Dual-purpose printing equipment with functions of transfer printing and direct printing

A printing and direct printing technology, applied in transfer printing, rotary printing machine, printing and other directions, can solve the problems of large volatilization of organic solvents, difficult production costs and reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Embodiment 1 Transfer printing production of transfer printing and direct printing dual-purpose printing equipment.

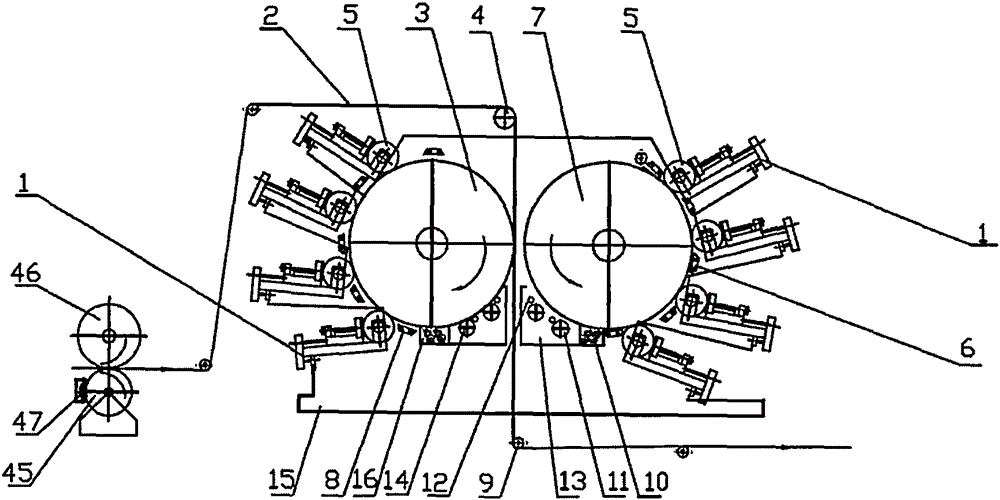

[0071] The pretreatment device of the transfer printing and direct printing dual-purpose printing equipment used for transfer printing is composed of an anilox roller (45) and a pressure roller (46), and the pressure roller (46) of the pretreatment device is Independent pressure roller, which is as attached figure 1 The shown pre-processing independent transfer and direct printing dual-purpose printing equipment.

[0072] After the fabric to be printed (2) is processed by the pre-processing device, it is guided between the front and rear main rolls by the traction roll (4). There are spiral guide pieces, and the bottom roller is covered with high-temperature-resistant and corrosion-resistant high-quality rubber. The shafts at both ends of the front main roller (3) are fixed on the wallboard (15) through bearings and flanges. Sprocket, the sprocket and ...

Embodiment 2

[0084] Embodiment 2 The direct printing production of transfer printing and direct printing dual-purpose printing equipment.

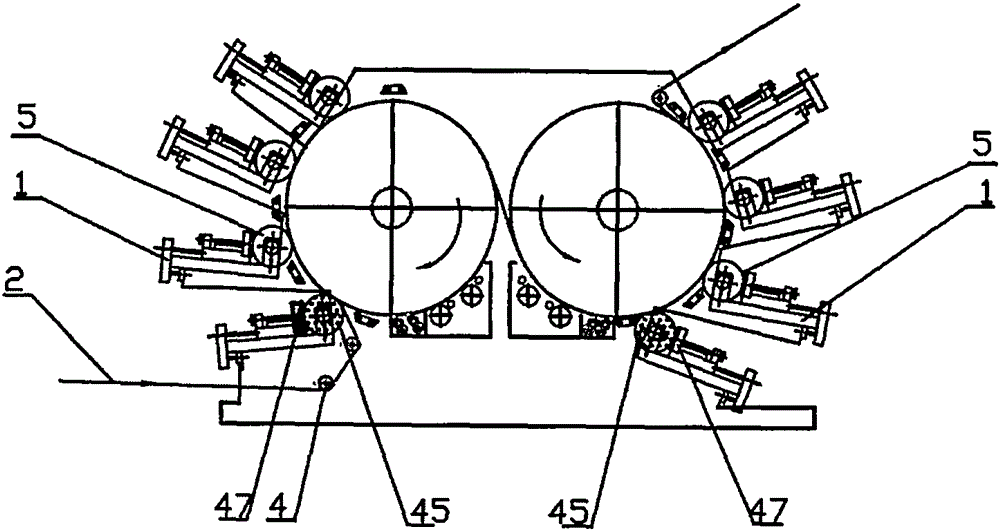

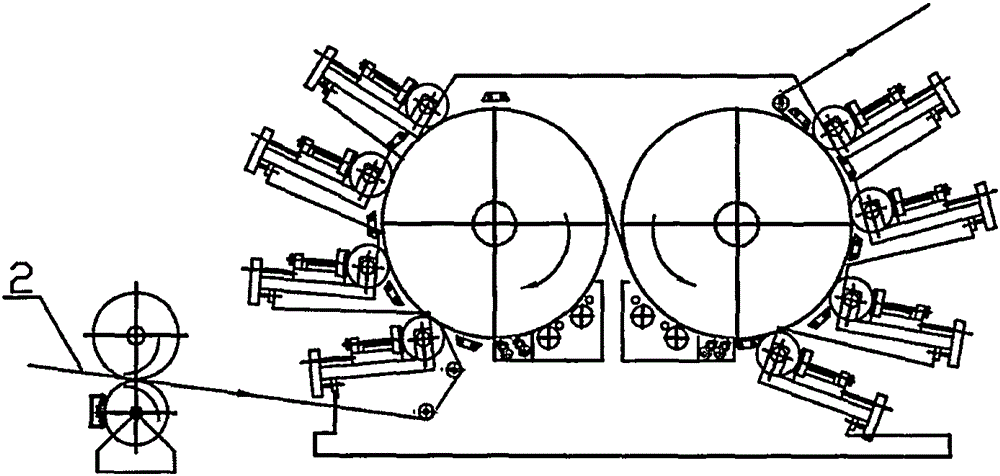

[0085] The pre-processing device of the transfer printing and direct printing dual-purpose printing equipment used for direct printing is composed of an anilox roller (45) and a pressure roller (46), and the pressure roller (46) of the pre-processing device is Independent pressure roller, the equipment is attached image 3 The dual-purpose printing equipment for transfer printing and direct printing independent of the pretreatment shown; or the main roller of the printing device as the pressure roller, then the equipment is an auxiliary figure 2 The shown is a pre-processing integrated transfer and direct printing dual-purpose printing equipment with the main roller of the printing device as the pressure roller.

[0086] The fabric to be printed (2) is introduced by the traction roller (4), and after being processed by the pre-processing device, it e...

Embodiment 3

[0097] Example 3 Comparison of printing cases of different fabrics by transfer printing and direct printing dual-purpose printing equipment:

[0098] The following transfer printing adopts the production method described in Example 1, and the direct printing adopts the production method described in Example 2.

[0099]

[0100]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com