Titanium silicalite molecular sieve synthesizing method

A technology of titanium-silicon molecular sieve and synthesis method, which is applied in the direction of crystalline aluminosilicate zeolite, etc., and can solve the problem of low activity of titanium-silicon molecular sieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0037] The synthetic method of titanium silicon molecular sieve provided by the present invention, a kind of preferred embodiment, comprises the following steps:

[0038] (1) Mix template agent, titanium source, organosilicon source, water, polyhydric alcohol and optional inorganic ammonium source to hydrolyze the titanium source and organosilicon source, and remove the produced monohydric alcohol from the mixture, i.e. hydrolyze Alcohol, and then add peroxide; Said hydrolysis of alcohol, usually at 0~150 ℃, such as 0~100 ℃, such as 50~95 ℃, the resulting mixture is stirred for at least 10 minutes, wherein the stirring time of stirring is 10 minutes~ 50 hours; where the inorganic ammonium source (as NH 4 + Calculated): Titanium source (as TiO 2 The molar ratio of meter) is 0~5:1;

[0039] (2) Aging the product obtained in step (1), the aging is to leave the product obtained in step (1) at room temperature to 50°C for 1 to 60 hours, such as 2 to 50 hours or 3 to 30 hours, fu...

Embodiment 1

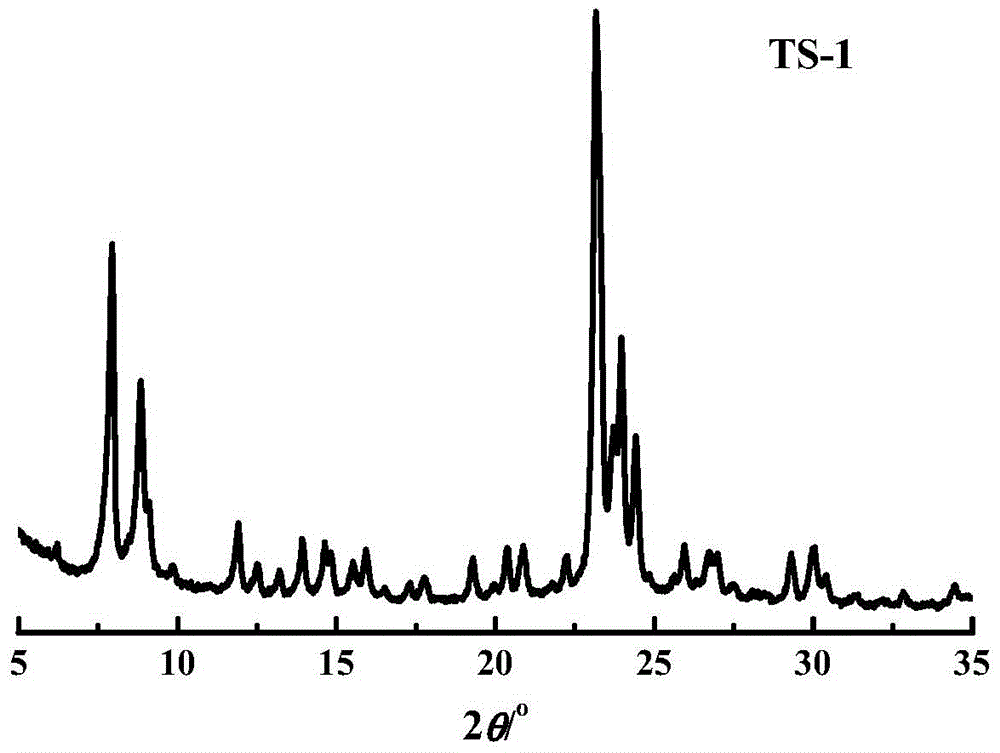

[0089] Mix 21.5g tetraethyl silicate, 1.11g glycerin and 6.50g tetrapropylammonium hydroxide aqueous solution (25.05% by weight), add 59.8g deionized water and mix evenly; then hydrolyze at 60°C for 1.0h to obtain silicic acid Hydrolyzate of tetraethyl ester. Then, under the action of vigorous stirring, a solution consisting of 1.1 g of tetrabutyl titanate and 5.0 g of isopropanol was slowly dropped into the above hydrolyzate, and the mixture was stirred at 75°C for 3 hours to obtain a clear and transparent colloid , adding 0.88g concentration of 30% by weight hydrogen peroxide. Then move the colloid into a closed stainless steel reaction kettle, and crystallize at a constant temperature at 170° C. for 3 days to obtain TS-1 molecular sieve. Its XRD analysis spectrum is as figure 1 As shown, it has an MFI structure.

Embodiment 2

[0095] (1) 15g concentration is the tetrapropyl ammonium hydroxide aqueous solution of 25.05% by weight, 2.04g tetrabutyl titanate, 8.5g tetraethyl silicate, 4.97g glycerol, 2.1g concentration is the ammoniacal liquor of 20% by weight and 35.6 Add g water into a 500ml beaker in turn, put it into a magnetic stirrer with heating and stirring functions, mix evenly, and heat at 80°C for 4 hours, and replenish the evaporated water at any time to obtain a colorless transparent hydrolyzate. Alcohol content is no more than 10ppm (mass), then add 1.2g of hydrogen peroxide with a concentration of 30% by weight, and stir evenly;

[0096] (2) aging the product obtained in step (1) at room temperature for 12 hours to obtain an aging product;

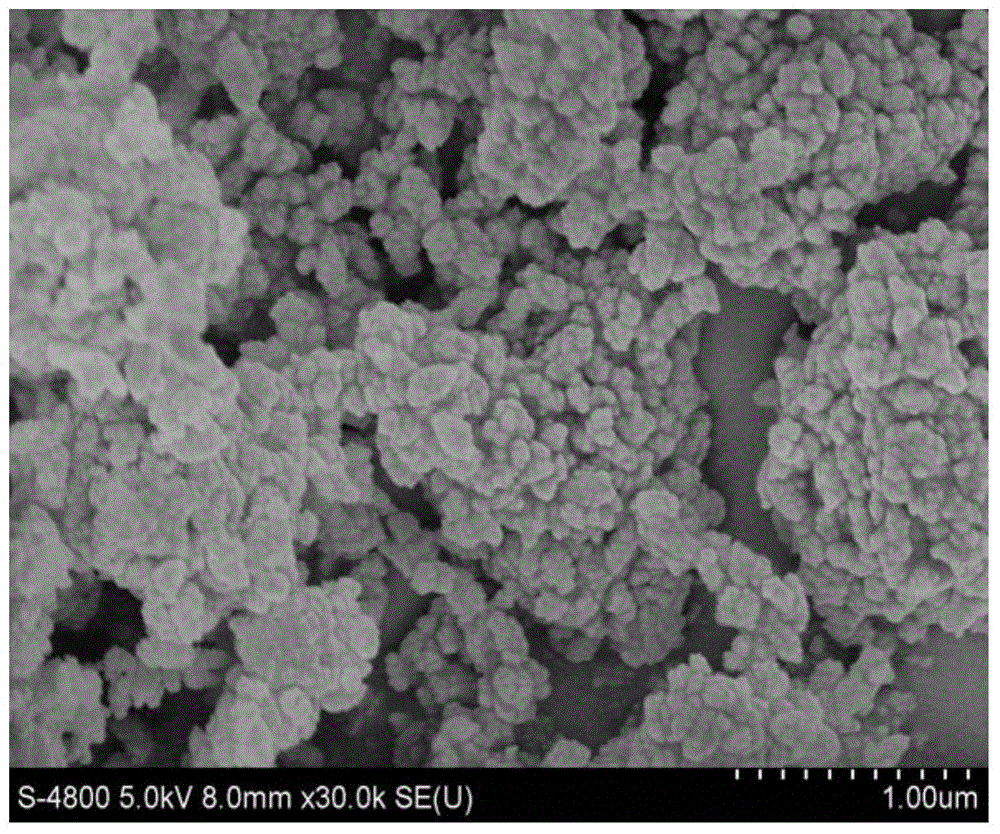

[0097] (3) Add 9.6g of white carbon black powder to the above aging product under stirring, and stir for 1 hour after adding, forming a "viscous body". After 2 days, the TS-1 sample was obtained. The obtained TS-1 sample was filtered, washed, dried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial length | aaaaa | aaaaa |

| Benzene adsorption | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com