Spherical nano-silica material with double particle size distribution and preparation method thereof

A nano-silica, dual particle size technology, applied in the direction of silica, silica, nanotechnology for materials and surface science, etc., can solve the problem of ignoring the anisotropy and importance of monodisperse nano-silica

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

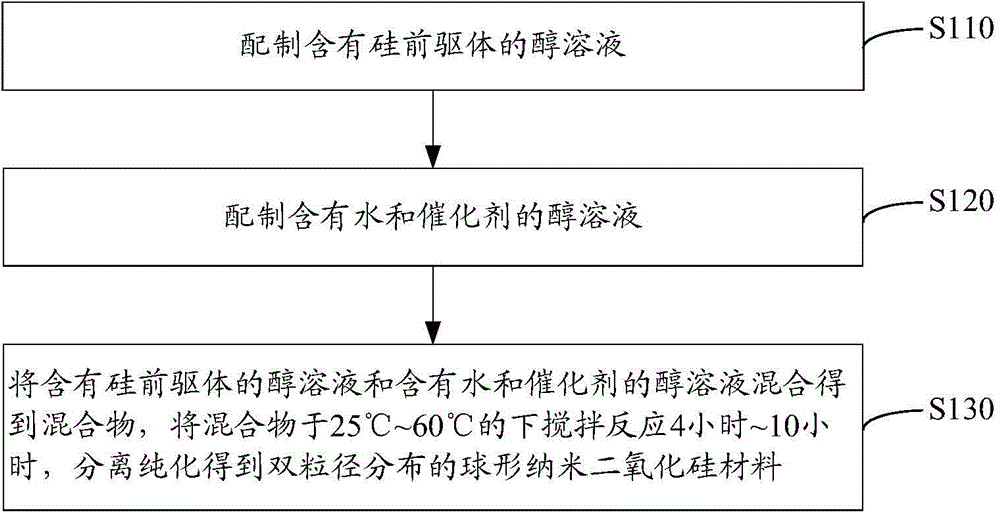

[0027] see figure 1 , the preparation method of spherical nano-silica material with double particle size distribution according to one embodiment, comprising the following steps S110 to S120.

[0028] Step S110: preparing an alcohol solution containing a silicon precursor.

[0029] The silicon precursor is preferably tetraethylorthosilicate, tetramethoxysilane, butyltrimethoxysilane, tetraethoxysilane, methyltriethoxysilane, amyltriethoxysilane, tetrapropoxy silane or tetrabutoxysilane.

[0030] The silicon precursor is dissolved in an alcohol solvent to prepare an alcohol solution containing the silicon precursor. The alcoholic solvent is preferably anhydrous methanol, anhydrous ethanol, isopropanol, n-propanol, n-butanol, isobutanol or pentanol.

[0031] Preferably, the silicon precursor is dissolved in an alcohol solvent, and then placed in an ultrasonic bath for 5 minutes to 30 minutes so that the silicon precursor is evenly dispersed.

[0032] Preferably, in the alcoh...

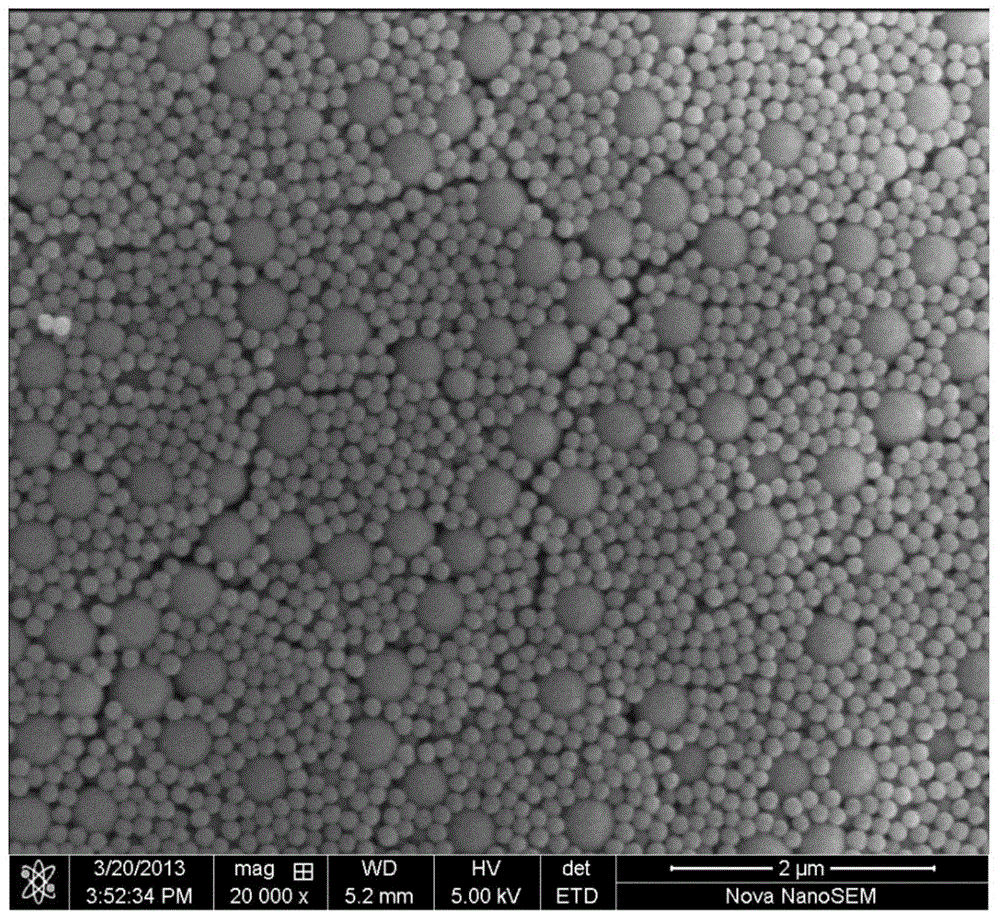

Embodiment 1

[0056] 1. Take 5mL of tetraethyl orthosilicate, add it to 45mL of absolute ethanol, and sonicate in an ultrasonic bath for 5 minutes to obtain a uniformly dispersed ethanol solution containing tetraethyl orthosilicate; among them, tetraethyl orthosilicate The concentration is 0.45mol / L;

[0057] 2. Take 2.5mL of deionized water and 4mL of ammonia water, add them to 41mL of absolute ethanol, and sonicate in an ultrasonic bath for 5 minutes to obtain a uniformly dispersed ethanol solution containing water and ammonia water; the concentration of water is 6.0mol / L, the concentration of ammonia is 1.1mol / L;

[0058] 3. Under mechanical stirring, inject the ethanol solution containing tetraethyl orthosilicate and the ethanol solution containing water and ammonia into the reactor at the same time at the feeding speed of 2mL / min and 4mL / min respectively, and react at 30°C After 10 hours of centrifugation, the lower precipitate was washed with absolute ethanol and repeated three time...

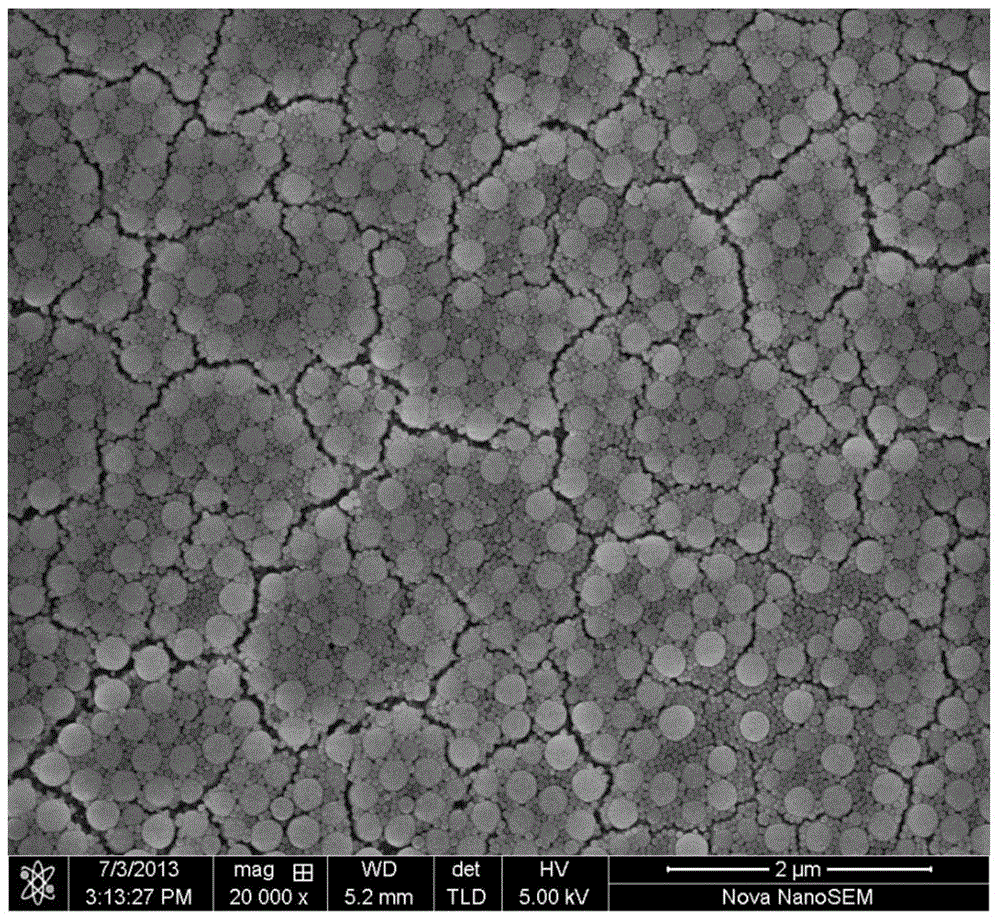

Embodiment 2

[0061] 1. Take 5mL of tetraethyl orthosilicate, add it to 45mL of absolute ethanol, and sonicate in an ultrasonic bath for 15 minutes to obtain a uniformly dispersed ethanol solution containing tetraethyl orthosilicate; among them, tetraethyl orthosilicate The concentration is 0.45mol / L;

[0062] 2. Take 6.5mL of deionized water and 4mL of ammonia water, add them to 39.5mL of absolute ethanol, and sonicate in an ultrasonic bath for 5 minutes to obtain a uniformly dispersed ethanol solution containing water and ammonia water; the concentration of water is 10.0mol / L, the concentration of ammonia is 1.0mol / L;

[0063] 3. Under mechanical stirring, inject the ethanol solution containing tetraethyl orthosilicate and the ethanol solution containing water and ammonia water into the reactor at the same time at the feeding speed of 1mL / min and 3mL / min respectively, and react at 60°C After 4 hours, filter and wash the filter cake with absolute ethanol, vacuum-dry the filter cake at 80...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com