Method for preparing fiber reinforced ceramic matrix composite material

A fiber-reinforced, composite material technology, applied in the field of composite material preparation technology, can solve the problems of increasing the preparation cycle of fiber-reinforced ceramic matrix composite materials, limiting the scope of application, expensive weaving costs, etc., to reduce production costs, save time, and improve mechanization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

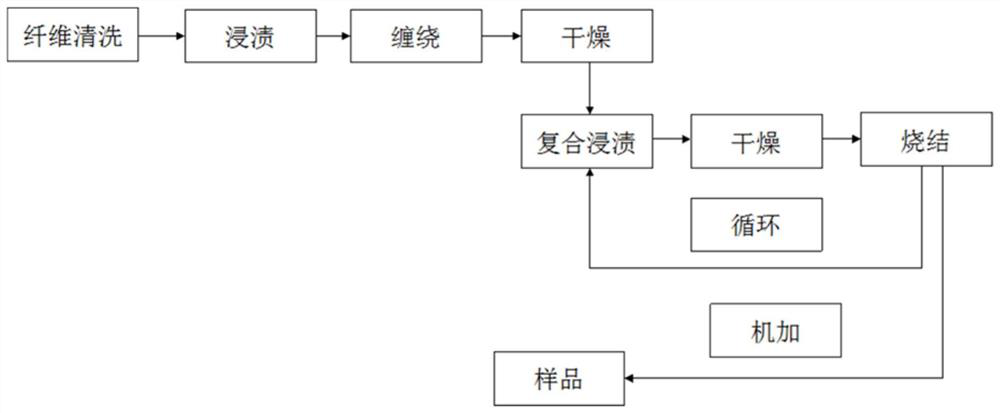

[0033] The process route of the method for preparing fiber-reinforced ceramic matrix composites of the present invention is as follows: figure 1 As shown, the specific steps are as follows:

[0034] Step 1, fiber pretreatment (fiber cleaning): There is often a thin layer of epoxy resin on the surface of the fiber, and its existence will affect the interface bonding strength between the fiber and the matrix material in the composite material. It is necessary to select a suitable fiber pretreatment process to remove the epoxy resin on the surface of the fiber and minimize the impact on the fiber strength. Boil the fiber with acetone for 36-48 hours, then replace with new acetone, continue to cook for 12-24 hours, and finally dry it in the explosion-proof room for 3-4 days.

[0035] Step 2, fiber impregnation: soak the fiber treated in step 1 in the sol (the density of the sol is 1.20~1.38g / cm 3 )2-5h to obtain fully impregnated fibers.

[0036] Step 3, fiber winding: accordin...

Embodiment 1

[0050] Boil the B-type quartz fiber with acetone for 36 hours, then replace with new acetone, continue to cook for 12 hours, and finally dry it in the explosion-proof room for 3-4 days; impregnate the cleaned quartz fiber with a density of 1.20g / cm 3 In the silica sol for 2 hours, completely impregnated fibers were obtained; according to the set winding procedure, the fibers were wound onto the mandrel of the round table through the winding machine; the wound samples were kept in an oven at 80°C for 12 hours; dried Put the good sample in the glue injection tank, the density is 1.25~1.32g / cm 3 Inject the silica sol into the tank, pressurize at 3.5-3.7MPa, and keep the pressure for 24 hours; after the pressure keeping, send the sample to an oven at 80°C for 12 hours; put the dried sample in the injection tank, and set the density 1.25~1.32g / cm 3 Inject the silica sol into the tank, pressurize at 3.5-3.7MPa, and keep the pressure for 24 hours; cool down, take off the mandrel use...

Embodiment 2

[0052] Boil Nextel720 alumina fiber with acetone for 36 hours, then replace with new acetone, continue to cook for 12 hours, and finally dry it in the explosion-proof room for 3-4 days; impregnate the cleaned alumina fiber in the 3 In the silica sol for 2 hours, completely impregnated fibers were obtained; according to the set winding procedure, the fibers were wound onto the plate-shaped mandrel by a winding machine; the wound samples were kept in an oven at 100°C for 12 hours; The dried sample is placed in the glue injection tank, and the density is 1.25 ~ 1.32g / cm 3 Inject the silica sol into the tank, pressurize at 3.5-3.7MPa, and keep the pressure for 24 hours; after the pressure keeping, send the sample to an oven at 80°C for 12 hours; put the dried sample in the injection tank, and set the density 1.25~1.32g / cm 3 Inject the silica sol into the tank, pressurize at 3.5-3.7MPa, and keep the pressure for 24 hours; cool down, take off the mandrel used for winding the sample...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com