A kind of preparation method of anti-aging zirconia ceramic ferrule

A zirconia ceramic and anti-aging technology, which is applied in the field of ceramic electronic components, can solve the problems of low pass rate of blank quality and poor anti-aging performance, and achieve the effects of good fluidity, strong mold release performance and high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The embodiment of the present invention discloses a method for preparing an anti-aging zirconia ceramic ferrule, which includes the following steps:

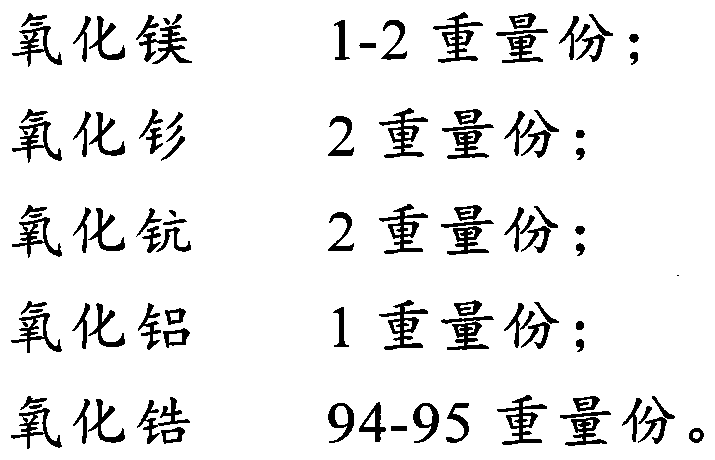

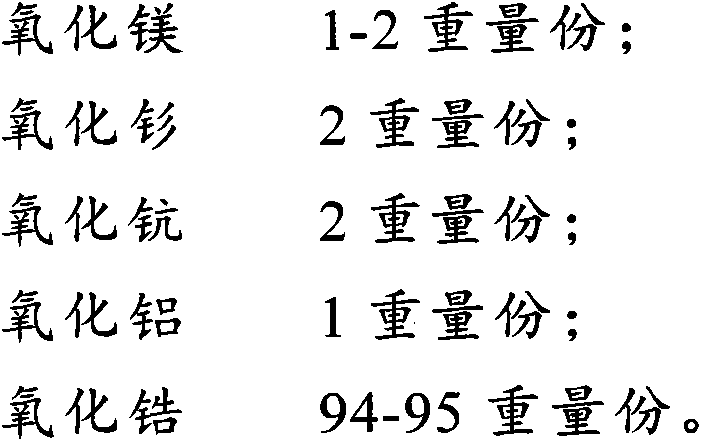

[0034] Step a) mixing magnesia, samarium oxide, scandium oxide, aluminum oxide and zirconia, and pre-calcining to obtain a zirconia powder composite substrate;

[0035] Step b) the zirconia powder composite substrate, dioctyl phthalate, ethylene-vinyl acetate copolymer, calcium stearate, polyvinyl chloride, thermoplastic polyester elastomer, linear low density polyethylene, micro Crystal wax and palm oil are mixed, added to a mixer for mixing, and the mixing temperature is 160-250°C to obtain a gelatinous substance;

[0036] Step c) compressing the gelatinous substance into tablets, pulverizing it, and obtaining a blank after injection molding;

[0037] Step d) performing degreasing treatment and high-temperature sintering on the blank in turn, and obtaining an anti-aging zirconia ceramic ferrule after cooling.

[0038]...

Embodiment 1

[0077] Step 1. Mix 1 part by weight of magnesium oxide, 2 parts by weight of samarium oxide, 2 parts by weight of scandium oxide, 1 part by weight of aluminum oxide and 95 parts by weight of zirconia, and pre-calcine at 1000 ° C to obtain Zirconia powder base.

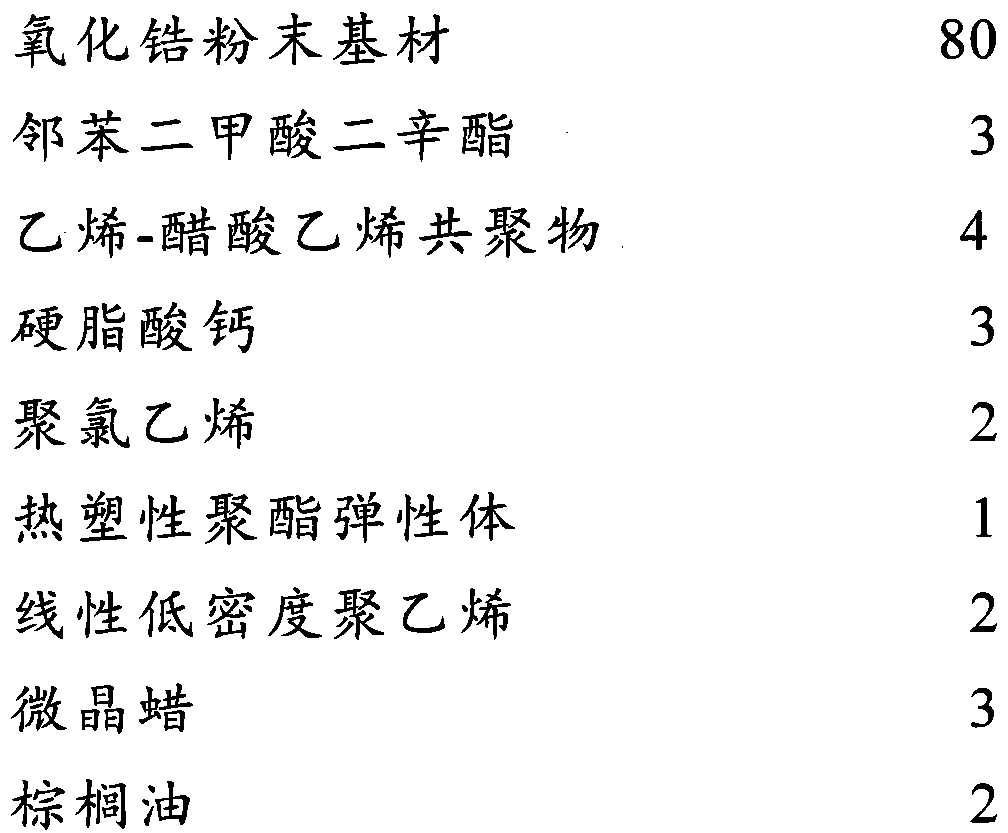

[0078] Step 2, mixing the zirconia powder base material and organic additives prepared above in a certain proportion, the raw materials used in this step include in parts by weight:

[0079]

[0080] The above-mentioned zirconia powder base material, dioctyl phthalate, ethylene-vinyl acetate copolymer, calcium stearate, polyvinyl chloride, thermoplastic polyester elastomer, linear low-density polyethylene, microcrystalline wax and palm oil were added into a mixer for mixing, the mixing temperature was 180° C., and the mixing time was set to 2 hours to obtain a gelatinous substance.

[0081] Step 3, compressing the colloidal substance into tablets with a thickness of 2-3 mm, and crushing the tablets into injection m...

Embodiment 2

[0096] Step 1. Mix 1 part by weight of magnesium oxide, 2 parts by weight of samarium oxide, 2 parts by weight of scandium oxide, 1 part by weight of aluminum oxide and 95 parts by weight of zirconia, and pre-calcine at 1000 ° C. A zirconia powder base material is obtained.

[0097] Step 2, mixing the zirconia powder base material and organic additives prepared above in a certain proportion, the raw materials used in this step include in parts by weight:

[0098]

[0099] The above-mentioned zirconia powder base material, dioctyl phthalate, ethylene-vinyl acetate copolymer, calcium stearate, polyvinyl chloride, thermoplastic polyester elastomer, linear low-density polyethylene, microcrystalline wax 1. Palm oil was added into a mixer for mixing, the mixing temperature was 200° C., and the mixing time was set to 3 hours to obtain a gelatinous substance.

[0100] Step 3, compressing the colloidal substance into tablets with a thickness of 2-3 mm, and crushing the tablets into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com