Multifunctional modified resin blended prepreg hydrocarbon composition, application thereof and method for preparing high-frequency and high-speed copper-clad plate by adopting prepreg hydrocarbon composition

A hydrocarbon composition and modified resin technology, applied in the field of high-frequency communication materials, can solve the problems of poor heat resistance, poor peel strength, affecting the application of hydrocarbon cured sheets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

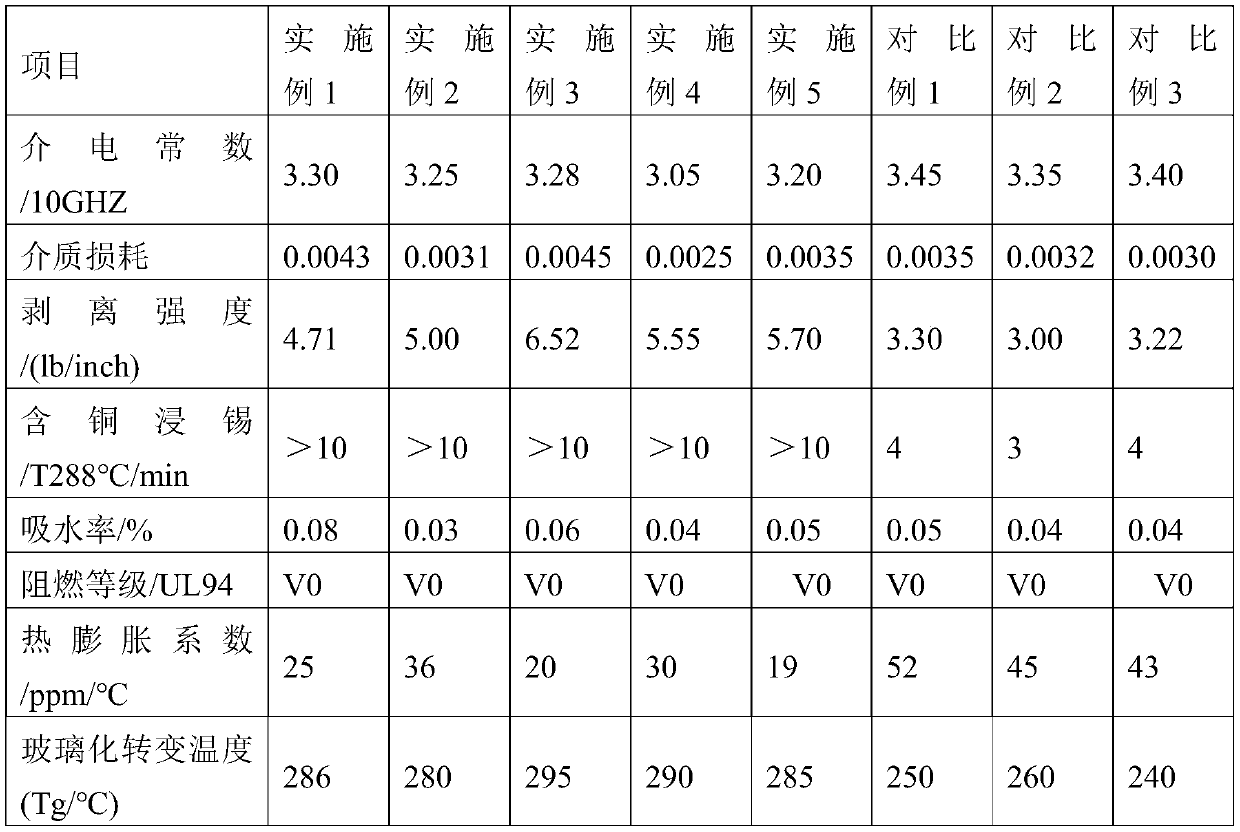

Examples

Embodiment 1

[0032] A prepreg hydrocarbon composition blended with a multifunctional modified resin provided in this embodiment includes the following components by weight components:

[0033] 20 parts of styrene-butadiene-styrene copolymer;

[0034] 10 parts of isoprene-butadiene copolymer;

[0035] 10 parts of hydroxyl modified polybutadiene;

[0036] 30 parts of inorganic filler fumed silica;

[0037] 15 parts of flame retardant melamine polyphosphate;

[0038] 1 part of antioxidant 4,4'-thiobis(6-tert-butyl-3-methylphenol);

[0039] 2 parts of crosslinking agent divinylbenzene;

[0040] 1 part of crosslinking agent dicumyl peroxide.

[0041] According to weight components, the styrene-butadiene-styrene copolymer, isoprene-butadiene copolymer, hydroxyl-modified polybutadiene, fumed silica, melamine, etc. Add polyphosphate, 4,4'-thiobis(6-tert-butyl-3-methylphenol), divinylbenzene and dicumyl peroxide into toluene in sequence, mix well, and use No. 3 viscosity The cup is used as a...

Embodiment 2

[0043] A prepreg hydrocarbon composition blended with a multifunctional modified resin provided in this embodiment includes the following components by weight components:

[0044]20 parts of styrene-butadiene-styrene copolymer;

[0045] 10 parts of isoprene-butadiene copolymer;

[0046] 10 parts of polyether modified polybutadiene;

[0047] 20 parts of inorganic filler fumed silica;

[0048] 10 parts of inorganic filler alumina;

[0049] 20 parts of flame retardant melamine polyphosphate;

[0050] 0.5 part of antioxidant 2,4-bis(n-octylsulfamethylene)-6-methylphenol;

[0051] 2 parts of crosslinking agent triallyl isocyanate;

[0052] 1 part of crosslinking agent dicumyl peroxide.

[0053] According to weight components, the styrene-butadiene-styrene copolymer, isoprene-butadiene copolymer, polyether modified polybutadiene, fumed silica, Alumina, melamine polyphosphate, 2,4-bis(n-octylsulfamethylene)-6-methylphenol, triallyl isocyanate, and dicumyl peroxide were added t...

Embodiment 3

[0055] A prepreg hydrocarbon composition blended with a multifunctional modified resin provided in this embodiment includes the following components by weight components:

[0056] 20 parts of styrene-butadiene-styrene copolymer;

[0057] 10 parts of isoprene-butadiene copolymer;

[0058] 5 parts of hydroxyl modified polybutadiene-styrene copolymers;

[0059] 2 parts of hydroxyl modified polybutadiene;

[0060] 3 parts of polyether modified polybutadiene;

[0061] 30 parts of inorganic filler fumed silica;

[0062] 10 parts of inorganic filler magnesium hydroxide;

[0063] 10 parts of flame retardant melamine polyphosphate;

[0064] Antioxidant 4,4'-thiobis(6-tert-butyl-3-methylphenol) 0.5 parts;

[0065] 0.5 part of antioxidant 2,4-bis(n-octylsulfamethylene)-6-methylphenol;

[0066] 1 part of crosslinking agent divinylbenzene;

[0067] 1 part of crosslinking agent triallyl isocyanate;

[0068] 3 parts of crosslinking agent dicumyl peroxide.

[0069] According to weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com