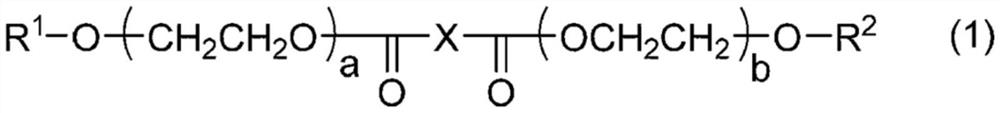

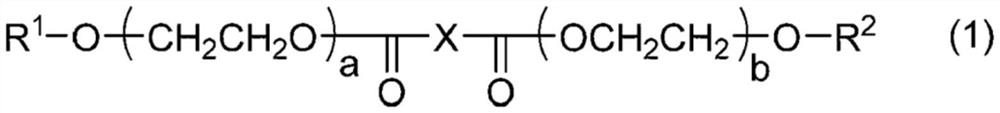

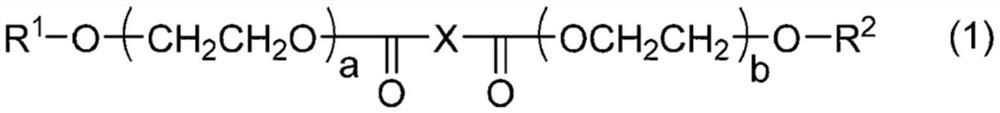

polyurethane resin composition

A technology of polyurethane resin and composition, which is applied in the direction of plastic/resin/wax insulator, other chemical processes, chemical instruments and methods, etc. It can solve problems such as cracks and loss of flexibility of polyurethane resin, and achieve hardness suppression and excellent volume resistance value , the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~11 and comparative example 1~6

[0267] Each component and 0.01 weight% of SC-5570 (silicone antifoaming agent) as an antifoaming agent were mix|blended according to the composition shown in Table 1, and various polyurethane resin compositions were prepared according to the following procedure.

[0268] The (B) polyol compound, (C) inorganic filler, (D) plasticizer, and (E) crosslinking shown in Table 1 were carried out at 2000 rpm using an autorotation / revolution mixer (degassing Rentaro, manufactured by THINKY Co., Ltd. agent, (F) defoamer and (G) polymerization catalyst were mixed for 1 minute.

[0269] The (A) polyisocyanate compound shown in Table 1 was added to the said mixing component, and it mixed for 1 minute at 2000 rpm using the autorotation / revolution mixer (defoaming Rentaro, manufactured by THINKY company). The obtained mixture was degassed, and each polyurethane resin composition of Examples 1-11 and Comparative Examples 1-6 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com