Soluble casting core for metal matrix composite components and method of producing thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

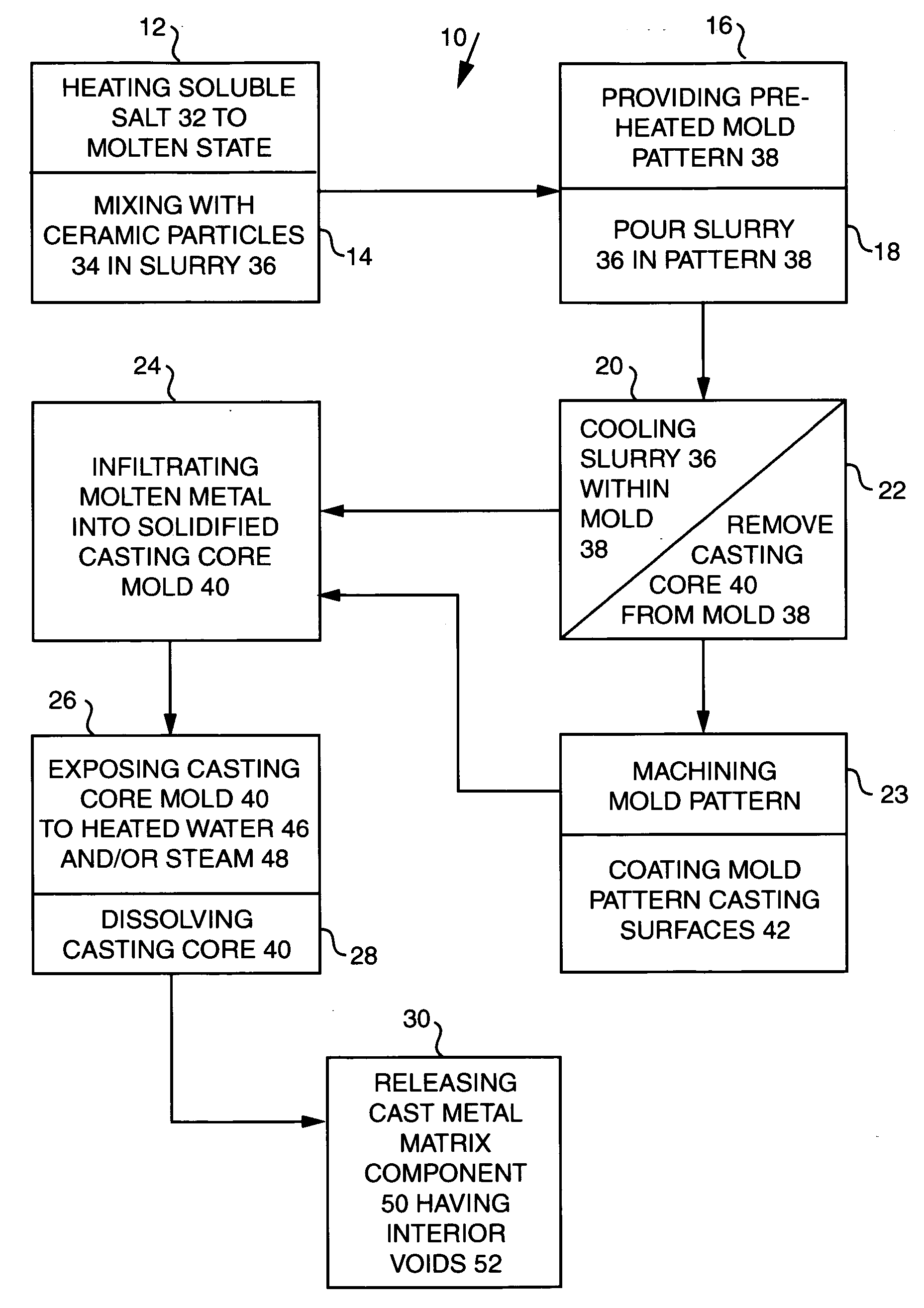

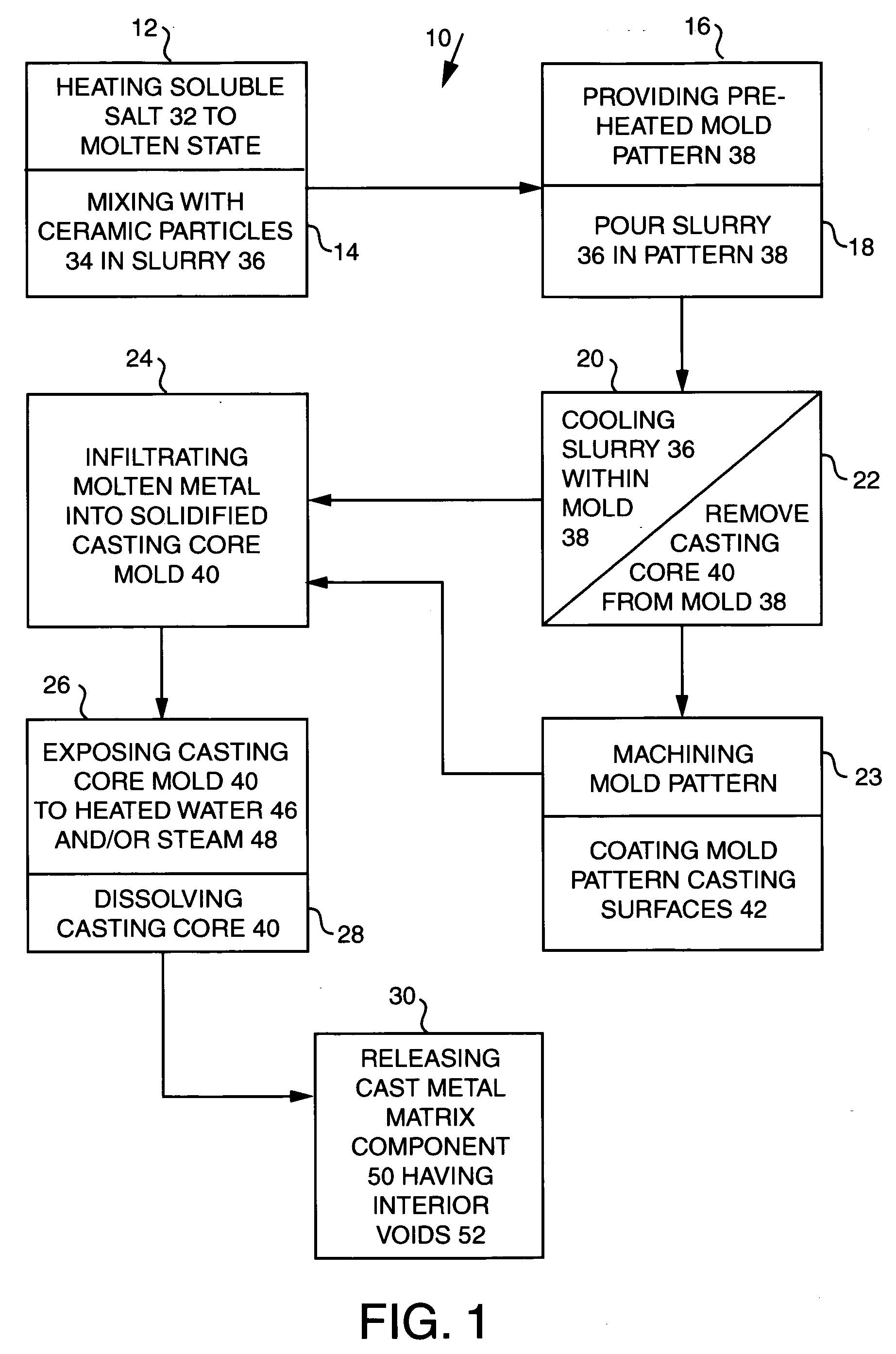

[0015] Referring now to FIG. 1, a process 10 of manufacturing a soluble casting core mold 40 is disclosed, with the soluble casting core mold 40 being composed of a salt material which is water soluble and mixed with metal oxide particulates forming a slurry mixture when molten which is readily poured for casting, and is impervious to molten metal when the slurry mixture is solidified into the core mold which is readily dissolved when exposed to heated water in order to free a complex shaped cast MMC component 50 formed within the soluble casting core mold 40. The soluble casting core mold 40 is utilizable in pressure casting processes such as a pressure infiltration casting process. Benefits of utilizing the soluble casting core mold 40 include the core mold is impermeable when exposed to molten metal under typical pressure and temperatures used for pressure infiltration casting. Further, the core mold is readily dissolved in non-corrosive solutions such as heated water for rapid r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com