Method for preparing rolling anisotropic magnetic powder and magnet

An anisotropic magnetic and anisotropic technology, applied in the direction of magnetic objects, magnetic materials, inorganic materials, etc., can solve the problem of poor corrosion resistance of NdFeB, no rolling anisotropy, large powder particle size, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

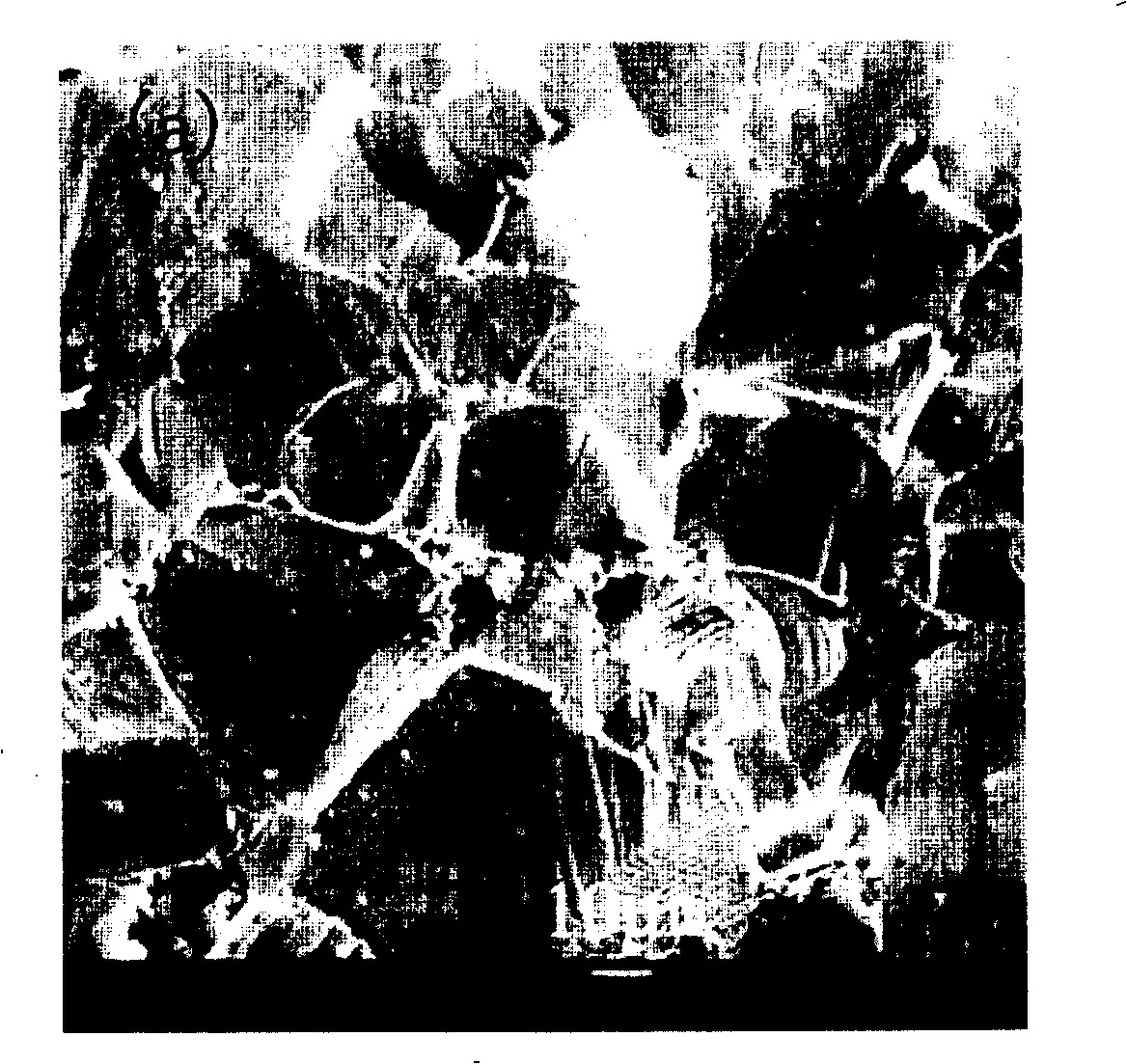

[0045] Composition is Nd 7.7 Fe 80.8 V 11.0 Si 0.5 , the master alloy was prepared by quick-setting thin sheet technology, and then heat-treated in a nitrogen atmosphere at 500 ° C, the nitrogen pressure was 0.1Mpa, and kept for 4 hours, and the corresponding nitride was formed through a gas-solid phase reaction, and its composition was Nd 6.7 Fe 75.1 V 9.8 Si 0.4 N 8.0 , The nitrides are developed into micropowders by using a ball mill, and the magnetic powders of different particle sizes are formed by controlling the ball milling time. Table 3 shows that the magnetic powder properties vary with the particle size of the magnetic powder.

[0046] Table 3.Nd 6.7 Fe 75.1 V 9.8 Si 0.4 N 8.0 The change of permanent magnetic properties of magnetic powder with the particle size of magnetic powder

[0047] Average particle size of magnetic powder (μm)

Embodiment 2

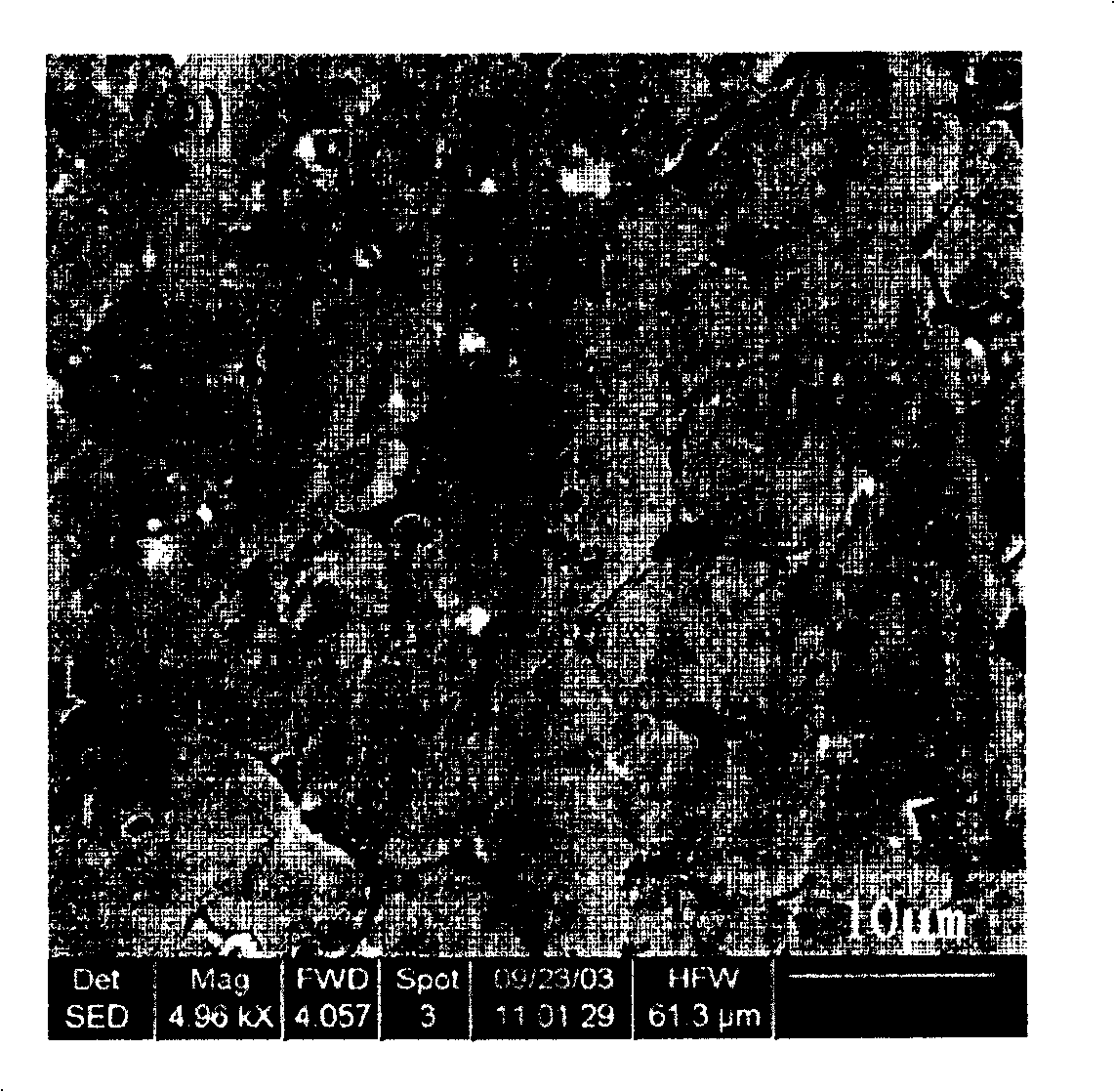

[0049] Calculated by weight percentage, according to the following formula to prepare rolling magnets: Nd 7.1 Fe 80.8 V 11.04 Si 0.46 N 8.8 Magnetic powder 93%, coupling agent 0.8%, chlorinated polyethylene (CPE) 5.4%, epoxy derivative plasticizer 0.3%, ketamine compound antioxidant 0.5%. The average particle size of the magnetic powder is 2.1 microns. The above materials were prepared and fully mixed, and then the mixture was added into an open mill for mixing. The temperature of the rolls of the open mill was 50° C., and the preheating time was 150 minutes. The roll speed ratio of the front and rear rolls is 1.15:1, and the roll distance is 0.3mm. When all the powders used are bonded into a whole, the mixing is considered to be over. The kneaded material is rolled. A flat rolled magnet was produced. The roll speed ratio of the front and rear rolls is 1:1, and the roll distance is 0.5 mm. The compression ratio is 4:1, and then the roller distance is adjusted to compr...

Embodiment 3

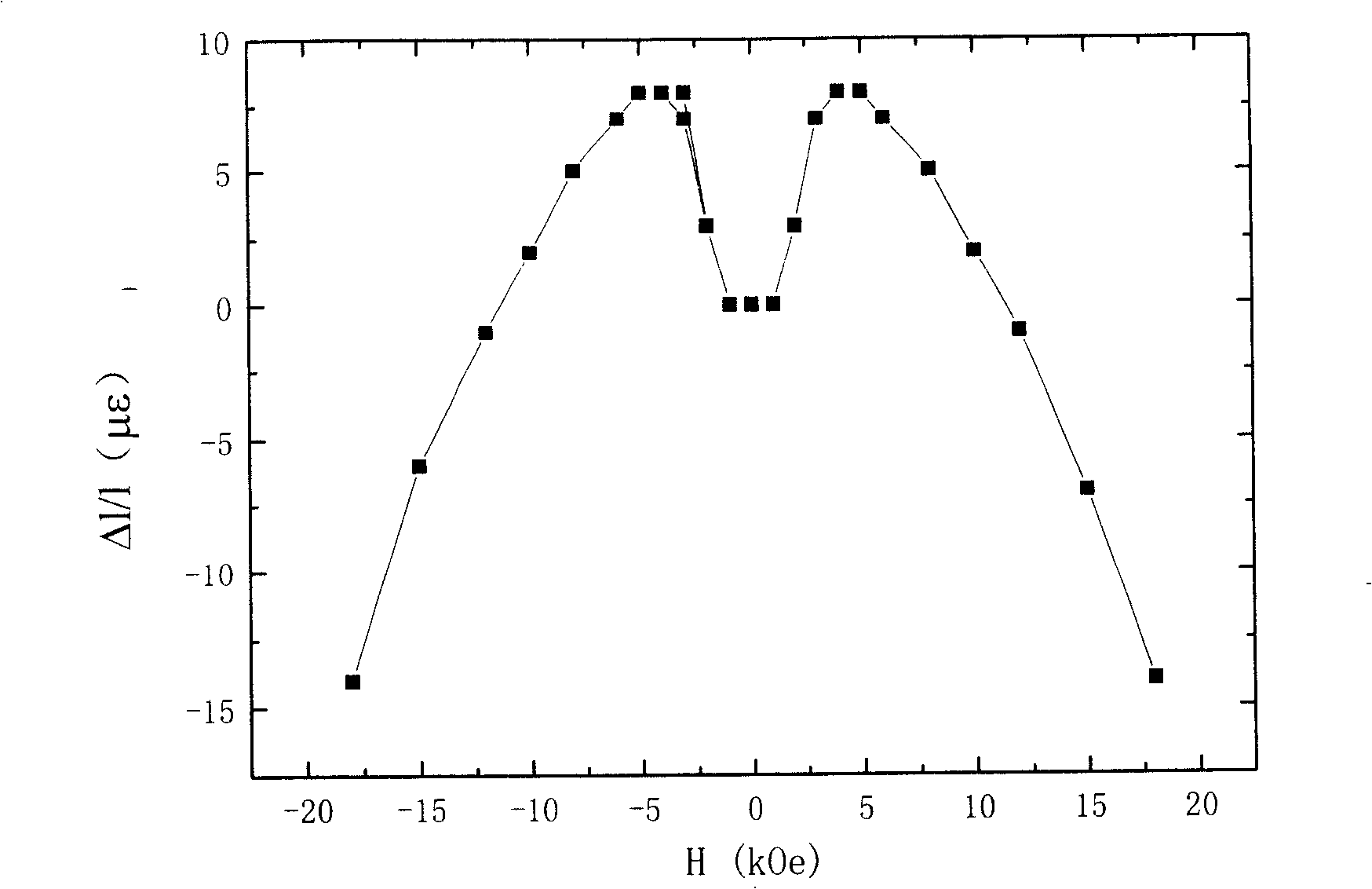

[0053] Completely follow the steps in Example 2 to the end of mixing. However, in order to take advantage of the magnetic crystal anisotropy and stress anisotropy of this magnetic powder, the mixed materials are oriented and pressed into flakes in a press and a magnetic field before kneading and rolling, with a pressure of 1 ton / cm 2 . The mixture pressed into a sheet was completely followed the steps in Example 2, kneaded and rolled, and finally the thickness of the magnet was pressed to 2.0 mm. The magnetically anisotropic rolled magnet of the present invention was obtained, and its properties are shown in Table 5.

[0054] Table 5.Nd 7.1 Fe 80.8 V 11.04 Si 0.46 N 8.8 Properties of Calendered Rubber Flexible Magnets

[0055] Br(kG)

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com