Ti-microalloyed Q345B steel plate and production method thereof

A technology of micro-alloying and steel plate, applied in the field of low-alloy high-strength structural steel, can solve problems such as rising cost, achieve the effect of good welding performance, low cost, and suitable for popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

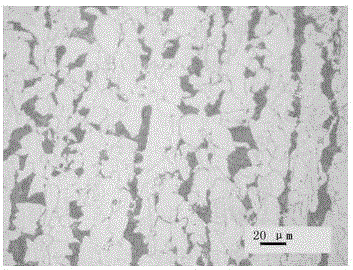

Image

Examples

Embodiment 1-8

[0012] Examples 1-8: The composition ratio and production method of the Ti microalloyed Q345B steel plate are as follows.

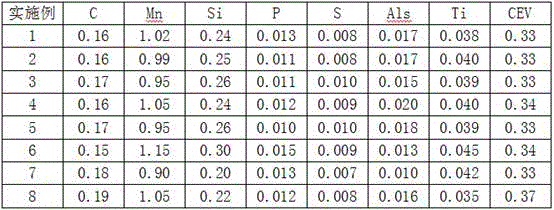

[0013] 1. Steelmaking process: molten steel is smelted in a converter, LF refining and continuous casting to obtain a continuous casting slab; the chemical composition of the continuous casting slab in each embodiment is shown in Table 1.

[0014] Table 1: Chemical composition of each continuous casting slab (wt%)

[0015]

[0016] In Table 1, CEV=C+Mn / 6+(Mo+Cr+V) / 5+(Ni+Cu) / 15, and the balance is iron and unavoidable impurities.

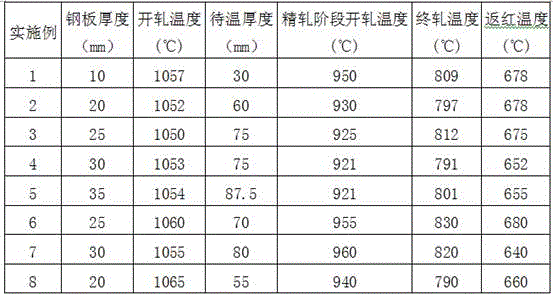

[0017] 2. Rolling process: the continuous casting slab is rolled to obtain the Q345B steel plate; the specific rolling process parameters of each embodiment are shown in Table 2.

[0018] Table 2: Rolling Process Parameters

[0019]

[0020] 3. Performance testing: The Q345B steel plate obtained in the embodiment was tested, and the performance results are shown in Table 3.

[0021] Table 3: Performance Results

[0022...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com