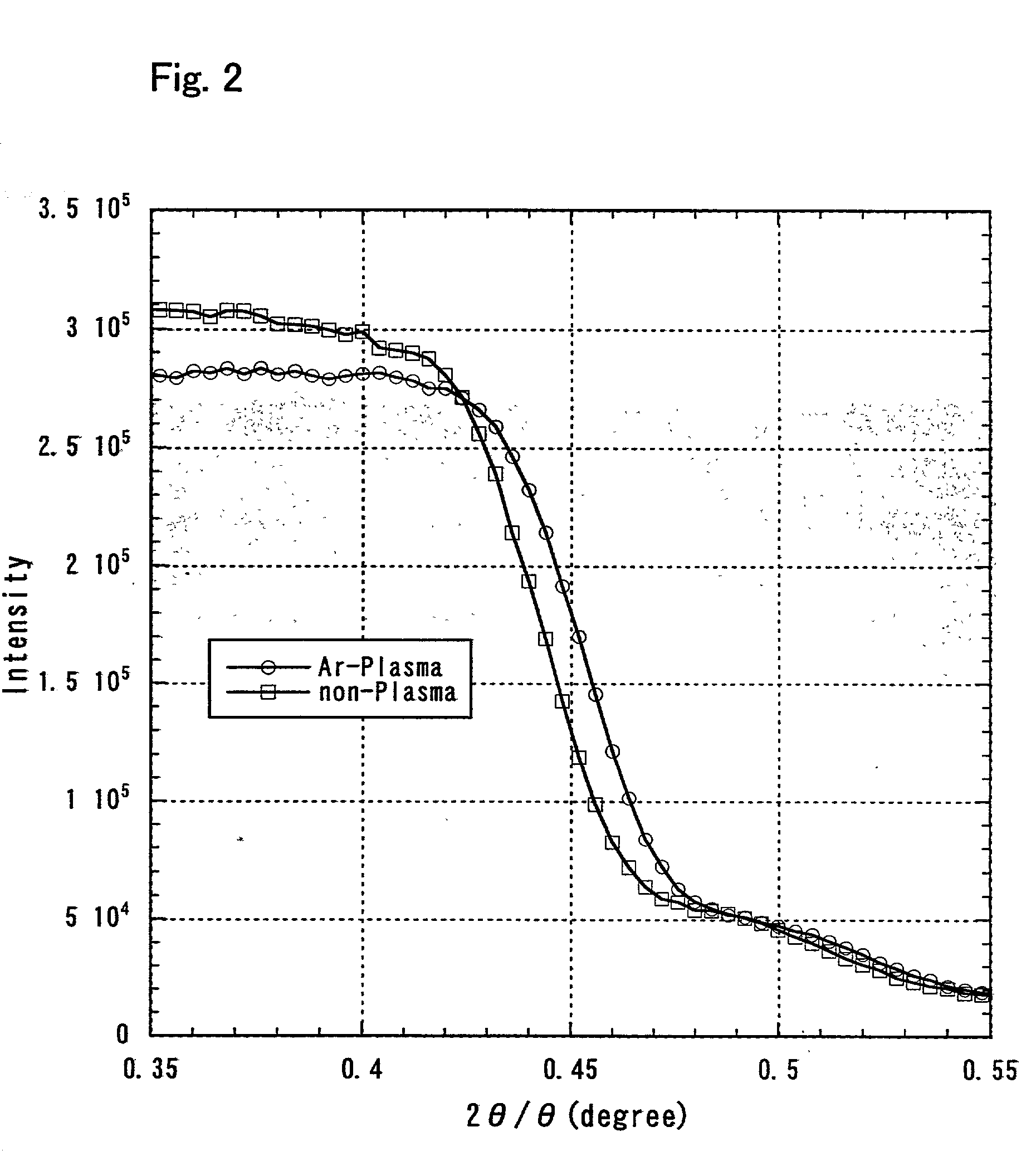

Method of manufacturing a semiconductor device having a crystallized semiconductor film

InactiveUS6830994B2High densityChemical potential of the semiconductor film is increasedTransistorSolid-state devicesAtmospheric airNitrogen

The number of grains in active regions of devices can be made uniform by making the grains of crystalline semiconductor films, obtained by thermal crystallization using a metal element, smaller. The present invention is characterized in that a semiconductor film is exposed within an atmosphere in which a gas, having as its main constituent one or a plurality of members from the group consisting of inert gas elements, nitrogen, and ammonia, is processed into a plasma, and then thermal crystallization using a metal element is performed. The concentration of crystal nuclei1 generated is thus increased, making the grain size smaller, by performing these processes. Heat treatment may also be performed, of course, after exposing the semiconductor film, to which the metal element is added, to an atmosphere in which a gas, having as its main constituent one or a plurality of members from the group consisting of inert gas elements, nitrogen, and ammonia, is processed into a plasma.

Owner:SEMICON ENERGY LAB CO LTD

Method of manufacturing a semiconductor device

InactiveUS20020155706A1High densityChemical potential of the semiconductor film is increasedTransistorSolid-state devicesAtmospheric airNitrogen

The number of grains in active regions of devices can be made uniform by making the grains of crystalline semiconductor films, obtained by thermal crystallization using a metal element, smaller. The present invention is characterized in that a semiconductor film is exposed within an atmosphere in which a gas, having as its main constituent one or a plurality of members from the group consisting of inert gas elements, nitrogen, and ammonia, is processed into a plasma, and then thermal crystallization using a metal element is performed. The concentration of crystal nuclei1 generated is thus increased, making the grain size smaller, by performing these processes. Heat treatment may also be performed, of course, after exposing the semiconductor film, to which the metal element is added, to an atmosphere in which a gas, having as its main constituent one or a plurality of members from the group consisting of inert gas elements, nitrogen, and ammonia, is processed into a plasma.

Owner:SEMICON ENERGY LAB CO LTD

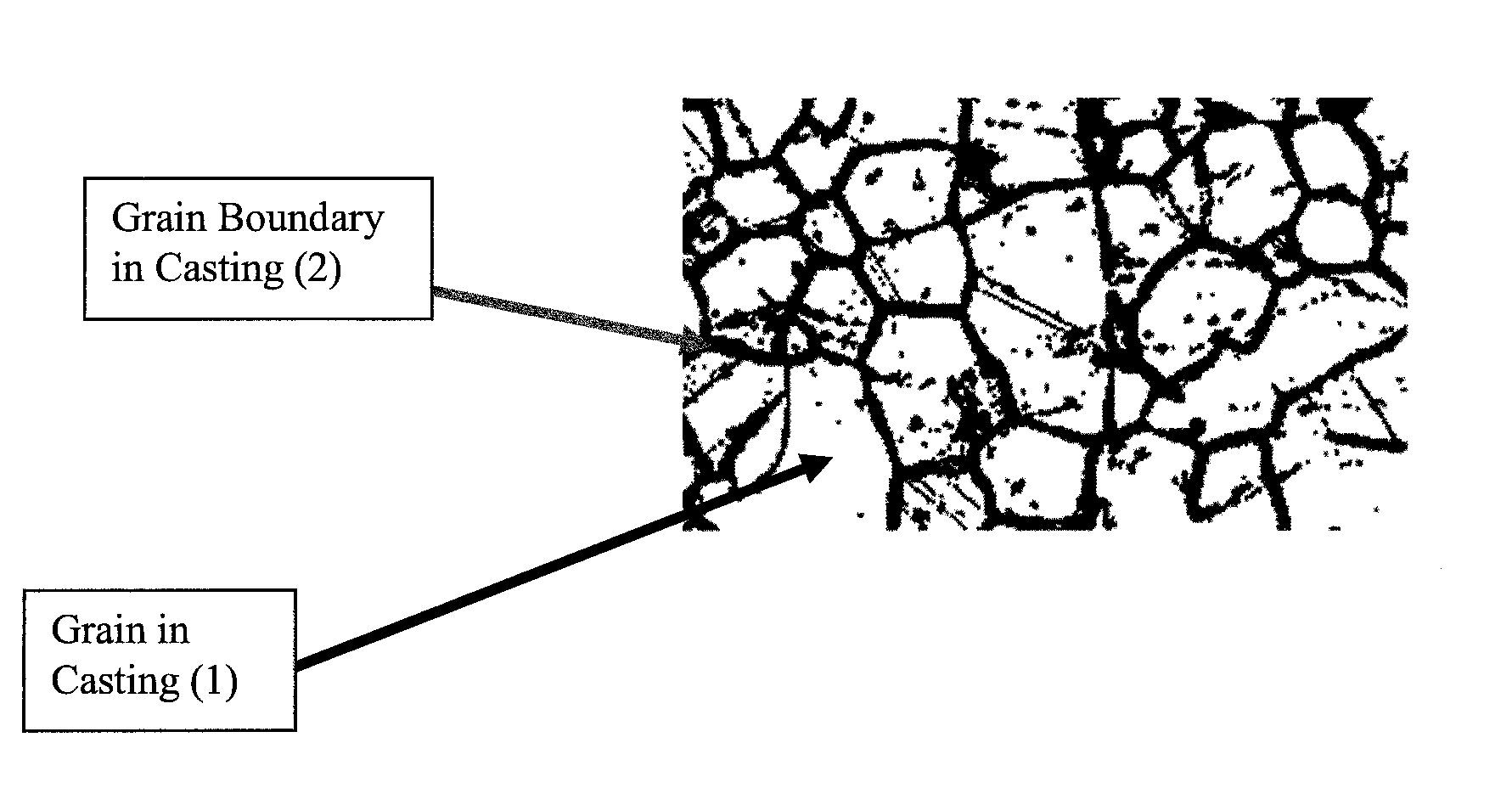

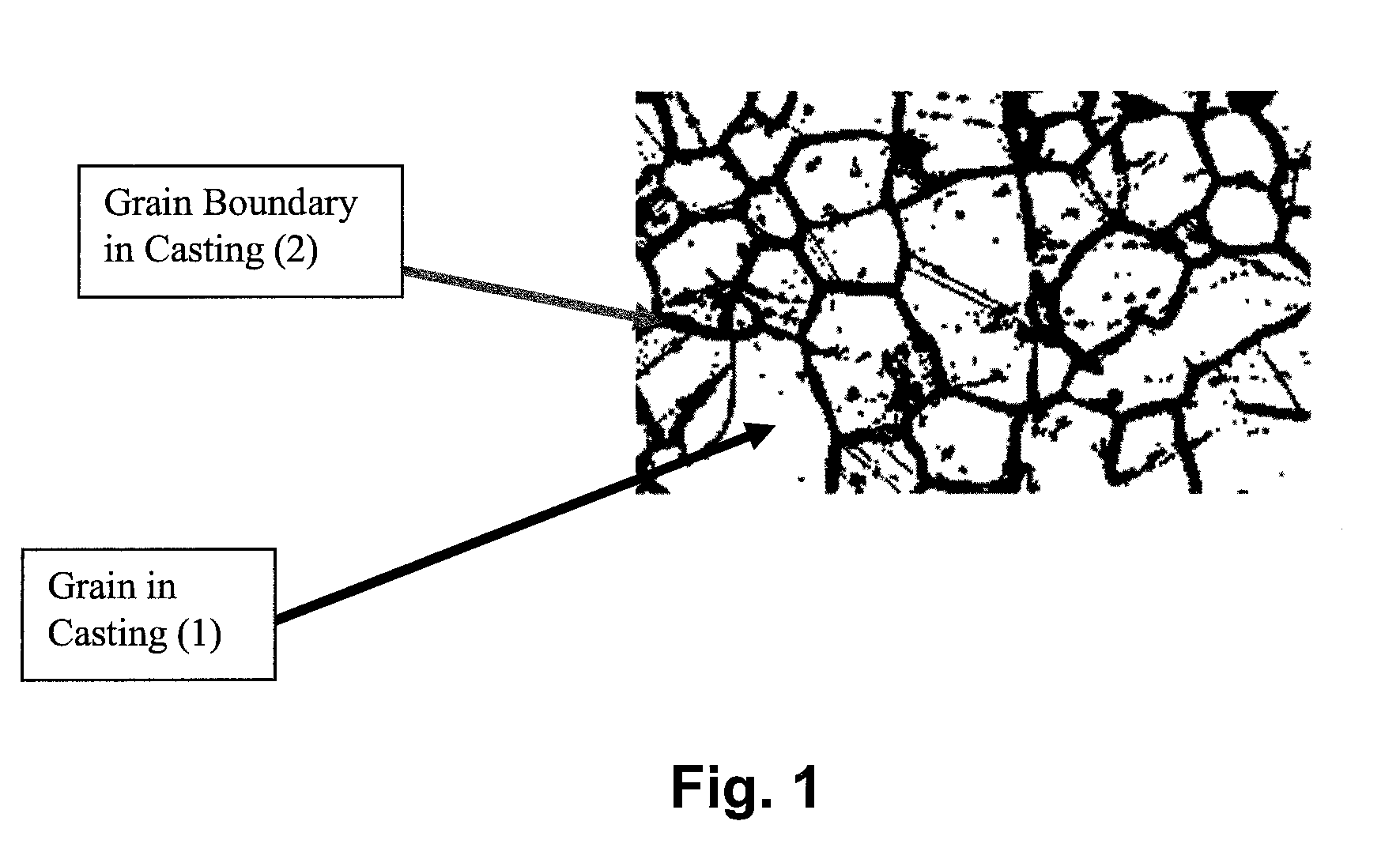

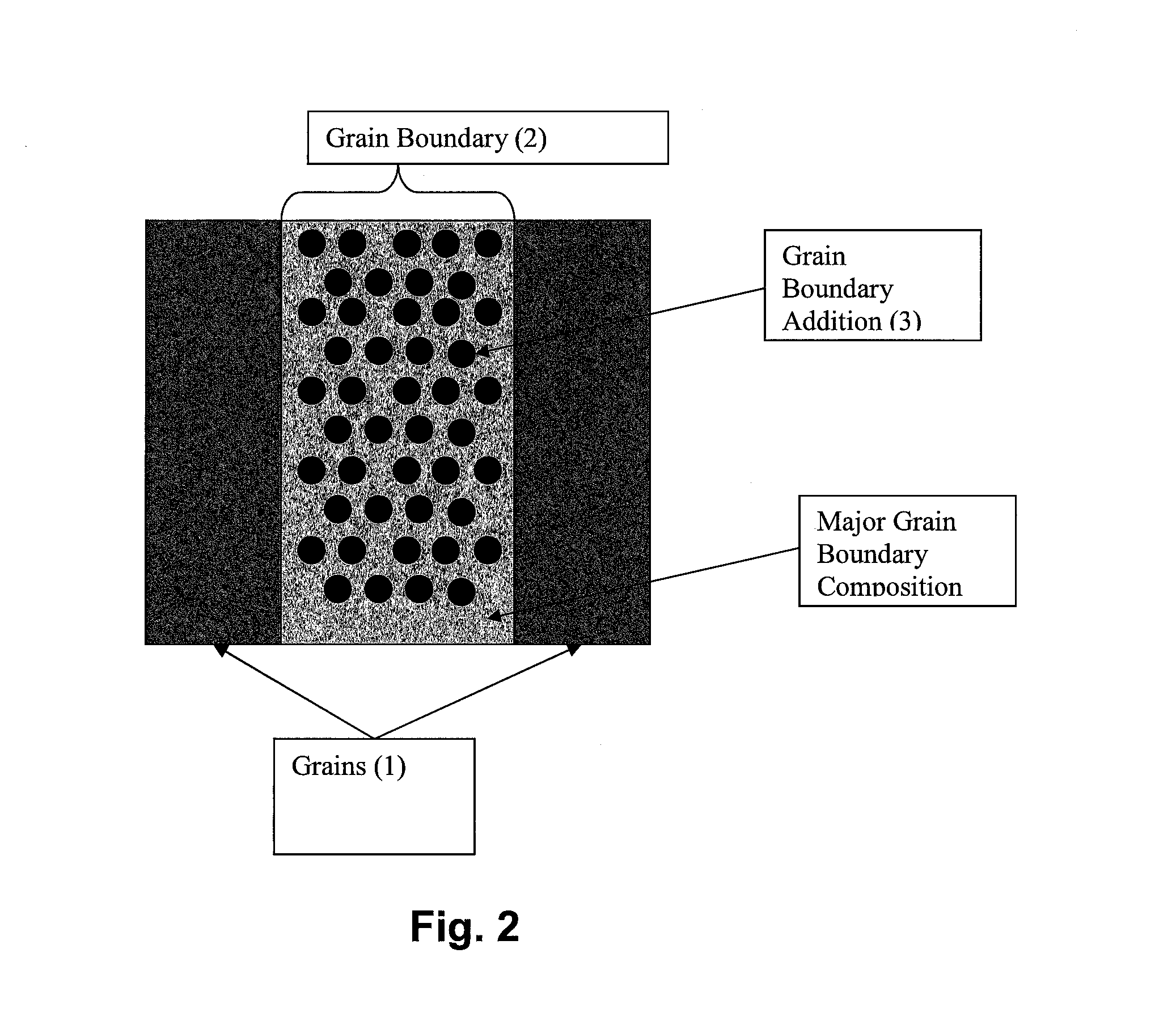

Manufacture of Controlled Rate Dissolving Materials

ActiveUS20150240337A1Improve ductilityImprove propertiesTransportation and packagingMetal-working apparatusAlloyBase metal alloy

A castable, moldable, or extrudable structure using a metallic base metal or base metal alloy. One or more insoluble additives are added to the metallic base metal or base metal alloy so that the grain boundaries of the castable, moldable, or extrudable structure includes a composition and morphology to achieve a specific galvanic corrosion rates partially or throughout the structure or along the grain boundaries of the structure. The insoluble additives can be used to enhance the mechanical properties of the structure, such as ductility and / or tensile strength. The insoluble particles generally have a submicron particle size. The final structure can be enhanced by heat treatment, as well as deformation processing such as extrusion, forging, or rolling, to further improve the strength of the final structure as compared to the non-enhanced structure.

Owner:TERVES

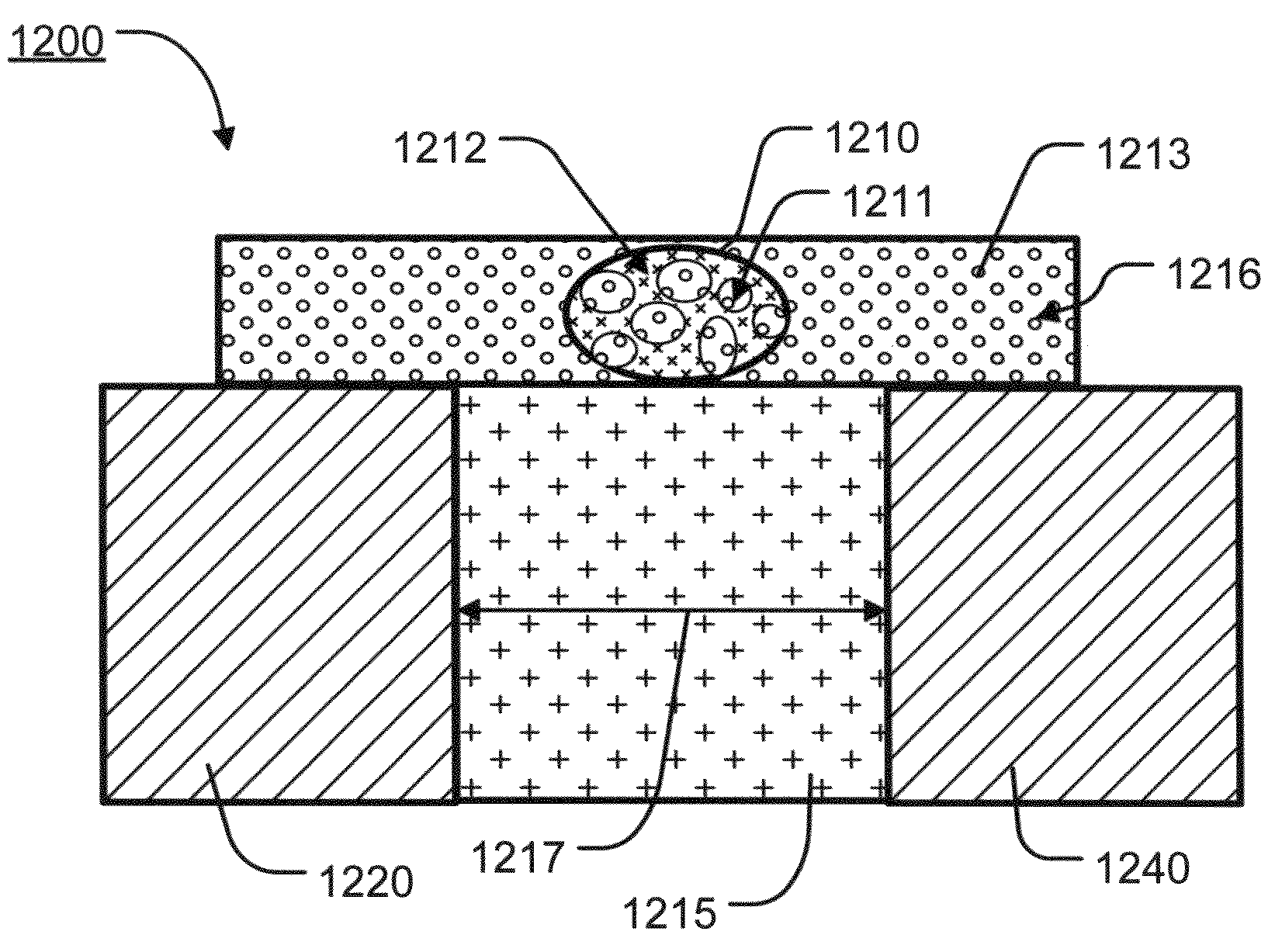

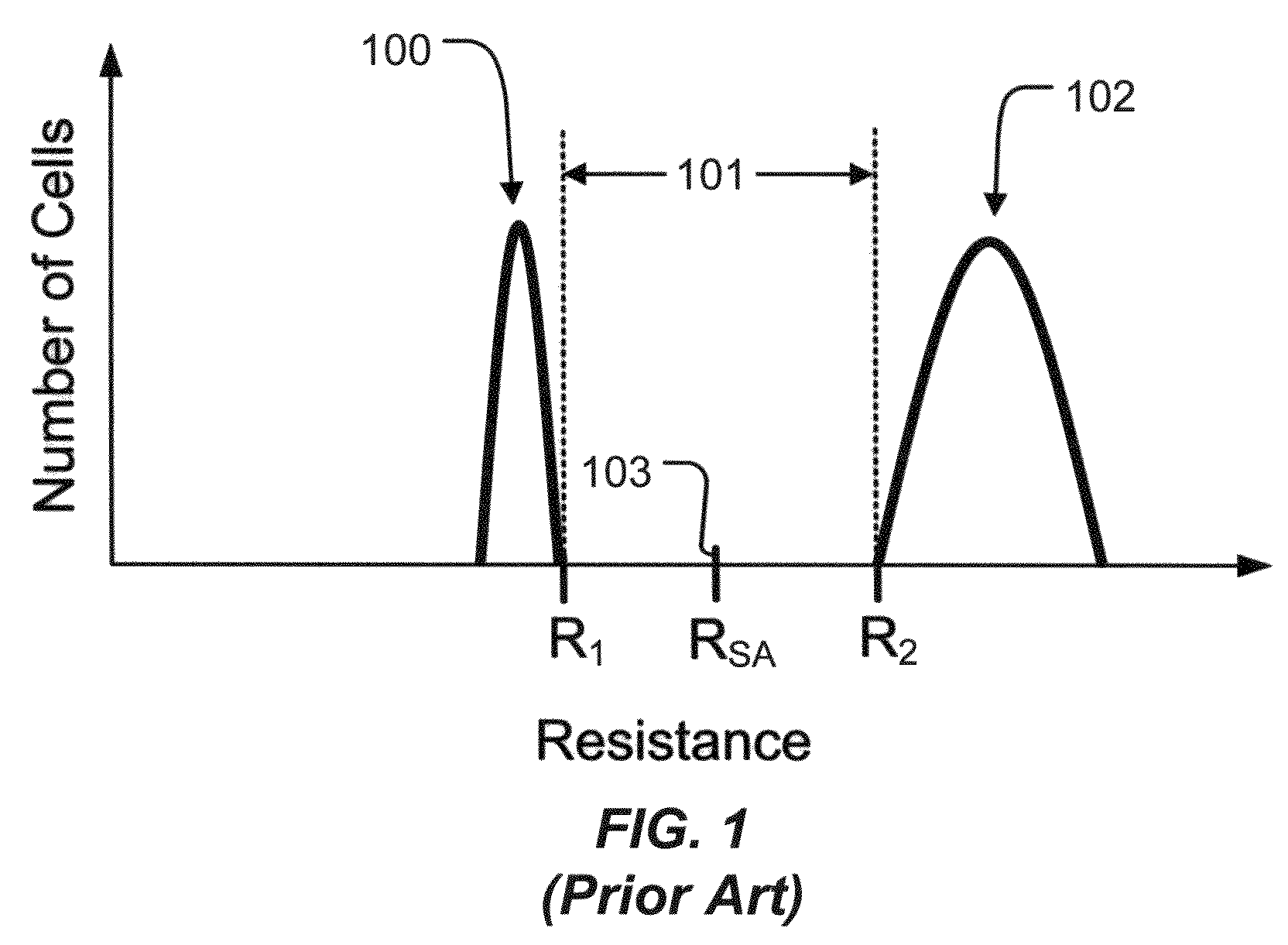

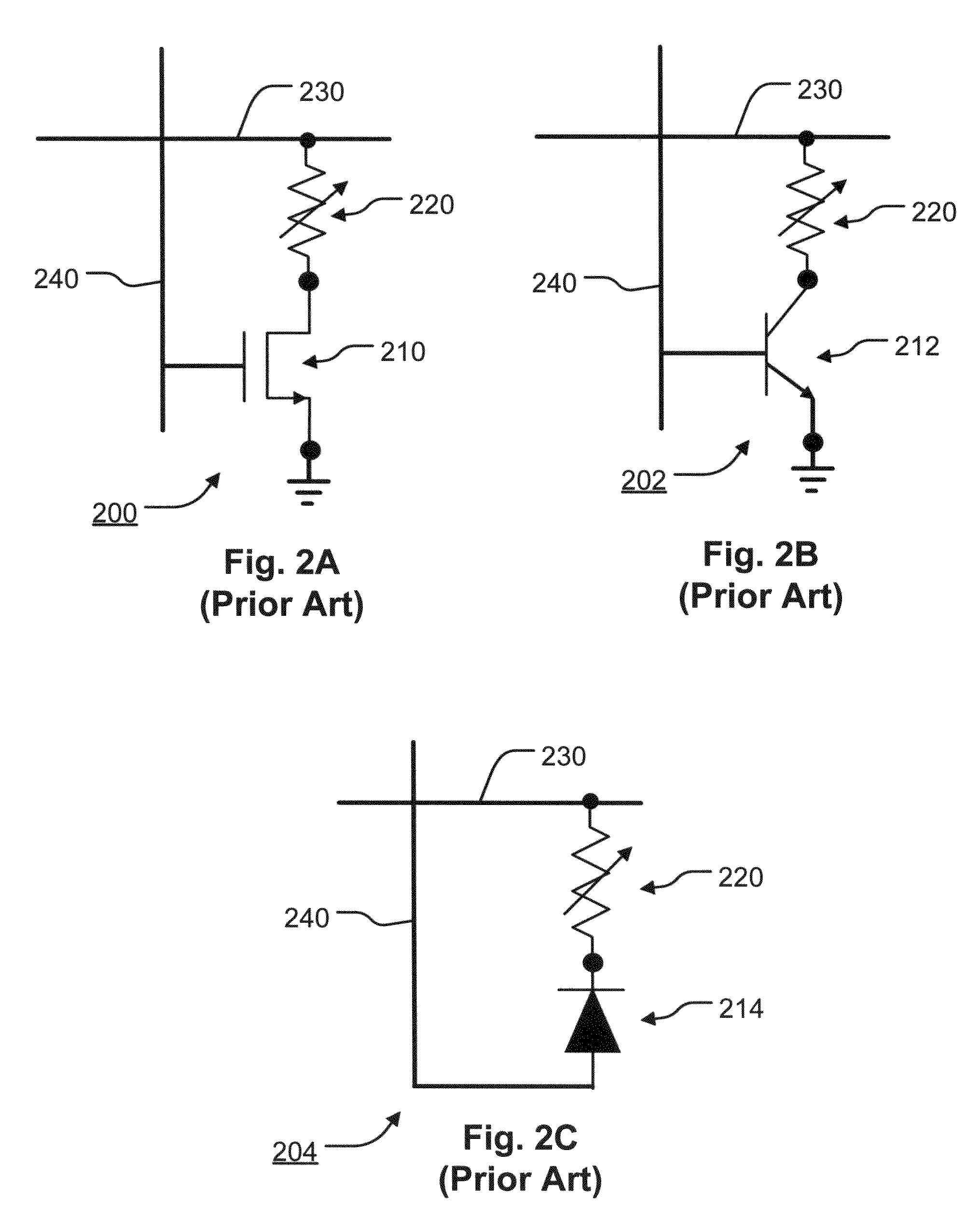

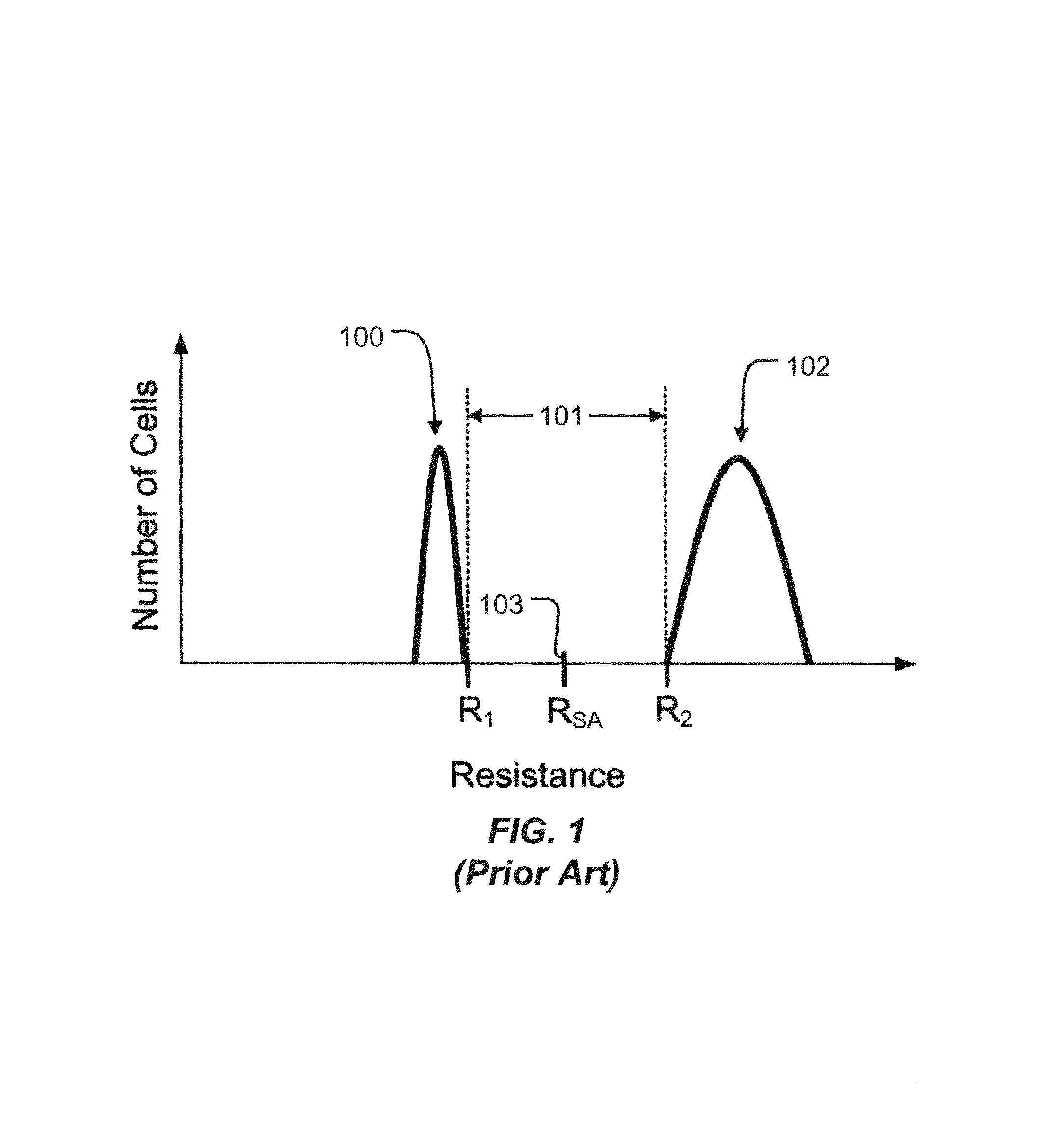

Dielectric mesh isolated phase change structure for phase change memory

ActiveUS20100084624A1Easy to optimizeSmall grain sizeSemiconductor/solid-state device manufacturingDigital storageDielectricPhase-change memory

A method for manufacturing a memory device, and a resulting device, is described using silicon oxide doped chalcogenide material. A first electrode having a contact surface; a body of phase change memory material in a polycrystalline state including a portion in contact with the contact surface of the first electrode, and a second electrode in contact with the body of phase change material are formed. The process includes melting and cooling the phase change memory material one or more times within an active region in the body of phase change material without disturbing the polycrystalline state outside the active region. A mesh of silicon oxide in the active region with at least one domain of chalcogenide material results. Also, the grain size of the phase change material in the polycrystalline state outside the active region is small, resulting in a more uniform structure.

Owner:GLOBALFOUNDRIES US INC

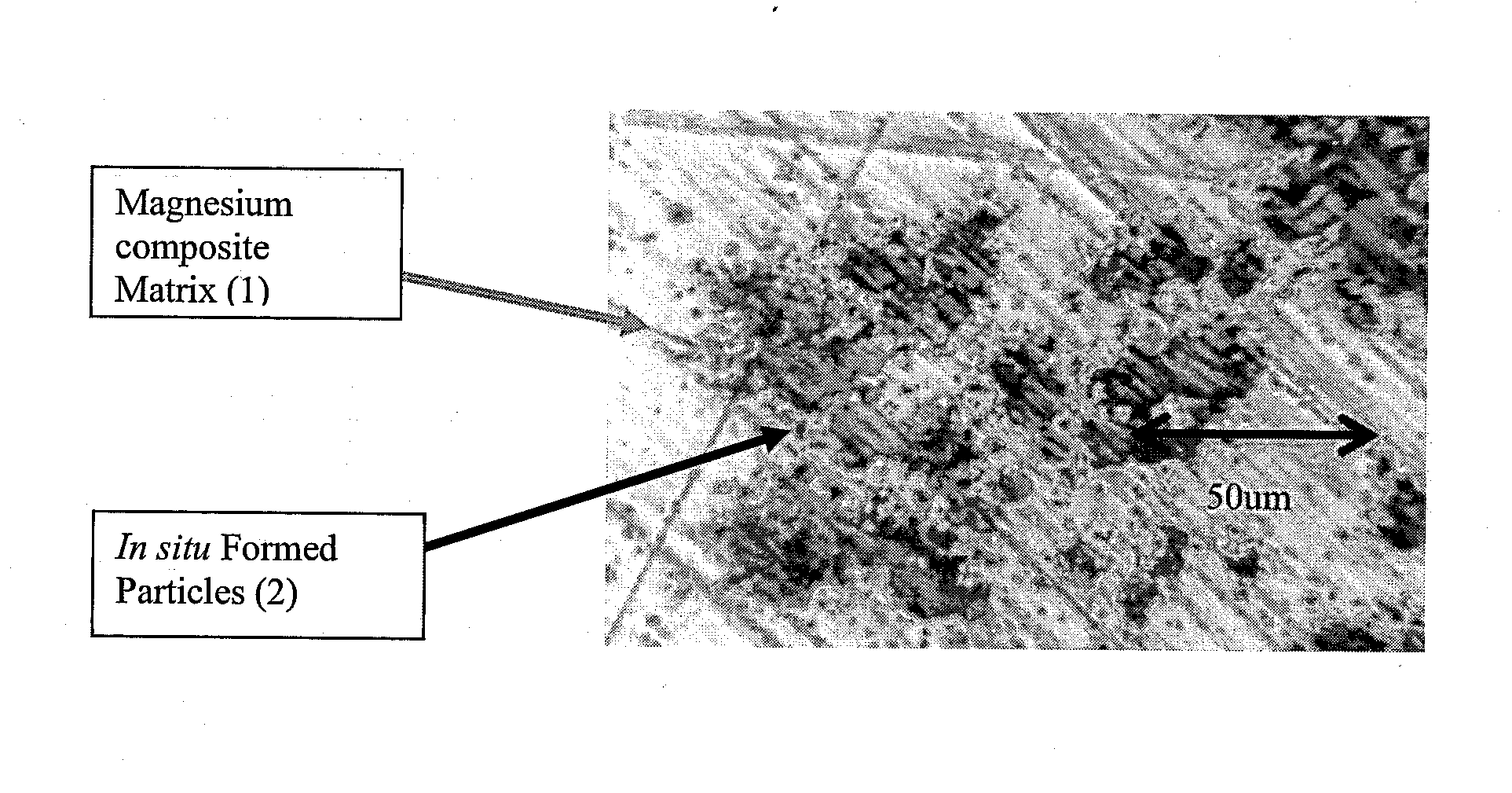

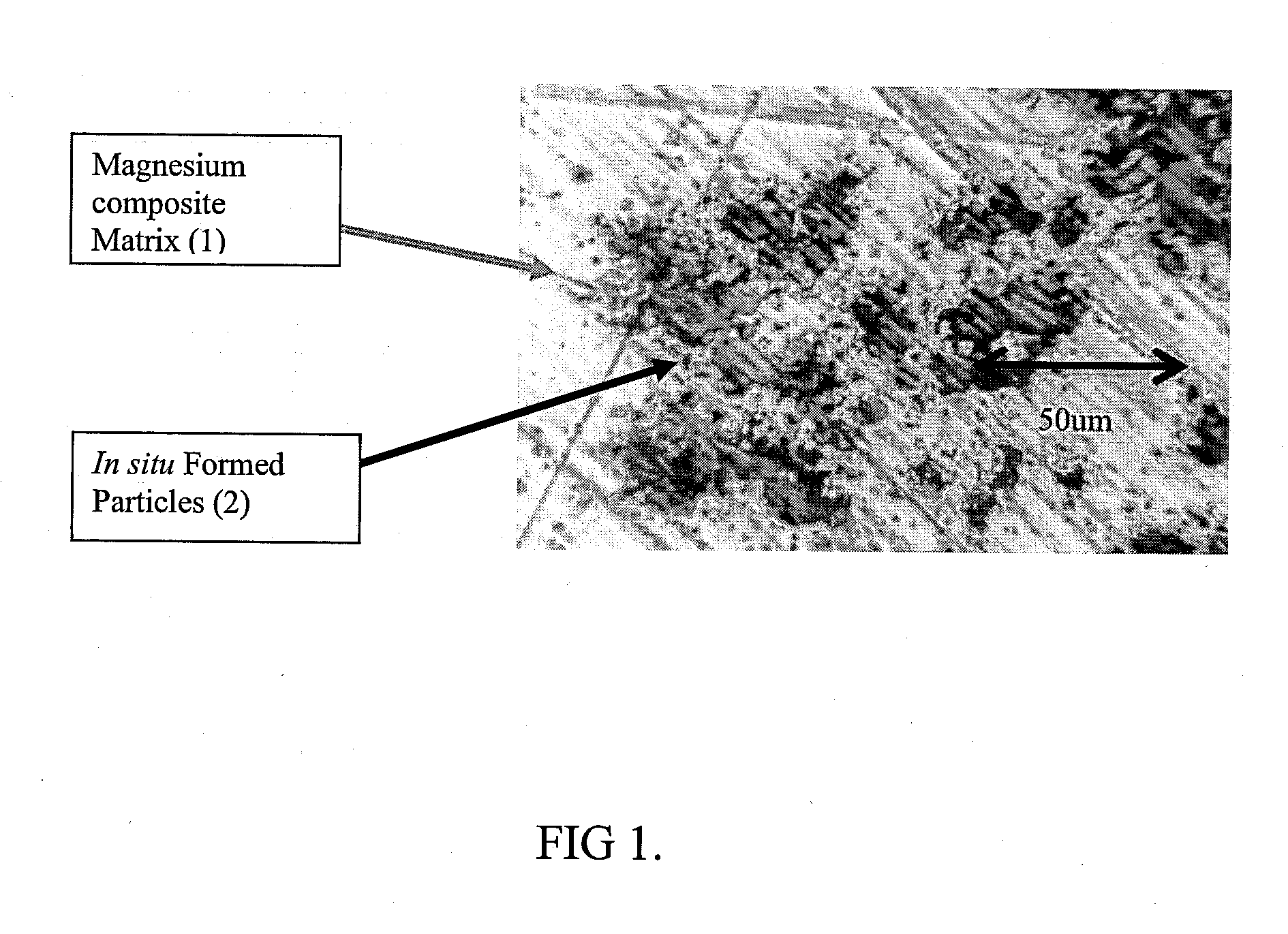

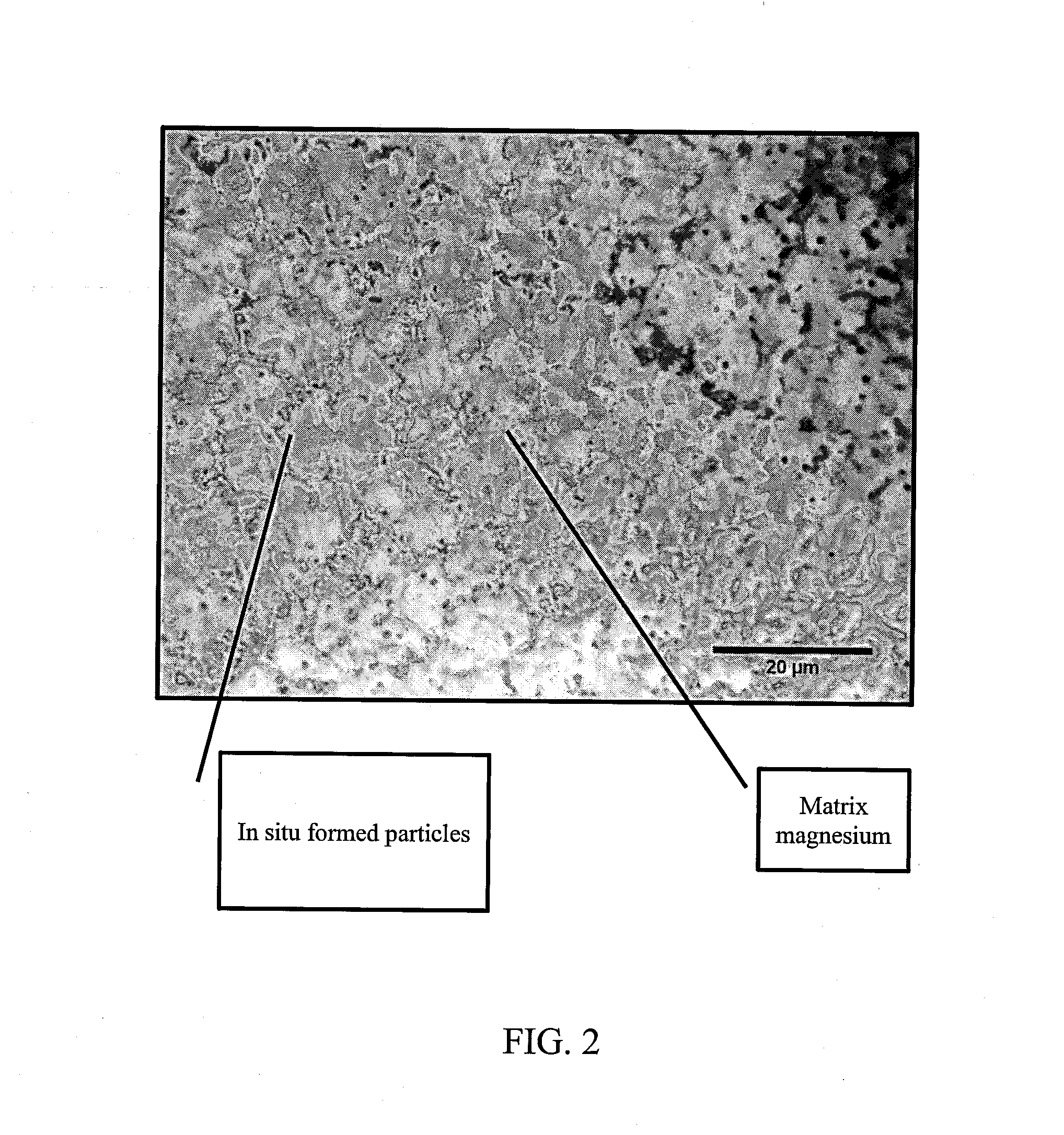

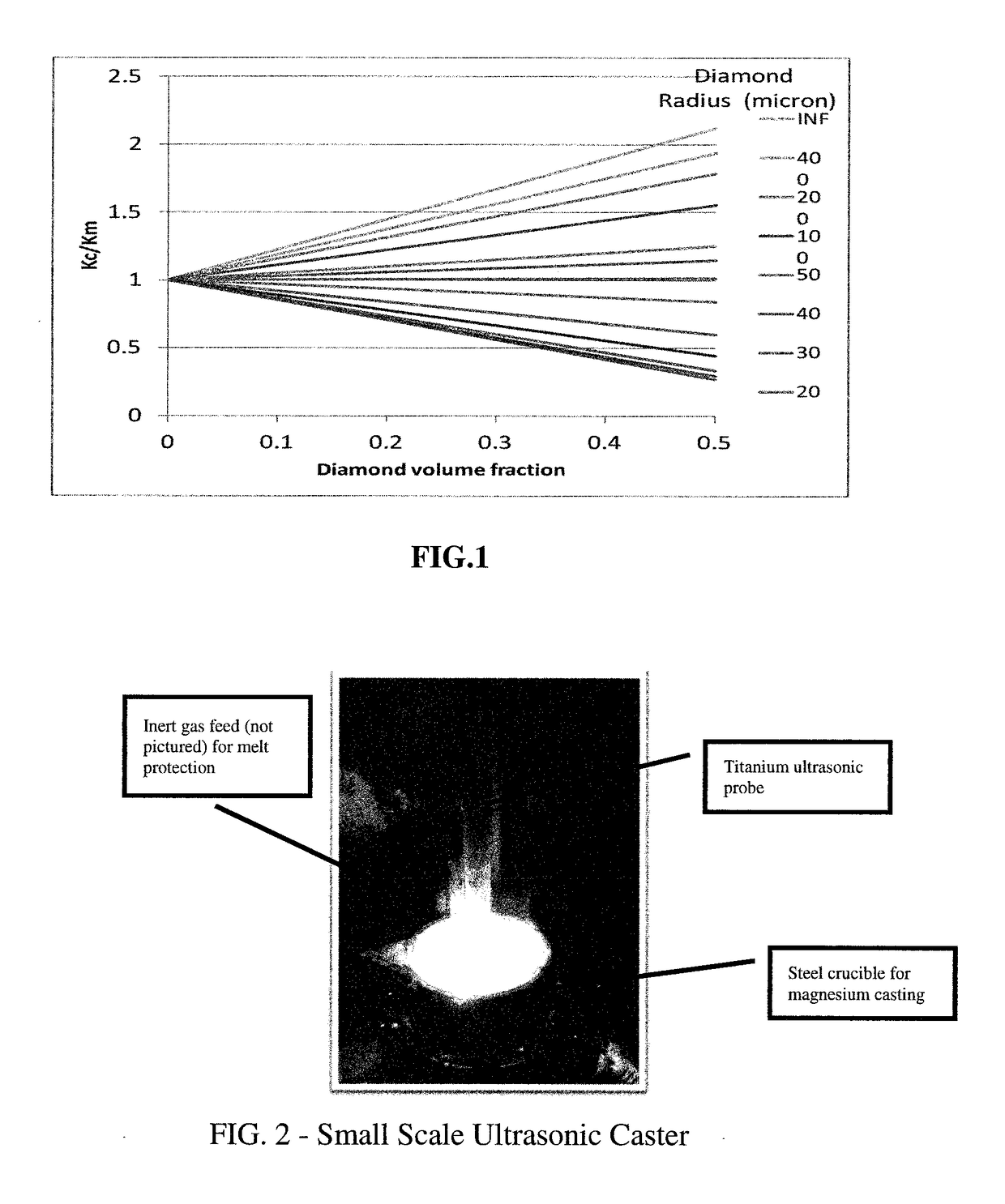

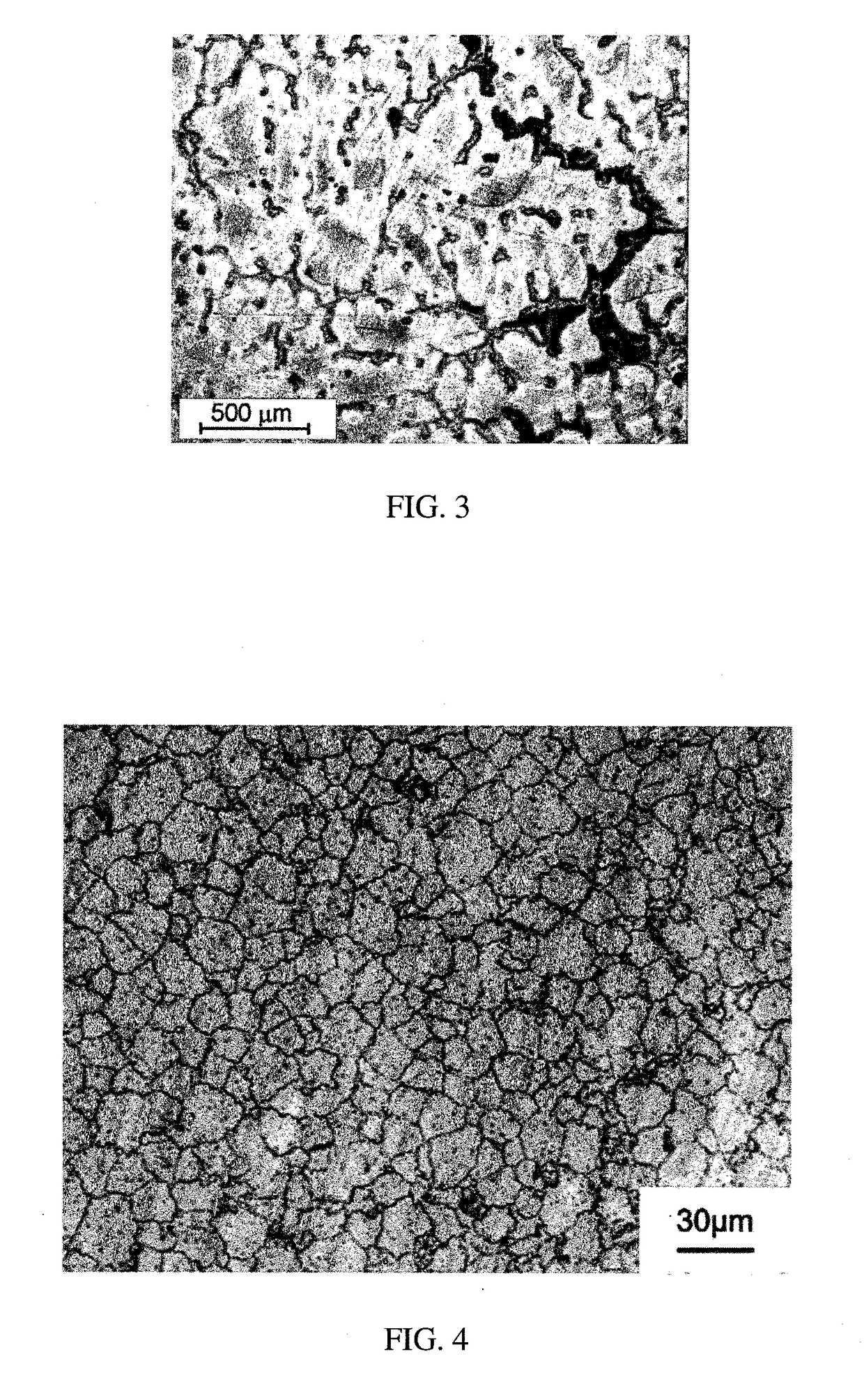

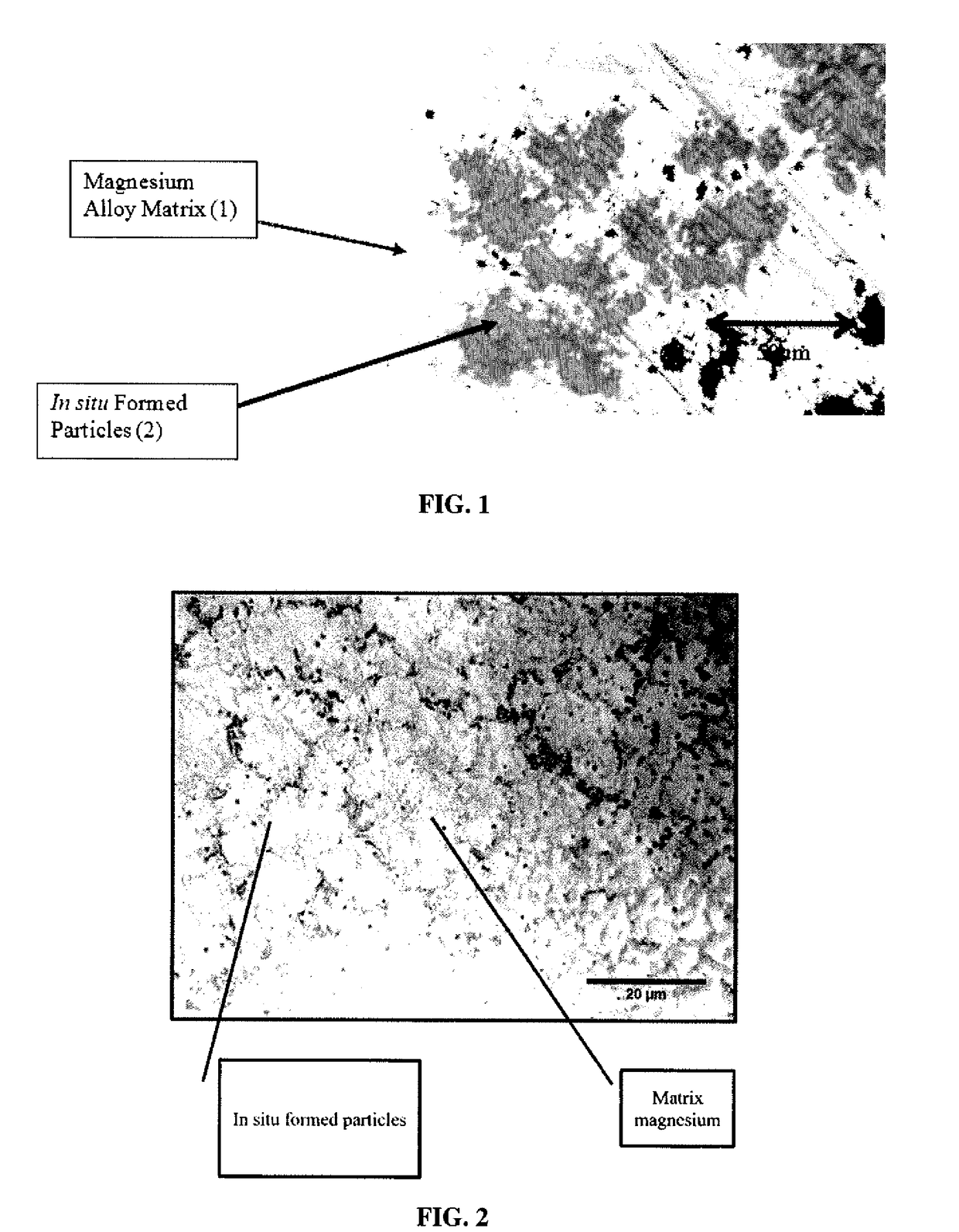

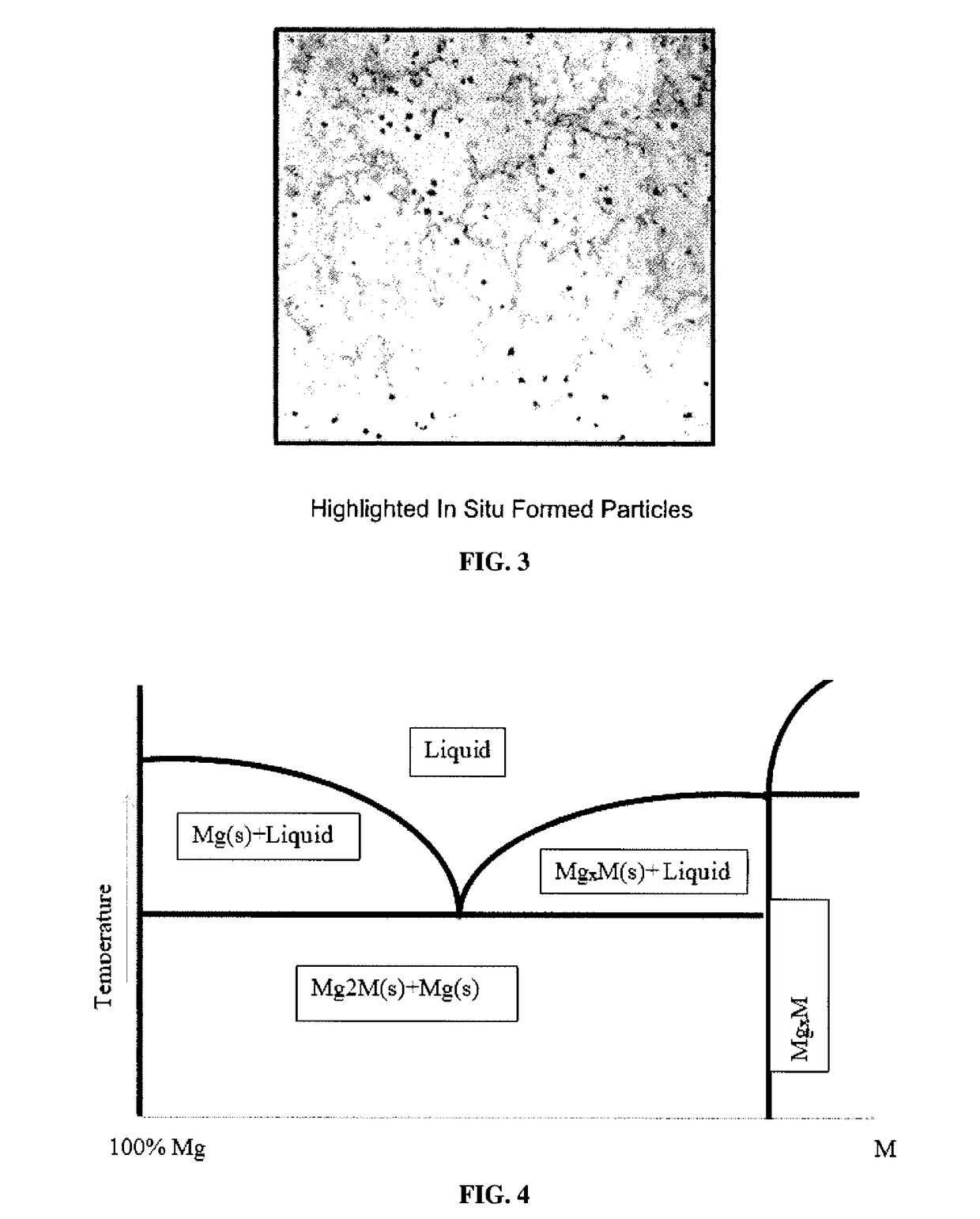

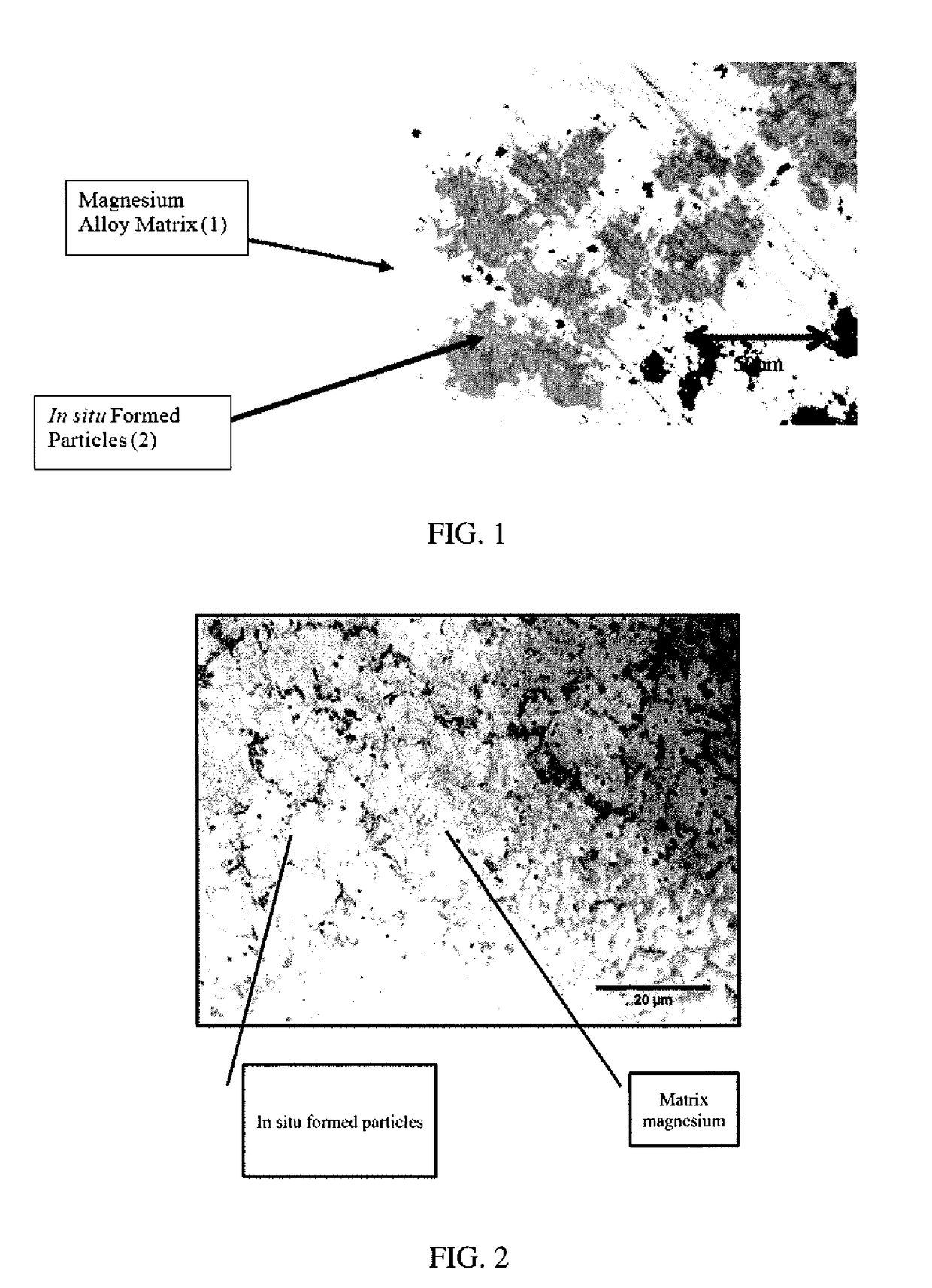

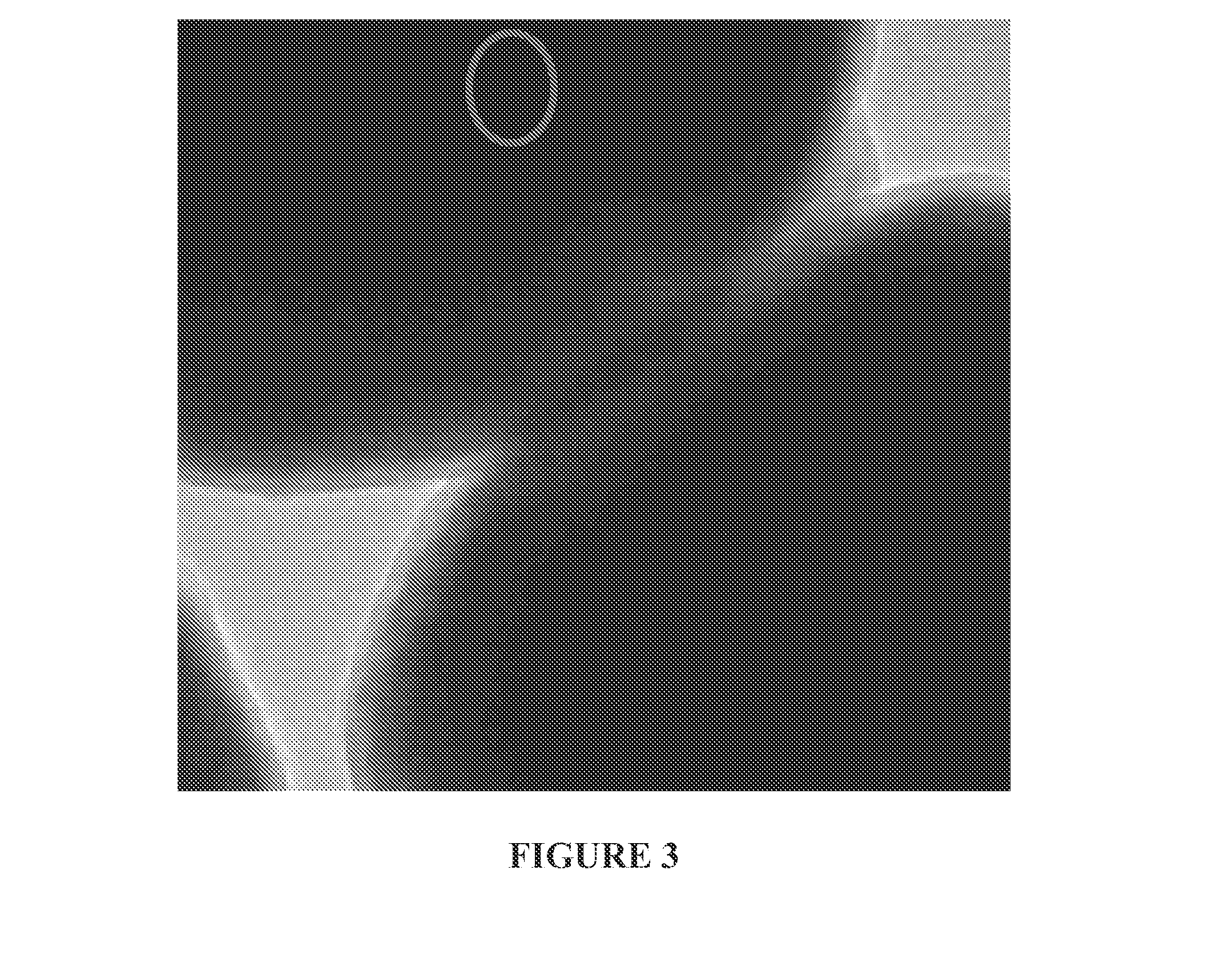

Galvanically-Active In Situ Formed Particles for Controlled Rate Dissolving Tools

A castable, moldable, and / or extrudable structure using a metallic primary alloy. One or more additives are added to the metallic primary alloy so that in situ galvanically-active reinforcement particles are formed in the melt or on cooling from the melt. The composite contain an optimal composition and morphology to achieve a specific galvanic corrosion rate in the entire composite. The in situ formed galvanically-active particles can be used to enhance mechanical properties of the composite, such as ductility and / or tensile strength. The final casting can also be enhanced by heat treatment, as well as deformation processing such as extrusion, forging, or rolling, to further improve the strength of the final composite over the as-cast material.

Owner:TERVES

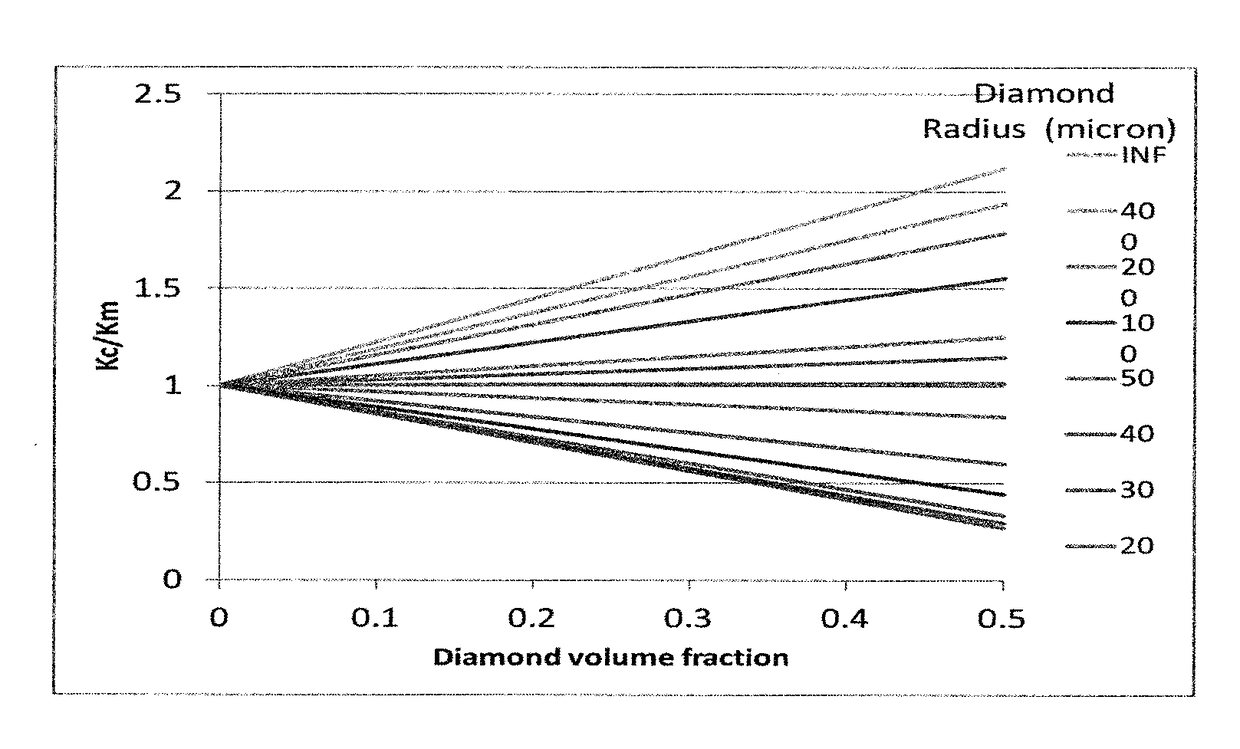

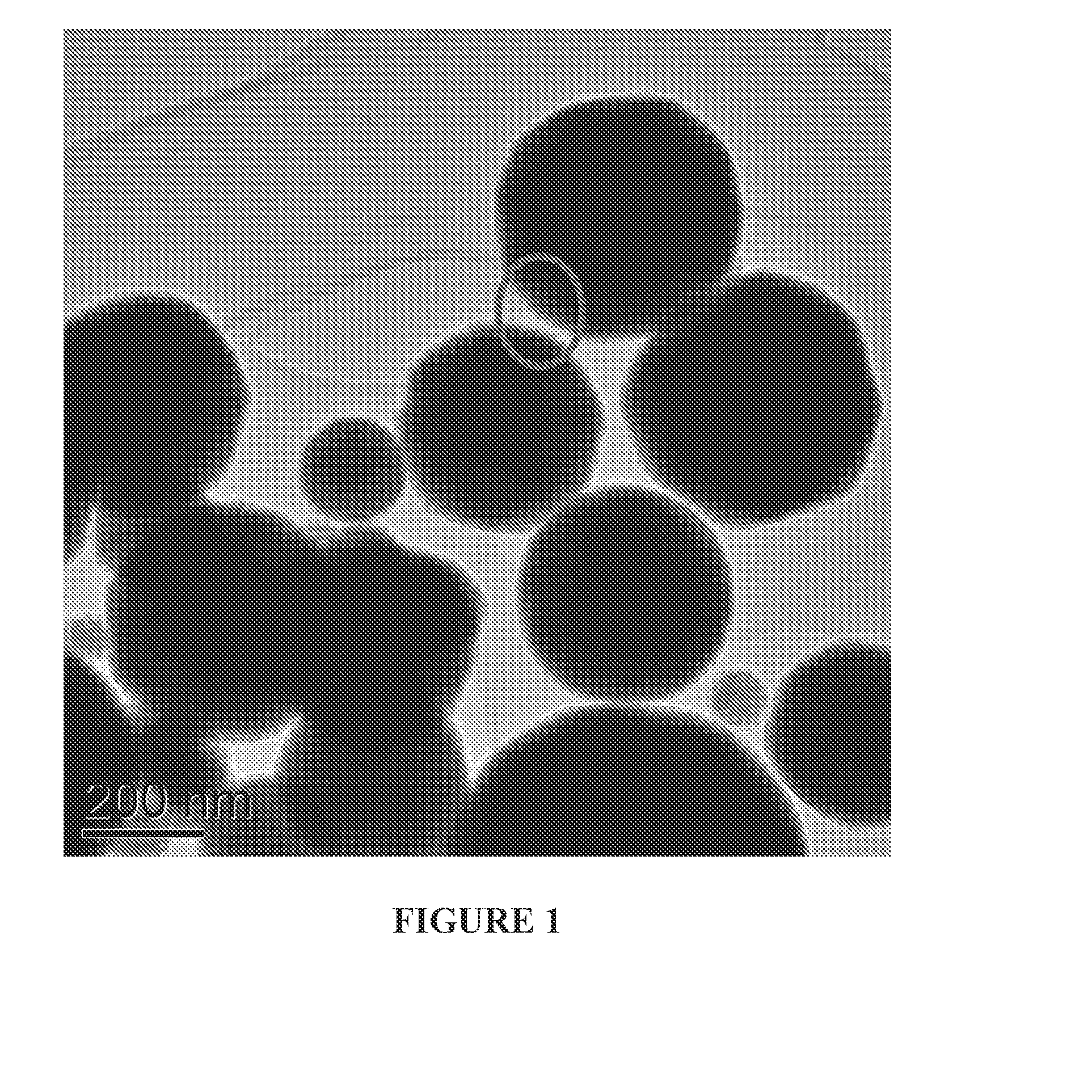

High Conductivity Magnesium Alloy

InactiveUS20170268088A1Improved thermalPhysical improvementMaterial nanotechnologyTransportation and packagingMagnesium matrix compositeNanoparticle

A castable, moldable, or extrudable magnesium-based alloy that includes one or more insoluble additives. The insoluble additives can be used to enhance the mechanical properties of the structure, such as ductility and / or tensile strength. The final structure can be enhanced by heat treatment, as well as deformation processing such as extrusion, forging, or rolling, to further improve the strength of the final structure as compared to the non-enhanced structure. The magnesium-based composite has improved thermal and mechanical properties by the modification of grain boundary properties through the addition of insoluble nanoparticles to the magnesium alloys. The magnesium-based composite can have a thermal conductivity that is greater than 180 W / m−K, and / or ductility exceeding 15-20% elongation to failure.

Owner:TERVES

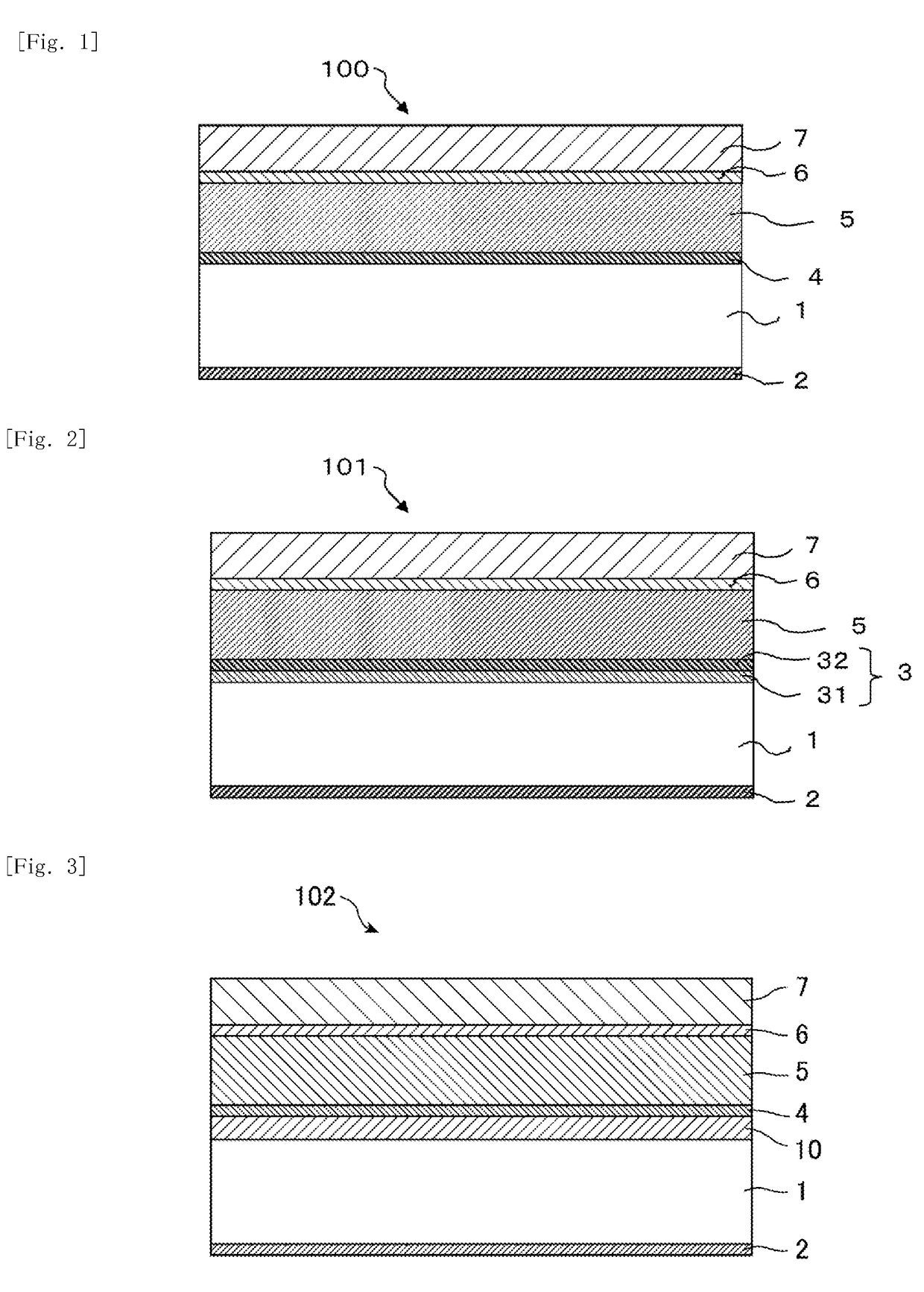

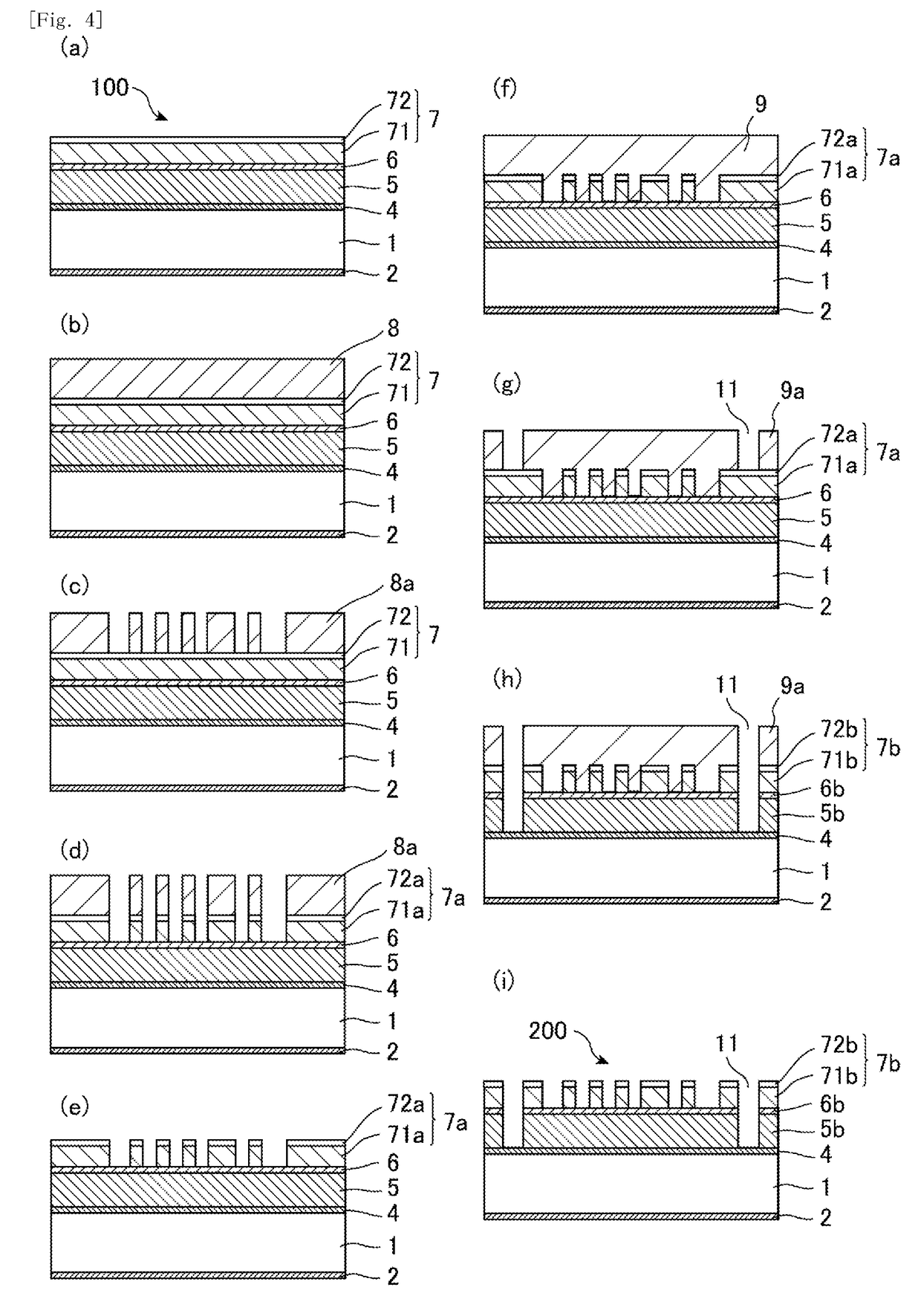

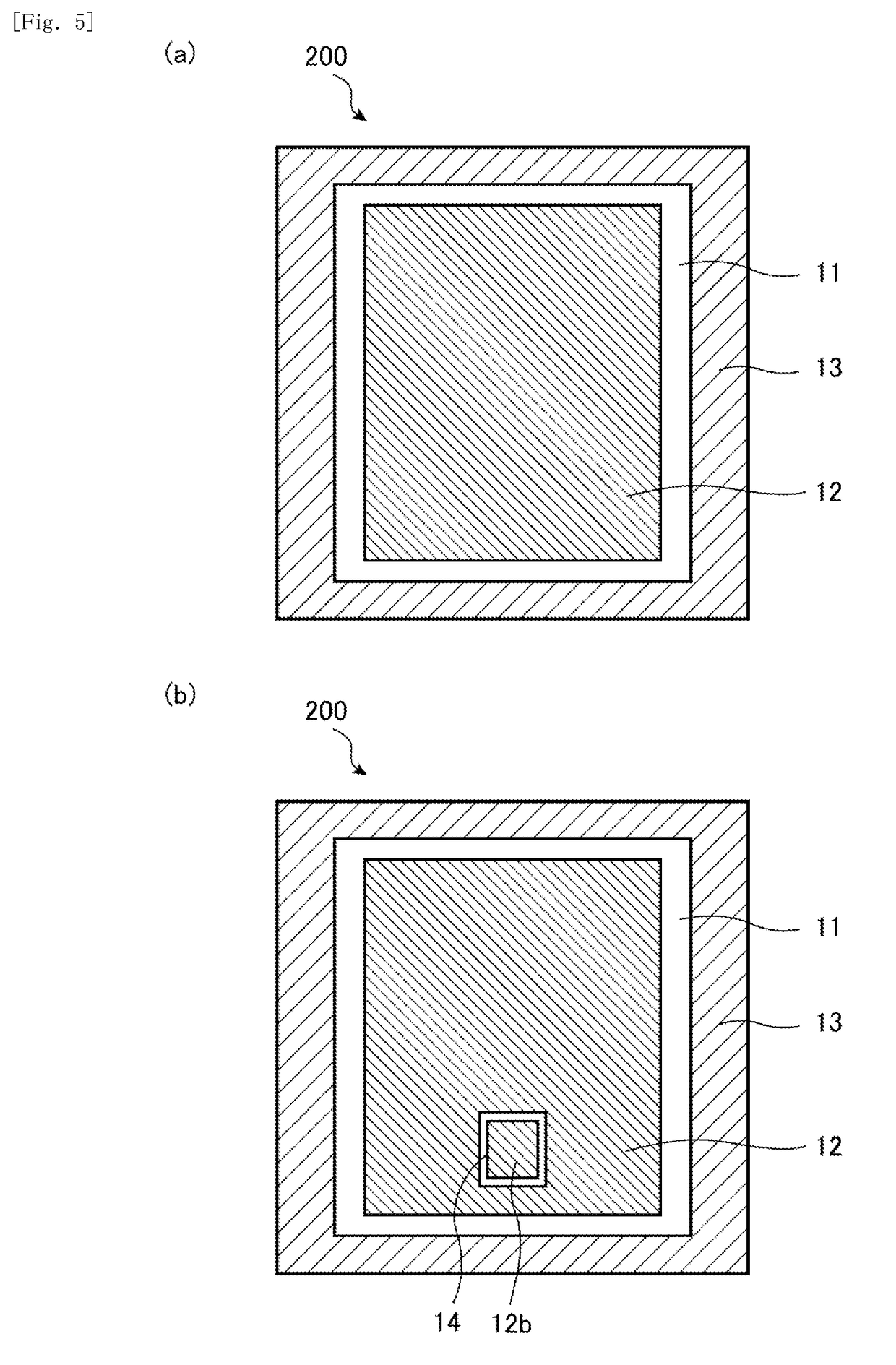

Reflective mask blank, method for manufacturing same, reflective mask, method for manufacturing same, and method for manufacturing semiconductor device

ActiveUS20170263444A1High dry etch resistanceAvoid chargingVacuum evaporation coatingSputtering coatingLithographic artistRuthenium

The present invention aims to provide a reflective mask blank and a reflective mask which have a highly smooth multilayer reflective film as well as a low number of defects, and methods of manufacturing the same, and aims to prevent charge-up during a mask defect inspection using electron beams.The present invention provides a reflective mask blank for EUV lithography in which a conductive underlying film, a multilayer reflective film that reflects exposure light, and an absorber film that absorbs exposure light are layered on a substrate, wherein the conductive underlying film is a single-layer film made of a tantalum-based material or a ruthenium-based material with a film thickness of greater than or equal to 1 nm and less than or equal to 10 nm that is formed adjacent to the multilayer reflective film, or the conductive underlying film is a multilayer film including a layer of a tantalum-based material with a film thickness of greater than or equal to 1 nm and less than or equal to 10 nm that is formed adjacent to the multilayer reflective film and a layer of a conductive material that is formed between the layer of the tantalum-based material and the substrate. The present invention also provides a reflective mask manufactured using the reflective mask blank. Furthermore, a semiconductor device is manufactured using the reflective mask.

Owner:HOYA CORP

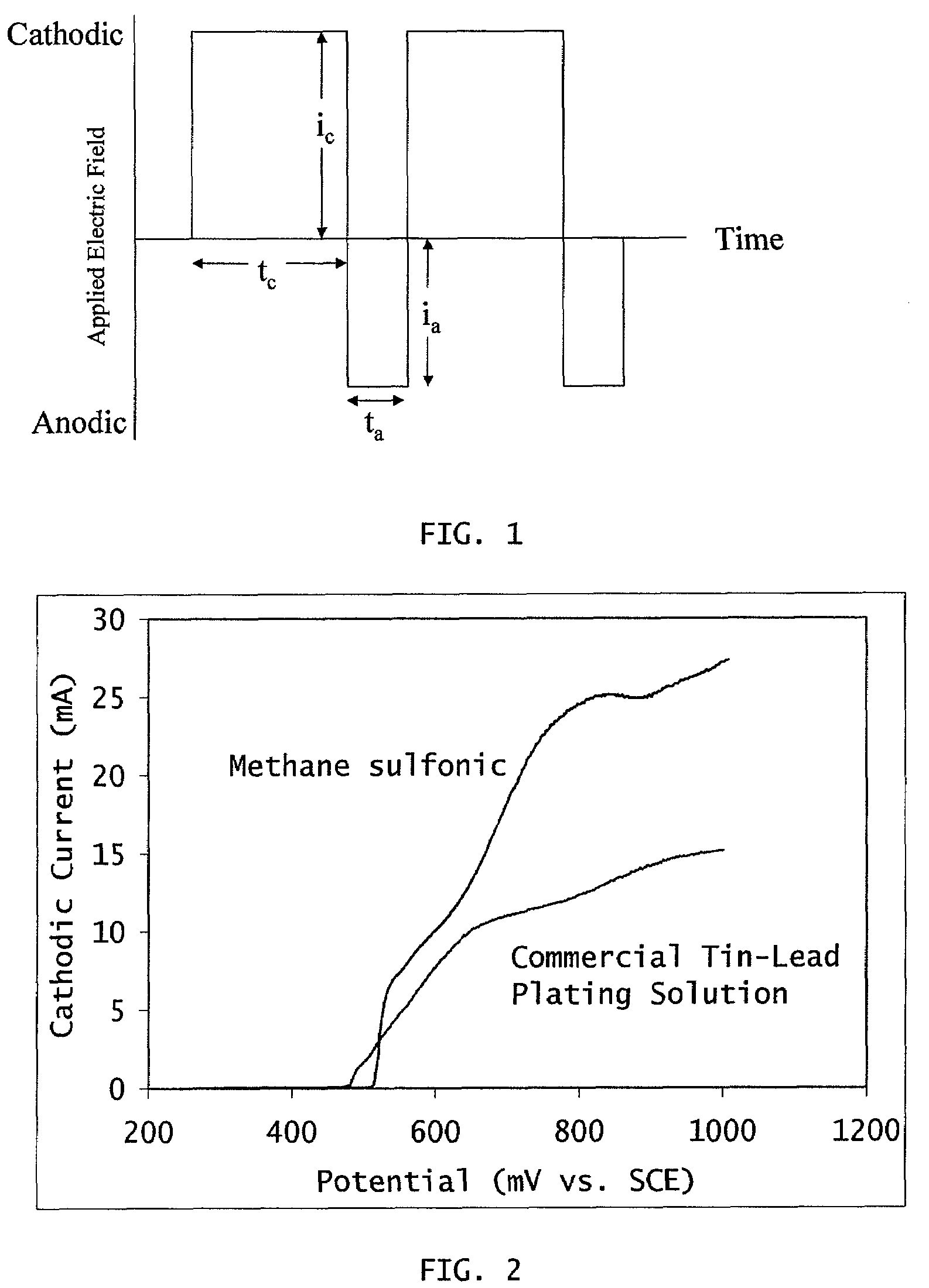

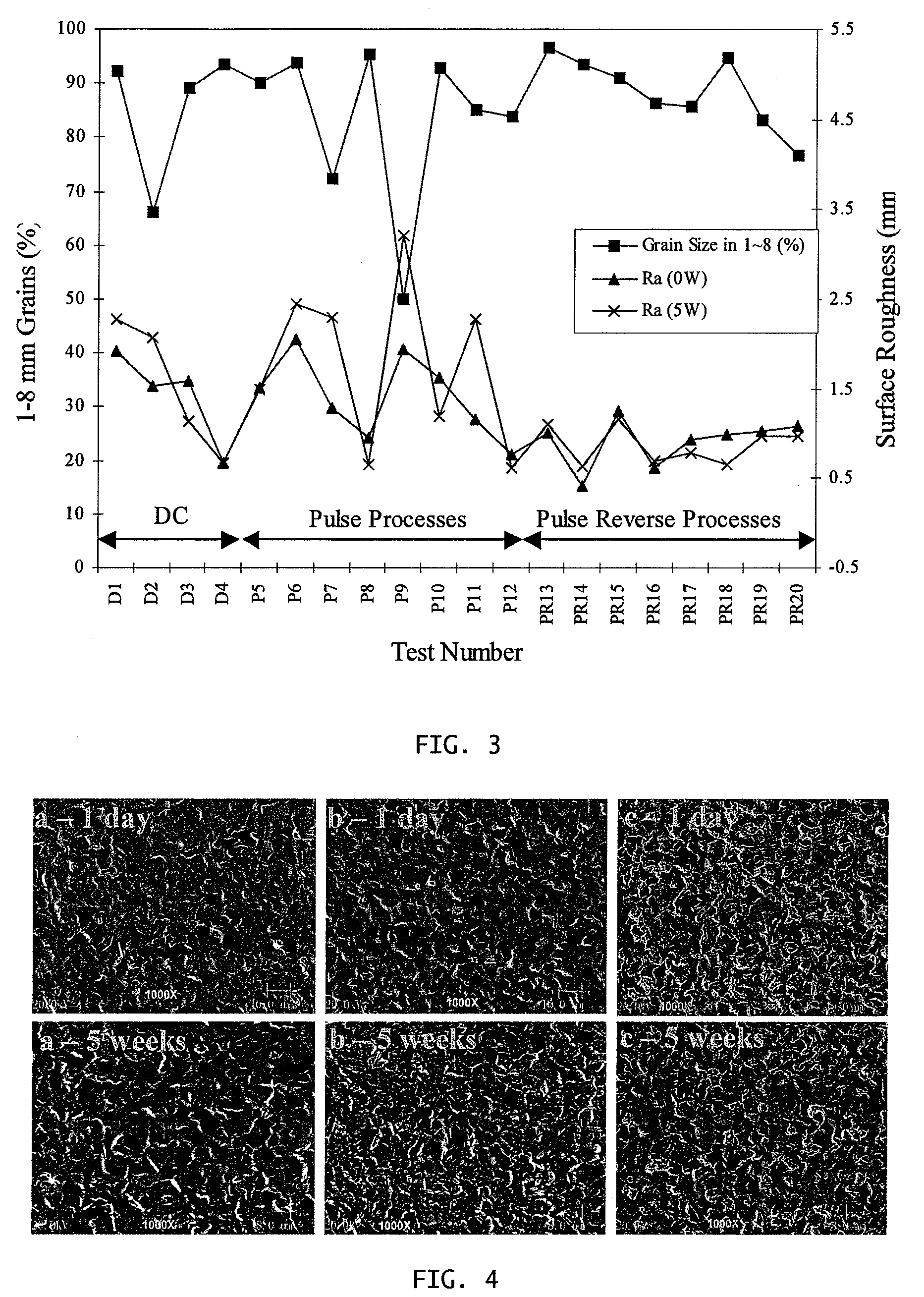

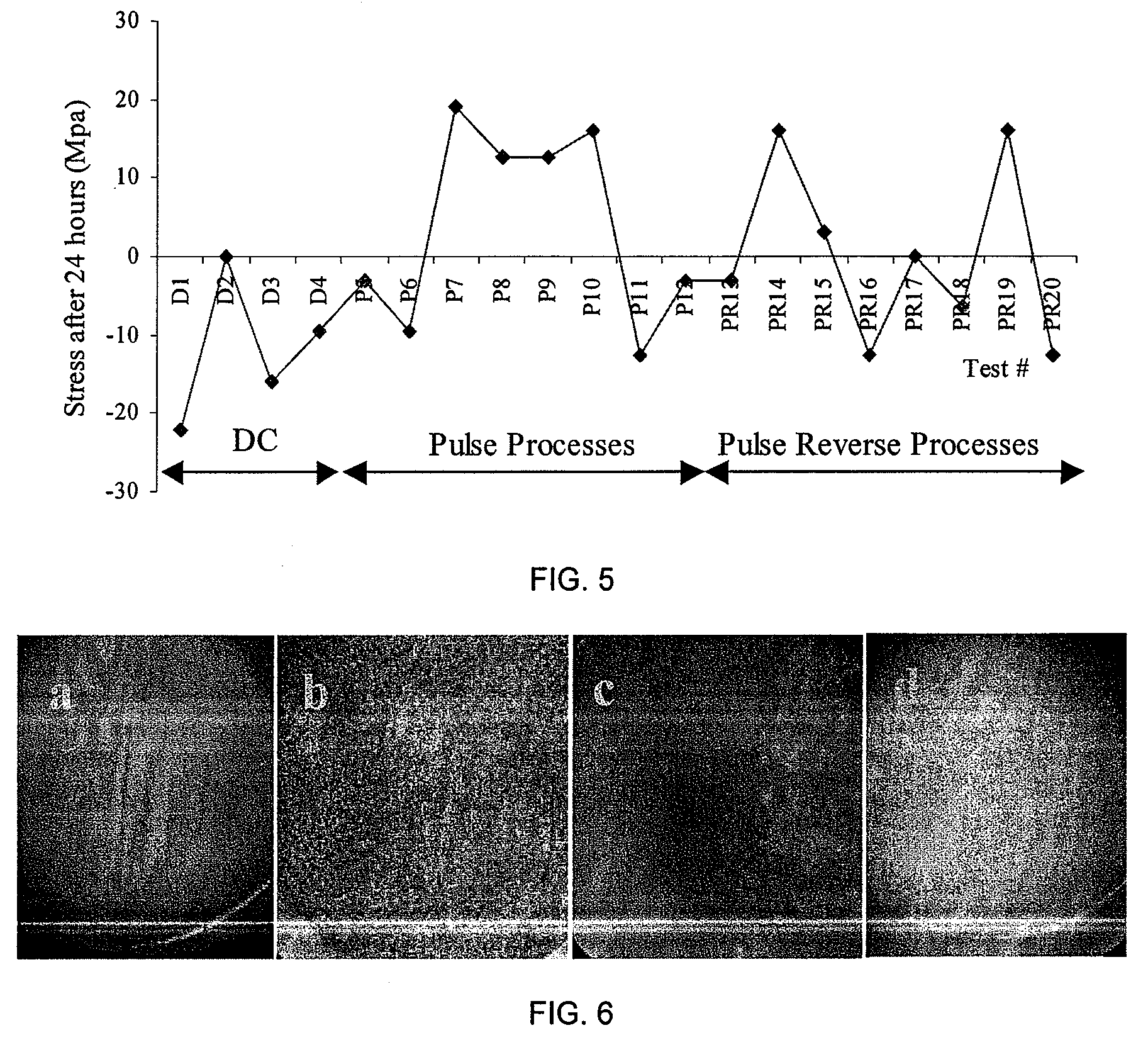

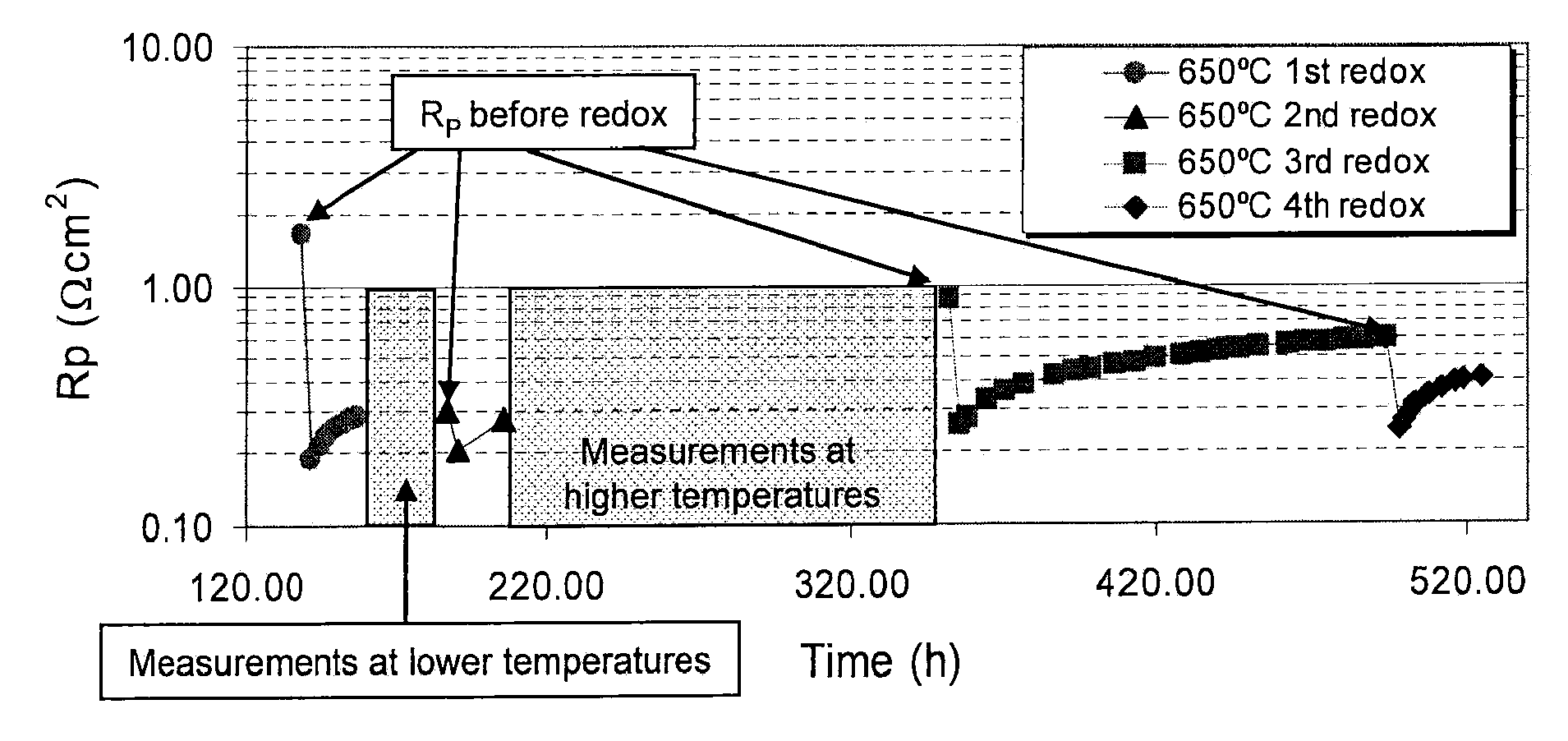

Tin and tin alloy electroplating method with controlled internal stress and grain size of the resulting deposit

ActiveUS20070158204A1Prevent deleterious whisker growthReduce grain sizePrinted circuit manufactureCrystalliteInternal stress

Owner:FARADAY TECH INC

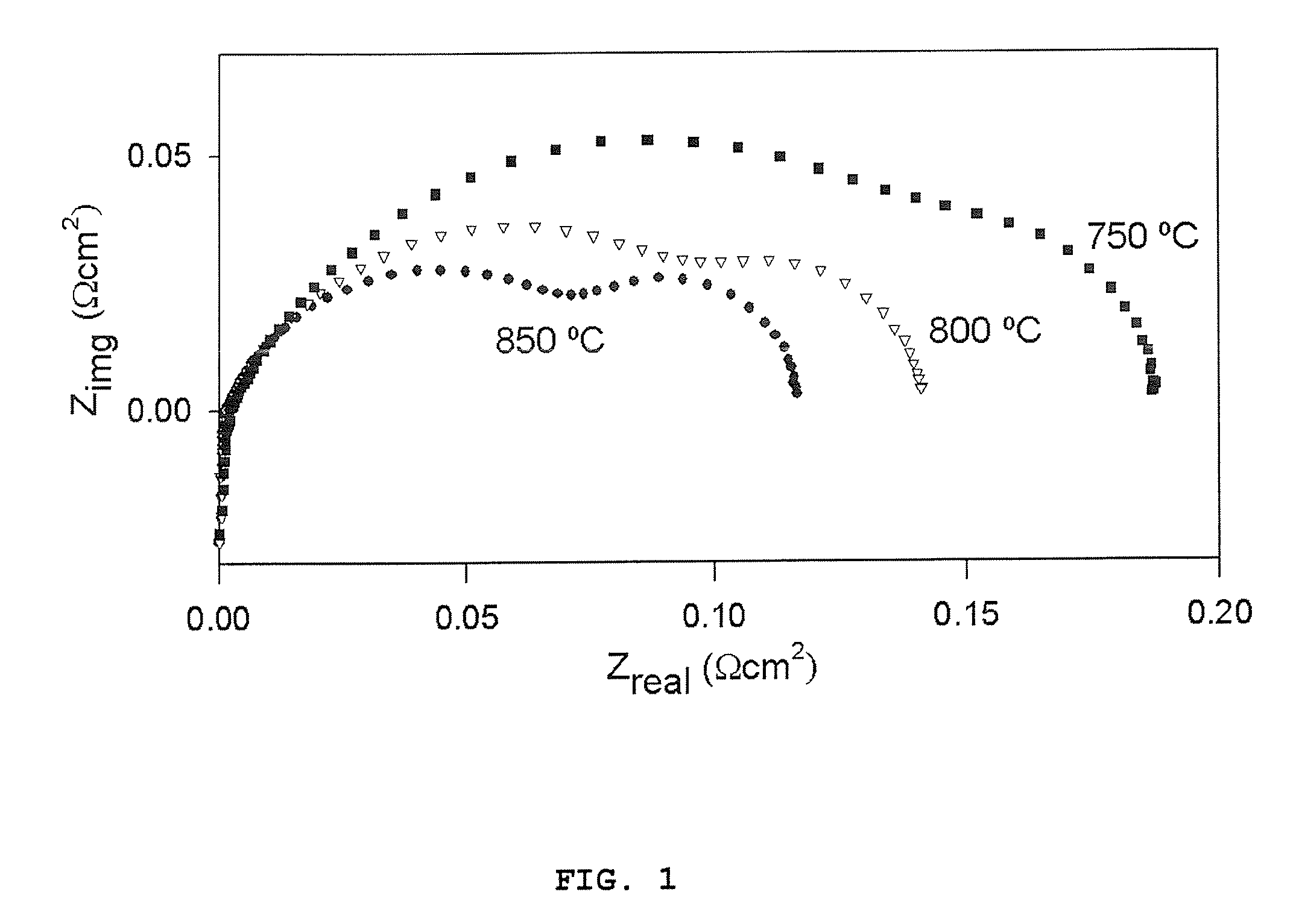

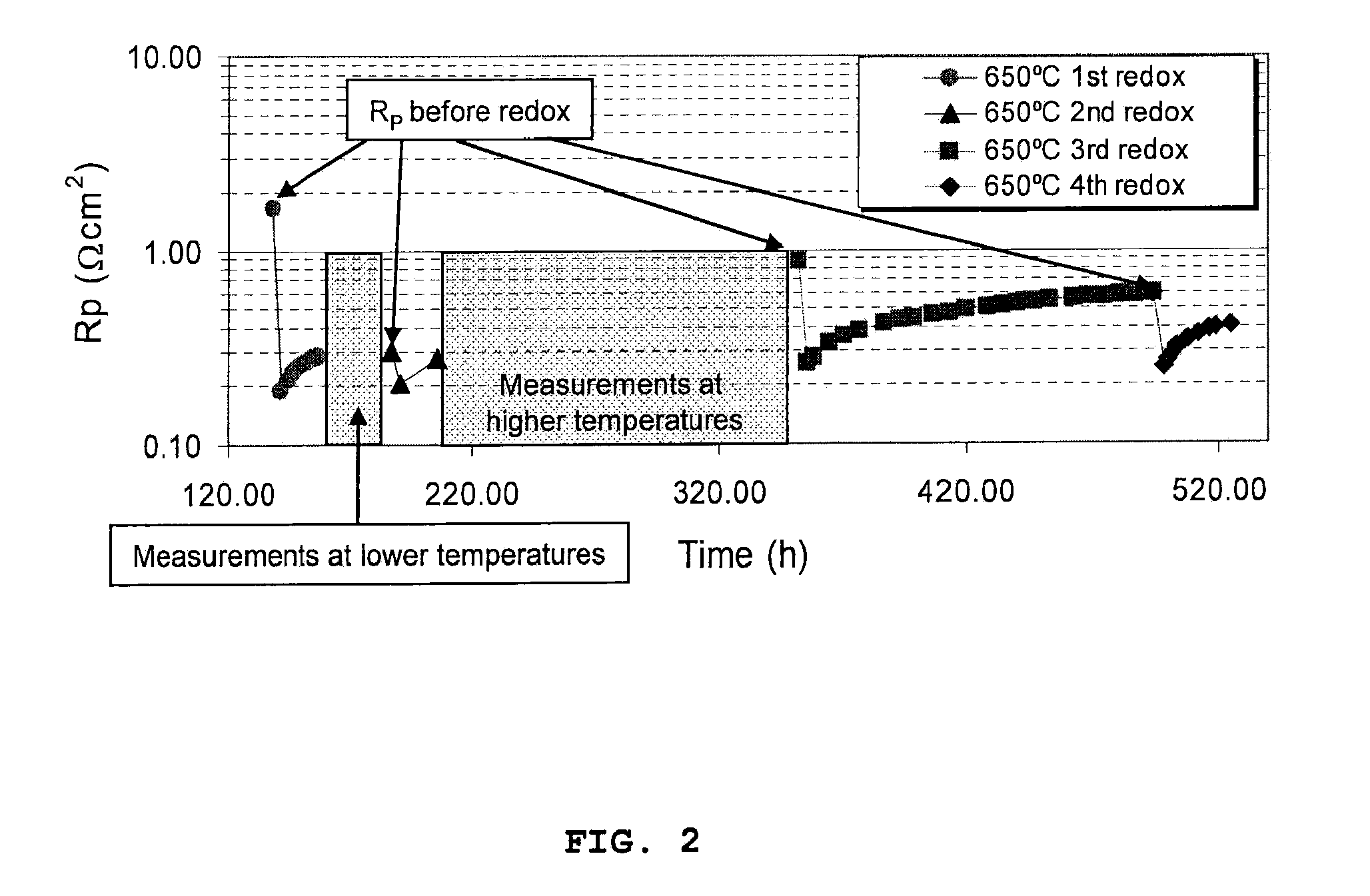

Ceria and strontium titanate based electrodes

InactiveUS20090061284A1High BET surface areaSpeed up calcination procedureFuel cells groupingCell electrodesStrontium titanateVanadium doping

A ceramic anode structure obtainable by a process comprising the steps of: (a) providing a slurry by dispersing a powder of an electronically conductive phase and by adding a binder to the dispersion, in which said powder is selected from the group consisting of niobium-doped strontium titanate, vanadium-doped strontium titanate, tantalum-doped strontium titanate, and mixtures thereof, (b) sintering the slurry of step (a), (c) providing a precursor solution of ceria, said solution containing a solvent and a surfactant, (d) impregnating the resulting sintered structure of step (b) with the precursor solution of step (c), (e) subjecting the resulting structure of step (d) to calcination, and (f) conducting steps (d)-(e) at least once.

Owner:DANMARKS TEKNISKE UNIV

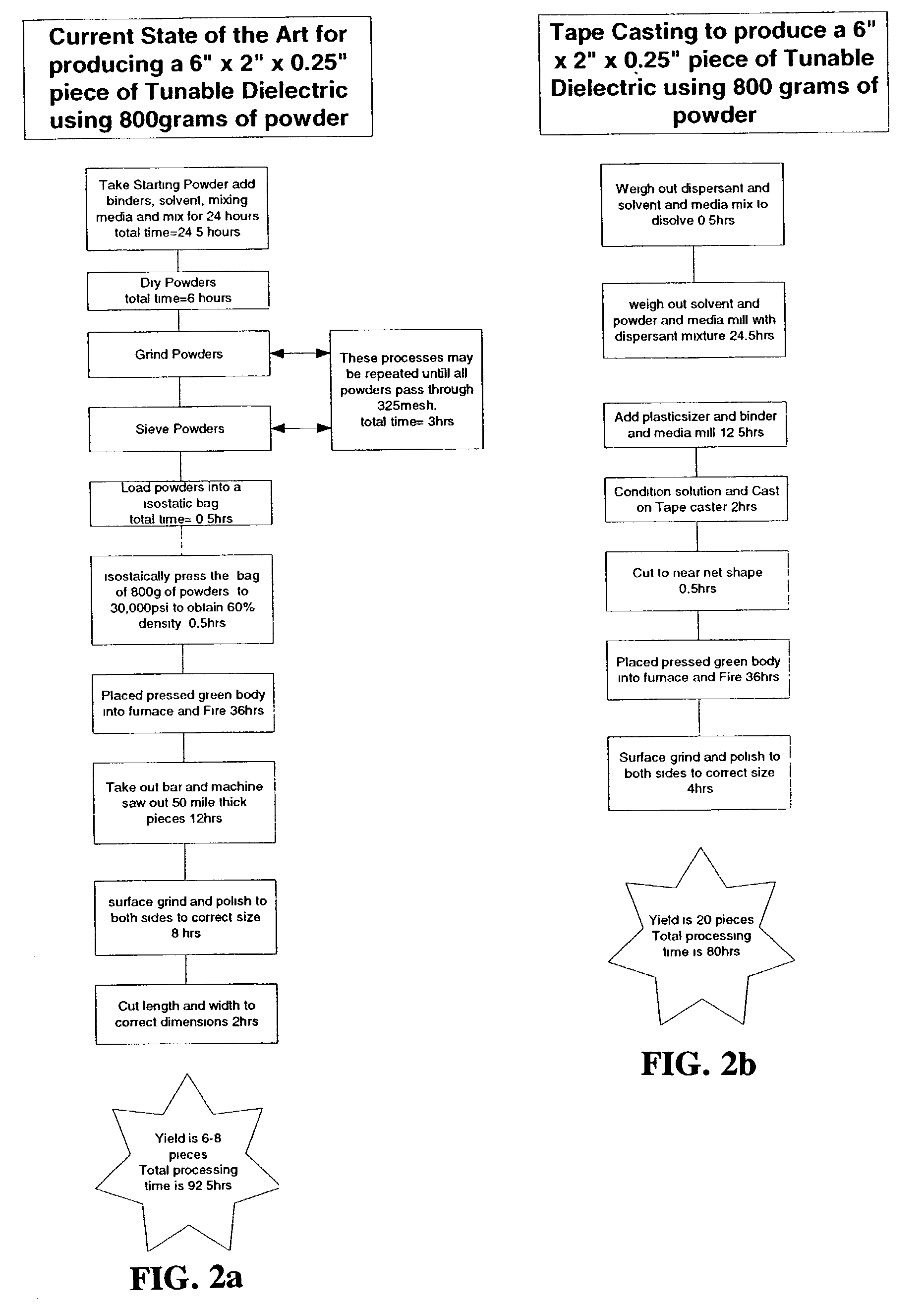

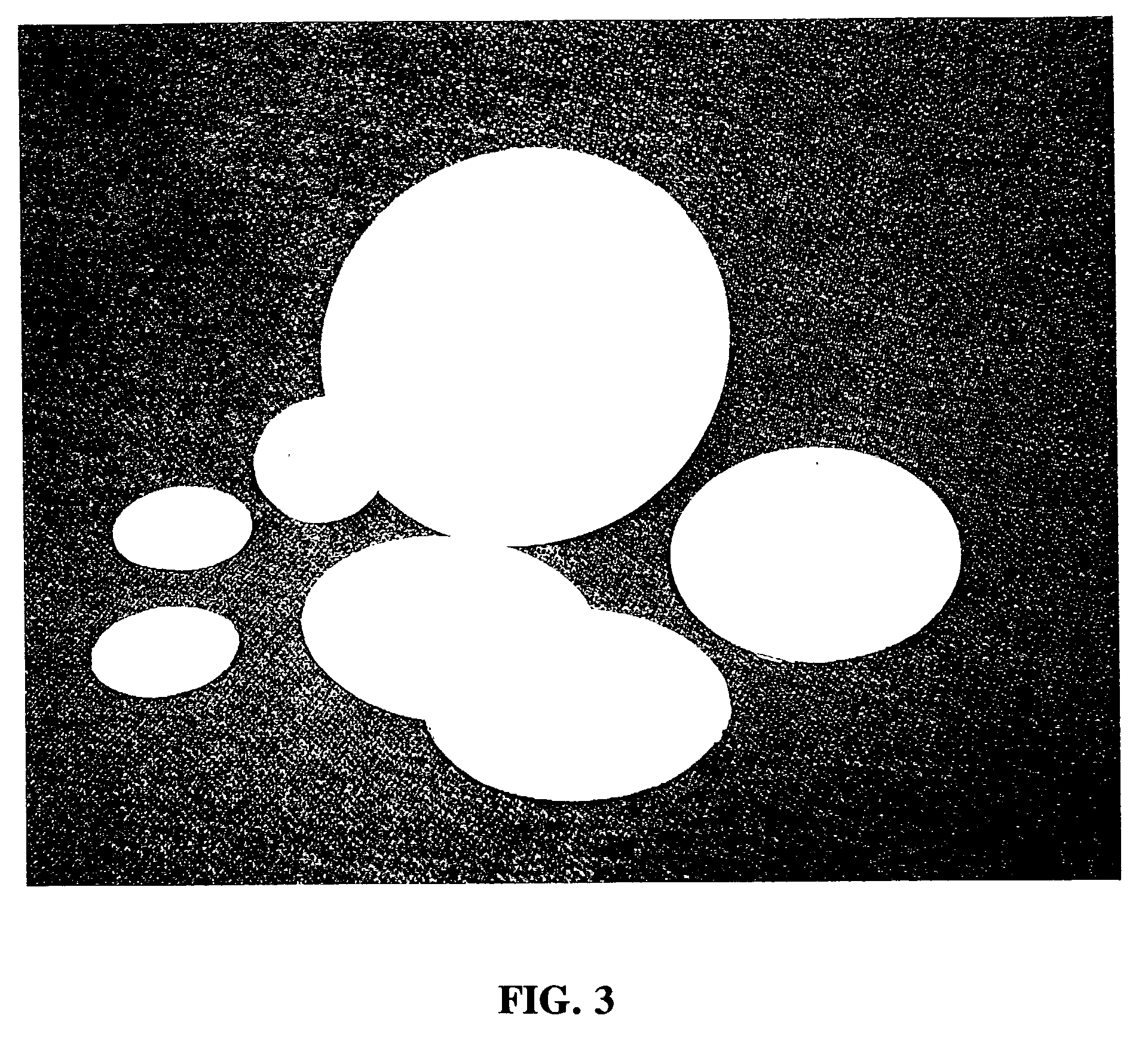

Method for producing low-loss tunable ceramic composites with improved breakdown strengths

InactiveUS20030119656A1Improved propertyLow cost productionLayered productsFixed capacitor dielectricBreakdown strengthMicrowave

The production of low-loss, tunable composite ceramic materials with improved breakdown strengths is disclosed. The composite materials comprise ferroelectric perovskites such as barium strontium titanate or other ferroelectric perovskites combined with other phases such as low-loss silicate materials and / or other low-loss oxides. The composite materials are produced in sheet or tape form by methods such as tape casting. The composite tapes exhibit favorable tunability, low loss and tailorable dielectric properties, and can be used in various microwave devices.

Owner:NXP USA INC

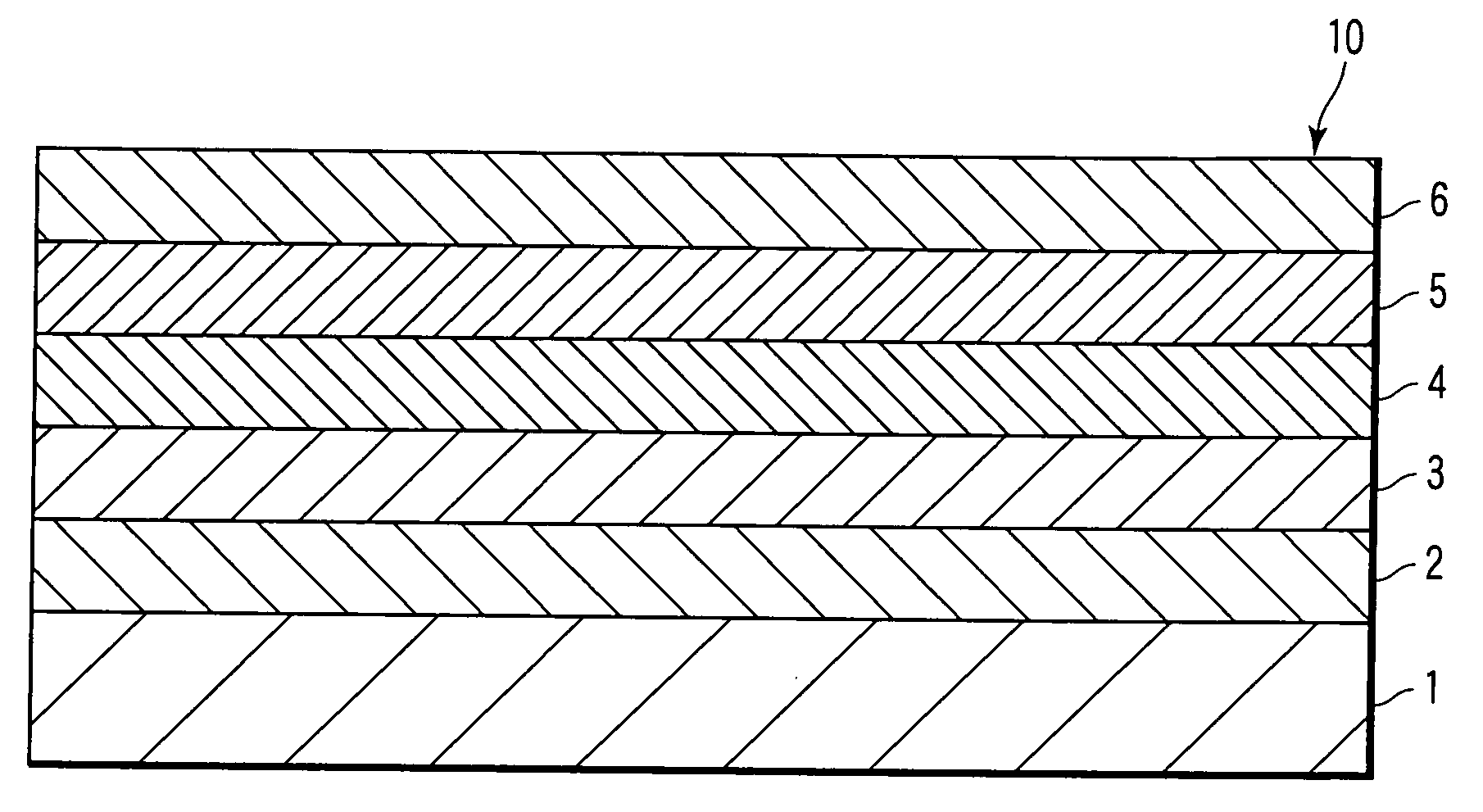

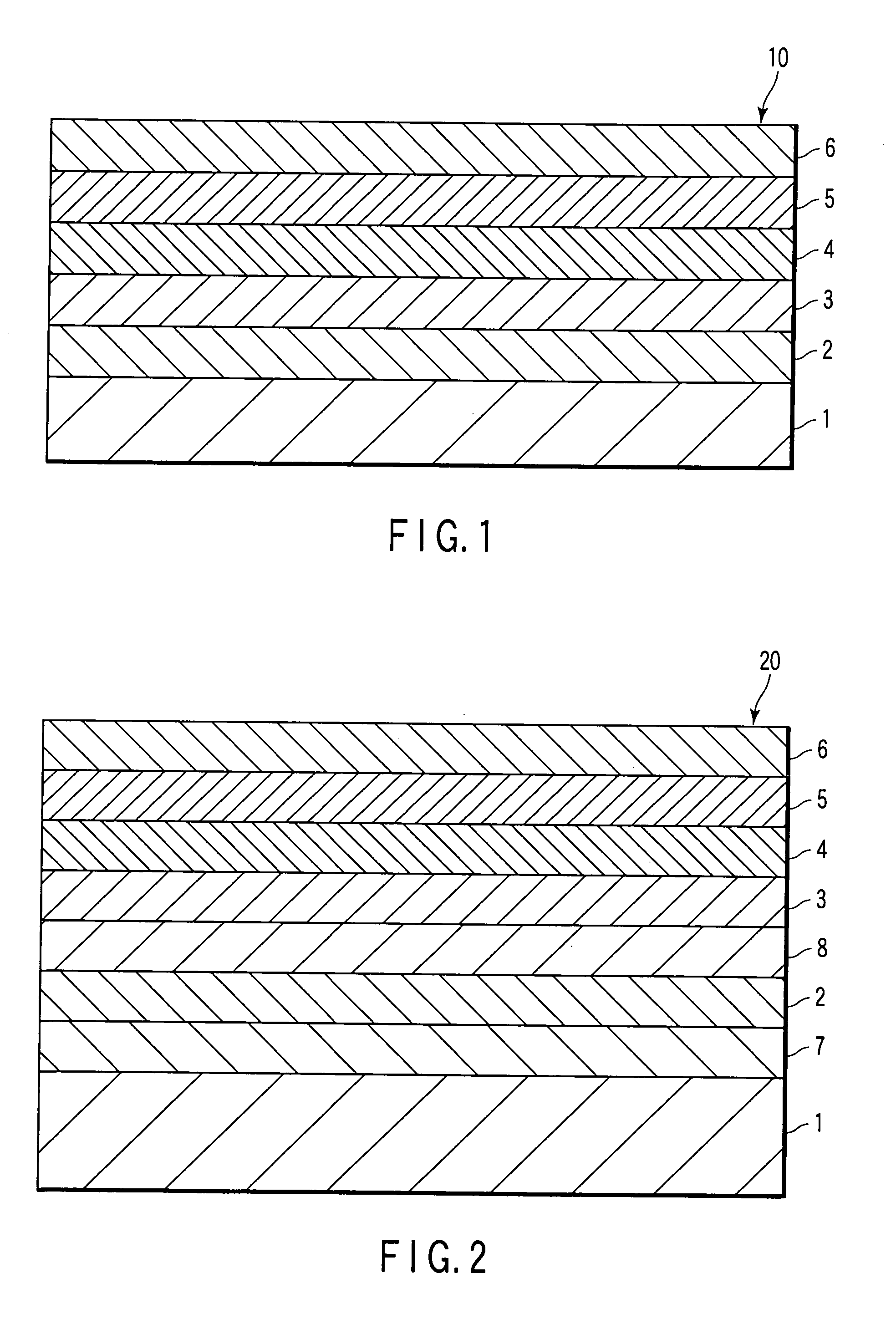

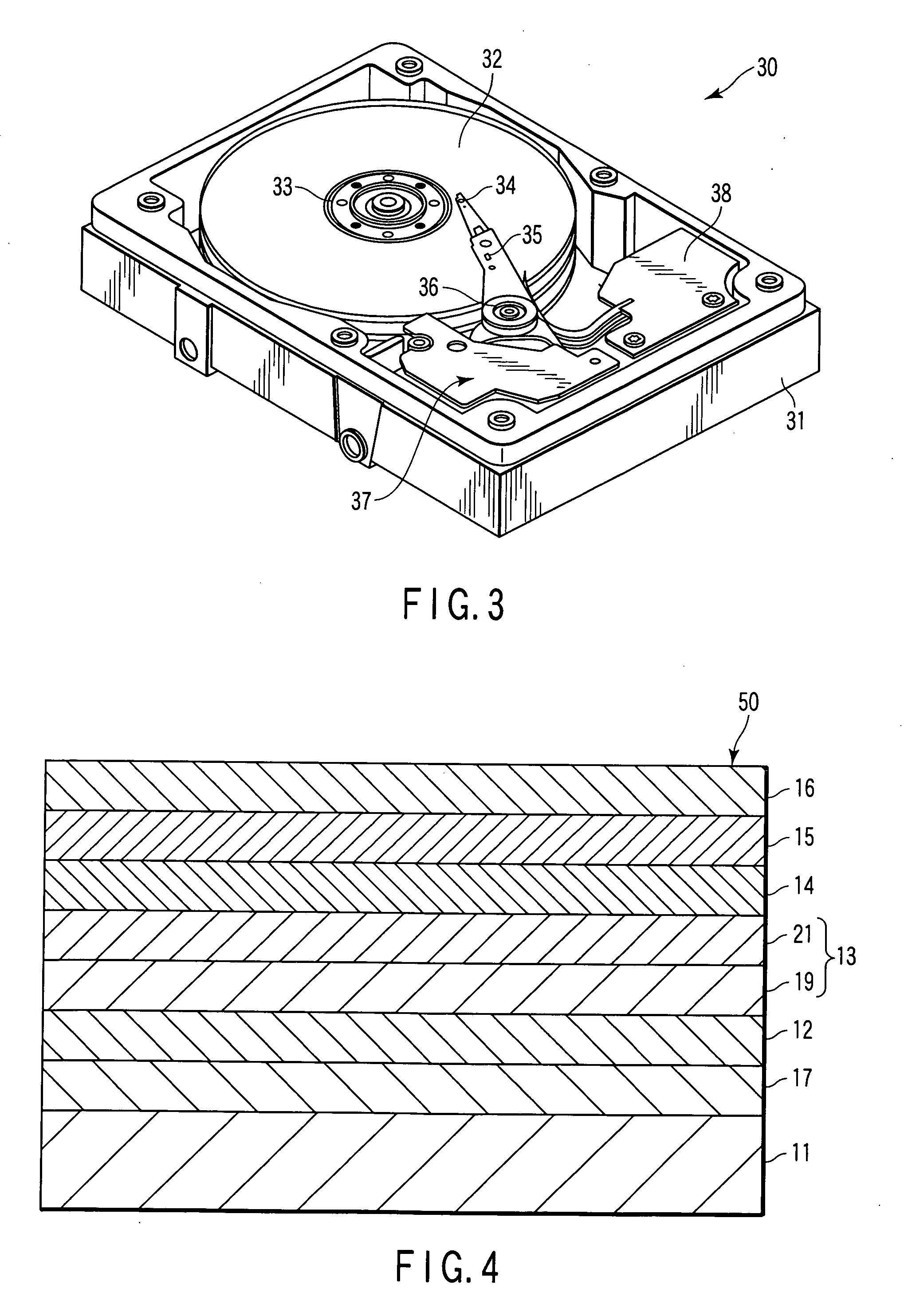

Perpendicular magnetic recording medium and magnetic recording/reproduction apparatus

ActiveUS20080182131A1Reduce grain sizeHigh-density recordingDisposition/mounting of recording headsRecord information storageMagnetic layerMaterials science

According to one embodiment, a soft magnetic layer, a first nonmagnetic underlayer having a fine crystal structure and made of Pd or a Pd alloy, a second nonmagnetic underlayer made of Ru or an Ru alloy, and a perpendicular magnetic recording layer are stacked on a nonmagnetic substrate.

Owner:KK TOSHIBA

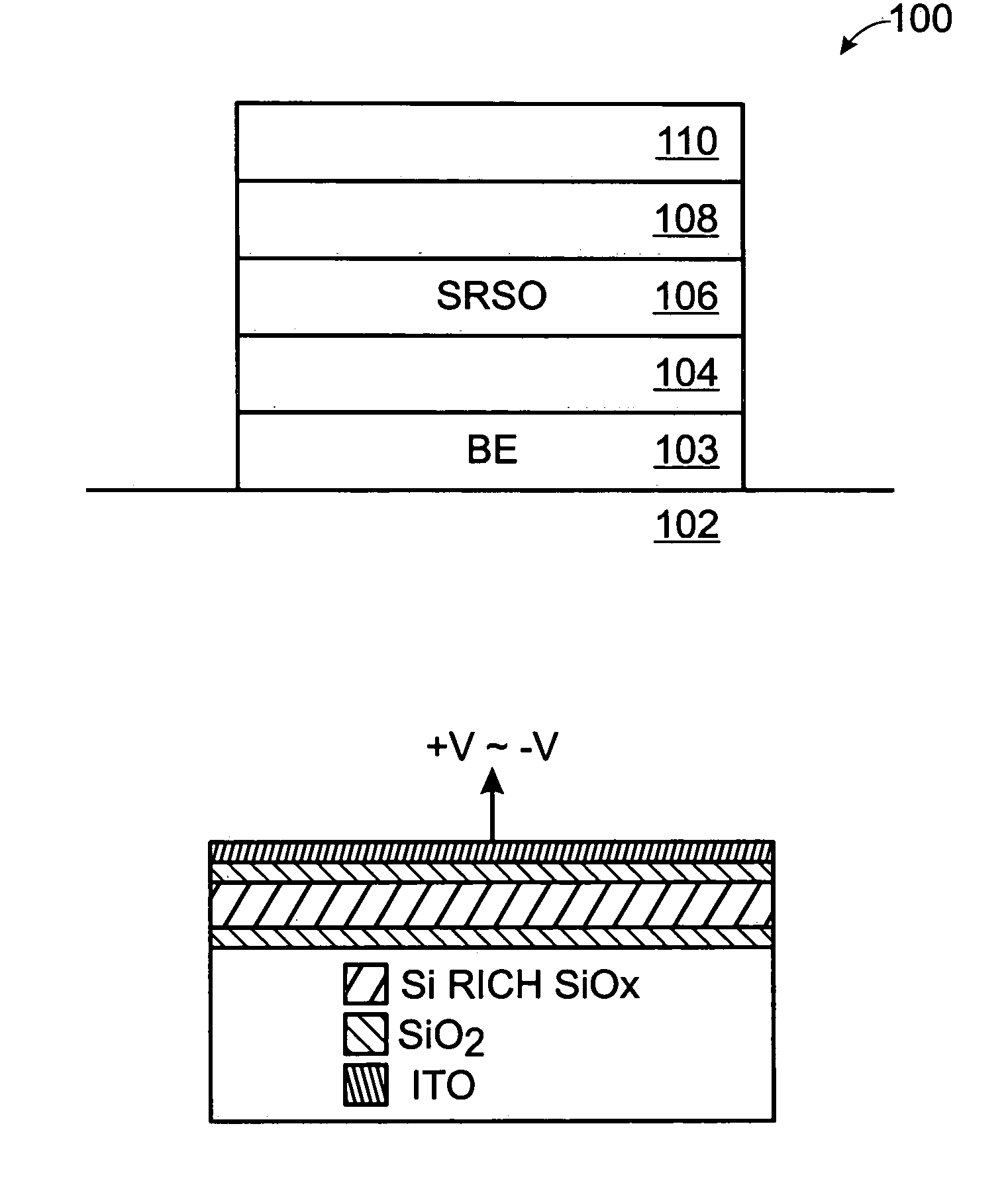

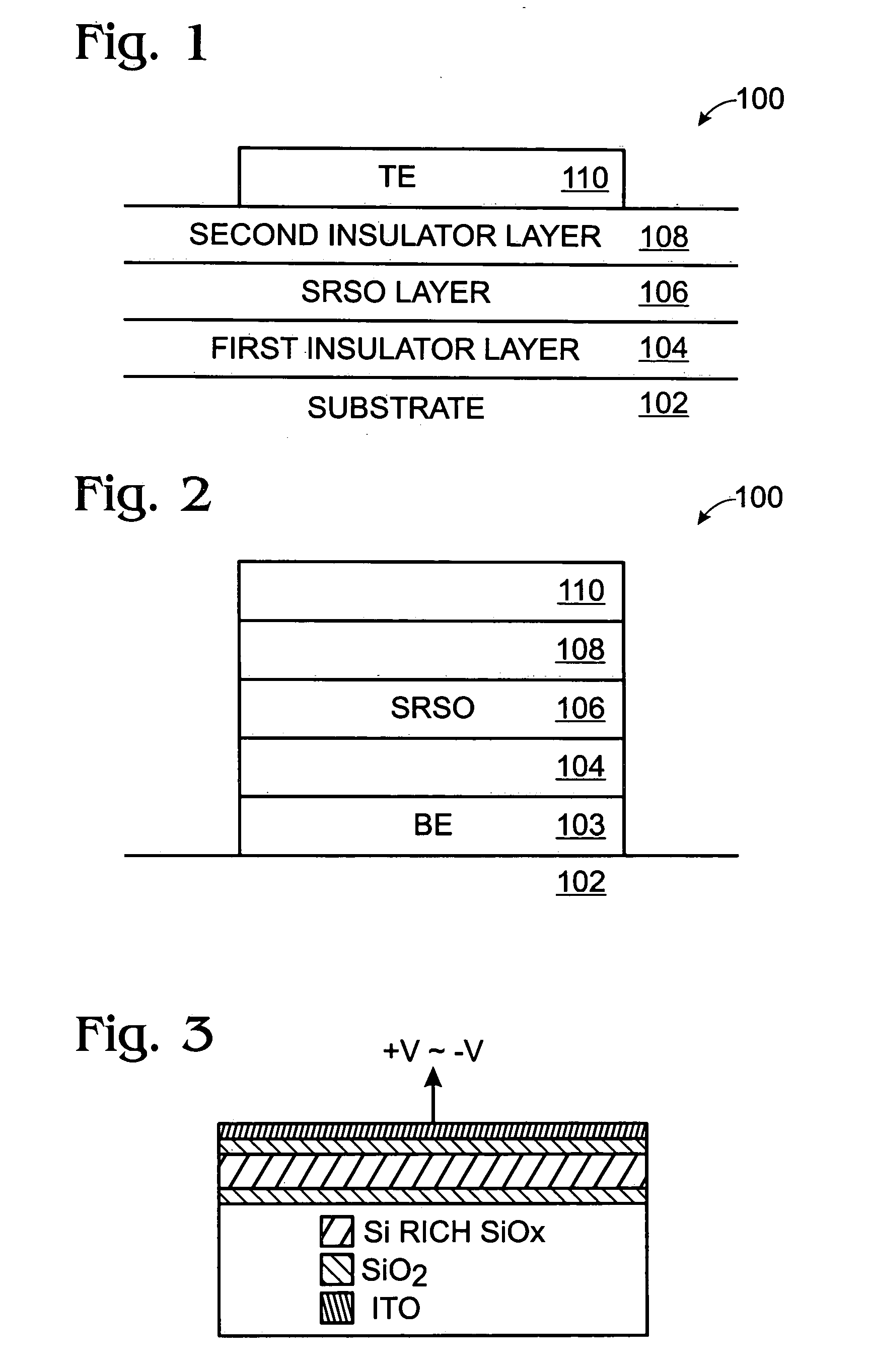

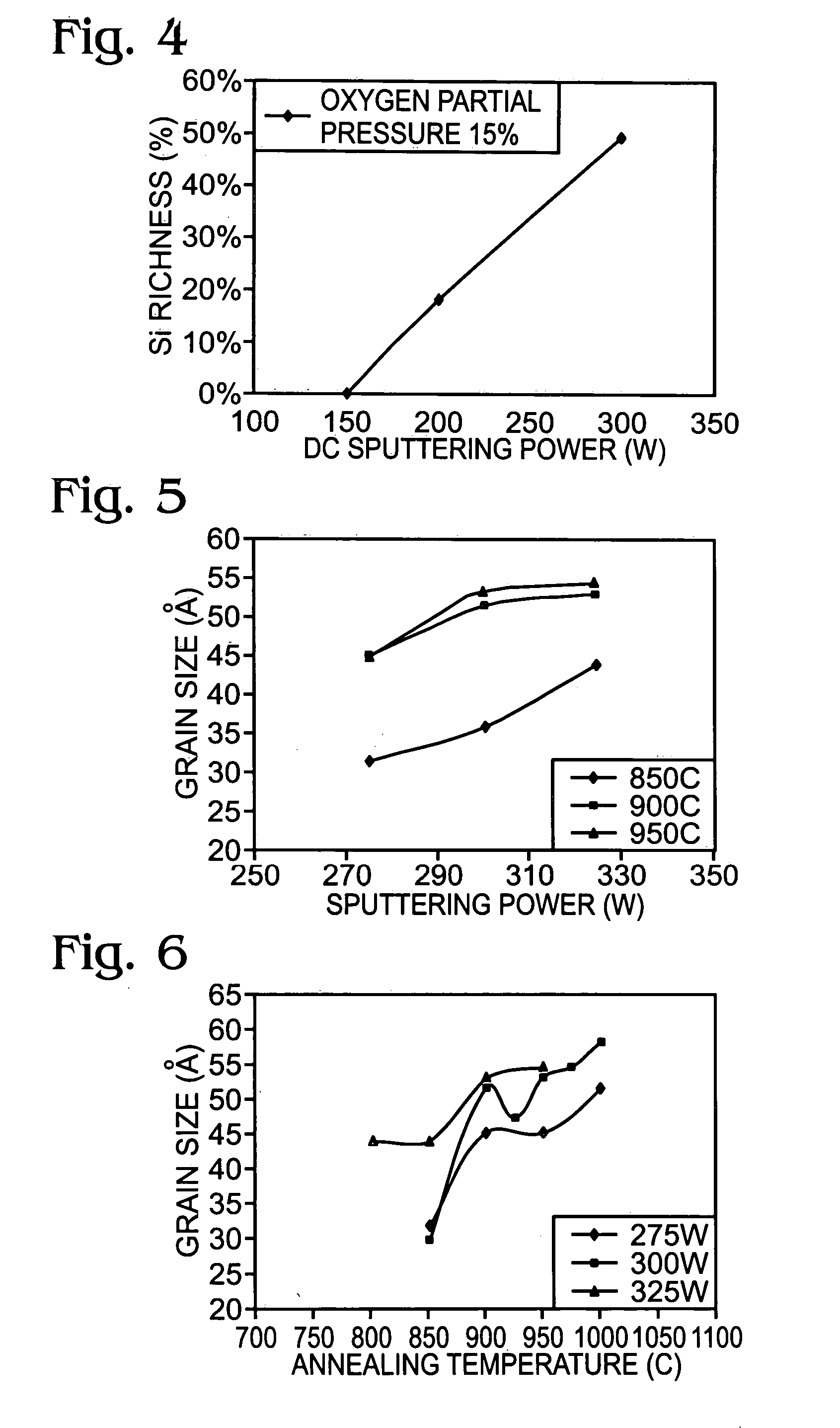

Wide wavelength range silicon electroluminescence device

InactiveUS20060180816A1Reduce defectsExtended wavelength rangeElectroluminescent light sourcesSolid-state devicesSilicon oxideLength wave

A method is provided for forming a Si electroluminescence (EL) device for emitting light at short wavelengths. The method comprises: providing a substrate; forming a first insulator layer overlying the substrate; forming a silicon-rich silicon oxide (SRSO) layer overlying the first insulator layer, embedded with nanocrystalline Si having a size in the range of 0.5 to 5 nm; forming a second insulator layer overlying the SRSO layer; and, forming a top electrode. Typically, the SRSO has a Si richness in the range of 5 to 40%. In one aspect, the SRSO layer is formed using a DC sputtering process. In another aspect, the SRSO formation step includes a rapid thermal annealing (RTA) process subsequent to depositing the SRSO. Likewise, thermal oxidation or plasma oxidation can be performed subsequent to the SRSO layer deposition. The size of Si nanocrystals is decreased in response to above-mentioned deposition, annealing, and oxidation processes.

Owner:SHARP LAB OF AMERICA INC

Galvanically-Active In Situ Formed Particles for Controlled Rate Dissolving Tools

A castable, moldable, and / or extrudable structure using a metallic primary alloy. One or more additives are added to the metallic primary alloy so that in situ galvanically-active reinforcement particles are formed in the melt or on cooling from the melt. The composite contains an optimal composition and morphology to achieve a specific galvanic corrosion rate in the entire composite. The in situ formed galvanically-active particles can be used to enhance mechanical properties of the composite, such as ductility and / or tensile strength. The final casting can also be enhanced by heat treatment, as well as deformation processing such as extrusion, forging, or rolling, to further improve the strength of the final composite over the as-cast material.

Owner:TERVES

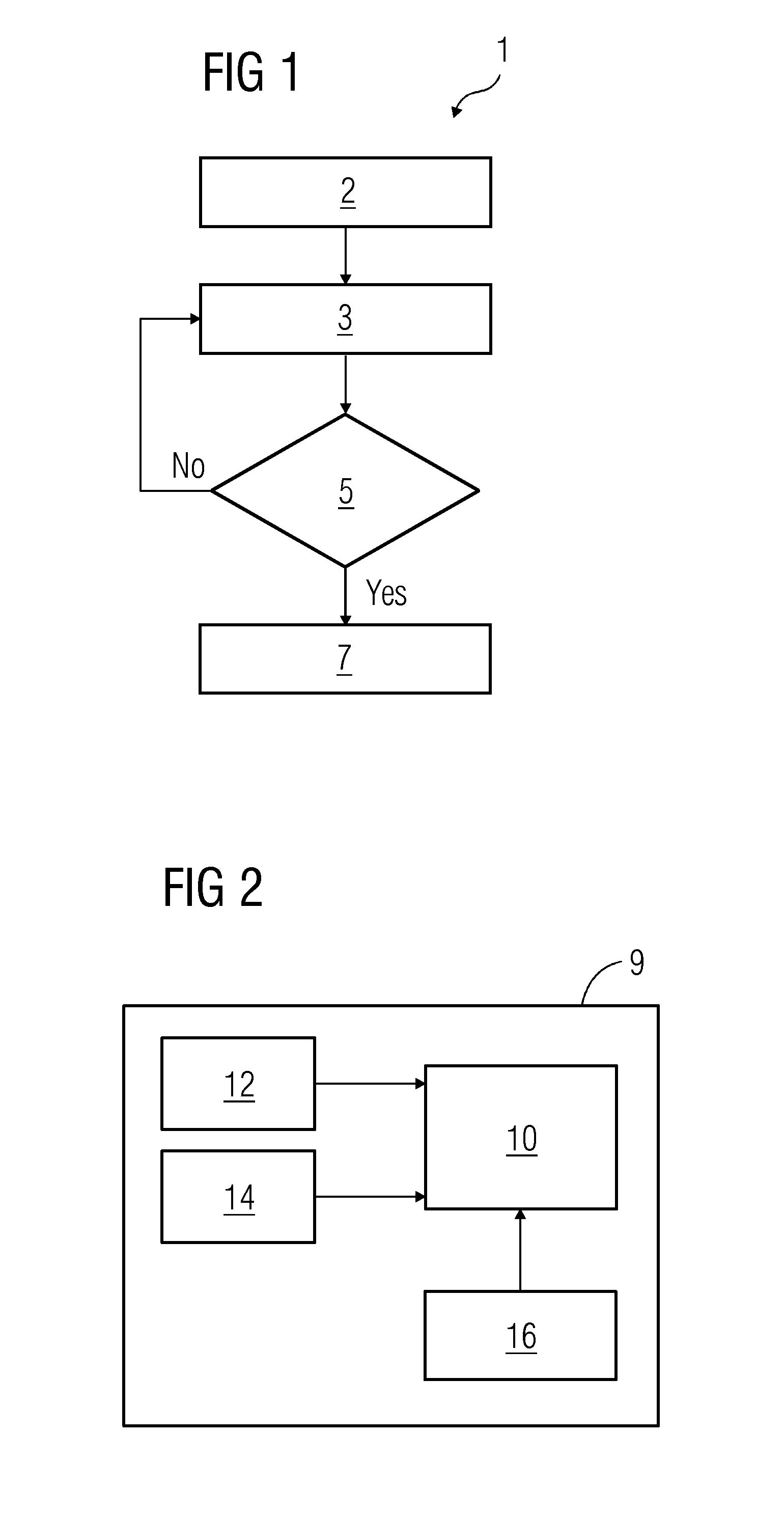

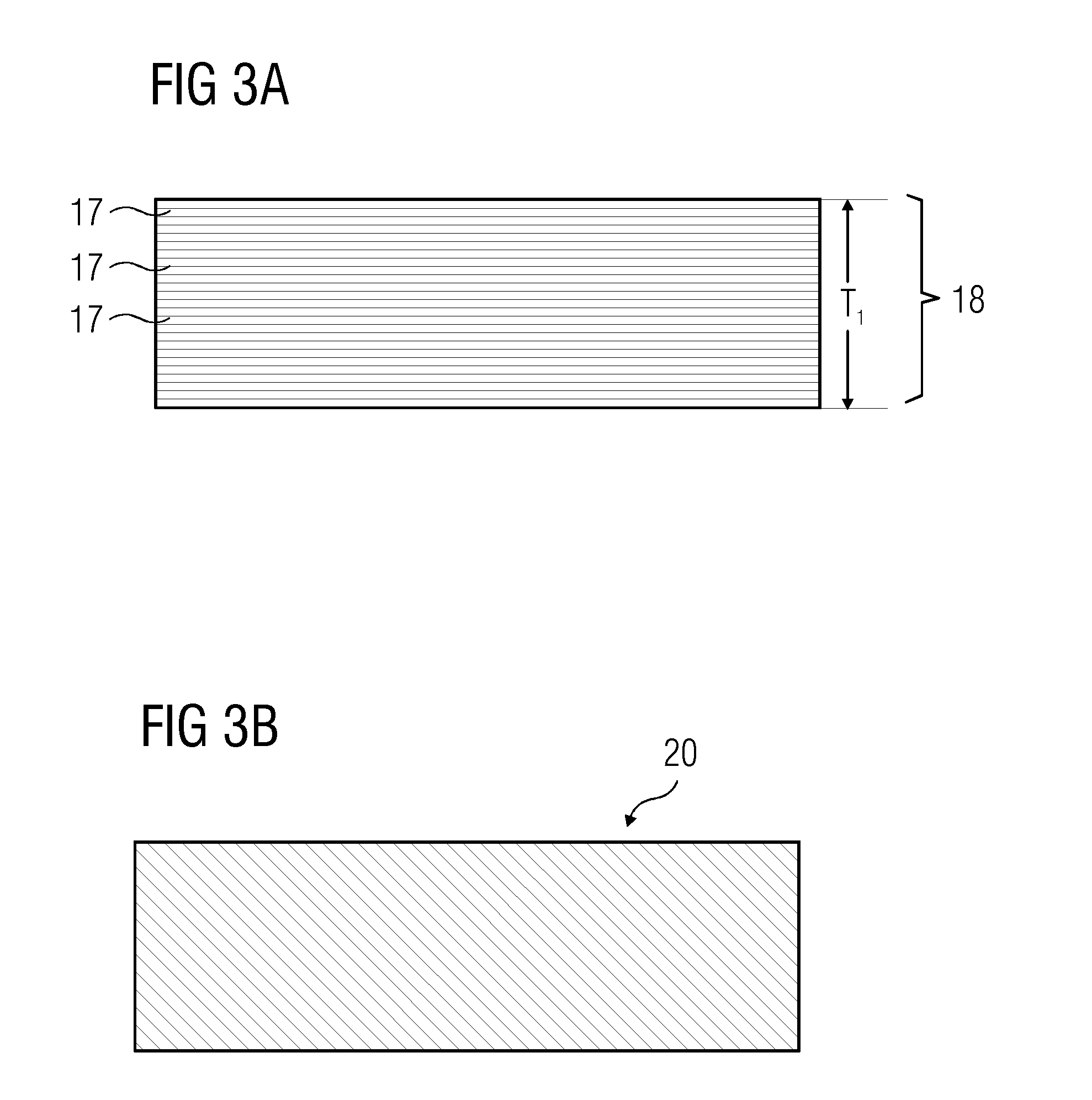

Method and an apparatus for controlling grain size of a component

InactiveUS20150266285A1Reduce grain sizeLarge grainAdditive manufacturing apparatusIncreasing energy efficiencyAdditive layer manufacturingCrystallite

A method and an apparatus for controlling a grain size of a component generated using an additive manufacturing process. Construct a first fused layer of the component by fusing a plurality of layers of a fusible material, wherein the first fused layer has a thickness T1. Thereafter, introduce stress through the first fused layer of the component. The component is generated by repeating the aforementioned steps. Further, the component is heated to a temperature above a recrystallization start temperature (Rxst) to control the grain size of the component.

Owner:SIEMENS AG

Hot-rolling transformation-induced plasticity steel plate and preparation method thereof

A hot-rolling transformation-induced plasticity steel plate and a preparation method thereof belong to the field of metallurgical technology. The steel plate comprises the following components by weight percentage: 0.18 to 0.20 percent of C, 1.30 to 1.45 percent of Mn, 0.60 to 0.70 percent of Si, 0.50 to 0.60 percent of Al, 0.009 percent or less than 0.009 percent of P, 0.007 percent or less than 0.007 percent of S, 0 to 0.040 percent of Nb and the balance of Fe. The preparation method thereof comprises the steps of: smelting low-silicon and low-carbon steel into steel ingot; heating the steel ingot to 1200 plus / minus 10 DEG C to obtain billet through forging; loading the billet into a heating furnace, heating the billet to 1200 plus / minus 10 DEG C and keeping temperature for 1 to 2 hours; carrying out rough rolling and precision rolling; air cooling till the temperature reaches 700 to 760 DEG C; accelerating cooling at a speed of reducing 40 to 50 DEG C per second; and adopting a reeling machine for reeling. The hot-rolling transformation-induced plasticity steel plate prepared by the method has high intensity of tension and better impact ductility.

Owner:NORTHEASTERN UNIV

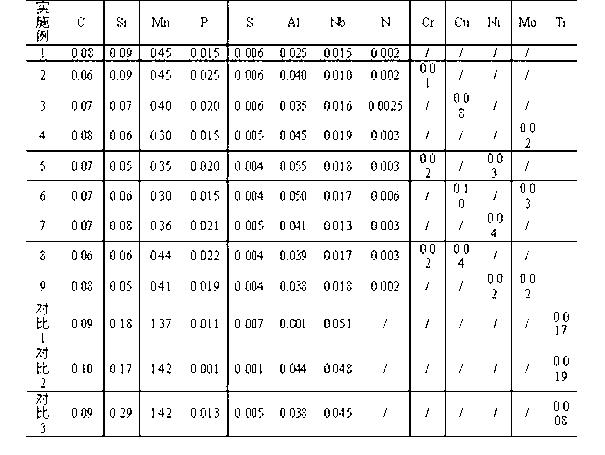

Steel for 300MPa-grade automobile structural part and production method for steel

The invention relates to steel for a 300MPa-grade automobile structural part and a production method for the steel. The steel comprises the following main components in percentage by weight: 0.06-0.08 percent of C, 0.05-0.09 percent of Si, 0.30-0.45 percent of Mn, 0.025-0.055 percent of Al, 0.015-0.025 percent of P, less than or equal to 0.006 percent of S, 0.010-0.019 percent of Nb, less than or equal to 0.006 percent of N and the balance of Fe and impurities. The production method comprises the production steps of molten iron desulfurization, converter smelting, ladle argon blowing, continuous casting, heating of a casting blank, hot rolling, winding, conventional pickling, cold rolling, continuous operation and flattening for later use. The production method disclosed by the invention has the advantages of short process flow, lower energy consumption and stable mechanical property; and in addition, on the premise that the yield strength of 300-340MPa and the tensile strength of 390-445MPa are met, the elongation percentage is not lower than 31 percent, the plastic strain ratio r is 1.45-1.80, a strain hardening index n is 0.16-0.20, a wide-cold test bending is 180 degrees and a bending diameter d is equal to 0; and in a metallographic structure, an equiaxed ferrite is 85-90 percent and a granular pearlite is 10-15 percent.

Owner:武汉钢铁有限公司

Metal halide perovskite light emitting device and method of manufacturing the same

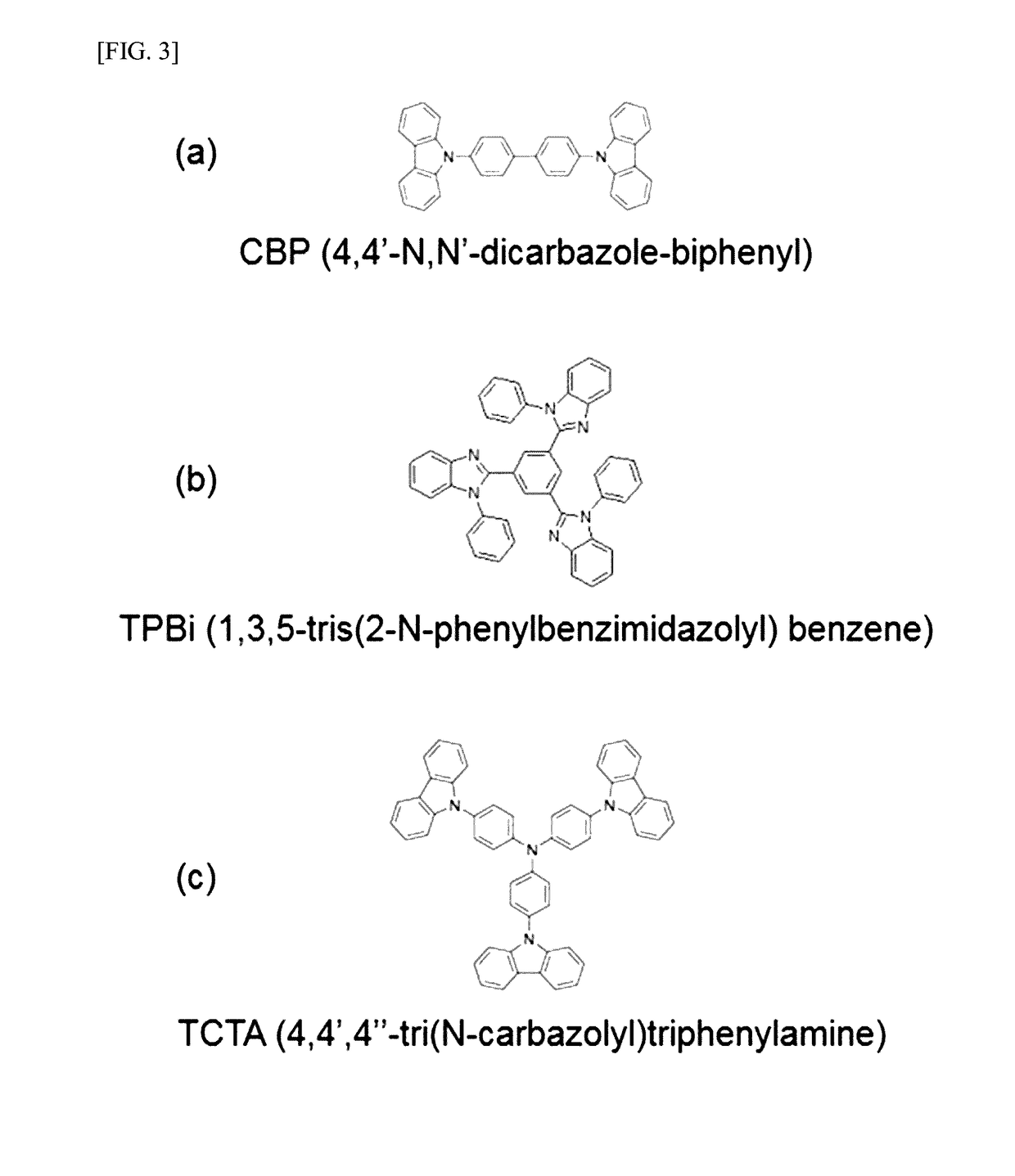

InactiveUS20170125747A1Small grain sizeExcellent electrical propertiesSolid-state devicesSemiconductor/solid-state device manufacturingMetal halidesLight emitting device

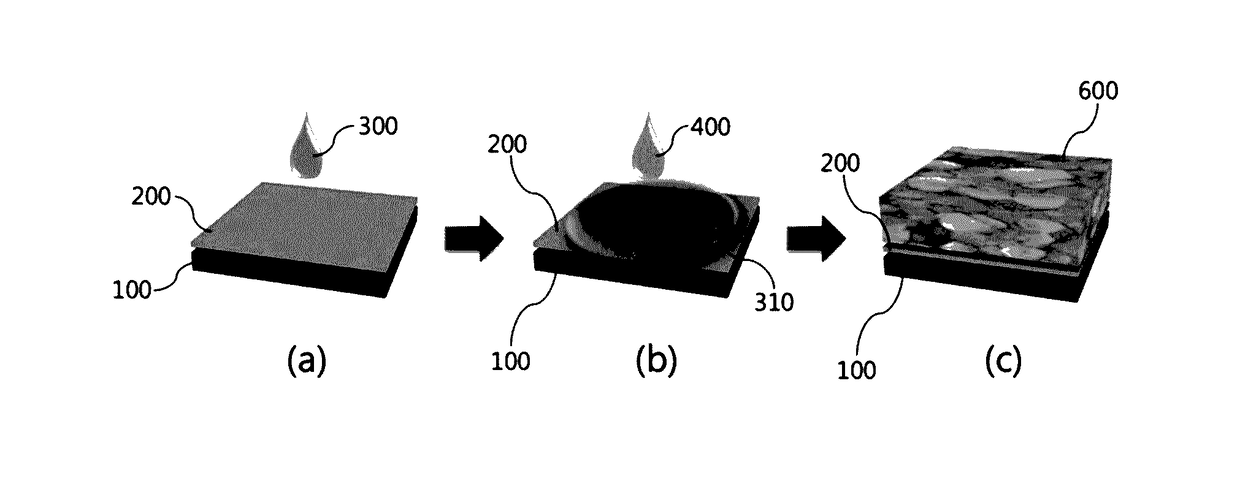

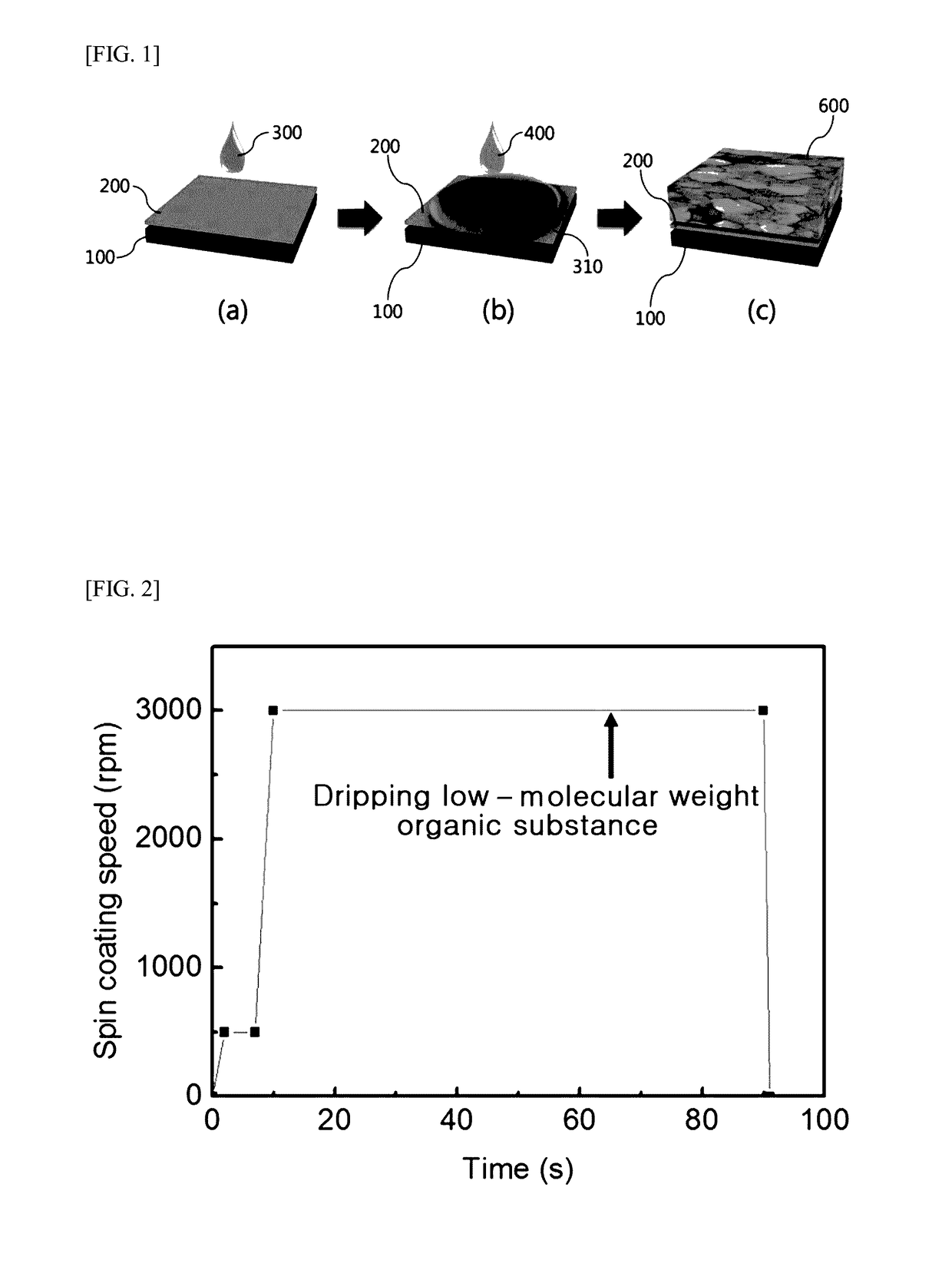

Provided are a metal halide perovskite light emitting device and a method of manufacturing the same. The method of manufacturing a metal halide perovskite light emitting device includes preparing a substrate having a positive electrode formed on an upper part thereof, starting coating the substrate on which the positive electrode is formed with a metal halide perovskite light emitting layer, forming a metal halide perovskite light emitting layer by dripping a low-molecular-weight organic substance solution during the coating of the metal halide perovskite light emitting layer, and forming a negative electrode on the light emitting layer. According to the present invention, a low-molecular-weight organic substance is included in a metal halide perovskite light emitting layer to reduce the sizes of grains in metal halide perovskites, to improve electrical characteristics by the effect of defect passivation on a metal halide perovskite, and to improve luminous efficiency of a thin film by reducing an exciton diffusion length by spatially trapping excitons well in decreased grains, thereby effectively improving efficiency of a metal halide perovskite light emitting diode and overcoming limitations in application.

Owner:POSTECH ACAD IND FOUND

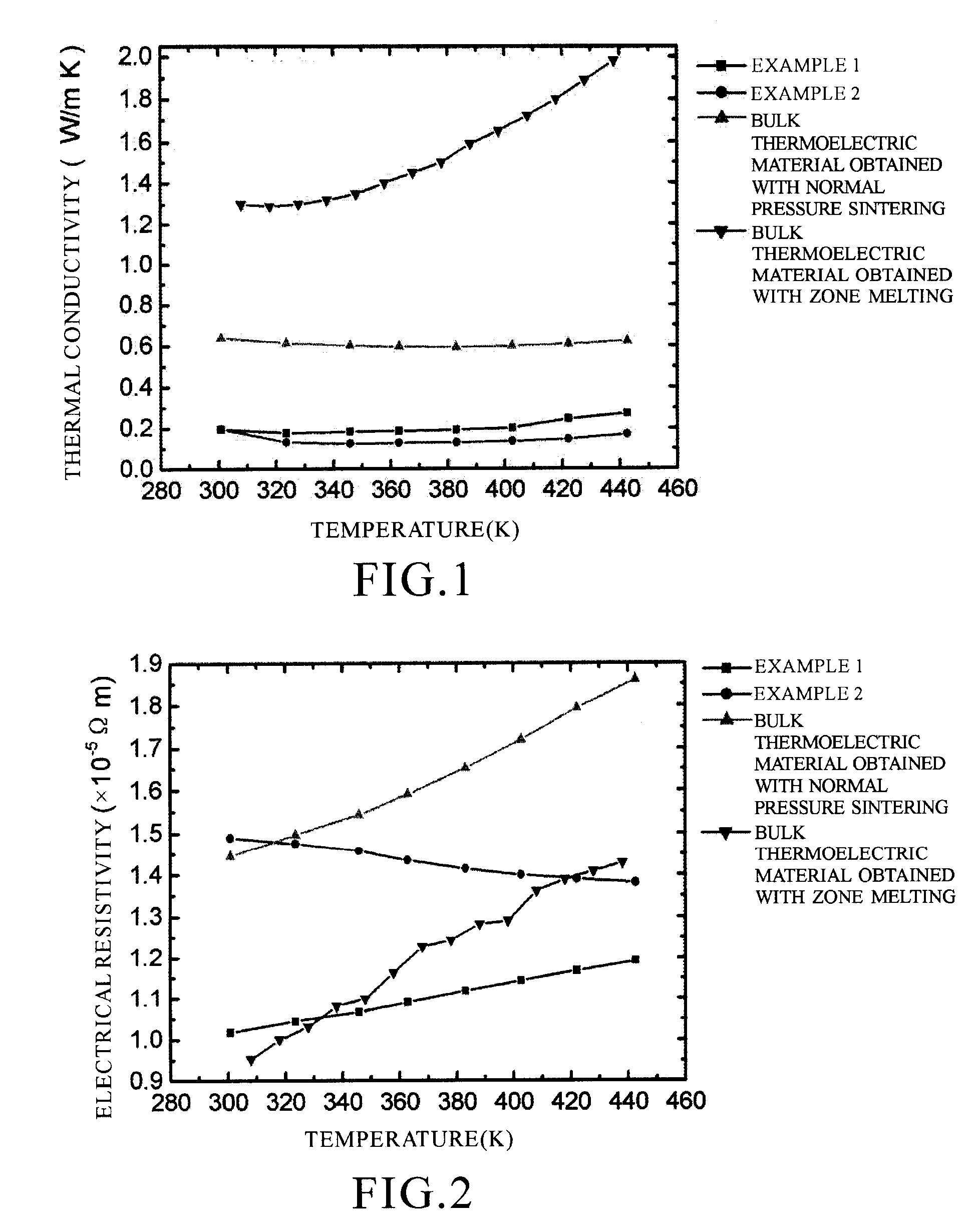

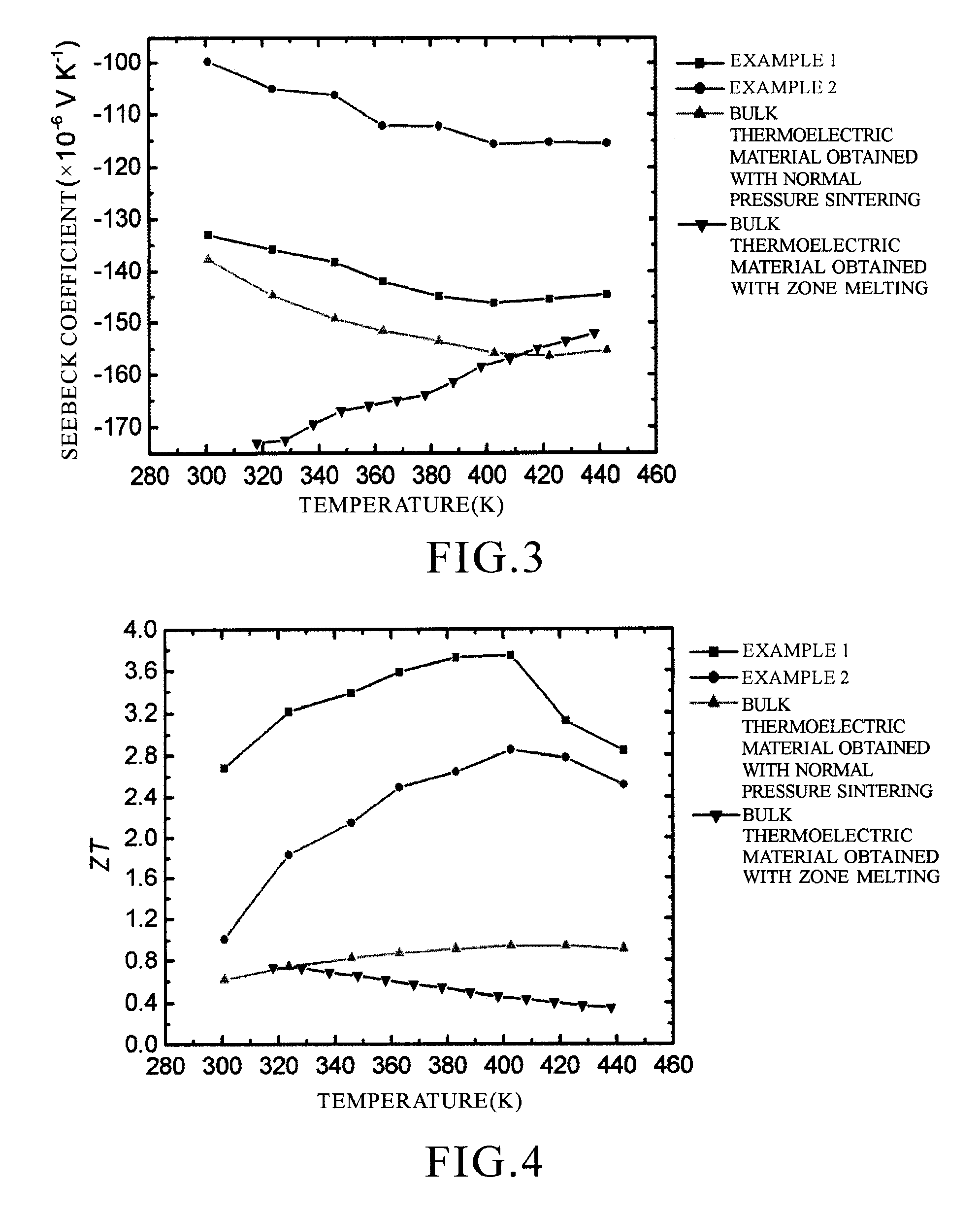

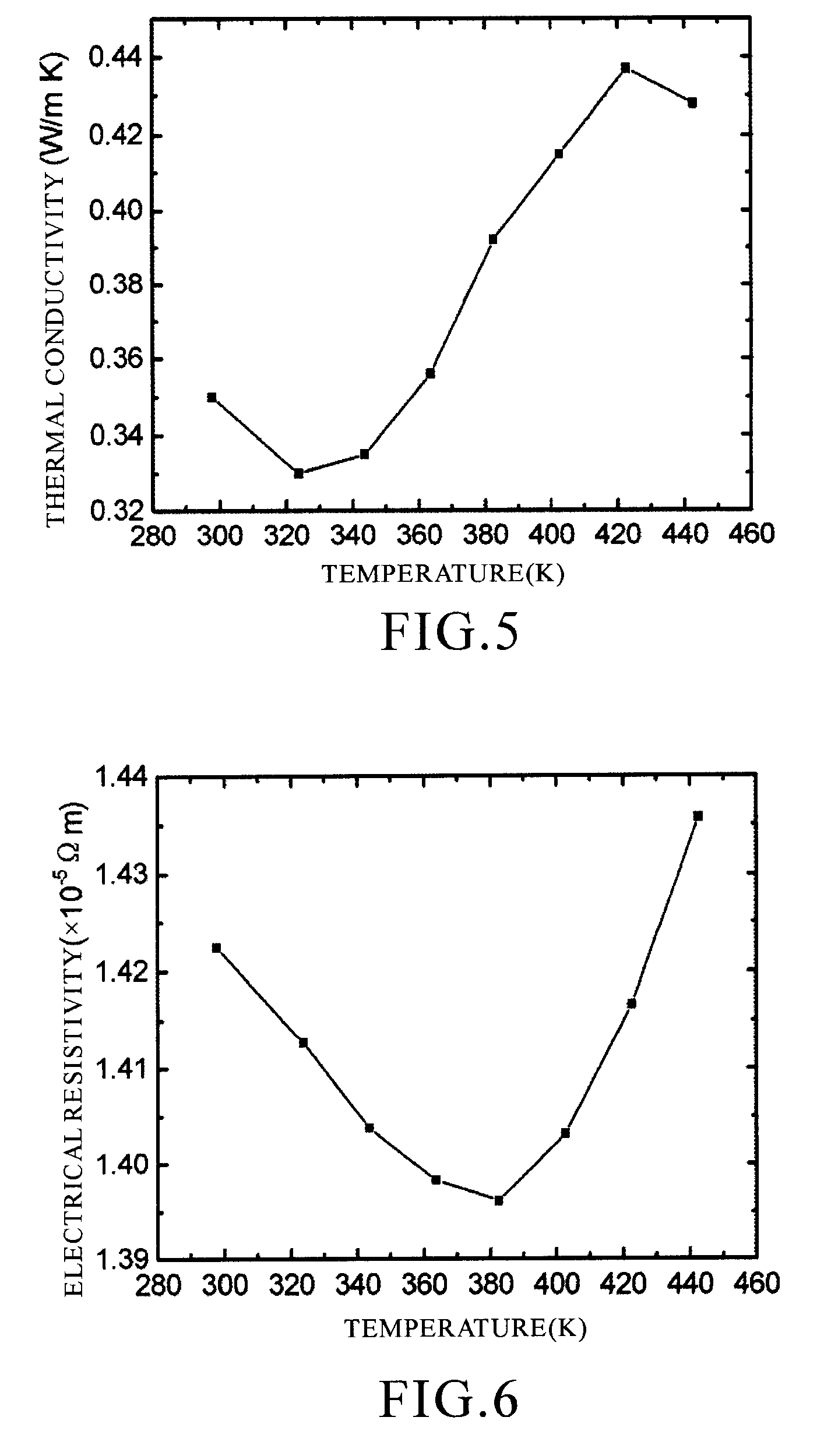

Fabrication of High Performance Densified Nanocrystalline Bulk Thermoelectric Materials Using High Pressure Sintering Technique

InactiveUS20100295202A1Low thermal conductivityIncrease valueMaterial nanotechnologyThermoelectric device manufacture/treatmentHigh densityAlloy

The present invention provides a method for the fabrication of high performance densified nanocrystalline bulk thermoelectric material, comprising: (1) preparing a thermoelectric alloy nanopowders by a ball milling process to achieve an average crystal size of 5-30 nm, and (2) preparing the nanocrystalline bulk thermoelectric material by high pressure sintering at a temperature of 0.25-0.8 Tm under a pressure of 0.8-6.0 GPa for 10-120 minutes, to achieve a relative density of 90-100% and an average grain size of 10-50 nm. The method is easy to operate and allows the production of a thermoelectric material with a ZT value higher than 2. In addition, the method can ensure both good thermoelectric properties and high density, and therefore have important applications for energy industry.

Owner:YANSHAN UNIV

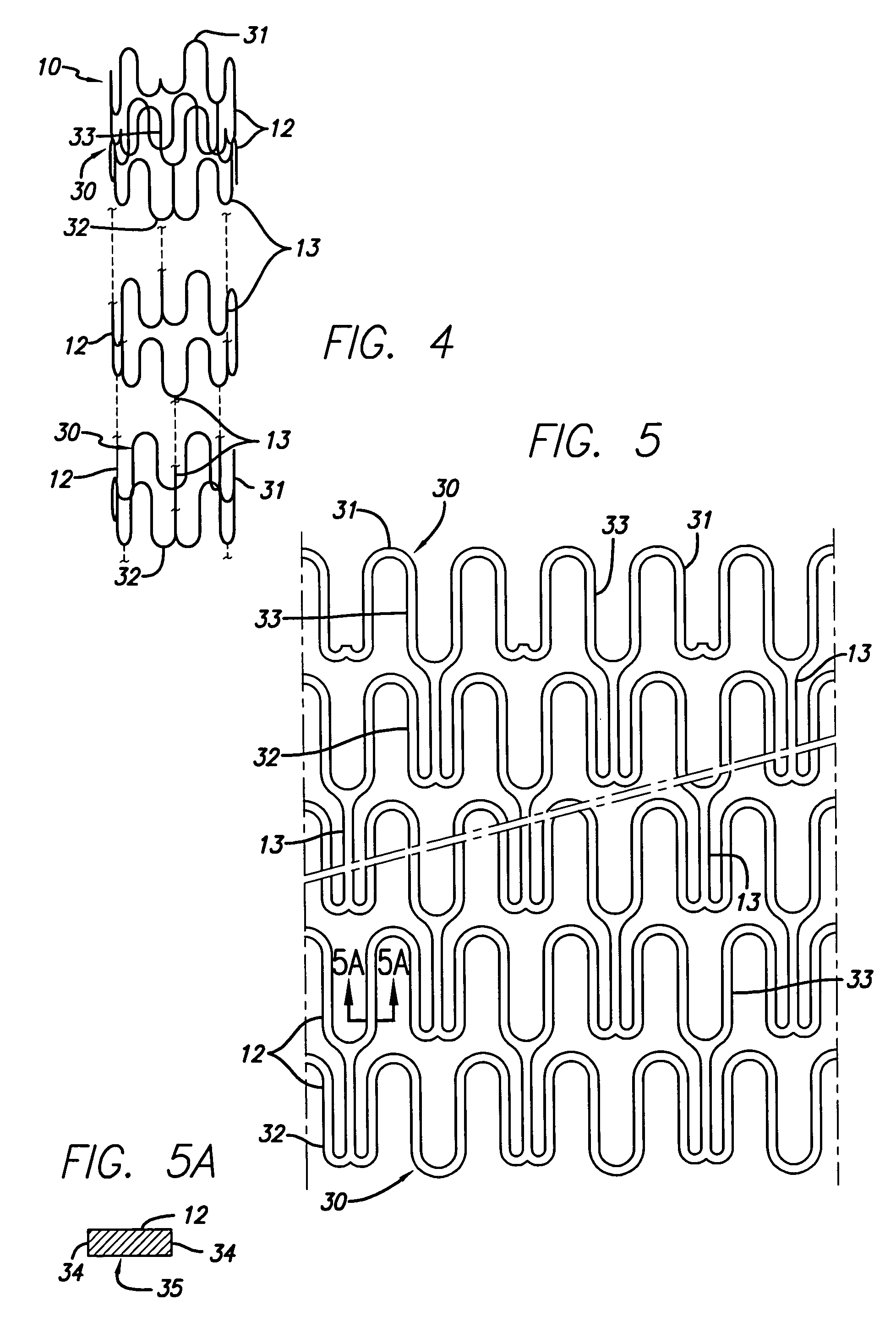

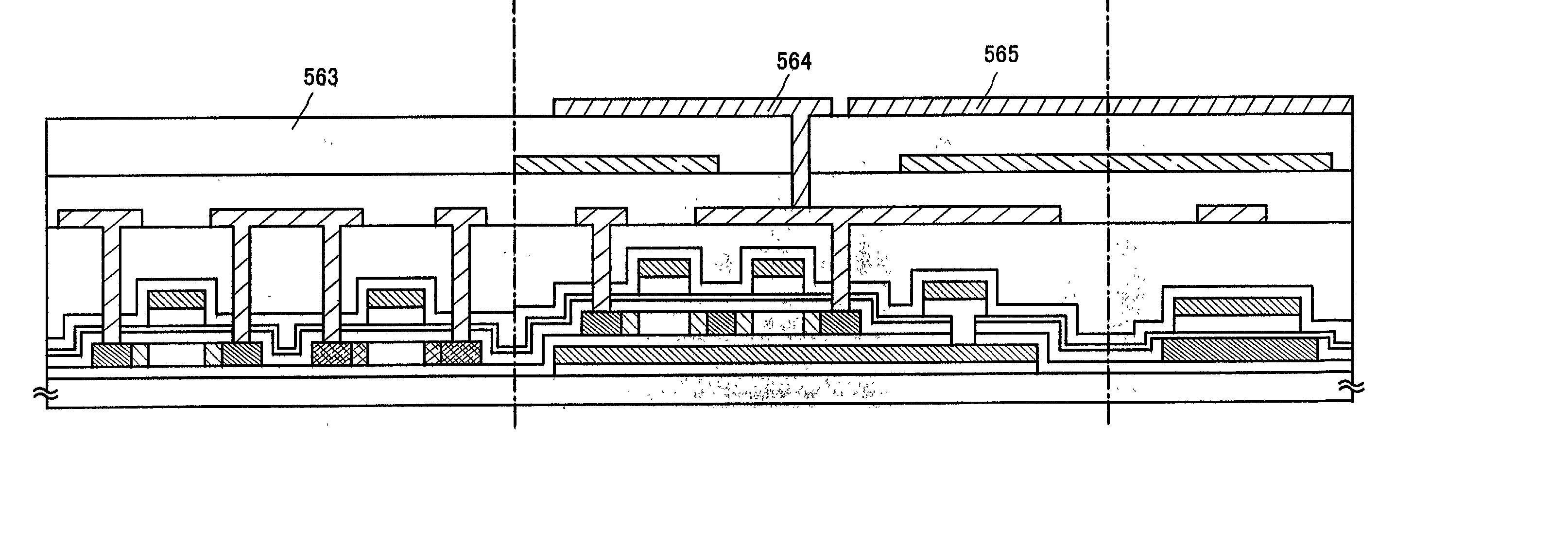

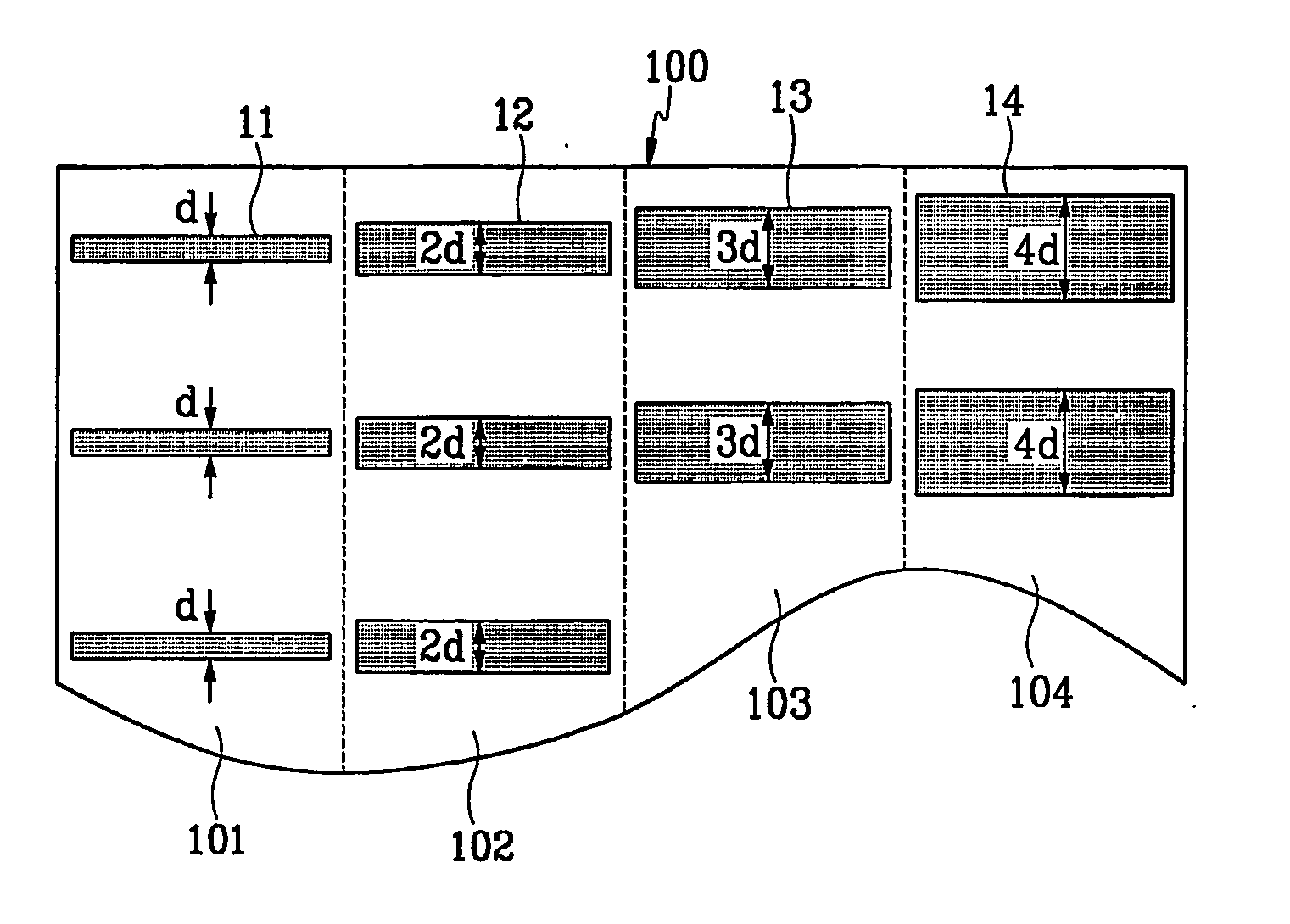

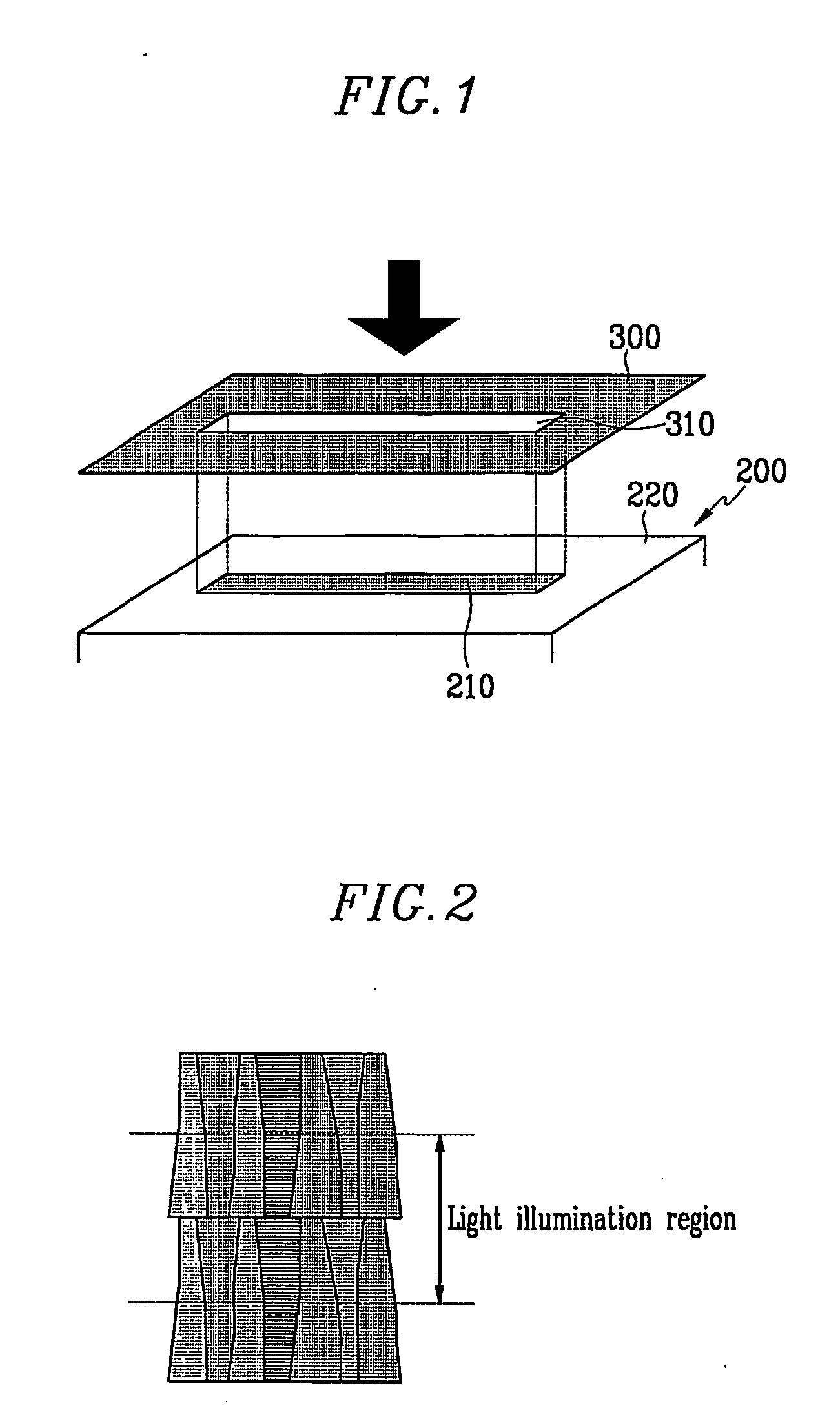

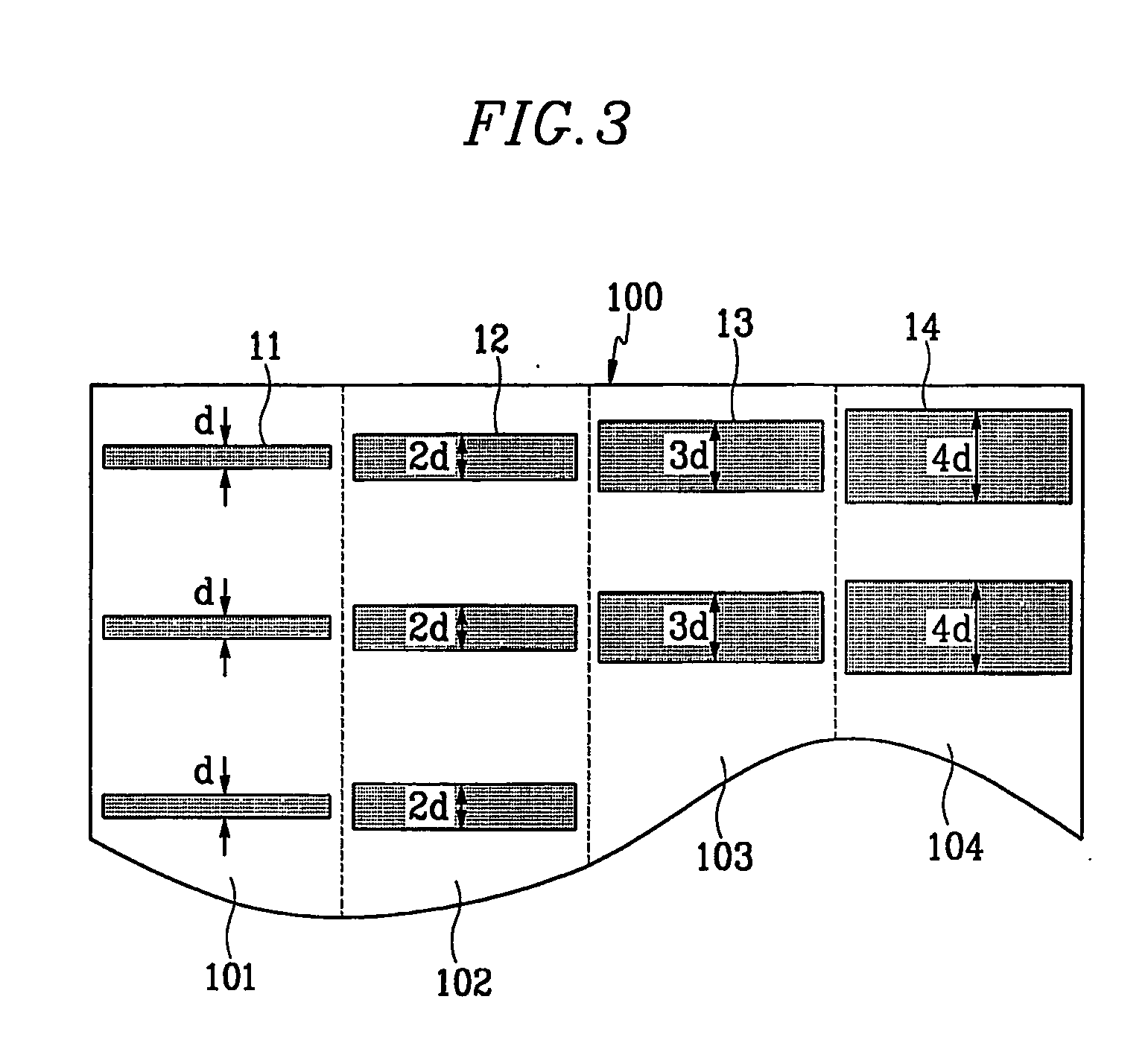

Mask for crystallizing polysilicon and a method for forming thin film transistor using the mask

InactiveUS20050079693A1Small grain sizeReduce grain sizeTransistorOther chemical processesReverse orderCrystallization

A mask for forming polysilicon has a first slit region where a plurality of horizontal slit patterns are arranged in the vertical direction while bearing the same width, a second slit region where a plurality of horizontal slit patterns are arranged in the vertical direction while bearing the same width, a third slit region where a plurality of horizontal slit patterns are arranged in the vertical direction while bearing the same width, and a fourth slit region where a plurality of horizontal slit patterns are arranged in the vertical direction while bearing the same width. The slit patterns arranged at the first to fourth slit regions are sequentially enlarged in width in the horizontal direction in multiple proportion to the width d of the slit pattern at the first slit region. The centers of the slit patterns arranged at the first to fourth slit regions in the horizontal direction are placed at the same line. The slit patterns arranged at the respective slit regions in the vertical direction are spaced from each other with a distance of 8*d. Alternatively, the first to fourth slit regions may be arranged in reverse order, or in the vertical direction.

Owner:SAMSUNG DISPLAY CO LTD

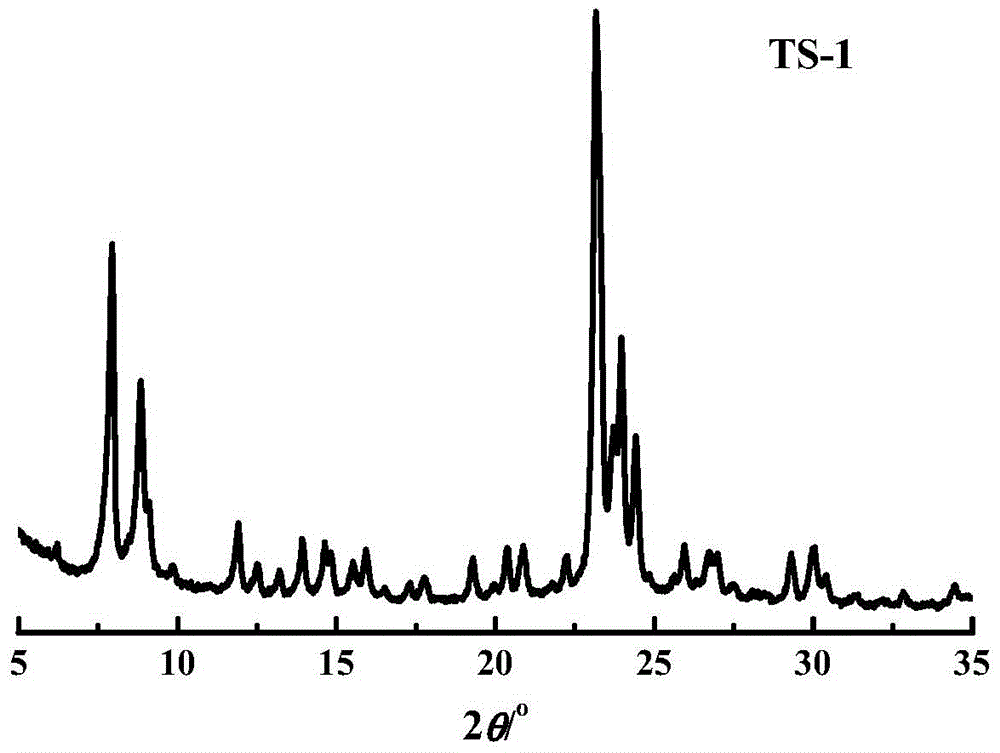

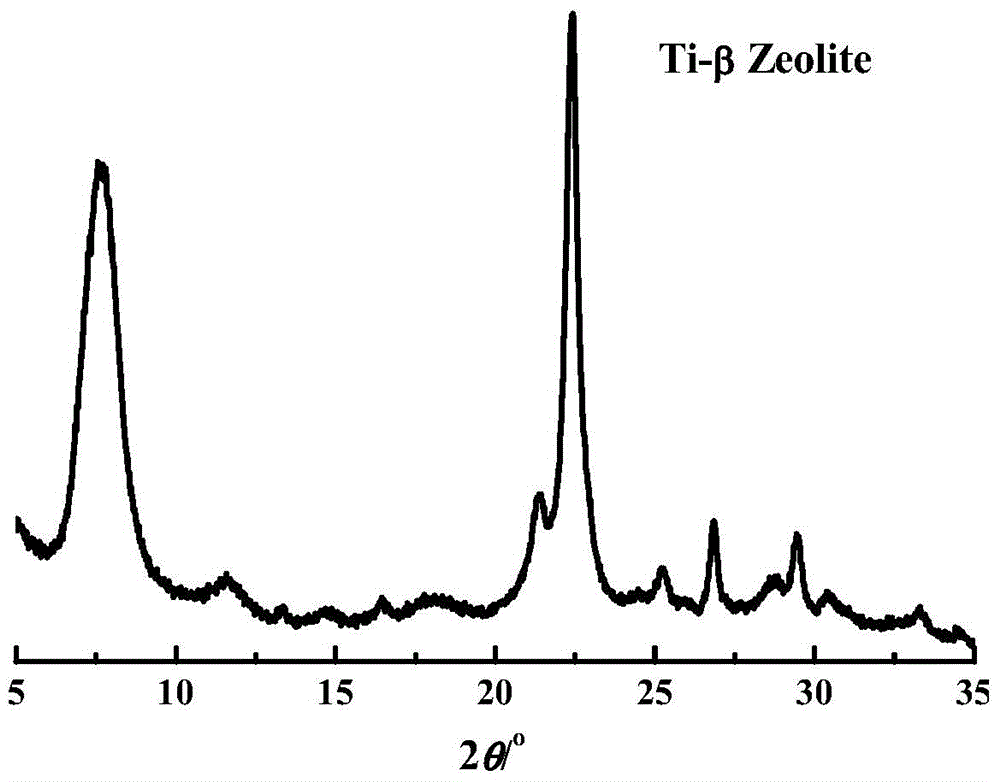

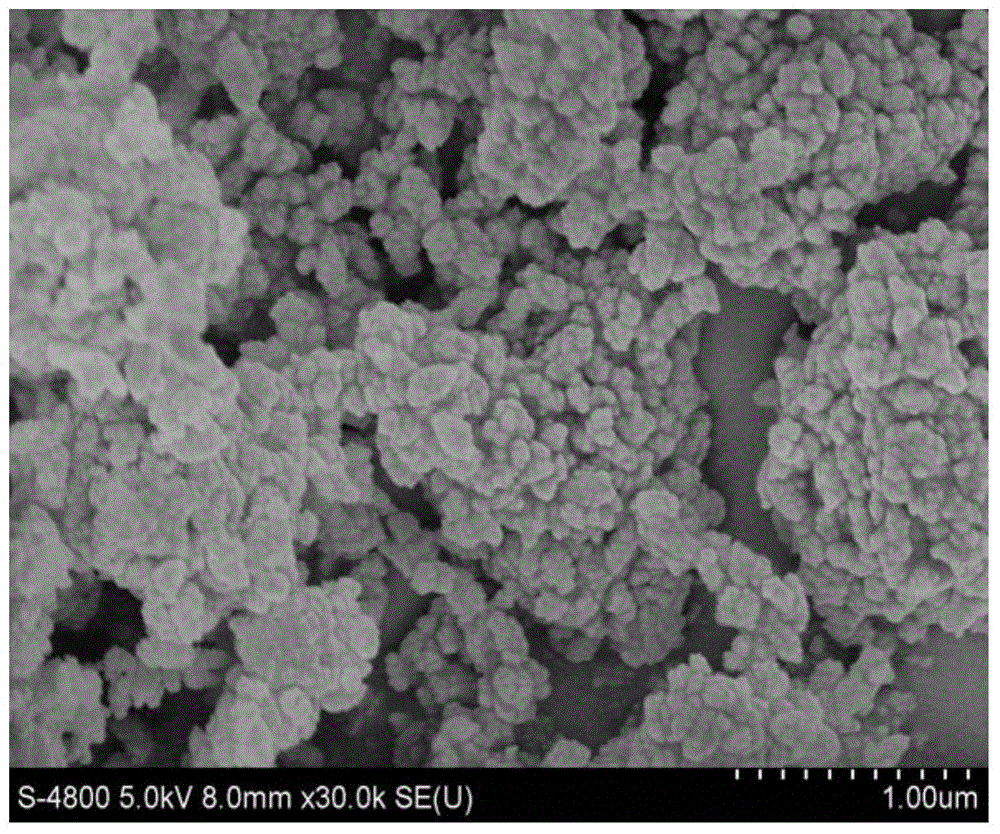

Titanium silicalite molecular sieve synthesizing method

ActiveCN104556115AIncrease profitReduce grain sizeCrystalline aluminosilicate zeolitesMolecular sieveTitanium

The invention discloses a titanium silicalite molecular sieve synthesizing method which comprises the following steps: forming a crystallization mixture from a titanium source, a template agent, water, polyhydric alcohols, peroxide, a silicon source and an optional inorganic ammonium source, crystallizing, and recycling the titanium silicalite molecular sieve, wherein the silicon source refers to an organic silicon source and / or a solid silicon source. According to the method, the activity of the synthesized titanium silicalite molecular sieve can be improved, and the grain size is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

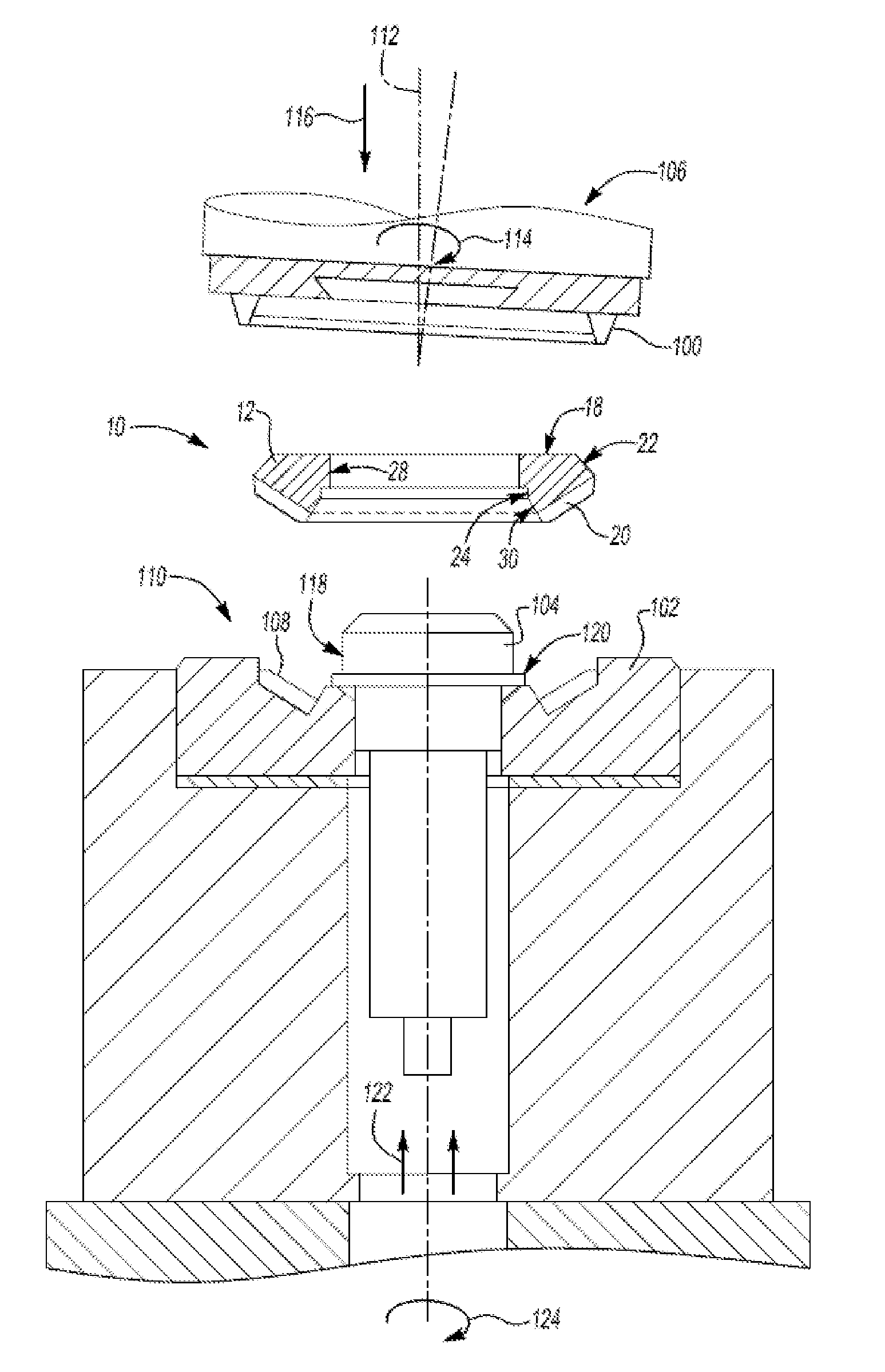

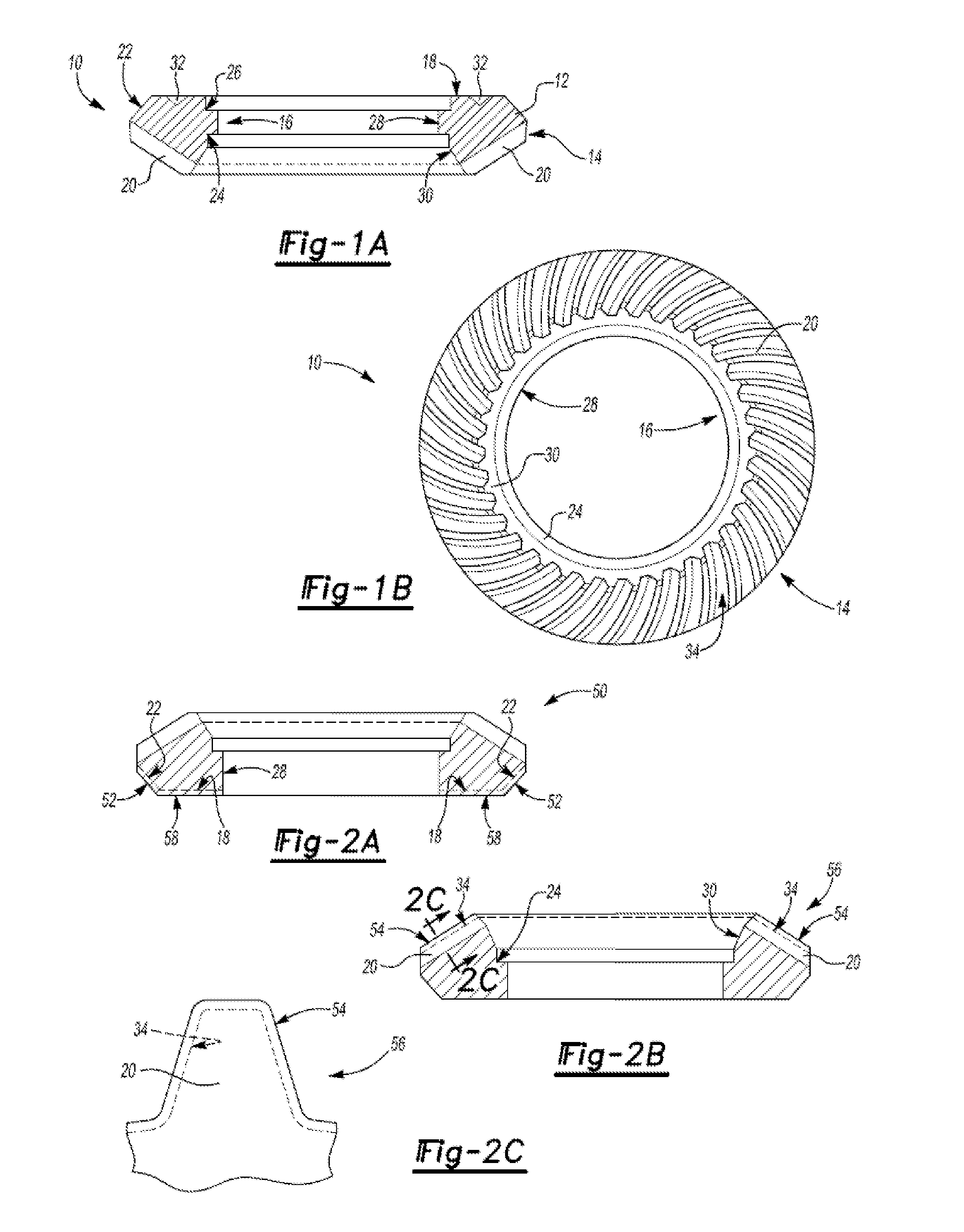

Bevel and hypoid gear and method of manufacture

InactiveUS20110126654A1Improve surface propertiesReduce molding processMetal-working apparatusPortable liftingRoll formingEngineering

Bevel and hypoid gears are used in power transmissions including automotive applications. Provided is a net shaped bevel or hypoid gear having a generally annular gear body including a plurality of radially outwardly extending gear teeth formed from a generally annular blank made of powdered metal. Also provided is a method for manufacturing a net shaped bevel or hypoid gear including the steps of providing and optionally heat treating a generally ring-shaped or annular blank made of metal powder, then incrementally deforming the blank by orbitally forming or roll forming to produce a net shaped gear member with a plurality of outwardly extending gear teeth, which may be of a bevel or hypoid type.

Owner:GM GLOBAL TECH OPERATIONS LLC

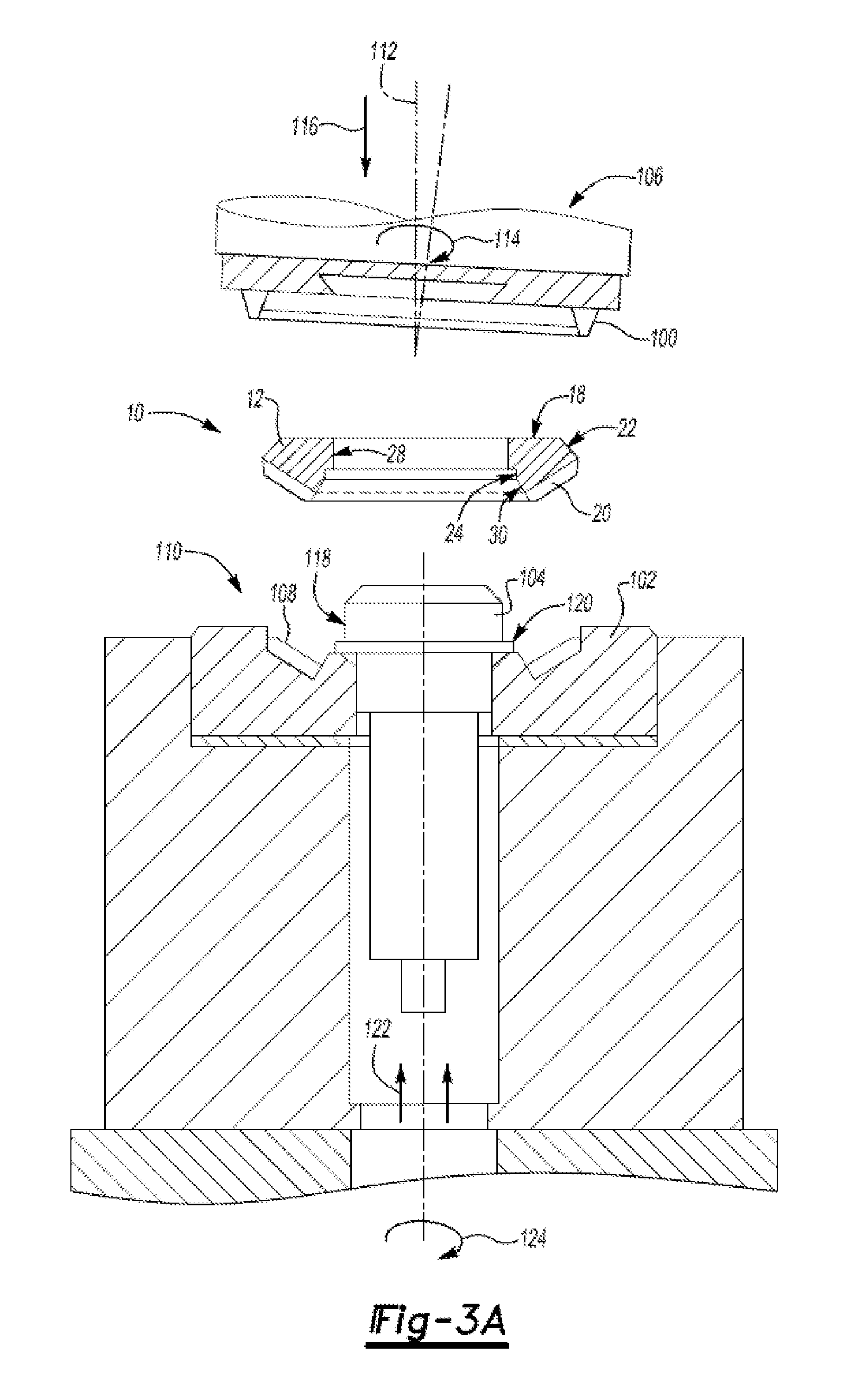

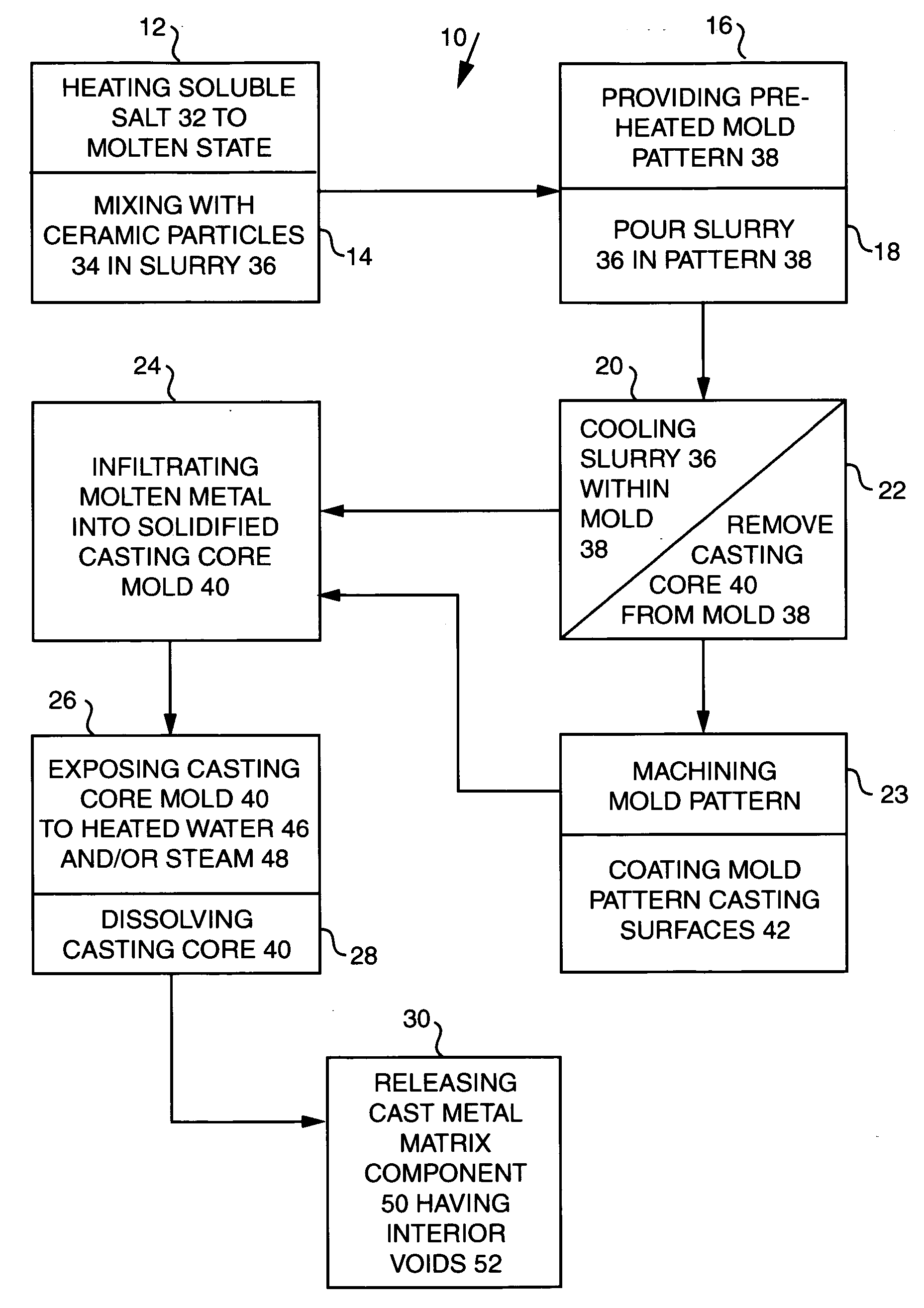

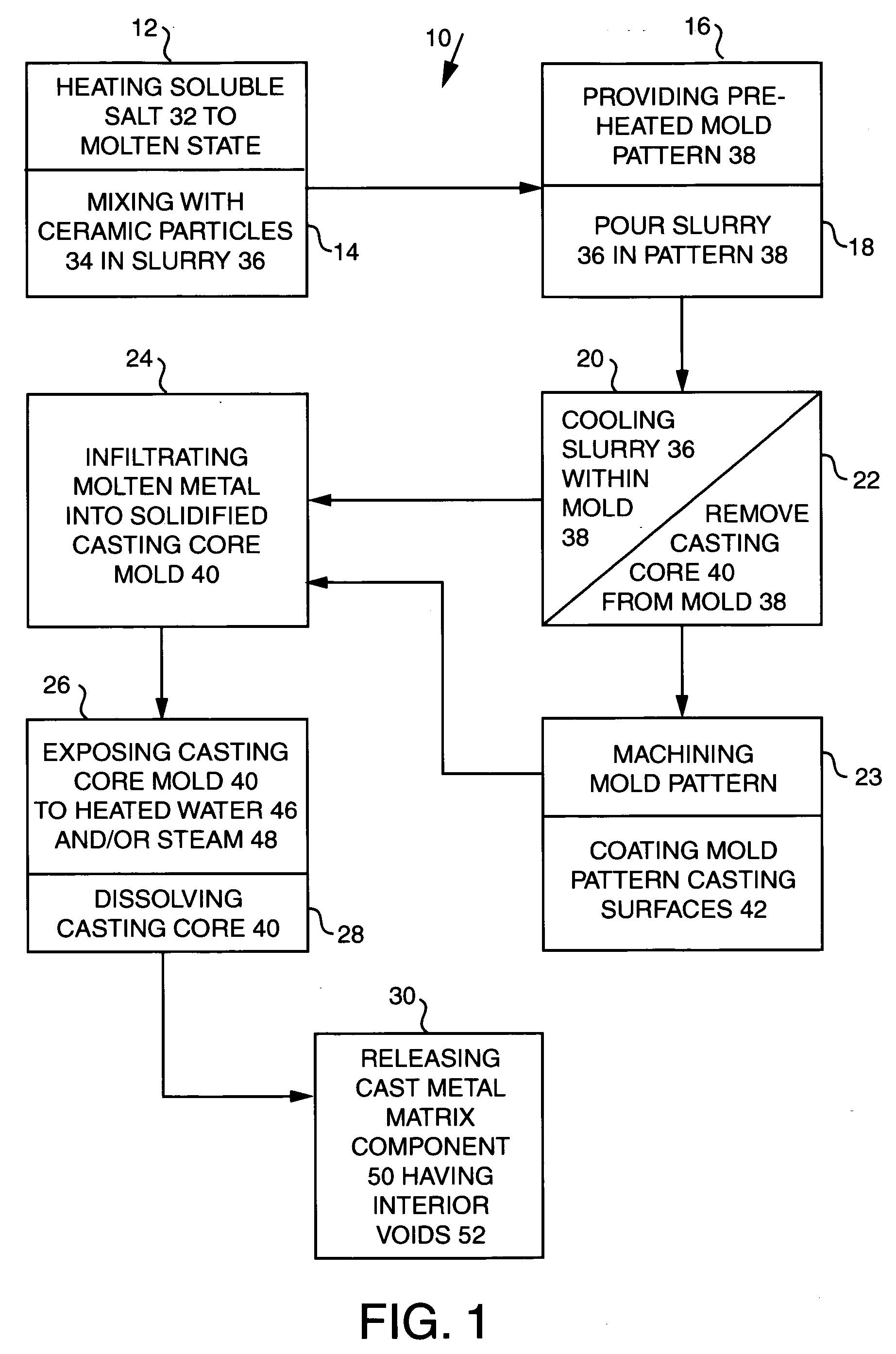

Soluble casting core for metal matrix composite components and method of producing thereof

InactiveUS20060243421A1Evenly dispersedSmall grain sizeFoundry mouldsFoundry coresParticulatesSlurry

A process for manufacturing a soluble casting core for use in casting complex shaped metal matrix composite components. The soluble casting core is generated by a sequence of steps which provide a molten slurry mixture composed of an alkali metal salt such as sodium carbonate and a plurality of ceramic particulates such as magnesium oxide dispersed therein. After heating and mixing the slurry mixture is solidified in a mold pattern to form a casting core configured to generate a complex shaped component during a casting process. The soluble casting core is used for casting molten metal alloys therein, without failure of the casting surfaces and forming of a complex shaped metal matrix composite component. The soluble casting core is readily dissolved and separated from the soluble casting core by immersing the core mold in heated water and / or exposing to steam, without damage to the metal matrix composite component.

Owner:ARMY UNITED STATES OF AMERICAN AS REPRESENTED BY THE SEC

Galvanically-Active In Situ Formed Particles for Controlled Rate Dissolving Tools

ActiveUS20190054523A1High incipient melting pointIncrease corrosion rateTransportation and packagingMetal-working apparatusAlloyElectrochemistry

A tastable, moldable, and / or extrudable structure using a metallic primary alloy. One or more additives are added to the metallic primary alloy so that in situ galvanically-active reinforcement particles are formed in the melt or on cooling from the melt. The composite contains an optimal composition and morphology to achieve a specific galvanic corrosion rate in the entire composite. The in situ formed galvanically-active particles can be used to enhance mechanical properties of the composite, such as ductility and / or tensile strength. The final casting can also be enhanced by heat treatment, as well as deformation processing such as extrusion, forging, or rolling, to further improve the strength of the final composite over the as-cast material.

Owner:TERVES

Passive electronics components comprising coated nanoparticles and methods for producing and using the same

ActiveUS20170022608A1Improve performanceImprove mean time between failuresFixed capacitor electrodesTransportation and packagingNanoparticleTransformer

Owner:PNEUMATICOAT TECH LLC

A high-size special-shape carbon-based composite material member and a preparing method thereof

The invention relates to a high-size special-shape carbon-based composite material member and a preparing method thereof. The member includes, by mass, 20-35% of carbon fibers, 35-75% of pyrolytic carbon and 5-15% of SiC. The preparing method includes needling the continuous carbon fibers into a prefabricated blank the density of which is 0.4-0.55 g / cm<3> according to a required shape of the member; then fixing the inner and outer surfaces of the prefabricated blank by adopting a graphite mold; and then performing high-temperature thermal treatment, a first time of carbon deposition, demolding, coarse machining, a second time of carbon deposition, graphite processing, silicon vapor bathing and finish machining in order to obtain a finished product. According to the member and the method, a problem that high-size special-shape carbon-based composite material members are liable to deform in long-time standing processes and preparing processes is overcome, and the obtained product has advantages of good mechanical performance, a low thermal expansion coefficient, high thermal conductivity, good chemical stability, and the like, is suitable for industrial production, and can be applied in the field of aviation and aerospace, the field of communication and transportation, the field of biomedicine, and the like.

Owner:CENT SOUTH UNIV

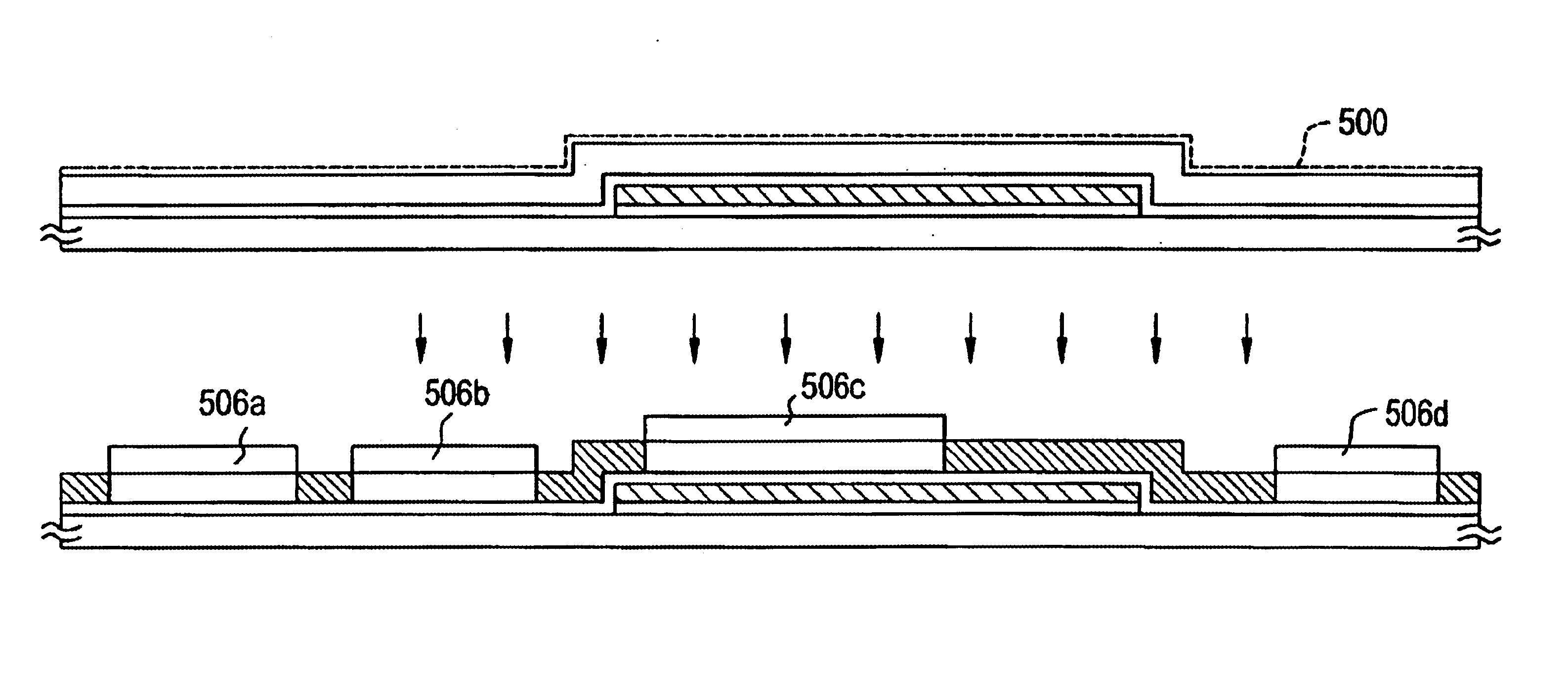

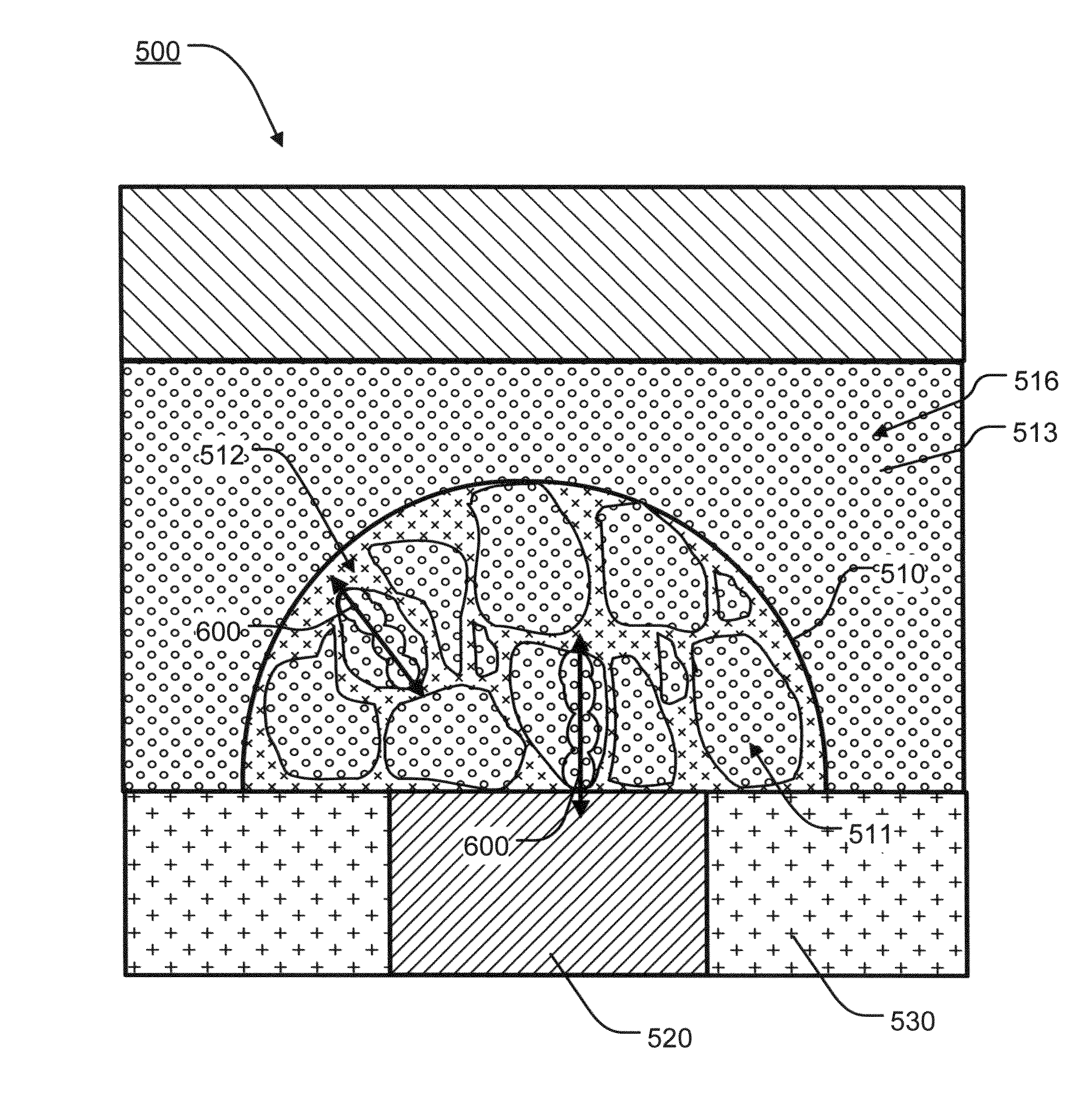

Dielectric mesh isolated phase change structure for phase change memory

ActiveUS8324605B2Improved memory cellReduce grain sizeSemiconductor/solid-state device manufacturingDigital storageDielectricPhase-change memory

A method for manufacturing a memory device, and a resulting device, is described using silicon oxide doped chalcogenide material. A first electrode having a contact surface; a body of phase change memory material in a polycrystalline state including a portion in contact with the contact surface of the first electrode, and a second electrode in contact with the body of phase change material are formed. The process includes melting and cooling the phase change memory material one or more times within an active region in the body of phase change material without disturbing the polycrystalline state outside the active region. A mesh of silicon oxide in the active region with at least one domain of chalcogenide material results. Also, the grain size of the phase change material in the polycrystalline state outside the active region is small, resulting in a more uniform structure.

Owner:GLOBALFOUNDRIES US INC

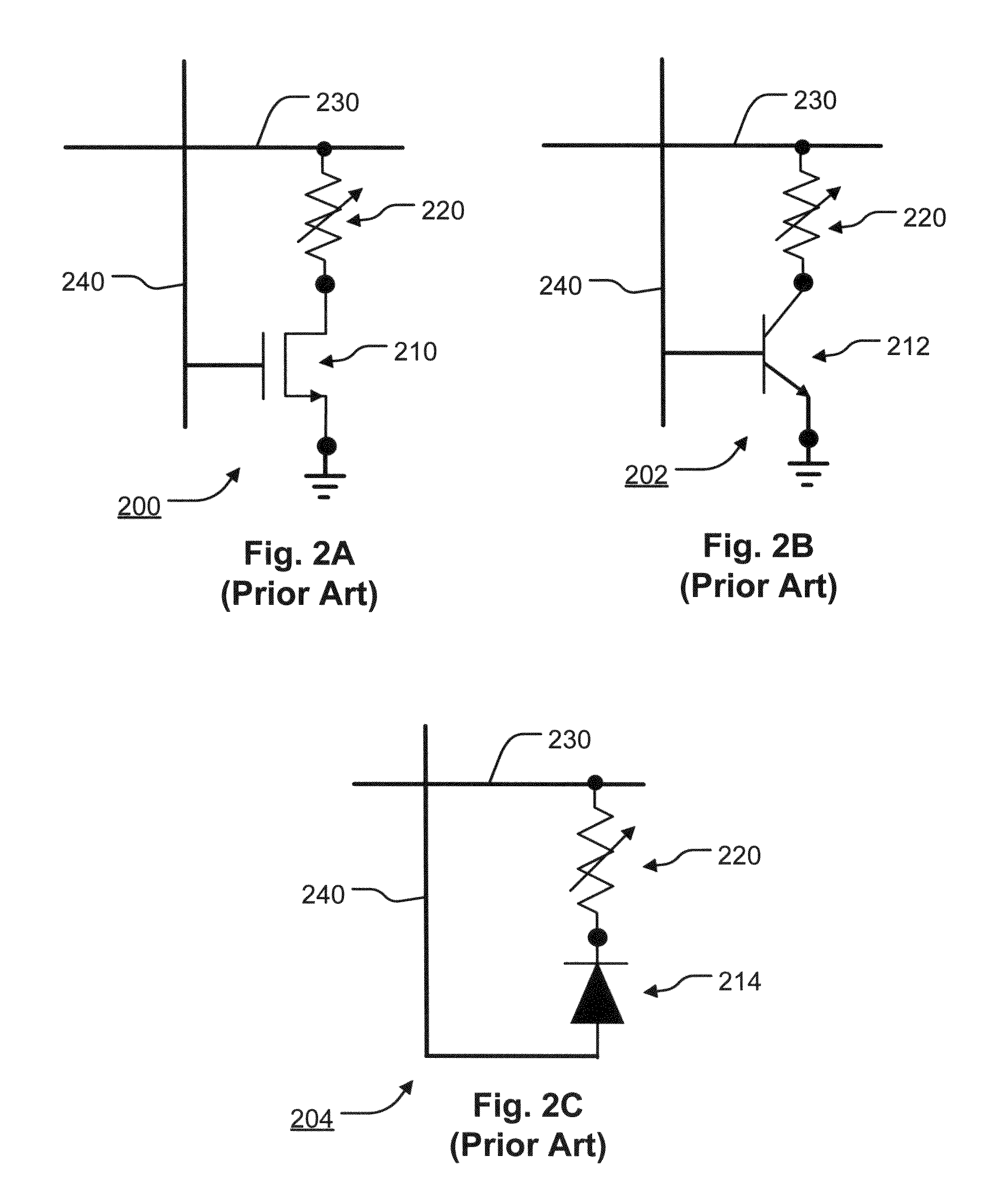

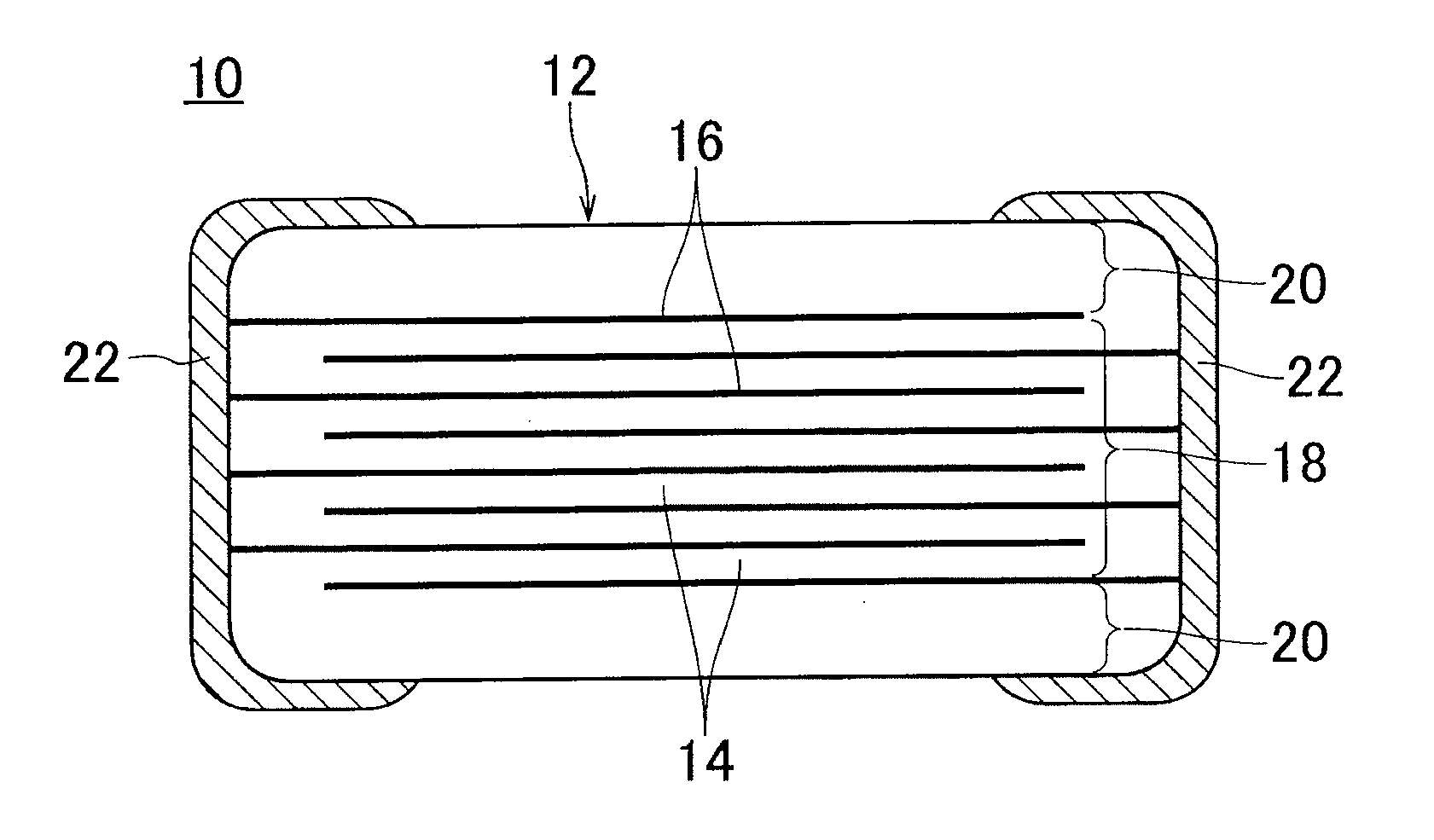

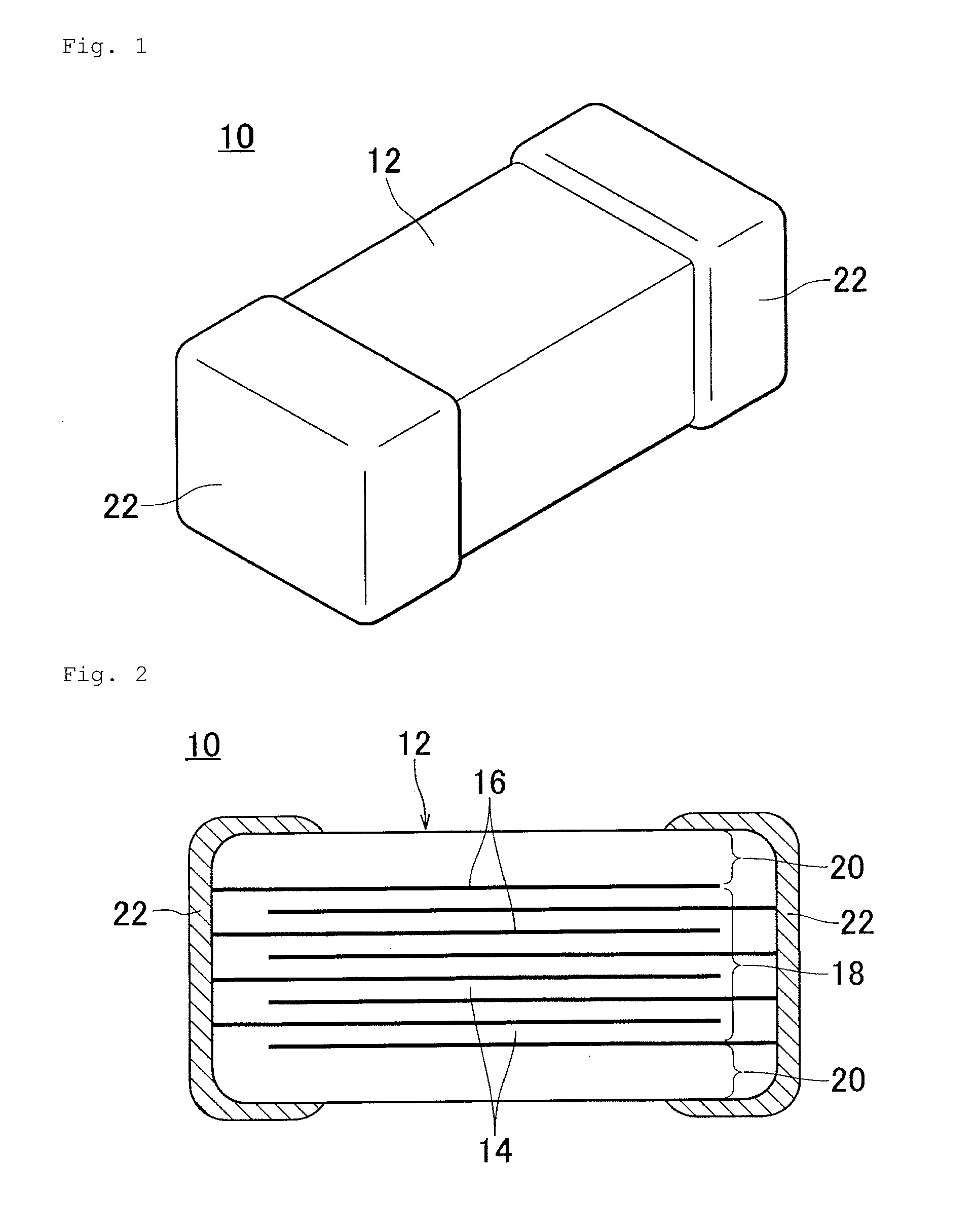

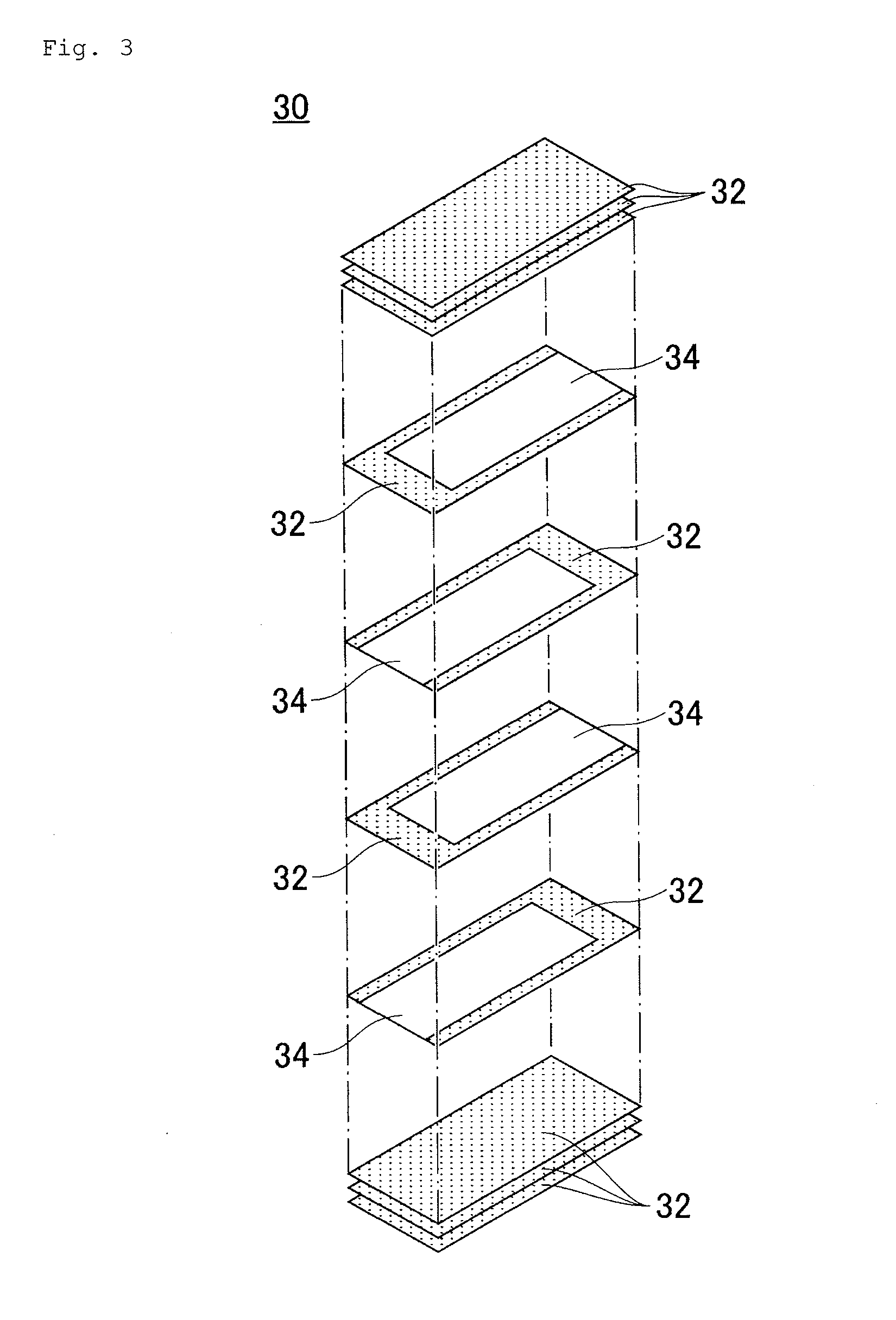

Laminated ceramic capacitor

ActiveUS20140043722A1Decrease bond strengthImproved chemical stabilityStacked capacitorsCeramic layered productsCeramicDielectric

laminated ceramic capacitor which has favorable moisture resistance includes an inner layer section that has dielectric ceramic layers and internal electrodes stacked alternately, and outer layer sections formed outside the inner layer section. The dielectric ceramic layers have a perovskite-type compound including a main constituent containing Ca and Zr, and an additive containing Si and Mn. The average grain size in the dielectric ceramic layers constituting the outer layer sections is smaller than the average grain size in the dielectric ceramic layers constituting the inner layer section. The Si / Mn molar ratio in the dielectric ceramic near the interfaces between the internal electrodes and the dielectric ceramic layers is ≦15.

Owner:MURATA MFG CO LTD

Aluminium alloy refiner and preparation method and application thereof

The present invention provides an aluminium alloy refiner. The aluminium alloy refiner is characterized by comprising 7 to 10 parts of Ti, 2 to 3 parts of B and the balance of Al by weight, for example, 8 parts of Ti, 3 parts of B and 89 parts of Al by weight. The aluminium alloy refiner is prepared by rapid solidification. After the refiner is added to A356.2 aluminium alloy, the grain size of the alloy is significantly reduced than that of the aluminium alloy treated by a conventional refiner. Moreover, the solubility of metals in liquid may be increased due to rapid solidification, such that the refiner is more easily absorbed by the aluminium alloy melt after being added to the aluminium alloy.

Owner:CITIC DICASTAL +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com