Thermosetting polymer aqueous dispersion as well as preparation method and application thereof

A water-based dispersion, polymer technology, applied in the direction of graft polymer adhesive, adhesive type, coating, etc., can solve the problems of unstable storage, performance problems, etc., achieve good film uniformity, improve Thermomechanical properties, high universal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

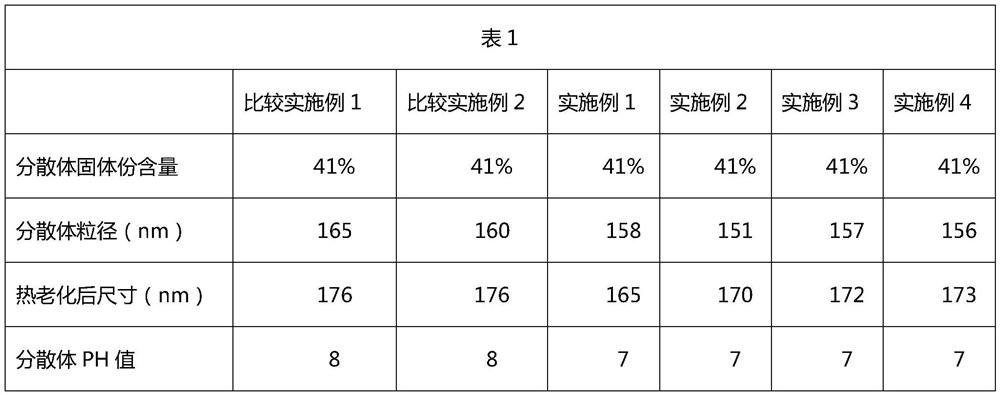

Embodiment 1

[0016] The first step: the preparation of polyurethane acrylic polymer monomer:

[0017] Take 10g of polyester polyol XCP1500NH, 9g of 4,4'-dicyclohexylmethane diisocyanate, 0.1g of catalyst benzyldimethylamine (BDMA), blow nitrogen, heat to 80 degrees, and react for 1 hour. Then add 5 g of nitrogen methylpyrrolidone (NMP), mix for 10 minutes, add 2 g of 2,2-dimethylolpropionic acid (DMPA) dropwise, and continue the reaction at 80 degrees for 3 hours. Then, 11 g of glycidyl methacrylate was continued to be added dropwise, the temperature was lowered to 40° C., 1.5 g of triethylamine was added, and the mixture was mixed and stirred for 30 minutes.

[0018] The second step: the preparation of polymer monomer aqueous dispersion:

[0019] Prepare a four-necked flask, add 72.2g of deionized water, start stirring at 30 degrees, slowly add the polymer monomer prepared in the first step into the reactor dropwise, after the dropwise addition is completed, add 20g of ethylenediamine, ...

Embodiment 2

[0021] The first step: the preparation of polyurethane acrylic polymer monomer:

[0022] Take 9g of polyester polyol Piothane2000NA, 6g of isophorone diisocyanate (IPDI), 0.15g of catalyst benzyldimethylamine (BDMA), blow nitrogen, heat to 80 degrees, and react for 1 hour. Then add 5 g of nitrogen methylpyrrolidone (NMP), mix for 10 minutes, add 2 g of 2,2-dimethylolpropionic acid (DMPA) dropwise, and continue the reaction at 80 degrees for 3 hours. Then continue to drop 5 g of butyl methacrylate and 6 g of glycidyl methacrylate, cool down to 40 degrees, add 1.5 g of triethylamine, and mix and stir for 30 minutes.

[0023] The second step: the preparation of polymer monomer aqueous dispersion:

[0024] Prepare a four-necked flask, add 66.5g of deionized water, start stirring at 30 degrees, slowly add the polymer monomer prepared in the first step into the reactor dropwise, after the dropwise addition is completed, add 20g of ethylenediamine, Stir for 5 minutes. At the same ...

Embodiment 3

[0026] The first step: the preparation of polyurethane acrylic polymer monomer:

[0027] Take 12g of polyester polyol XCP-3000N, 5g of isophorone diisocyanate (IPDI), 0.2g of catalyst benzyldimethylamine (BDMA), blow nitrogen, heat to 80 degrees, and react for 1 hour. Then add 8 g of nitrogen methylpyrrolidone (NMP), mix for 10 minutes, add 2 g of 2,2-dimethylolpropionic acid (DMPA) dropwise, and continue the reaction at 80 degrees for 3 hours. Then continue to dropwise add 5 g of styrene and 7 g of glycidyl methacrylate, cool down to 40 degrees, add 1.5 g of triethylamine, and mix and stir for 30 minutes.

[0028] The second step: the preparation of polymer monomer aqueous dispersion:

[0029] Prepare a four-necked flask, add 68g of deionized water, start stirring at 30 degrees, slowly add the polymer monomer prepared in the first step into the reactor dropwise, after the dropwise addition is completed, add 20g of ethylenediamine, and stir 5 minutes. At the same time, 0.2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com