Preparation method of electrospun high-performance polyphenylene derivative nanofibers

A technology of polyphenylene derivatives and nanofibers, which is applied in the chemical characteristics of fibers, single-component synthetic polymer rayon, textiles and papermaking, etc., can solve the problem that polyphenylene derivatives are not soluble and difficult to prepare electrospun nanofibers , low molecular weight of polyphenylene derivatives, etc., to achieve the effect of high strength, high modulus and moderate elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention provides a method for preparing electrospun high-performance polyphenylene derivative nanofibers, comprising the following steps:

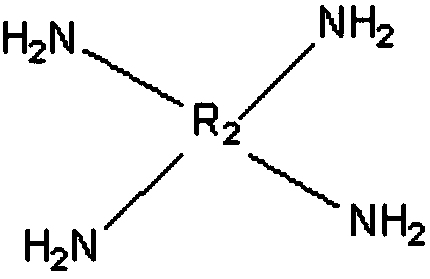

[0034] (1) dissolving substituted benzene oligomers and aromatic tetraamine monomers terminated by o-dicarboxybenzene in a solvent to prepare a precursor solution;

[0035] (2) In the precursor solution described in step (1), add a filament forming agent to form a spinning mixed solution, and form a blended nanofiber precursor by an electrospinning method;

[0036] (3) After drying the blended nanofiber precursor described in step (2), heat treatment is performed to obtain polyphenylene derivative nanofibers.

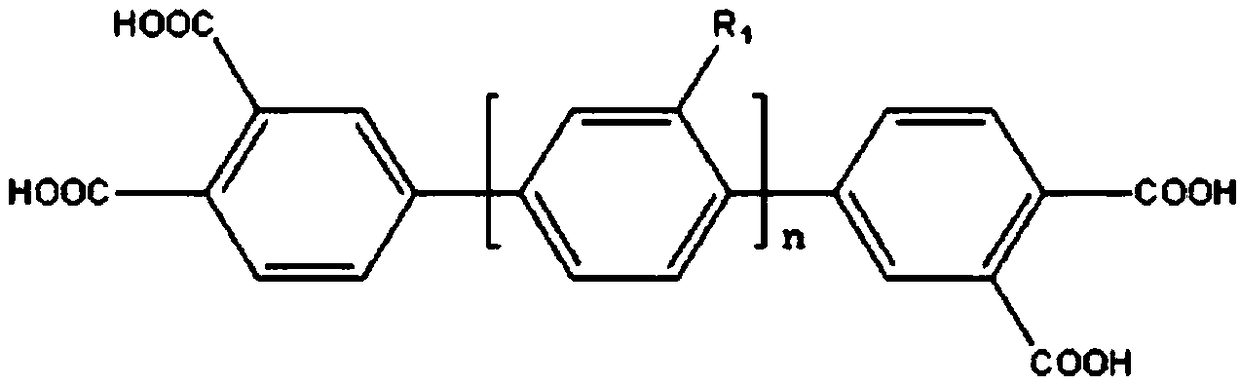

[0037] Odicarboxybenzene-terminated substituted benzene oligomers:

[0038] The general structural formula of the substituted benzene oligomers end-capped by o-dicarboxybenzene described in the present invention:

[0039]

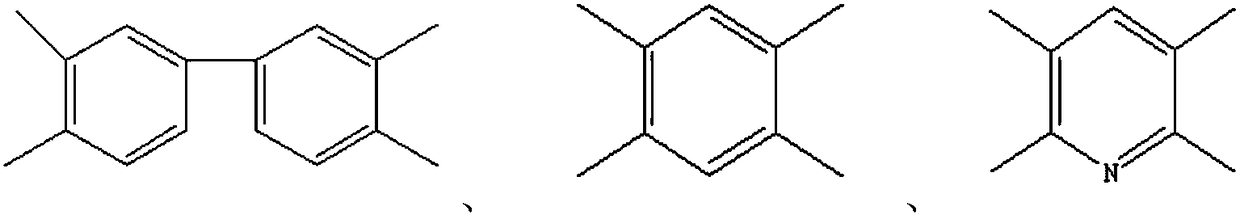

[0040] where R 1 Choose from any of the following structures:

[0041] CH 3 O-; R 1 p...

Embodiment 1

[0069] At room temperature, the molar ratio of 1:1 with Add o-dicarboxybenzene-terminated substituted benzene oligomers and 3,3',4,4'-biphenyltetramine as substituent groups into N,N-dimethylformamide solution, and magnetically stir for 2 hours to form Mix the solution and label it as A solution.

[0070] In solution A, weigh an appropriate amount of PVP (Mr=30000) to prepare a solution with a concentration of 30%. Stir magnetically at room temperature for 1 h, let stand for 1 h, and label the resulting solution as B solution.

[0071] Place the prepared B solution in the spinning device, adjust the solidification distance to 14cm and the voltage to 21kV, connect the negative electrode to the wire mesh, and the polyphenylene nanofiber precursor will be collected on the wire mesh as the negative electrode.

[0072] The obtained polyphenylene nanofiber precursor was dried under reduced pressure at 40°C, and heated to 420°C under nitrogen to obtain polyphenylene nanofibers wit...

Embodiment 2

[0083] At room temperature, the molar ratio of 1:1 with Add o-dicarboxybenzene-terminated substituted benzene oligomers and 3,3',5,5'-benzophenonetetramine as substituent groups to N,N-dimethylformamide solution, and magnetically stir for 2h, A mixed solution was formed and labeled as A solution.

[0084] In solution A, weigh an appropriate amount of PMMA to prepare a solution with a concentration of 40%. Stir magnetically at room temperature for 1 h, let stand for 1 h, and label the resulting solution as B solution.

[0085] Place the prepared B solution in the spinning device, adjust the curing distance to 16cm and the voltage to 25kV, connect the negative electrode to the wire mesh, and the polyphenylene nanofiber precursor will be collected on the wire mesh as the negative electrode.

[0086] The obtained polyphenylene nanofiber precursor was dried under reduced pressure at 50°C, and heated to 450°C under nitrogen to obtain polyphenylene nanofibers with benzimidazole as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com