Safe and flexible fire resistant cable

A fire-resistant cable and soft technology, which can be used in insulated cables, bendable cables, cables, etc., can solve the problems of large investment in manufacturing equipment, difficult market promotion and application, and high hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

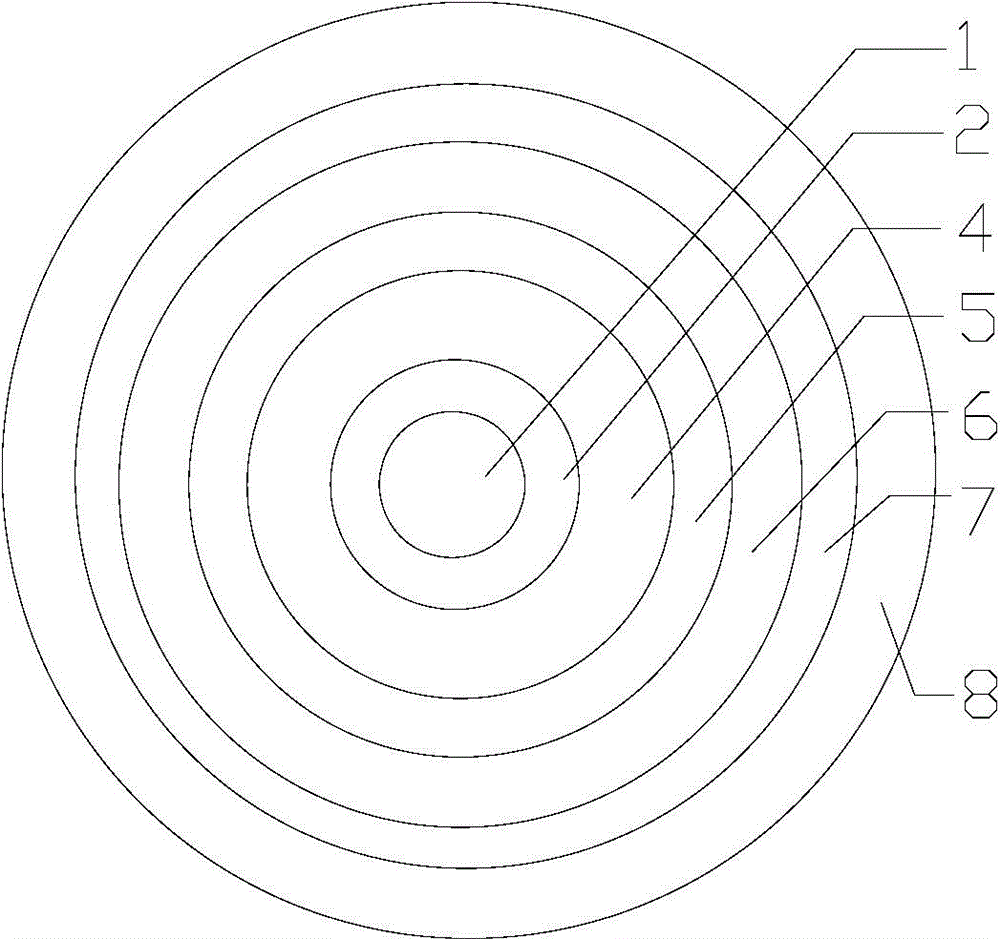

[0026] A safe and flexible fire-resistant cable, the structure of which is as follows figure 1 As shown, it consists of conductor 1, wrapped refractory mica tape 2, wrapped ceramic fiber tape 4, extruded and coated corrugated aluminum tube 5, extruded polymer precursor 6, wrapped fire barrier layer 7, extruded halogen-free low made of smoke flame-retardant sheath 8, wrapping refractory mica tape 2 on the outside of conductor 1 to form a cable wire, wrapping ceramic fiber tape 4, extruding and coating corrugated aluminum tube 5, extruding polymer precursor 6, wrapping The fire barrier layer 7 and the extruded halogen-free low-smoke flame-retardant sheath 8 are sequentially coated on the outside of the cable conductor from the inside to the outside. In addition, fine atomized silicone oil is sprayed on the surface of the wrapping refractory mica tape 2, the wrapping ceramic fiber tape 4 and the wrapping fire insulation layer 7, and the fire resistance of the cable made has passe...

Embodiment 2

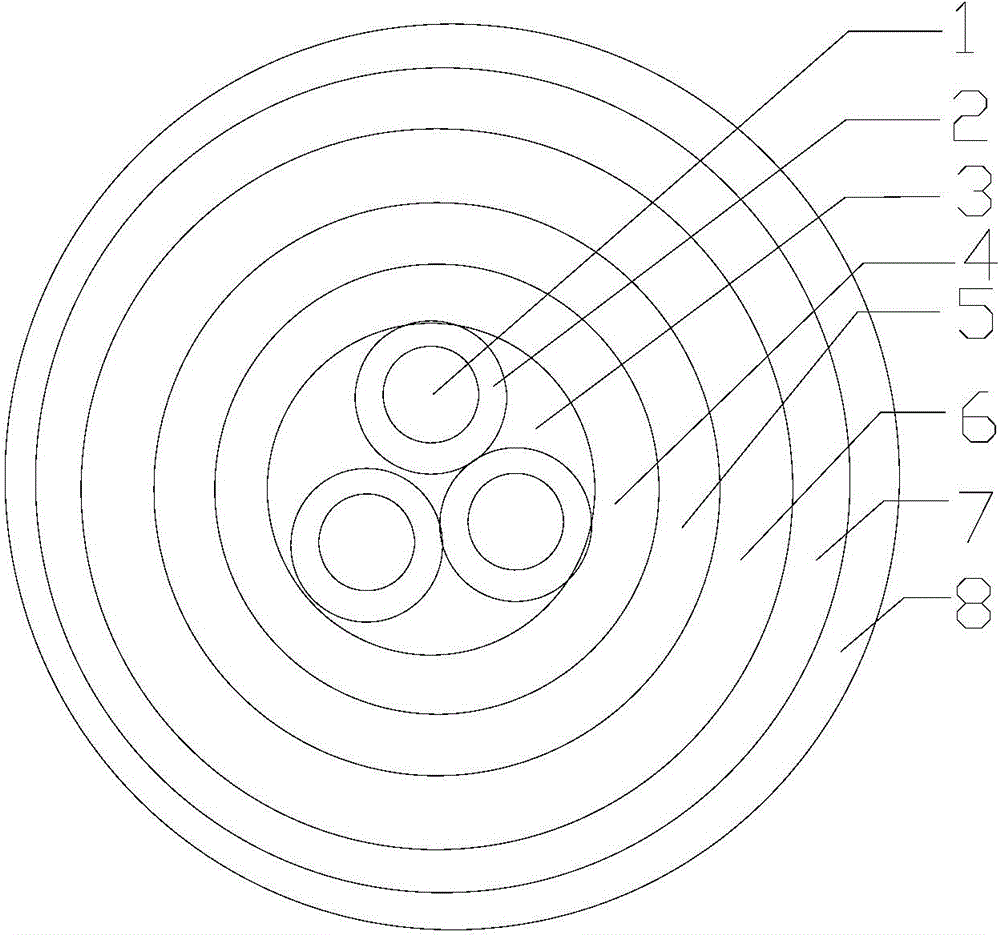

[0028] A safe and flexible fire-resistant cable, the structure of which is as follows figure 2 As shown, it consists of conductor 1, wrapped refractory mica tape 2, filled ceramic fiber rope 3, wrapped ceramic fiber tape 4, extruded and coated corrugated aluminum tube 5, extruded polymer precursor 6, wrapped fire barrier layer 7 1. Made of extruded halogen-free low-smoke flame-retardant sheath 8, wrapped with refractory mica tape 2 and wrapped on the outside of conductor 1 to form a cable wire, filled with ceramic fiber rope 3, wrapped with ceramic fiber tape 4, extruded and coated with corrugated aluminum The tube 5, the extruded polymer precursor 6, the wrapped fire barrier layer 7, and the extruded halogen-free low-smoke flame-retardant sheath 8 are sequentially coated on the outside of the cable conductor from the inside to the outside. In addition, finely atomized silicon oil is sprayed on the surface of the wrapped refractory mica tape 2 and the filled ceramic fiber rop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume resistivity | aaaaa | aaaaa |

| Insulation resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com