High Conductivity Magnesium Alloy

a high-conductivity, magnesium alloy technology, applied in the direction of material nanotechnology, transportation and packaging, foundation engineering, etc., can solve the problems of limited strength, increased brittleness of alloys, poor reliability, etc., to enhance mechanical properties of magnesium-based composites such as ductility and/or tensile strength, and improve thermal, physical and mechanical properties. , the effect of improving the mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0152]An AZ91D magnesium alloy having 9 wt. % aluminum, 1 wt. % zinc and 90 wt. % magnesium was melted to above 700° C. About 2 vol. % nano iron particles and about 2 vol. % nano graphite particles were added to the AZ91D magnesium alloy using ultrasonic mixing. The melt was cast into steel molds. The iron particles and graphite particles did not fully melt during the mixing and casting processes. The material dissolved at a rate of 2 mg / cm2−min in a 3% KCl solution at 20° C. The material dissolved at a rate of 20 mg / cm2−hr in a 3% KCl solution at 65° C. The material dissolved at a rate of 100 mg / cm2−hr in a 3% KCl solution at 90° C. The dissolving rate of magnesium-based composite for each these test was generally constant.

example 2

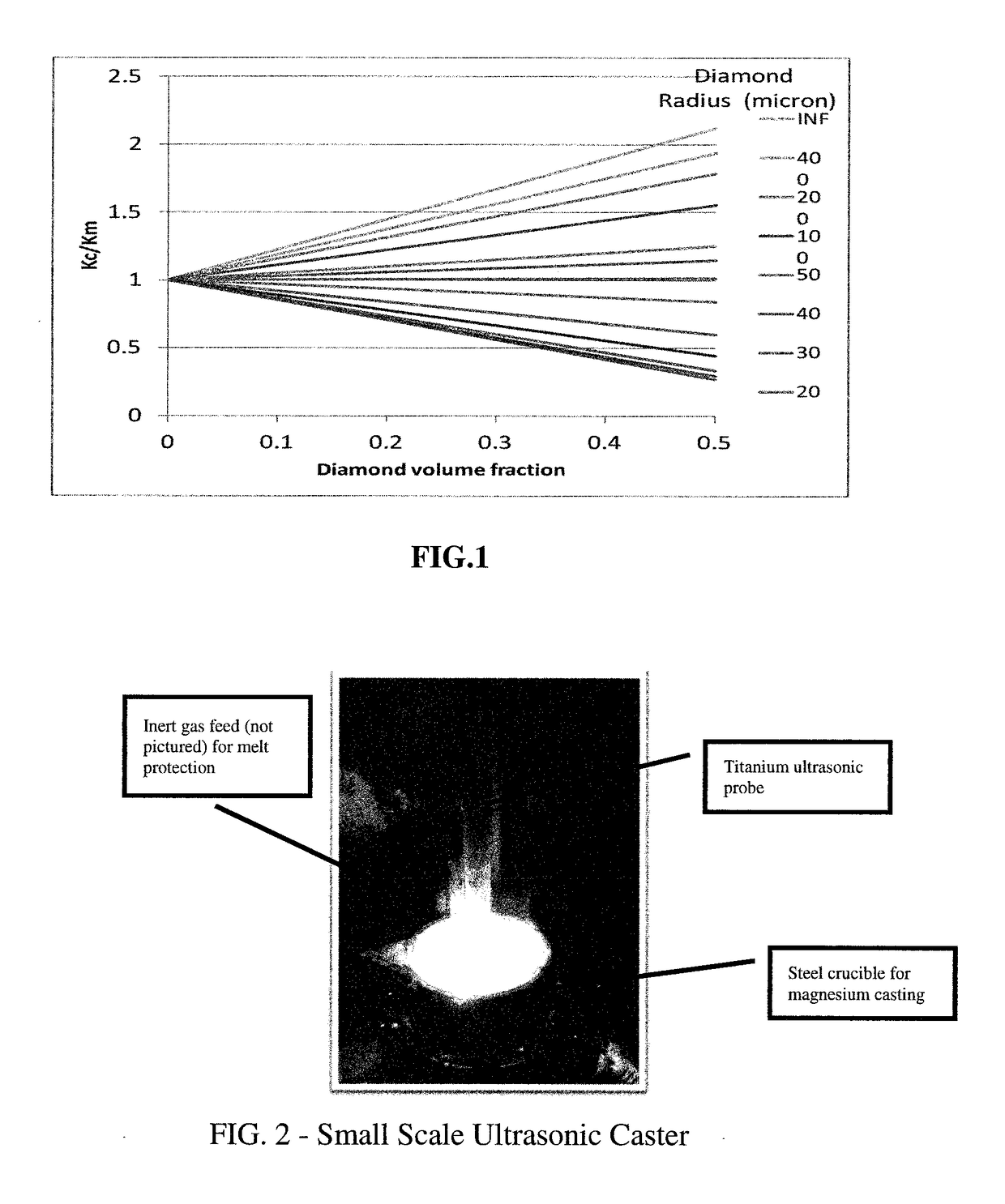

[0153]Carbon nanotubes and / or finely divided copper nanoparticle powder were added to pure magnesium and an AZ91 magnesium alloy (having 9 wt. % aluminum, 1 wt. % zinc and 90 wt. % magnesium) when in molten form. The AZ91 magnesium alloy was melted to above 700° C. Insoluble nanoparticles in the form of carbon nanotubes (multiwall, high thermal conductivity) were added to the molten AZ91 magnesium alloy. The insoluble carbon nanotubes were added by consolidating the carbon nanotubes into a magnesium rod by mechanically blending the carbon nanotubes with magnesium powder and then cold pressing the mixture of carbon nanotubes and magnesium powder into a rod. The rod containing the carbon nanotubes was fed / inserted into the molten AZ91 magnesium alloy. The insoluble carbon nanotubes were dispersed in the molten AZ91 magnesium alloy by ultrasonic mixing wherein the rod was directed into the ultrasonic sweet spot to melt the rod at a melt temperature of 700° C. The carbon nanotubes const...

PUM

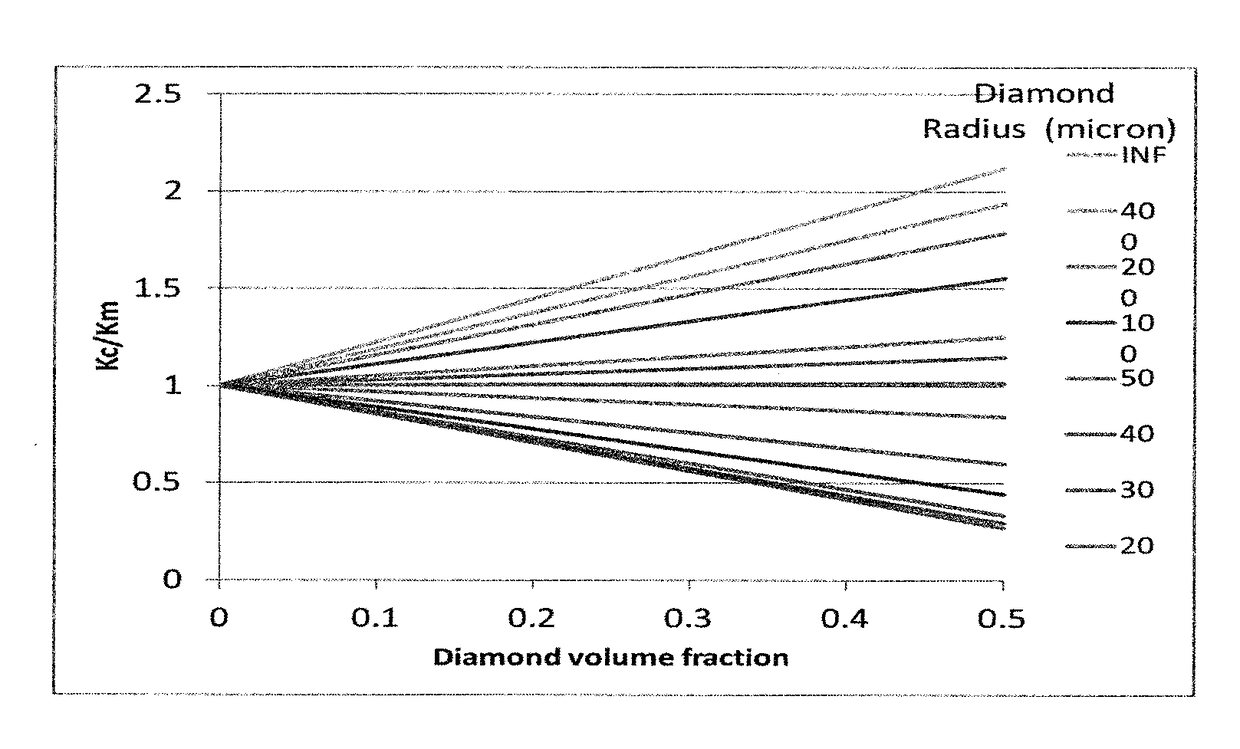

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com