Economic sintering permanent-magnet ferrite and preparing method thereof

A permanent magnet ferrite, sintering temperature technology, applied in the field of sintered permanent magnet ferrite and its preparation, sintered permanent magnet ferrite, can solve the problems of declining market competitiveness, high price, and increased cost of sintered ferrite raw materials, etc. Achieving the effects of low cost, reduced addition amount, and good intrinsic coercive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

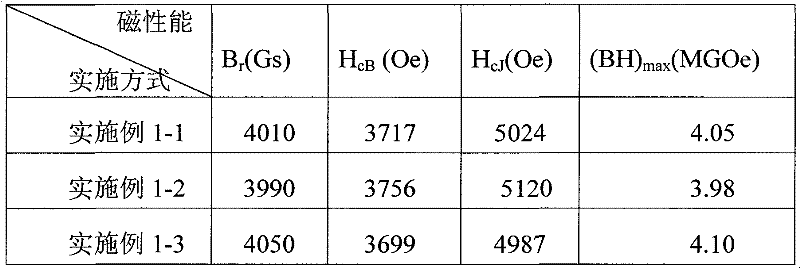

Embodiment 1

[0031] The batching process selects raw materials as follows:

[0032] Fe 2 o 3 powder (of which Fe 2 o 3 The purity of the powder ≥ 99.1wt%, the original average particle size of the particles: 1.0um) 85.3wt%;

[0033] SrCO 3 Powder (purity ≥ 98.0wt%, original average particle size of particles: 2.0um) 12.2wt%;

[0034] La 2 o 3 Powder (purity ≥ 99.0wt%, original average particle size of particles: 0.8um) 1.4wt%;

[0035] Al 2 o 3 Powder (purity ≥ 99.0wt%, original average particle size of particles: 1.2um) 1.1wt%;

[0036] The above-mentioned raw materials were weighed and mixed in a wet ball mill, then dried, and pre-fired in the air. The main phase formula of can be expressed as: Sr 0.9 La 0.1 Fe 11.72 Al 0.25 o 19 .

[0037] The organic dispersant calcium gluconate of 0.4wt% is added to the calcined material of gained; Then calcined material is carried out coarse pulverization and added additive carry out the dry formula coarse pulverization of 5 minutes ...

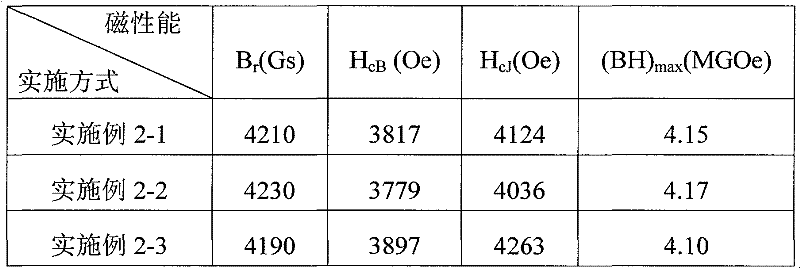

Embodiment 2

[0045] Raw material selection is the same as implementation example 1, just with La 2 o 3 Change to Bi 2 o 3 , the addition amount of each raw material is as follows: Fe 2 o 3 Powder, 85.95wt%; SrCO 3 Powder, 13.16 wt%; Bi 2 o 3 Powder, 0.42wt%; Al 2 o 3 Powder, 0.47 wt%.

[0046] After pre-firing in the same process, the pre-fired temperature is 1240°C, and the holding time is 1 hour. The components of the obtained pre-fired material can be expressed as Sr 0.98 Bi 0.02 Fe 11.89 Al 0.12 o 19 .

[0047] The organic dispersant sorbitol of 0.8wt% is added to the calcined material of gained; Subsequently, the calcined material is carried out coarse pulverization and the dry formula coarse pulverization of adding additive in 5 minutes in the continuous type dry vibration ball mill, after pulverizing The average particle size of the powder was 4.5 μm.

[0048] Next, weigh 450 grams of the coarsely pulverized material produced in the above-mentioned manner, add 0.5wt%...

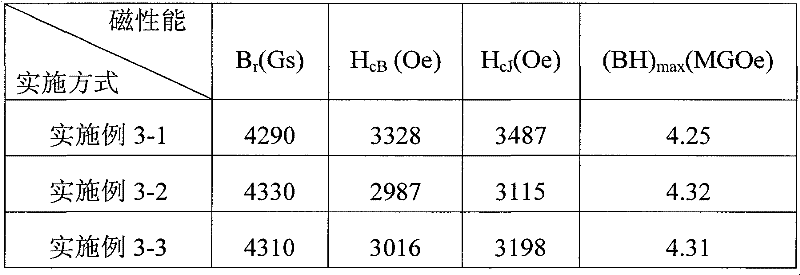

Embodiment 3

[0054] Raw material selection is the same as implementation example 2, and each raw material addition is as follows: Fe 2 o 3 Powder, 86.16 wt%; SrCO 3 Powder, 12.95wt%; Bi 2 o 3 Powder, 0.64wt%; Al 2 o 3 Powder, 0.25 wt%.

[0055] After pre-firing in the same process, the pre-fired temperature is 1240°C, and the holding time is 1 hour. The components of the obtained pre-fired material can be expressed as Sr 0.97 Bi 0.03 Fe 11.89 Al 0.06 o 19 .

[0056] The calcium gluconate of 0.4wt% and the polyvinyl alcohol of 0.4wt% are added to the calcined material of gained, subsequently in the continuous type dry vibration ball mill, the calcined material is carried out coarse pulverization and the added additive is carried out the dry type coarse grinding of 3 minutes. Pulverize, the average particle size of the pulverized powder is 5.8 μm.

[0057] Next, weigh 450 grams of the coarsely pulverized material produced in the above-mentioned manner, add 0.5wt% SiO 2 , 0.75wt%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com