PBS composite material containing PBST toughening agent and preparation method of composite material

A composite material and toughening agent technology, applied in the field of bio-based degradable materials, can solve the problems of incomplete degradation, large amount of plasticizer added, high cost, etc., and achieve the effect of reducing white pollution and improving thermal aspects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

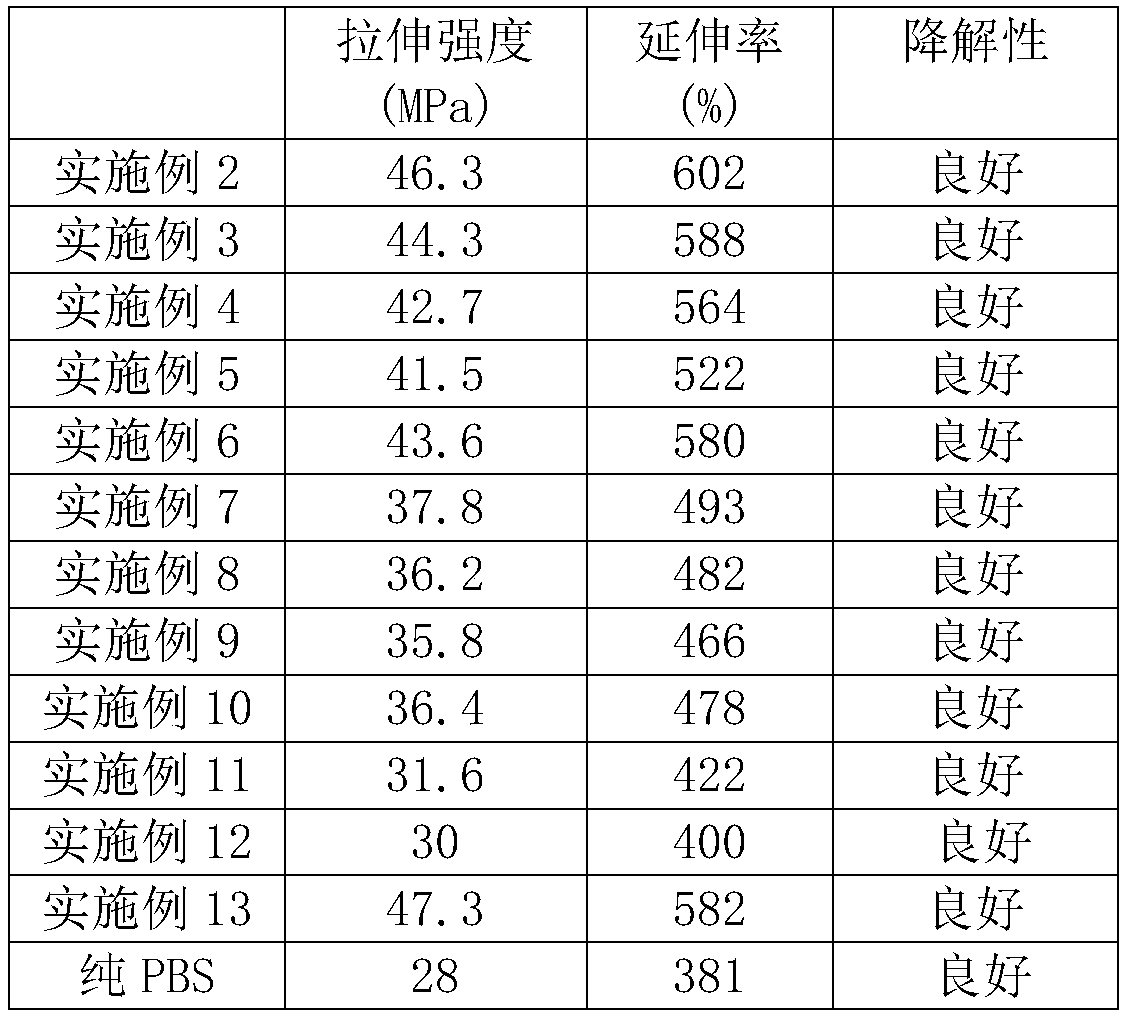

Examples

Embodiment 1

[0023] This embodiment provides a preparation method of succinic acid / butanediol / 1,5-pentanediol copolyester, specifically as follows:

[0024] 1) Add succinic acid, butanediol, and 1,5-pentanediol according to the acid-alcohol molar ratio of 1:1.2, and the mass percentages of butanediol and 1,5-pentanediol are 80% and 20% , in the reactor in two stages: first stage esterification reaction temperature 200°C, reaction time 2h; second stage polycondensation reaction temperature 200°C, reaction time 2h, namely PBST-1.

[0025] 2) Add succinic acid, butanediol, and 1,5-pentanediol according to the acid-alcohol molar ratio of 1:1.2, and the mass percentages of butanediol and 1,5-pentanediol are 90% and 10% , in the reactor in two stages: first stage esterification reaction temperature 200°C, reaction time 1h; second stage polycondensation reaction temperature 200°C, reaction time 3h, namely PBST-2.

[0026] 3) Add succinic acid, butanediol, and 1,5-pentanediol according to the aci...

Embodiment 2

[0032] The present embodiment provides a kind of preparation method of the PBS composite material containing PBST toughening agent, and it comprises the steps:

[0033] Put 5% of PBST-1 and 95% of PBS, which account for the total mass percentage of the PBS composite material, into a mixer and mix evenly, then melt and blend the PBST plasticizer and PBS resin at 130-180°C, inject The pellets of the PBS composite material containing the PBST toughening agent can be obtained after being cooled and pelletized.

Embodiment 3

[0035] The present embodiment provides a kind of preparation method of the PBS composite material containing PBST toughening agent, and it comprises the steps:

[0036] PBST-1, which accounts for 3% of the total mass percentage of the PBS composite material, and PBS, which accounts for 95%, are put into a mixer and mixed evenly, and then the PBST plasticizer and PBS resin are melt blended at 130-180 ° C, The pellets of the PBS composite material containing the PBST toughening agent can be obtained after injection, cooling, and pelletizing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com