A kind of nanometer silver solder paste connects the power module manufacturing method of bare copper DBC

A power module and nano-silver technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problem that the diffusion connection between nano-silver and bare copper substrates or copper-clad substrates cannot be realized, and nano-silver cannot be well moistened. Wet substrates, affecting the reliability of chip connection, etc., to achieve the effect of improving connection strength and reliability, low elastic modulus, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

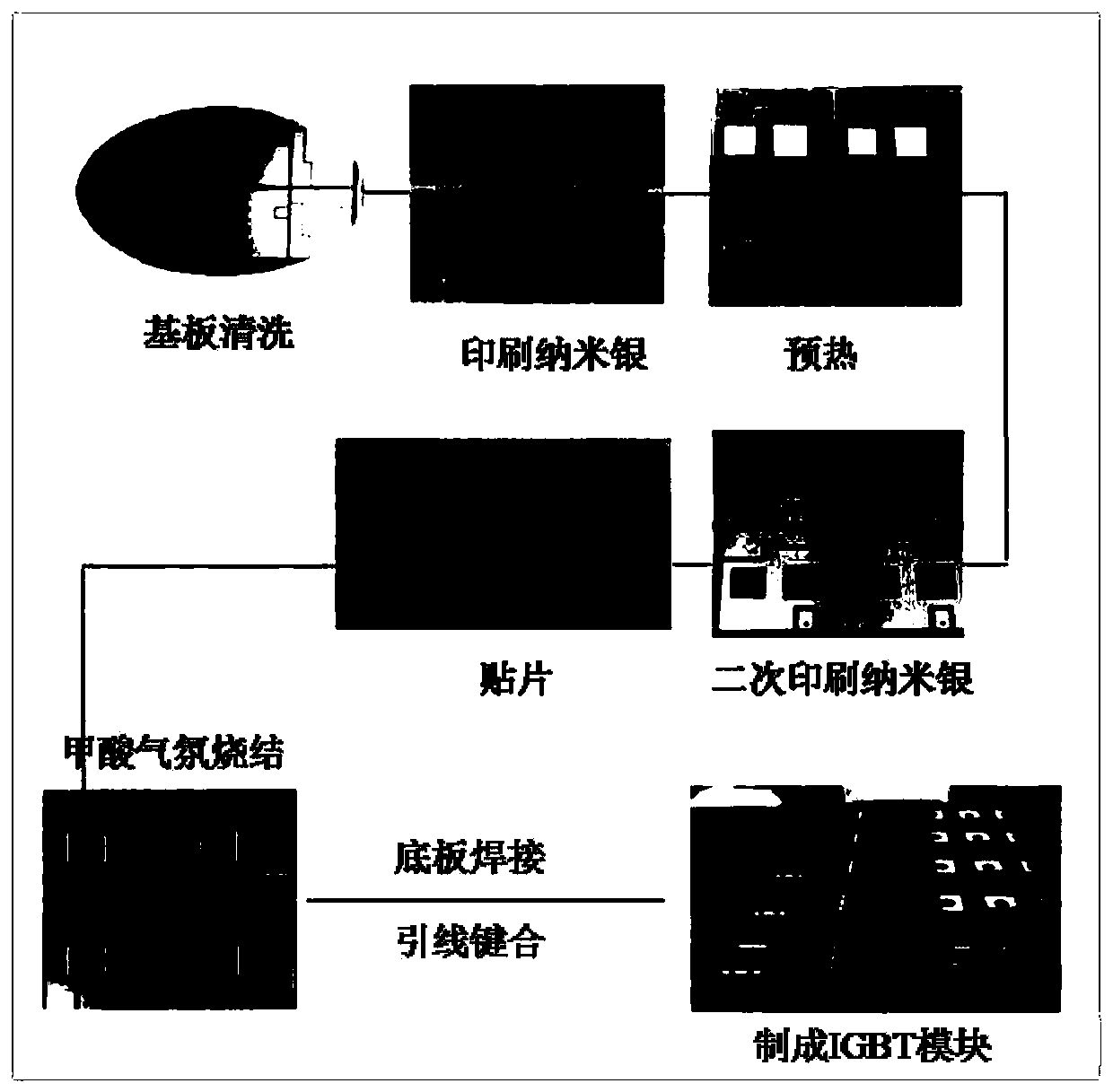

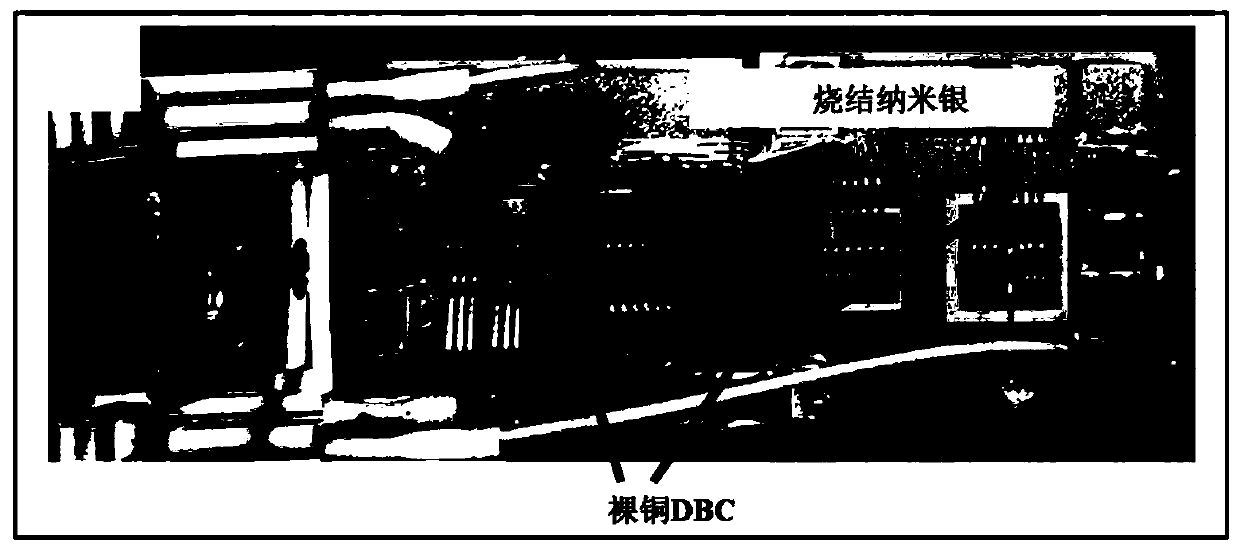

[0031] (1) if figure 1 Shown is the manufacturing process of a high-power semiconductor power module with nano-silver solder paste connected to a bare copper DBC substrate, which are DBC substrate cleaning, nano-silver printing, chip mounting, and nano-silver sintering.

[0032] (2) Cleaning process: first clean the bare copper DBC with dilute hydrochloric acid, and then use an ultrasonic cleaner to vibrate and clean for 1 min, then clean it with absolute ethanol, and use an ultrasonic cleaner to vibrate and clean for 10 min.

[0033] (3) Solder paste printing process, printing nano-silver on the cleaned bare copper DBC, using stencil printing technology to print nano-silver solder paste, preheating after the first printing, preheating temperature 150 ℃, holding time 20min, and then Make a second print.

[0034] (4) Mounting process, using a placement machine for placement, the placement pressure is 200gf. See attached Figure 4 ;

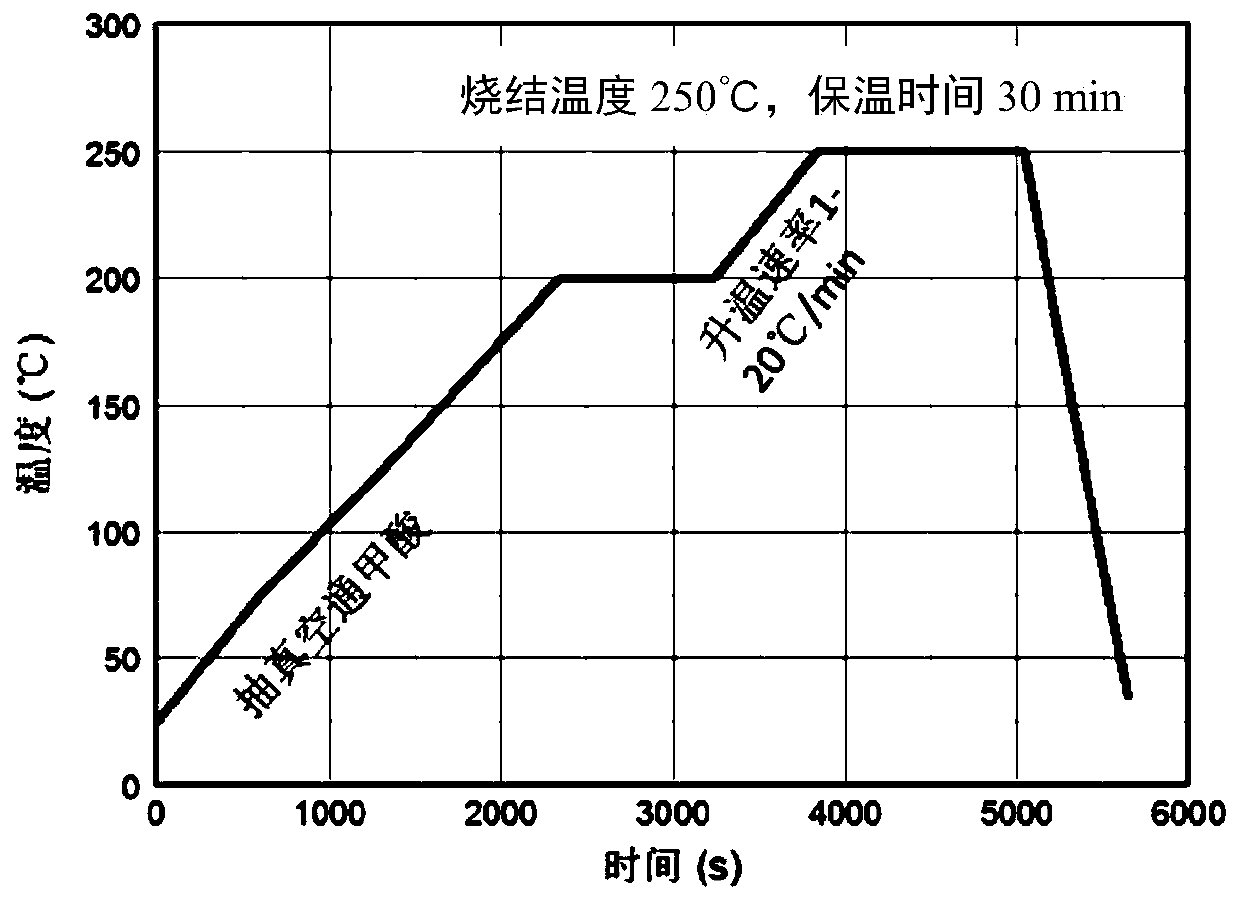

[0035] (5) Sintering process, vacuumize ...

Embodiment 2

[0038] (1) if figure 1 Shown is the manufacturing process of a high-power semiconductor power module with nano-silver solder paste connected to a bare copper DBC substrate, which are DBC substrate cleaning, nano-silver printing, chip mounting, and nano-silver sintering.

[0039] (2) Cleaning process: first clean the bare copper DBC with dilute hydrochloric acid, and then use an ultrasonic cleaner to vibrate and clean for 1 min, then clean it with absolute ethanol, and use an ultrasonic cleaner to vibrate and clean for 10 min.

[0040] (3) Solder paste printing process, printing nano-silver on the cleaned bare copper DBC, printing nano-silver solder paste with stencil printing technology, preheating after the first printing, preheating temperature 180 ℃, holding time 20min, and then Make a second print.

[0041] (4) Mounting process, using a placement machine for placement, the placement pressure is 200gf. See attached Figure 4 ;

[0042] (5) Sintering process, vacuumize t...

Embodiment 3

[0045] (1) if figure 1 Shown is the manufacturing process of a high-power semiconductor power module with nano-silver solder paste connected to a bare copper DBC substrate, which are DBC substrate cleaning, nano-silver printing, chip mounting, and nano-silver sintering.

[0046] (2) Cleaning process: first clean the bare copper DBC with dilute hydrochloric acid, and then use an ultrasonic cleaner to vibrate and clean for 1 min, then clean it with absolute ethanol, and use an ultrasonic cleaner to vibrate and clean for 10 min.

[0047] (3) Solder paste printing process, printing nano-silver on the cleaned bare copper DBC, using stencil printing technology to print nano-silver solder paste, preheating after the first printing, preheating temperature 200 ℃, holding time 20min, and then Make a second print.

[0048] (4) Mounting process, using a placement machine for placement, the placement pressure is 200gf. See attached Figure 4 ;

[0049] (5) Sintering process, vacuumize ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com