Patents

Literature

31results about How to "Low monomer residue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-smell environment-friendly polyurethane soft foam material as well as preparation method and application thereof

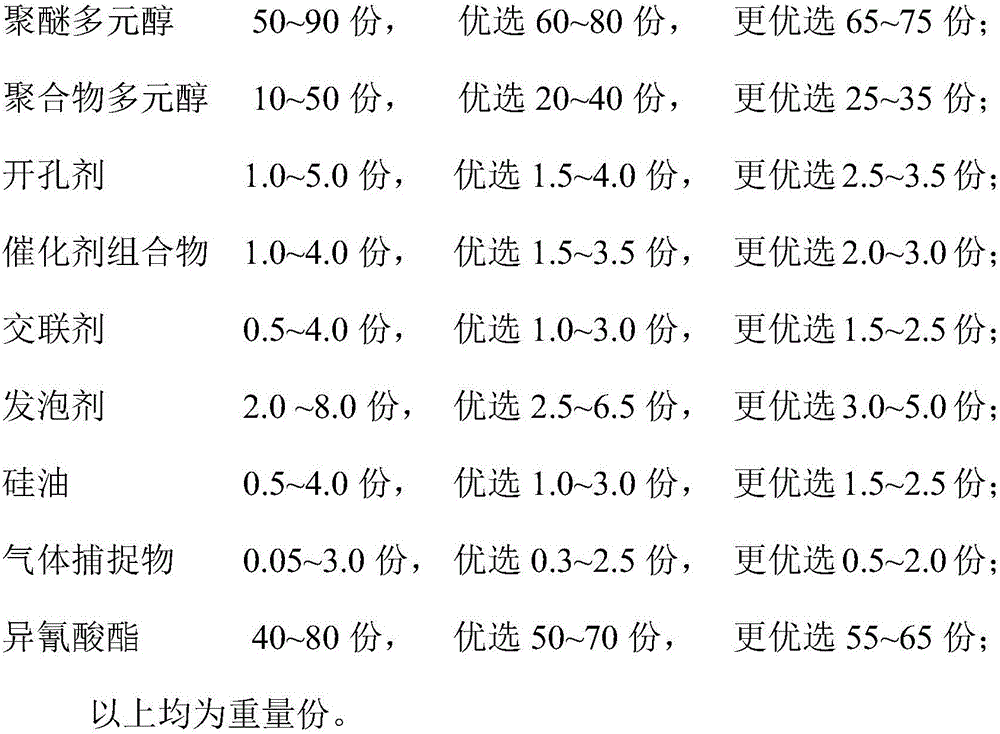

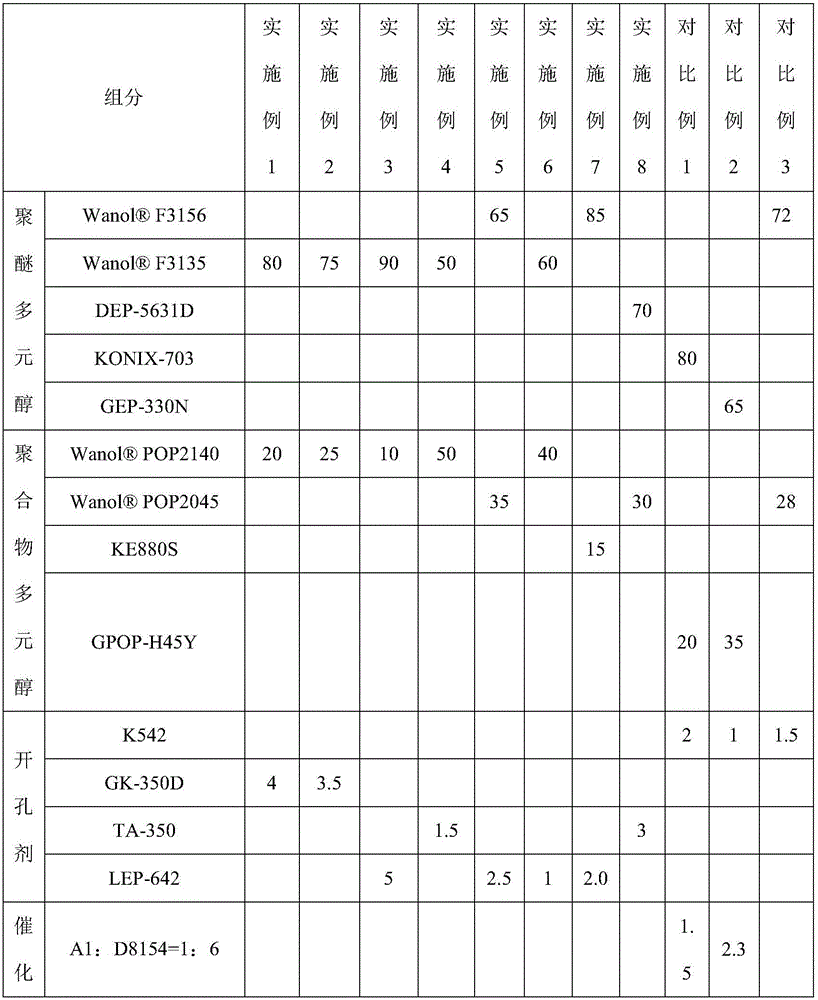

The invention relates to a low-smell environment-friendly polyurethane soft foam material as well as a preparation method and application thereof. According to the invention, the polyurethane soft foam material prepared from a low-smell catalyst compound, low-volatile silicone oil, a gas capturing matter, low-smell polyether polyhydric alcohols and polymer polyhydric alcohols has an obvious effect in the aspect of reducing smell and TVOC. In the compound bulk foaming technique and the molding foaming technique provided by the invention, the low-smell environment-friendly polyurethane soft foam material has the characteristics of technology stability, quick curing, low smell in production processes, environmental protection, and the like.

Owner:WANHUA CHEM GRP CO LTD

Environment-friendly building waterproof paint with low content of VOC and preparation method thereof

InactiveCN105385274ALow monomer residueLow content of volatile additivesAntifouling/underwater paintsPaints with biocidesSOAPMaterials science

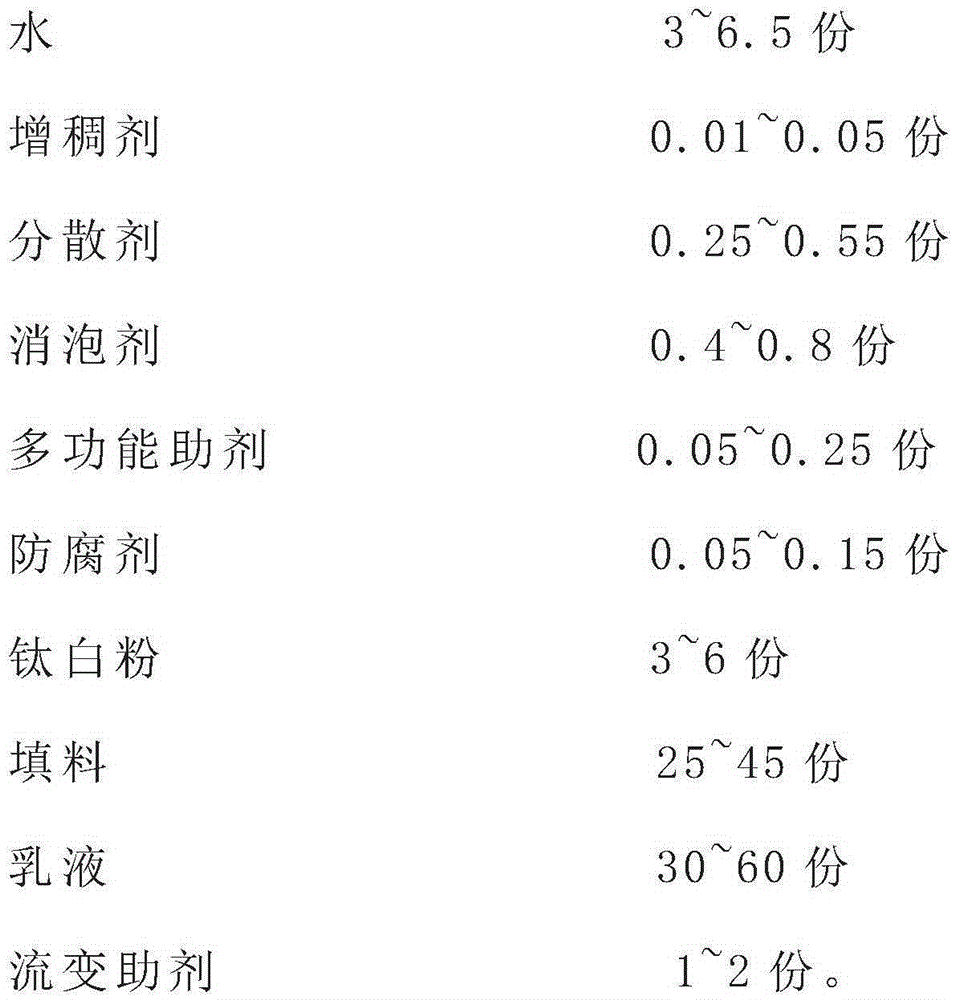

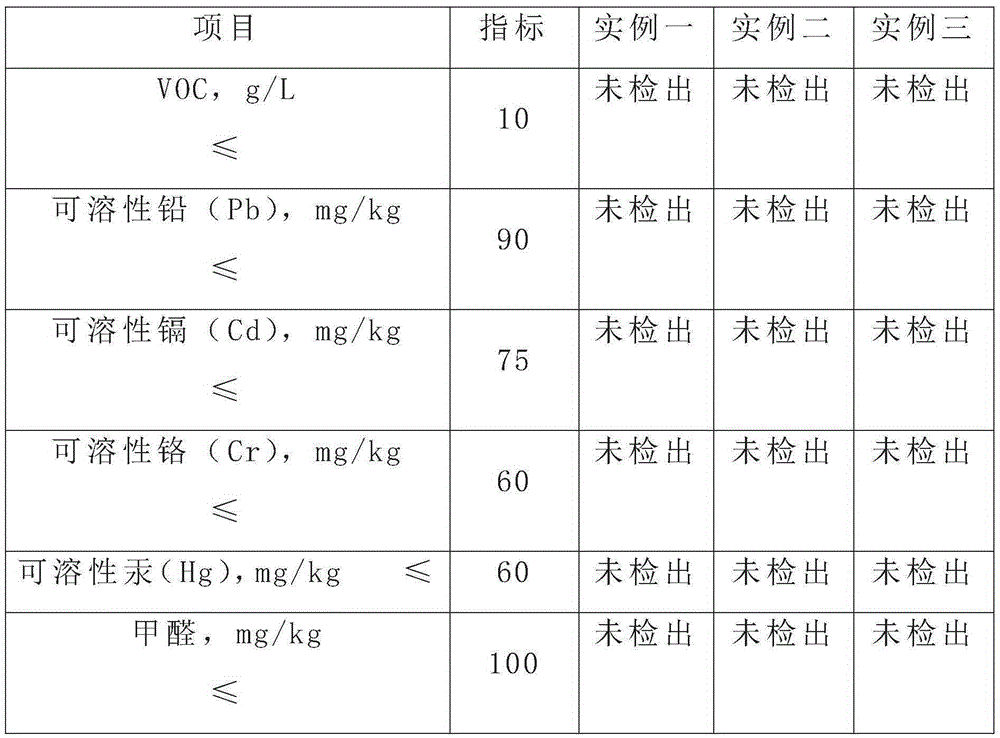

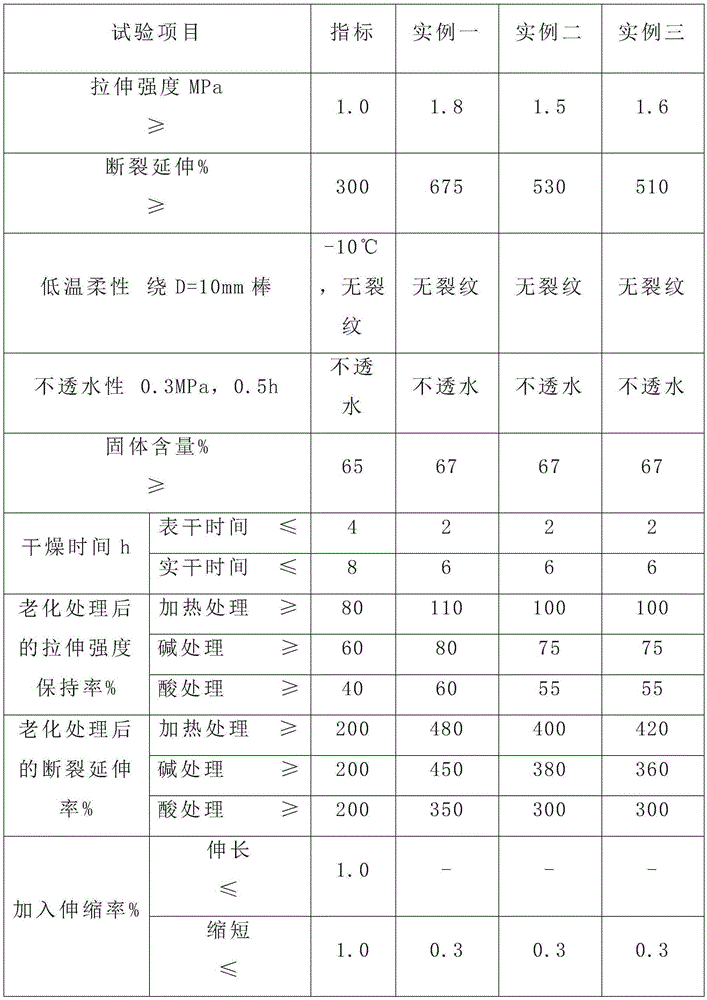

The invention discloses an environment-friendly building waterproof paint with a low content of VOC (volatile organic compound) and a preparation method thereof. The paint comprises the following components in parts by weight: 3 to 6.5 parts of water, 0.01 to 0.05 part of thickening agent, 0.25 to 0.55 part of dispersant, 0.4 to 0.8 part of antifoaming agent, 0.05 to 0.25 part of multifunctional auxiliary agent, 0.05 to 0.15 part of antiseptic, 3 to 6 parts of titanium dioxide, 25 to 45 parts of filling material, 30 to 60 parts of emulsion, and 1 to 2 parts of rheological additive. The paint is prepared by a ternary compounding technology, which compounds three components: low-VOC pure acrylic emulsion, low-VOC vinyl acetate-ethylene emulsion, and soap-free organic silicon rubber emulsion; a VOC-free composite rheological system blending technology and a composite silver ion sterilizing and anticorrosion technology. The paint has the advantages of low VOC content, green, no toxicity, high strength, convenience in construction, and stableness in storage.

Owner:苏州市姑苏新型建材有限公司

Method for synthesizing high water absorption resin by glutinous wheat starch

This invention relates to a method of using glutinous cereal wheat starch to synthesize water absorbent resina. The acroleic acid monomer after neutralizing generate acrylate which can takes reaction with glutinous cereal wheat starch, acroleic acid; under protective system of nitrogen, adopt proper initiator and cross-linking agent, through neutralization and cross linking reaction to generate water absorbent graft copolymer which possess certain crosslink density. This invention adopts typic ammonium persulfate for trigger off, and adopts N, N -methylene bisacrylamide to create proper crosslinking. The course of reaction is geniality, cost low, and product has no need of washing and saponification and so on aftertreatment process. The product can absorb deionized water 600g / g to 1200g / g, suck brine 50g / g to 100g / g. The water retentivity, thermostability and reusing quality of the product are better. It has extensive application prospects at aspect of waterholding material.

Owner:NORTHWEST A & F UNIV

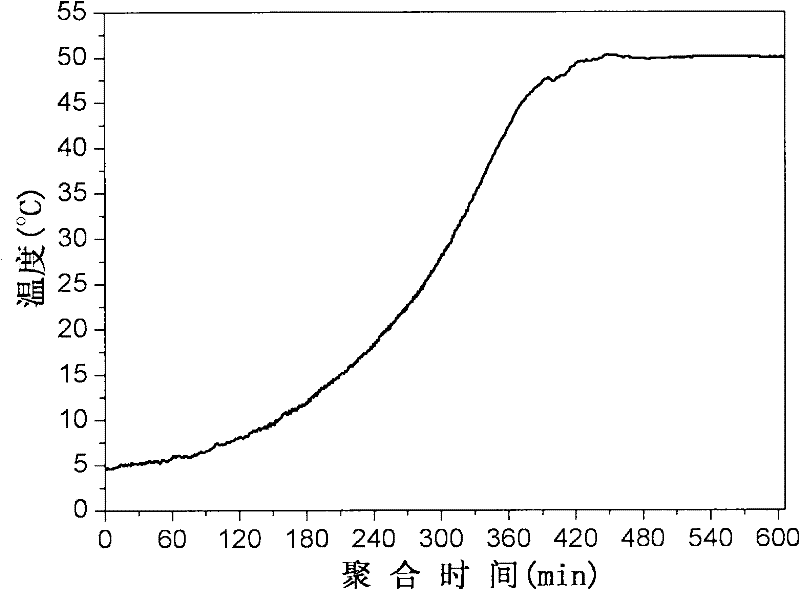

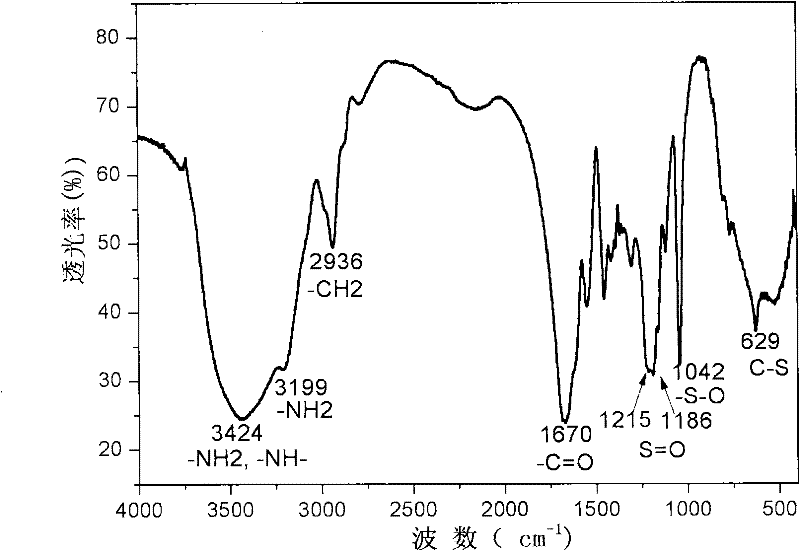

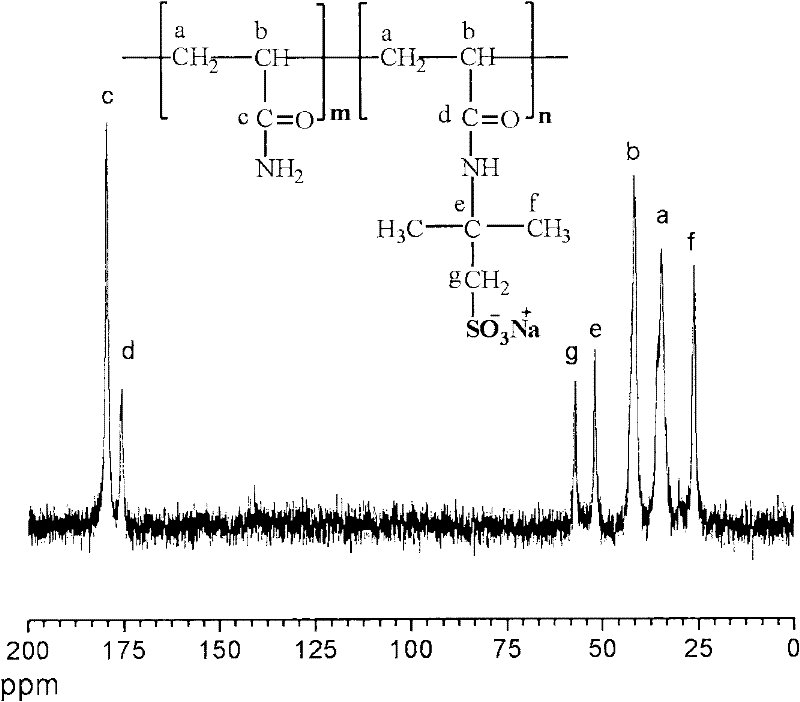

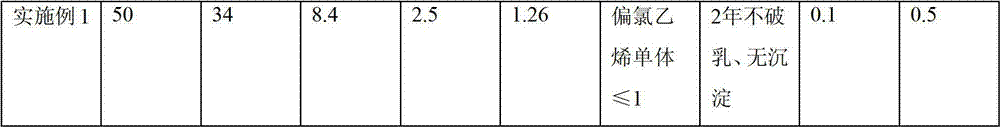

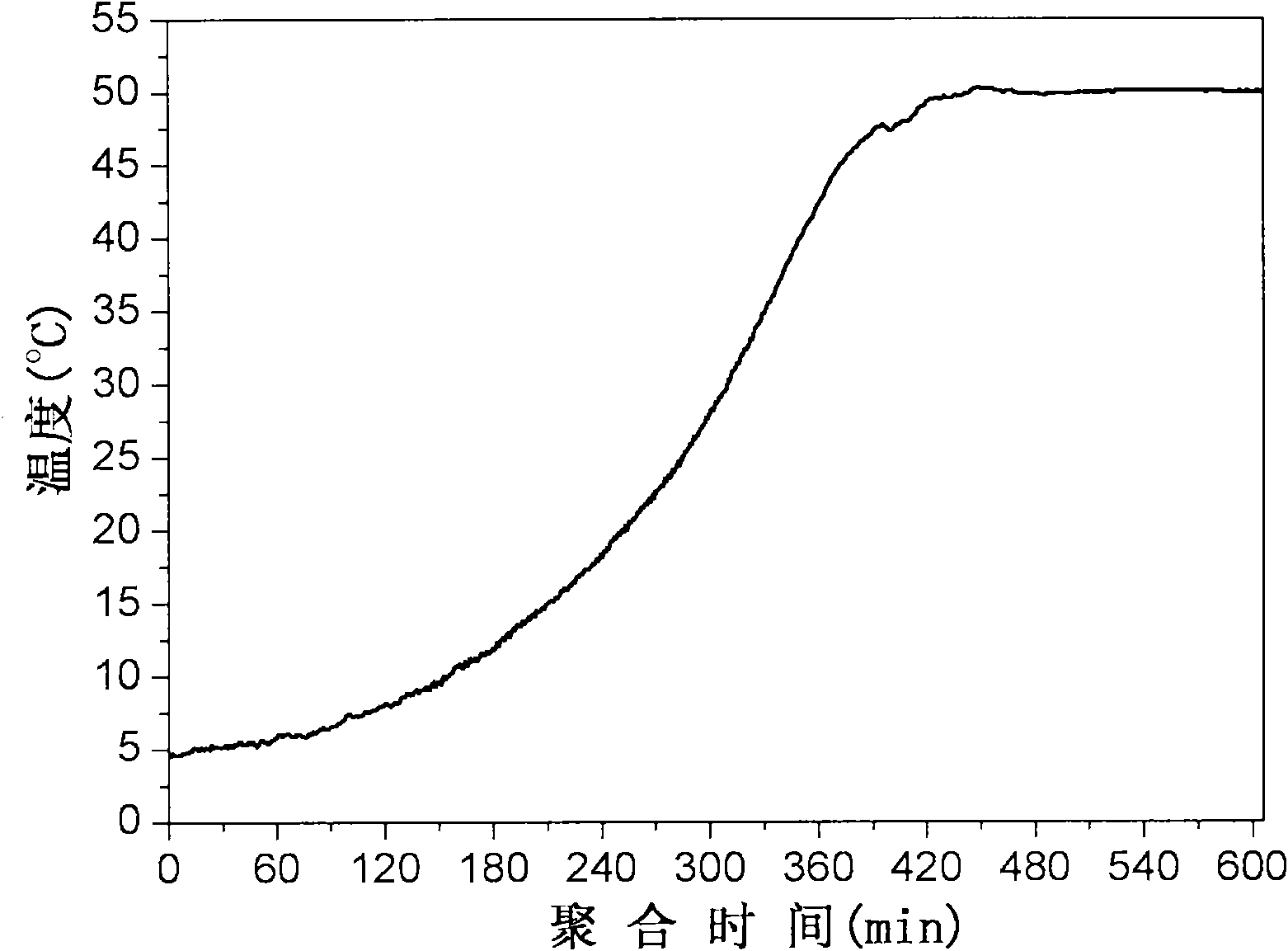

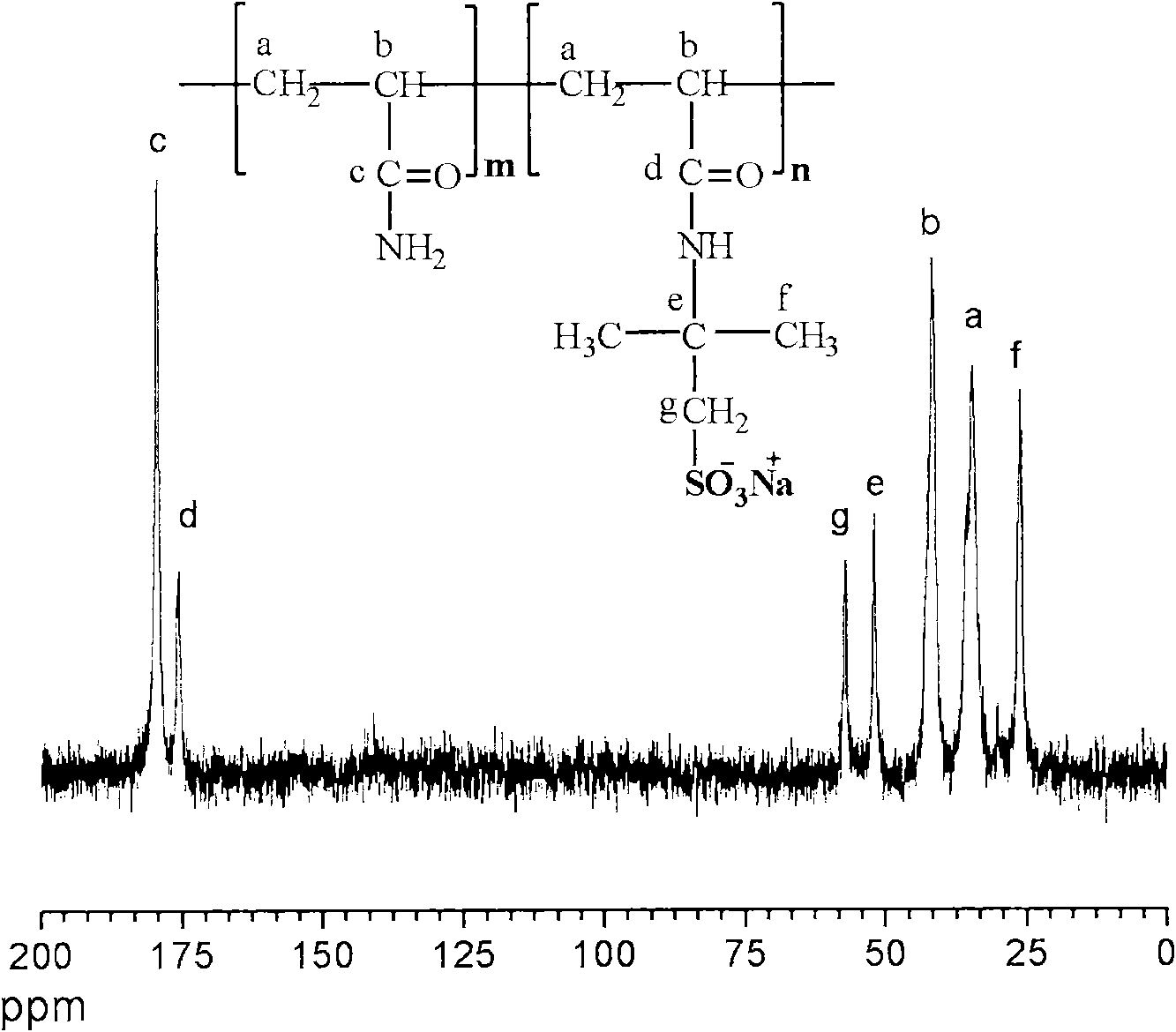

Preparation method of ultrahigh molecular weight sulfonic acid-type polyacrylamide

ActiveCN102453192AHigh molecular weightLow free monomer contentDrilling compositionSolubilityWater soluble

The invention relates to a preparation method of water-soluble polymer, and especially relates to a preparation method of ultrahigh molecular weight sulfonic acid-type polyacrylamide copolymer used for tertiary oil recovery oil displacement agents. The ultrahigh molecular weight heatproof salt-resistant sulfonic acid-type acrylamide copolymer prepared by the invention has a high molecular weight, good solubility and a low monomer residual quantity, and thus can be used for polymer oil displacement agents for high-temperature high-salt oil reservoirs. The invention is used in the petroleum exploitation field.

Owner:CHINA PETROLEUM & CHEM CORP +1

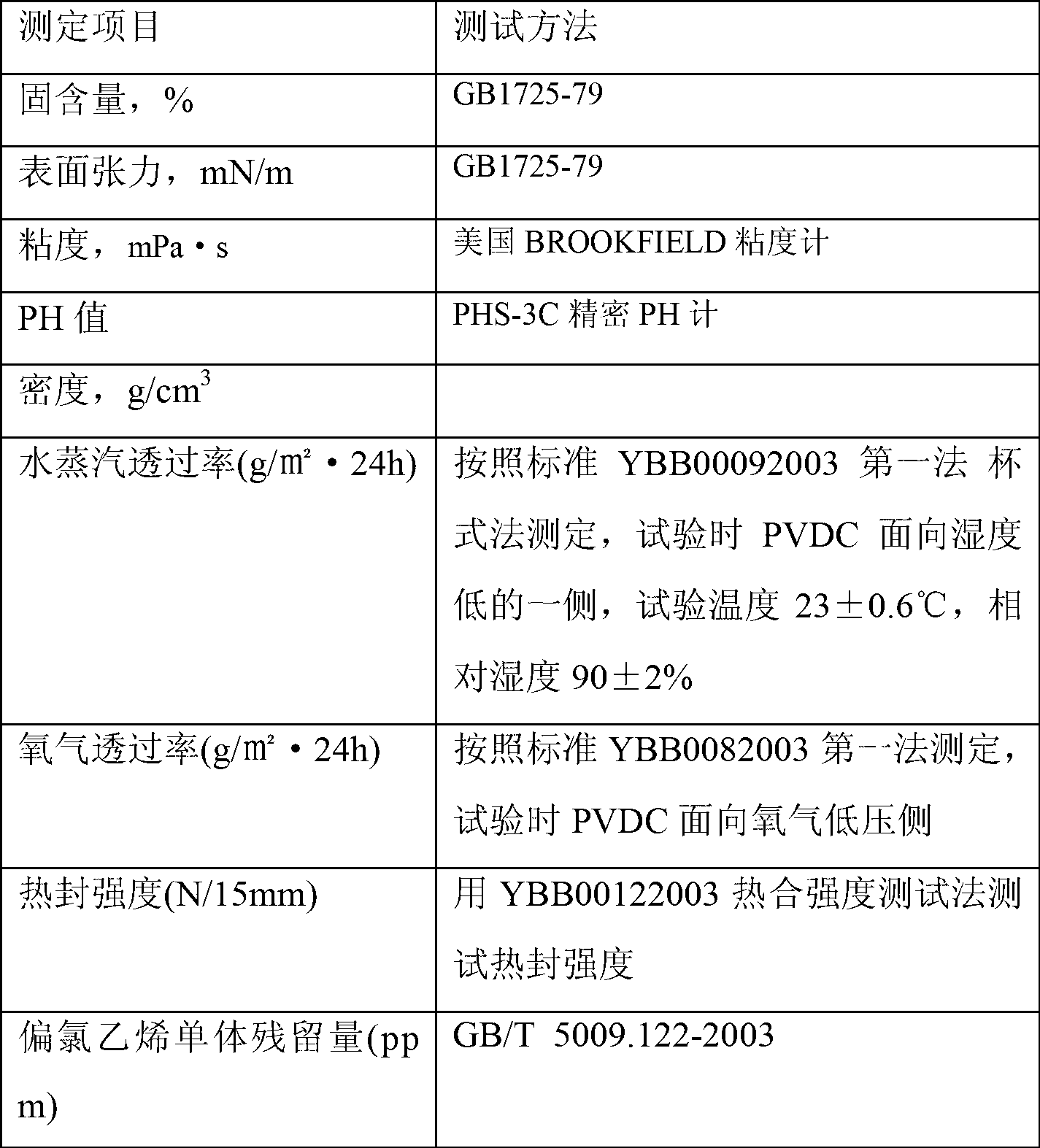

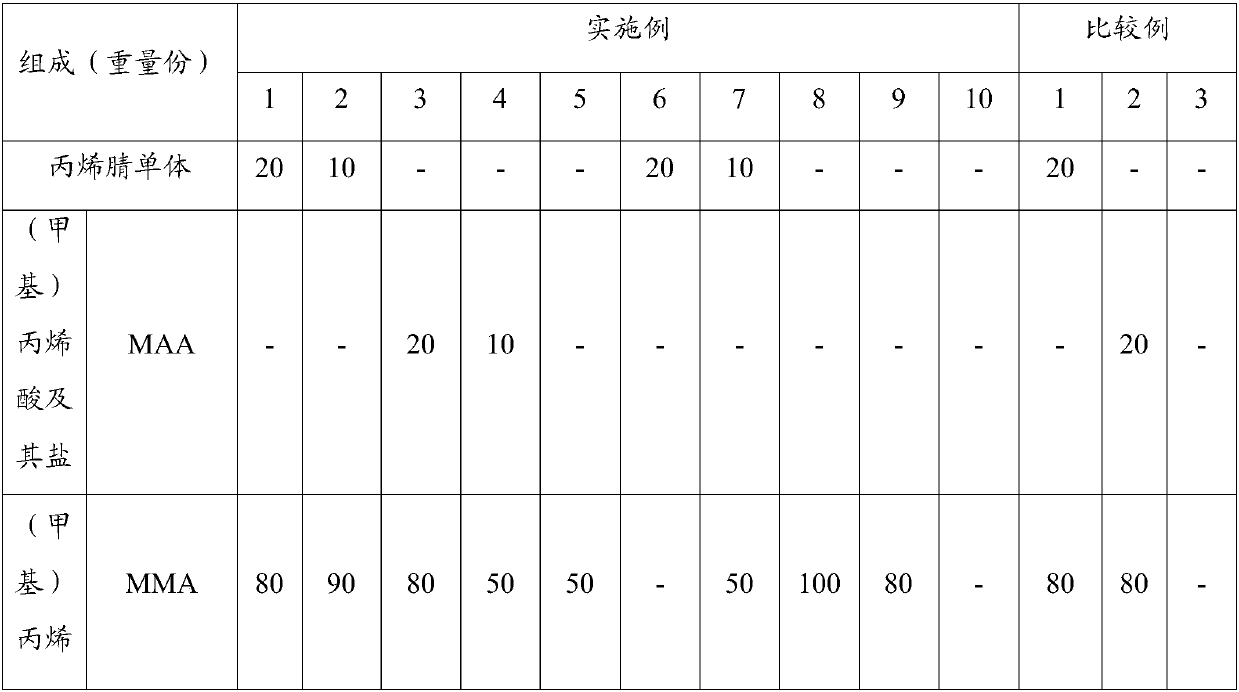

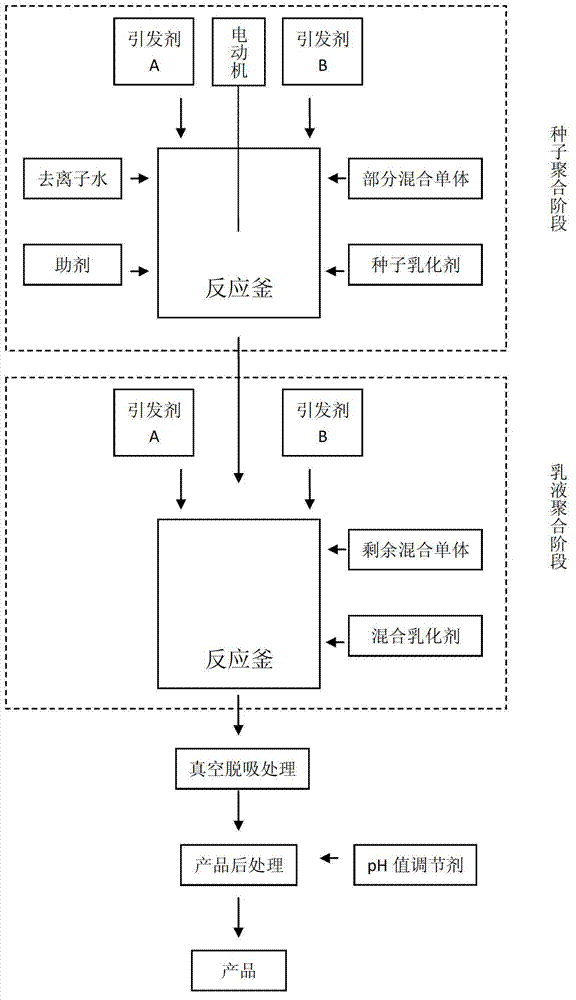

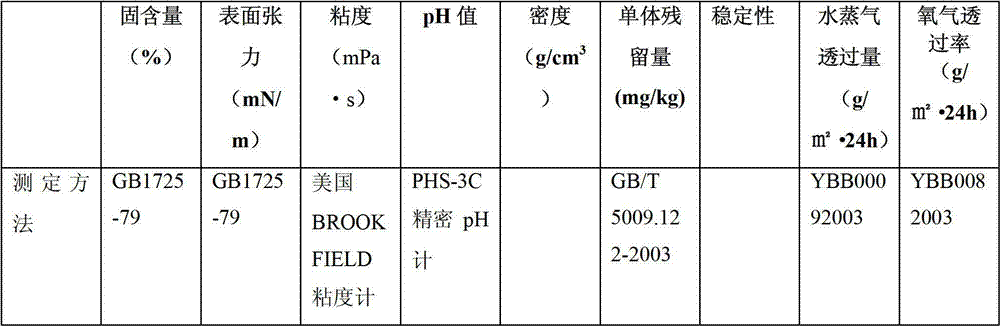

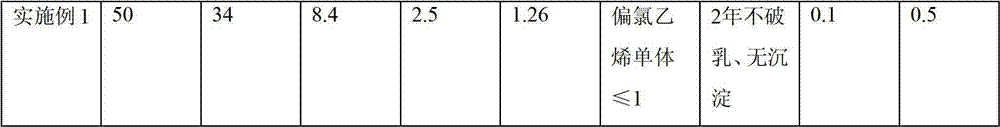

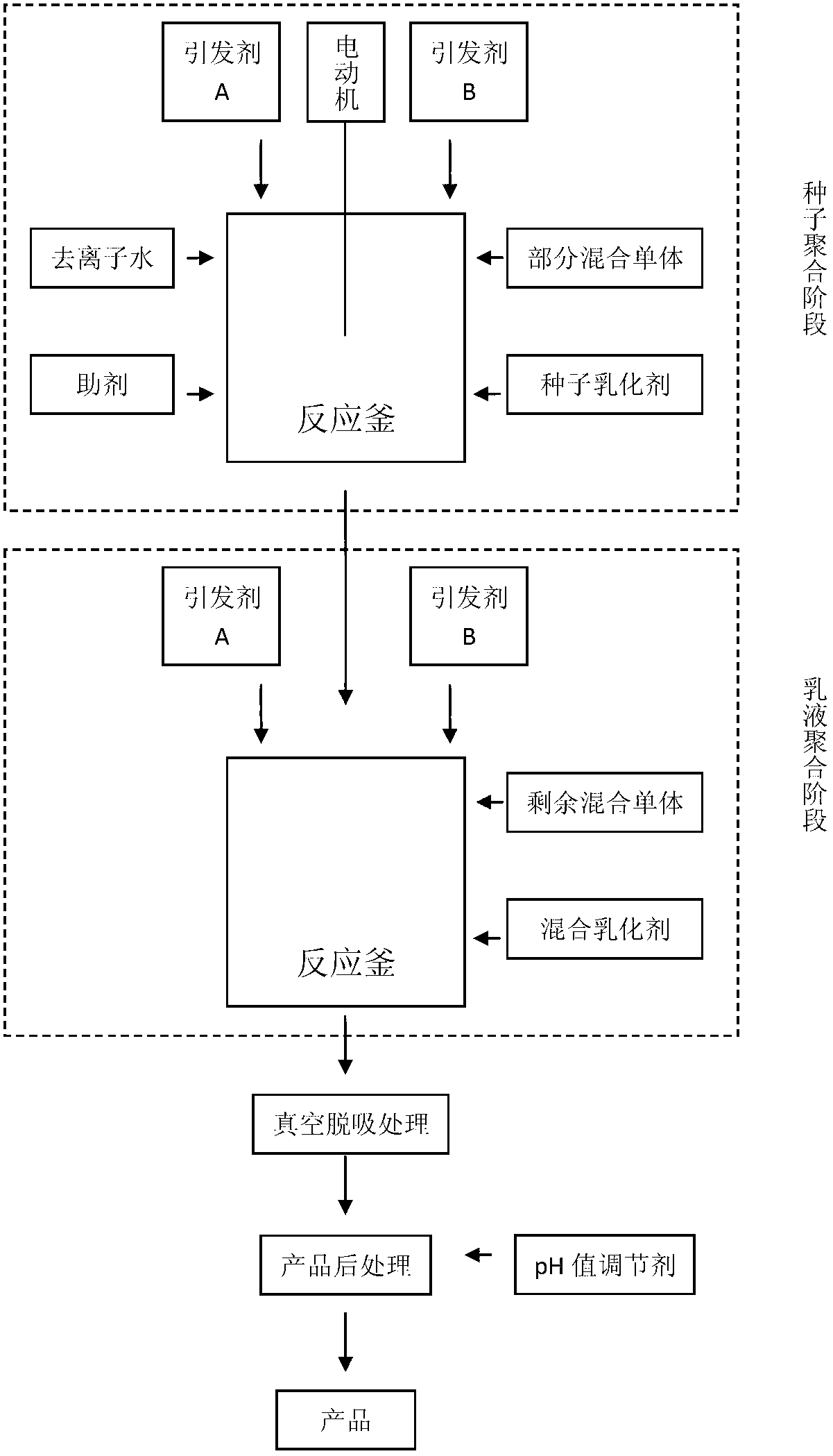

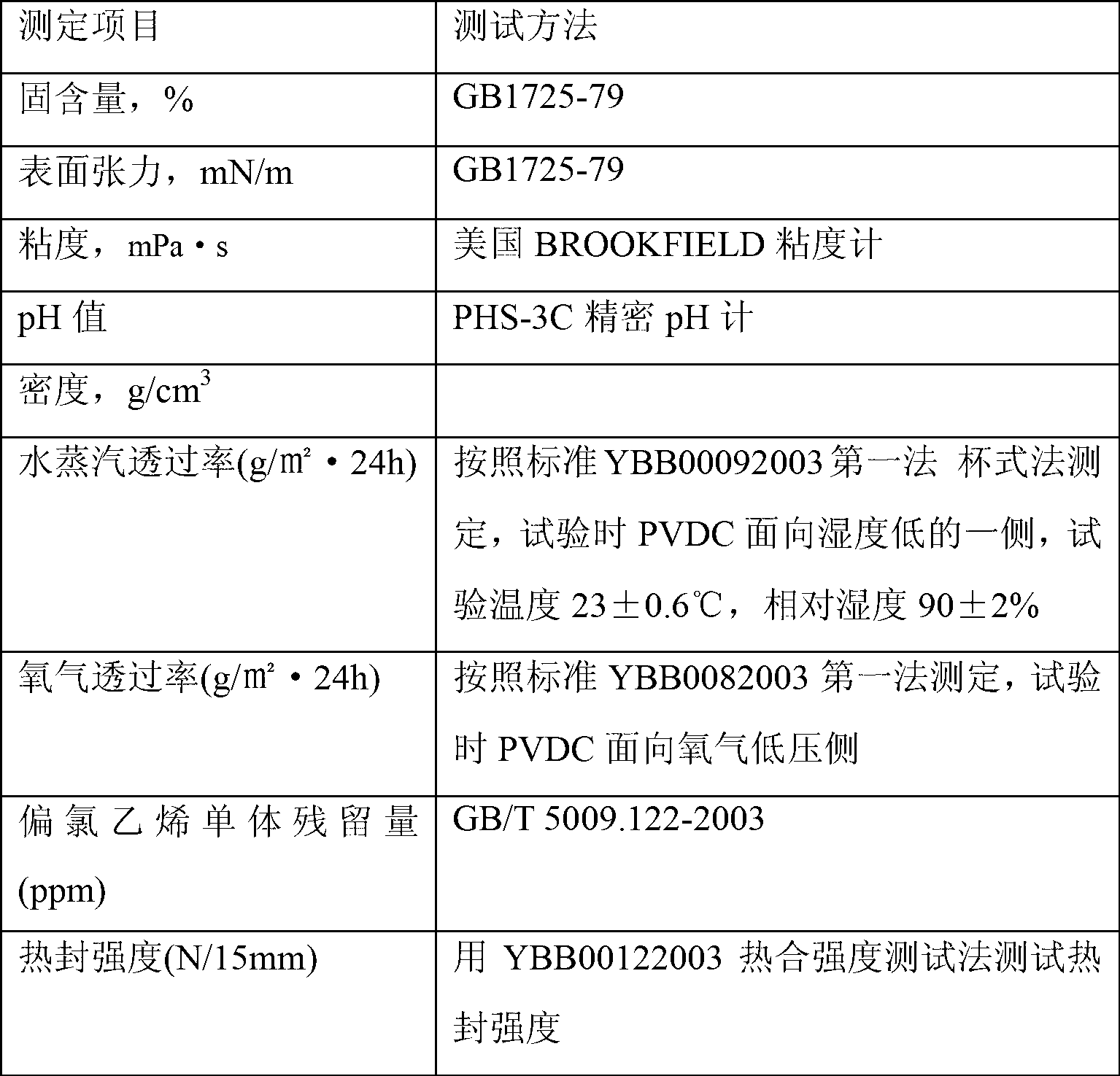

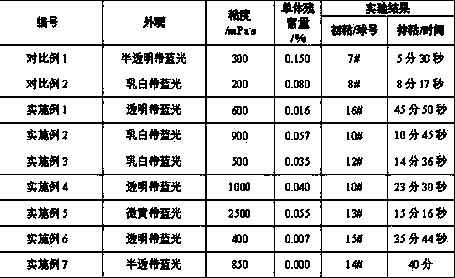

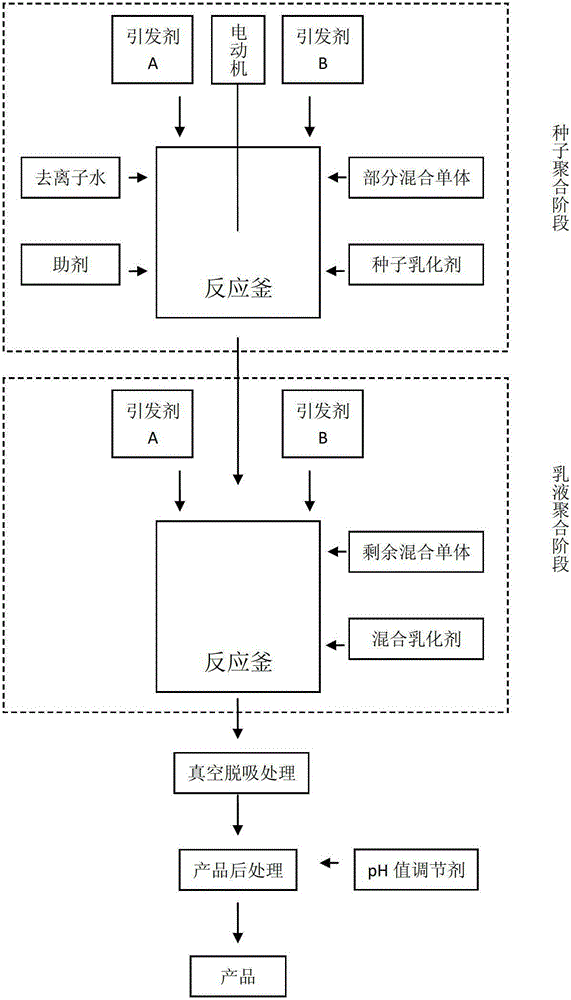

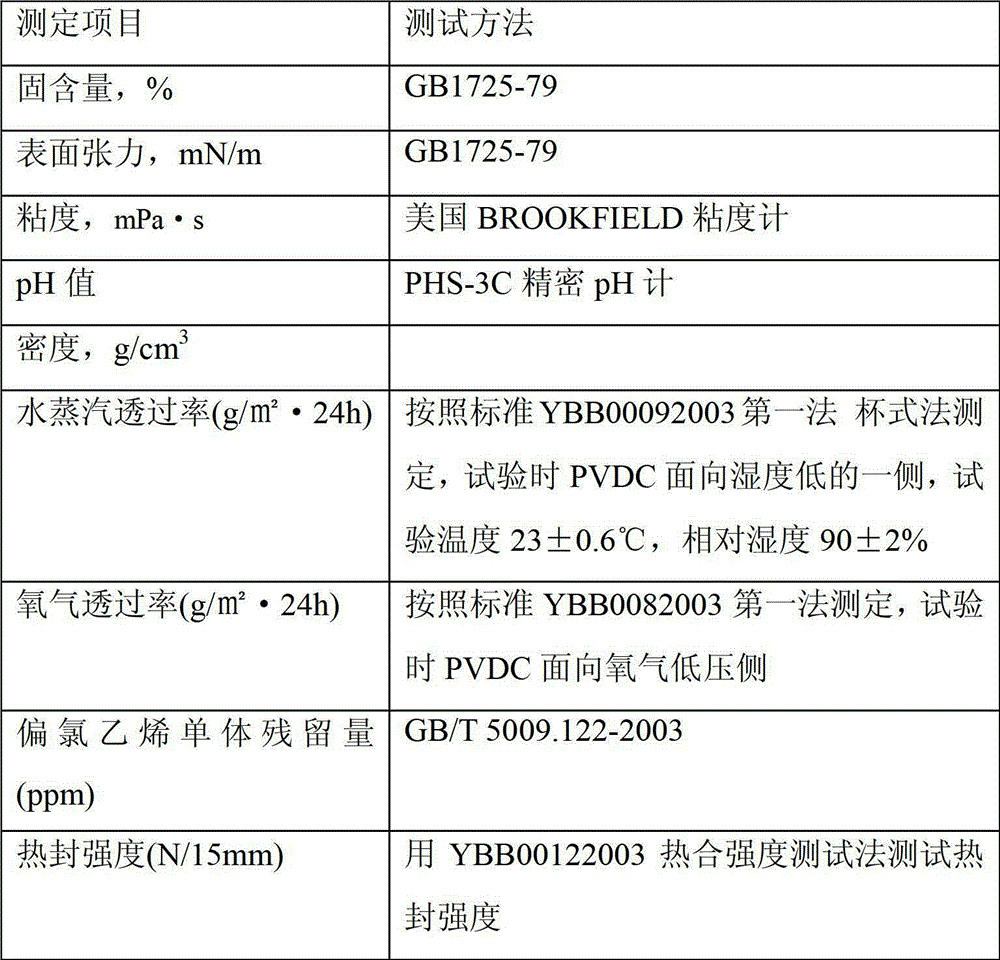

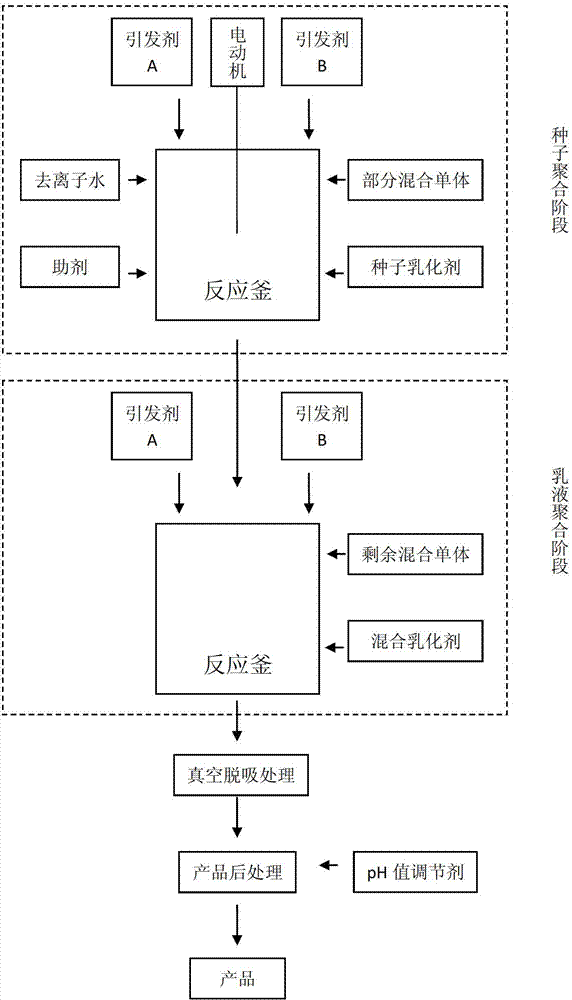

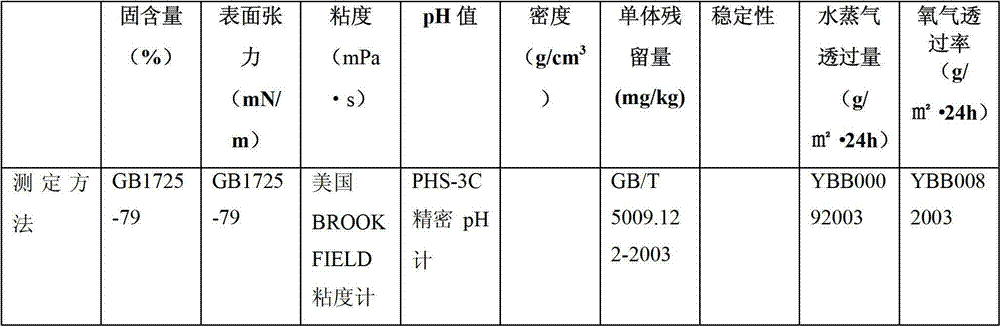

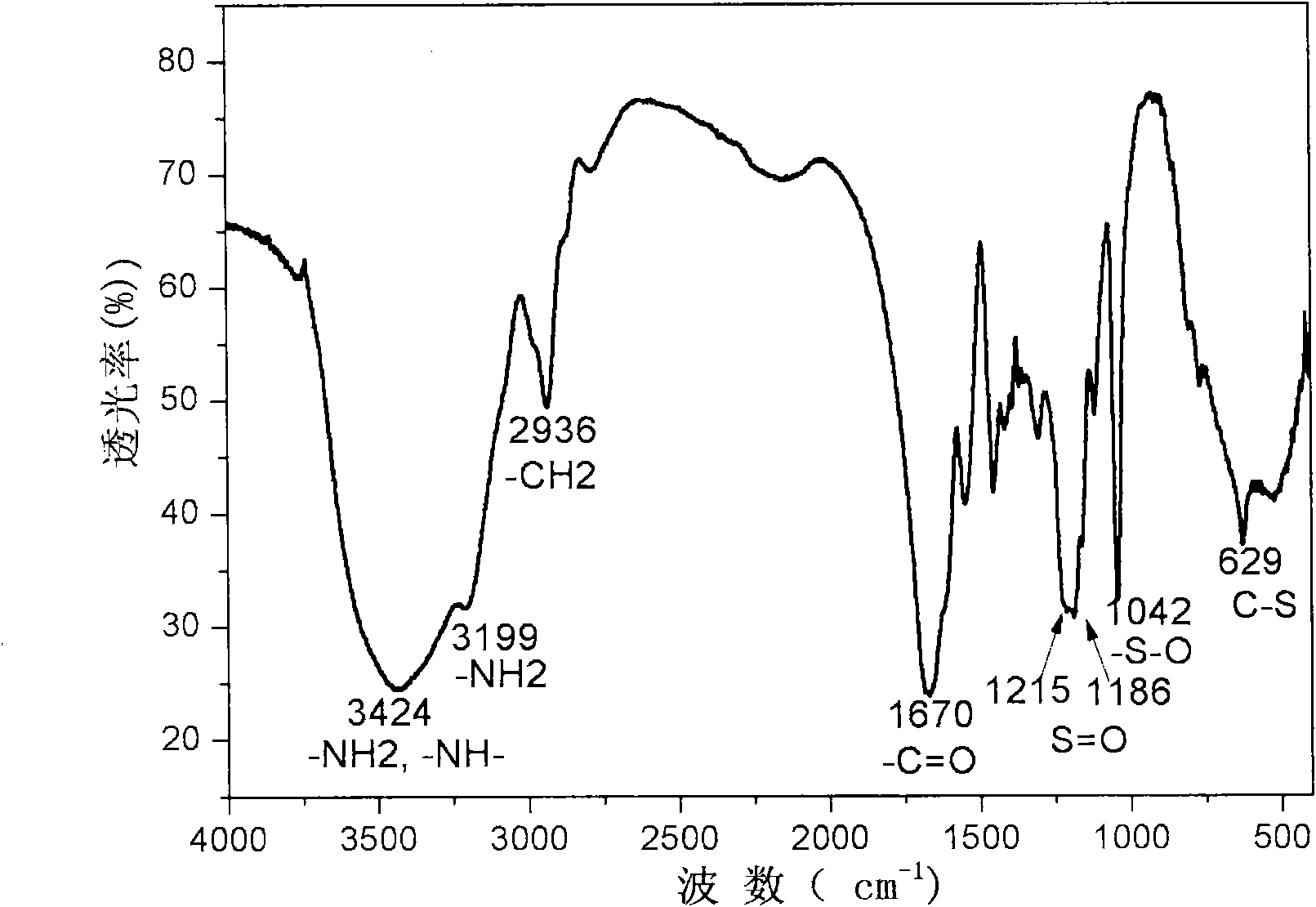

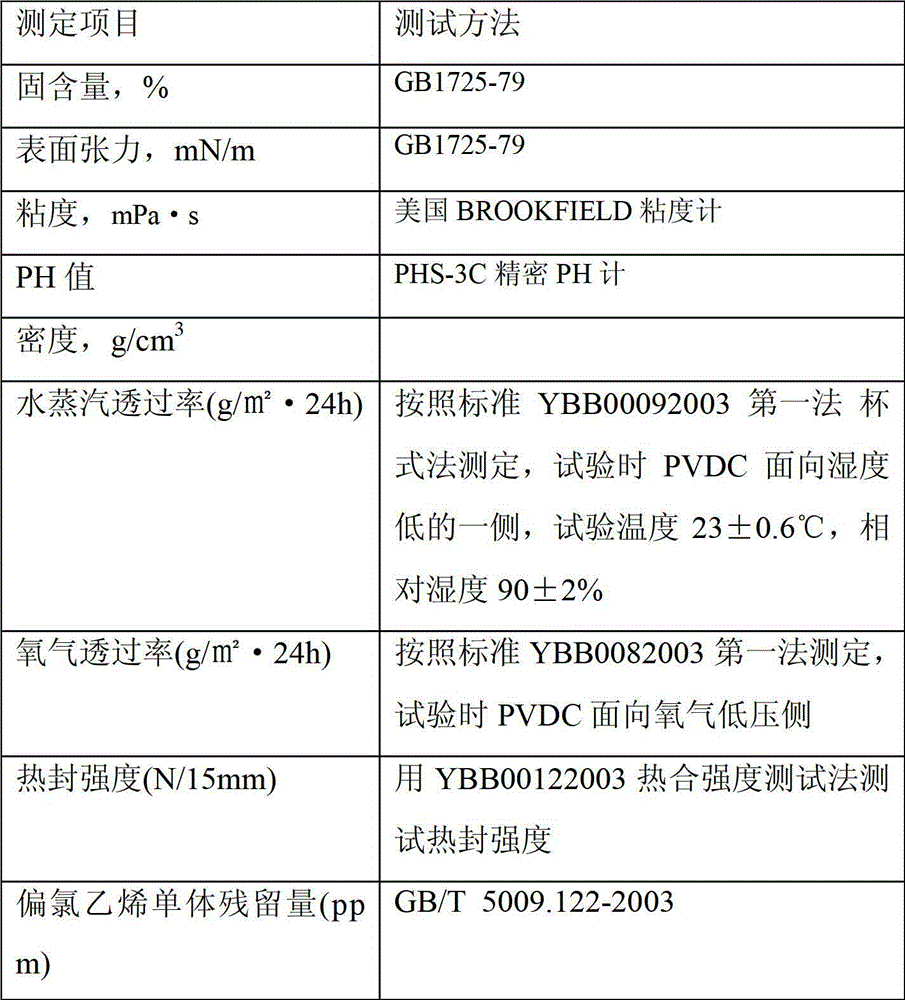

Polyvinyl dichloride (PVDC) latex special for kraft paper used for food packaging and preparation method thereof and application thereof

ActiveCN103059195AImprove stabilityLow monomer residuePaper coatingCoatingsOxygen permeabilityRelative humidity

The invention discloses a polyvinyl dichloride (PVDC) latex special for kraft paper used for food packaging and a preparation method thereof and application thereof. The kraft paper coated by the PVDC latex can be used for packaging of foods such as peanuts, melon seeds and walnuts. The PVDC latex is obtained by a mixed monomer, an auxiliary, an initiating agent, an emulsifying agent and a seeded emulsifying agent, wherein the mixed monomer contains a certain amount of vinylidene chloride, vinyl cyanide, butyl acrylate and acrylic acid, and the seeded emulsifying agent contains sodium dodecyl benzene sulfonate and a 2A-1 emulsifying agent. The prepared PVDC latex is good in stability and free of emulsification breaking and sediment after placed for 24 months under temperature of 30 DEG C and relative humidity (RH) of 70%. Monomer residual volume in the latex is lower. The kraft paper coated by the PVDC latex has the advantages of being environment-friendly, degradable, good in heat tightness, waterproof, damp proof and the like. When coating amount of the latex is 20g / m2, steam transit amount is less than or equal to 3g / m2.24h and oxygen permeability is less than or equal to 6g / m2.24h, monomer residual amount of the vinylidene chloride is less than or equal to 1ppm or not detected, and heating sealing intensity can reach 3N / 15mm.

Owner:HAINAN BNK WATER BASED NEW MATERIAL CO LTD

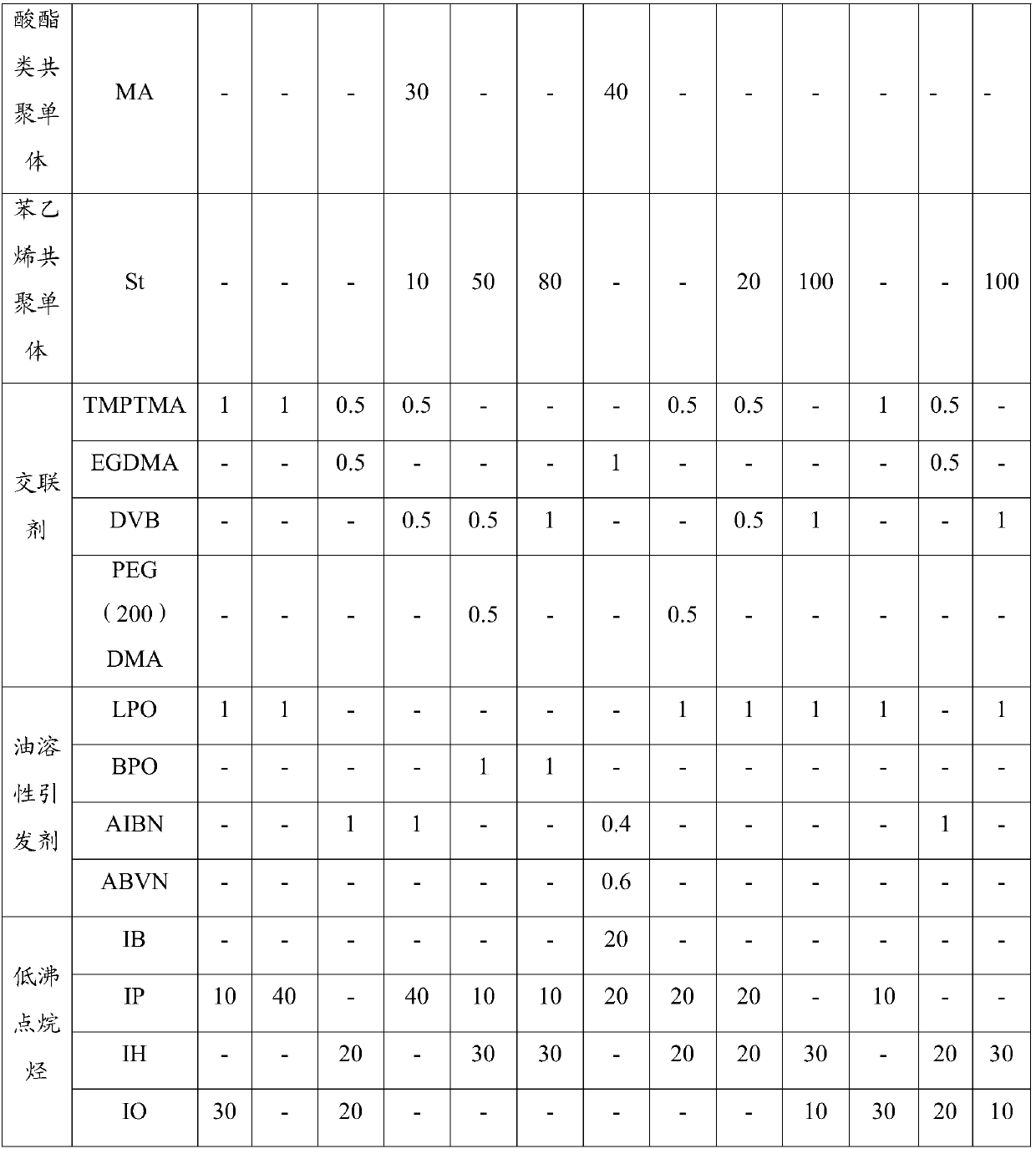

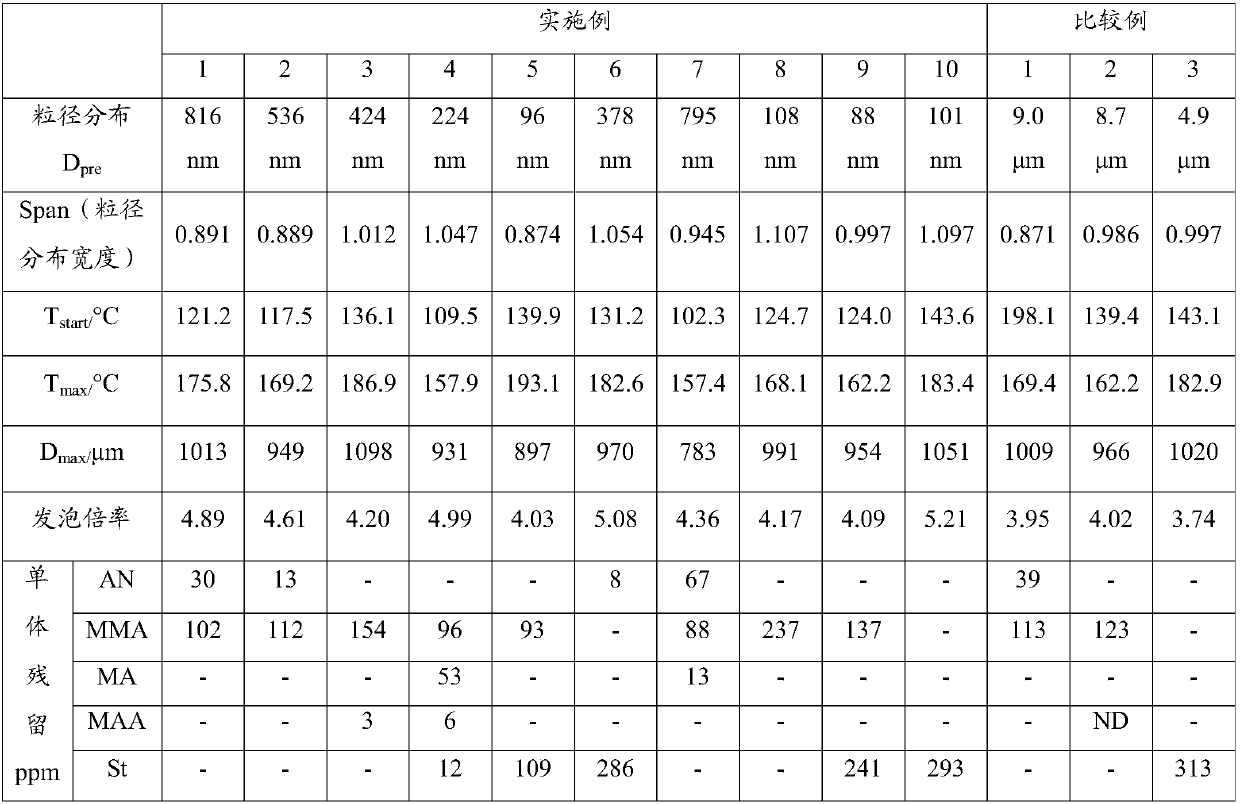

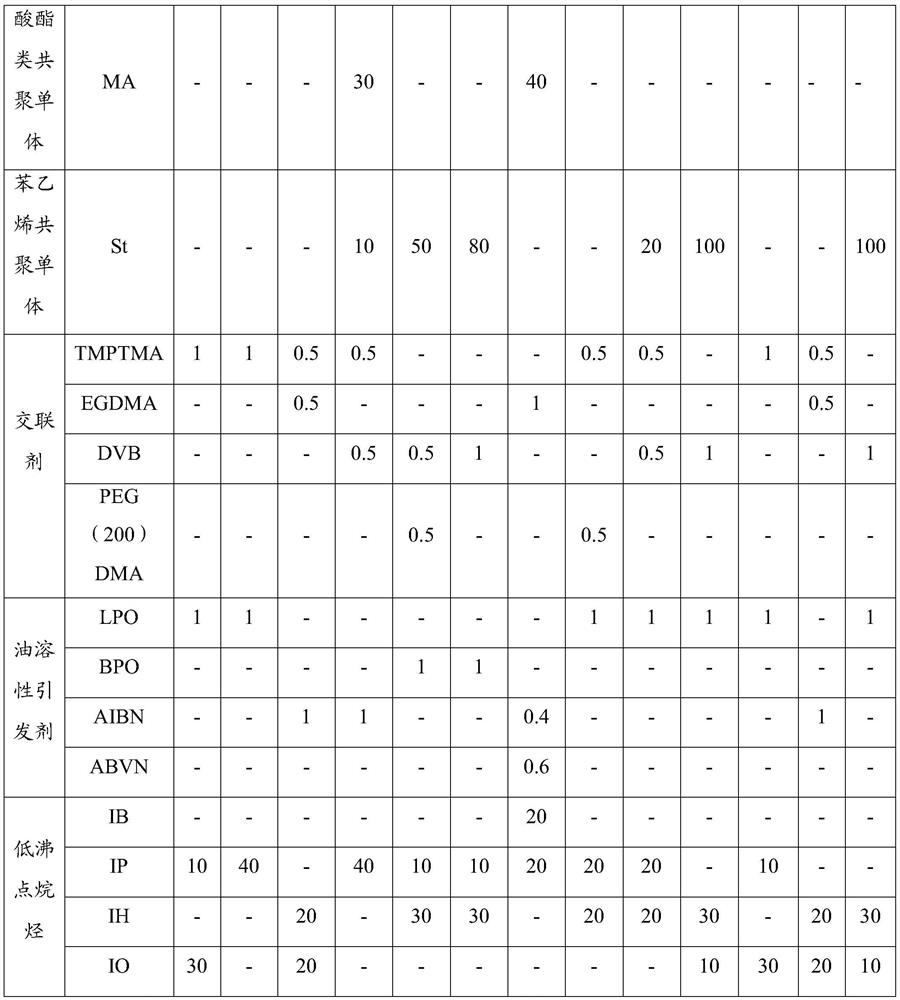

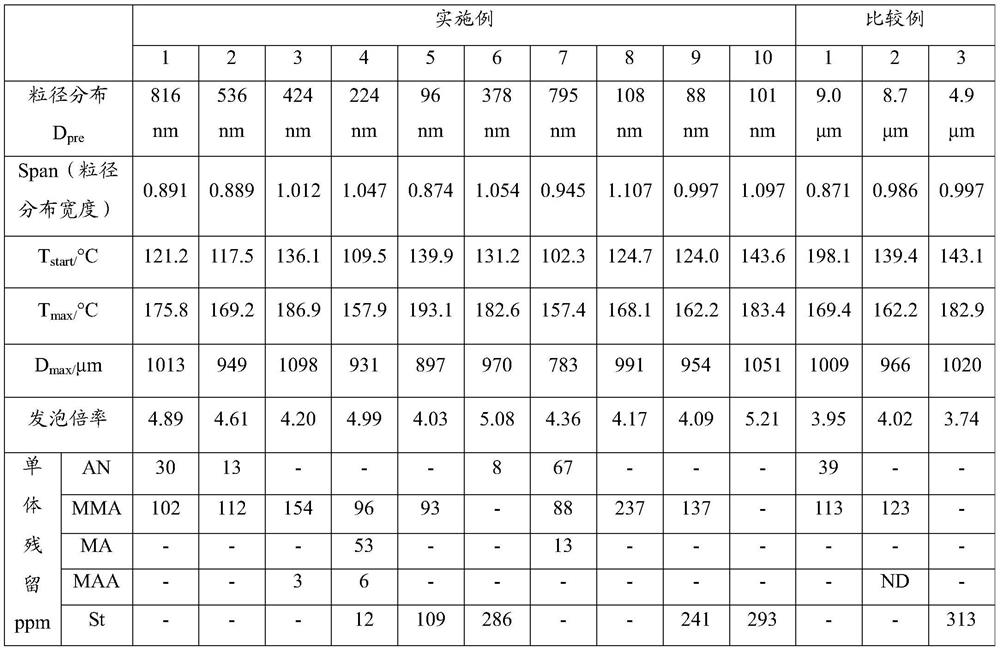

Superfine environment-friendly thermal expansion microcapsule and preparation method thereof

ActiveCN108097182ASimple and fast operationSimple preparation processMicroballoon preparationMicrocapsule preparationPolymer scienceEmulsion polymerization

The invention discloses a superfine environment-friendly thermal expansion microcapsule which is prepared from a suspension dispersing liquid of an oil phase composition and a water phase compositionby a microwave radiation emulsion polymerization method. A particle size of the superfine environment-friendly thermal expansion microcapsule is of a submicron level; and the microcapsule is high in foaming ratio, environment-friendly, nontoxic and applicable to the fields of textile, papermaking, printing ink, engineering plastics and the like. The invention further discloses a preparation methodof the superfine environment-friendly thermal expansion microcapsule. The thermal expansion microcapsule is prepared on a basis of a microwave radiation radical emulsion polymerization technology; and the preparation method is easy and simple to operate, simple in preparation technology and high in production efficiency.

Owner:三明市锦浪新材料科技有限公司

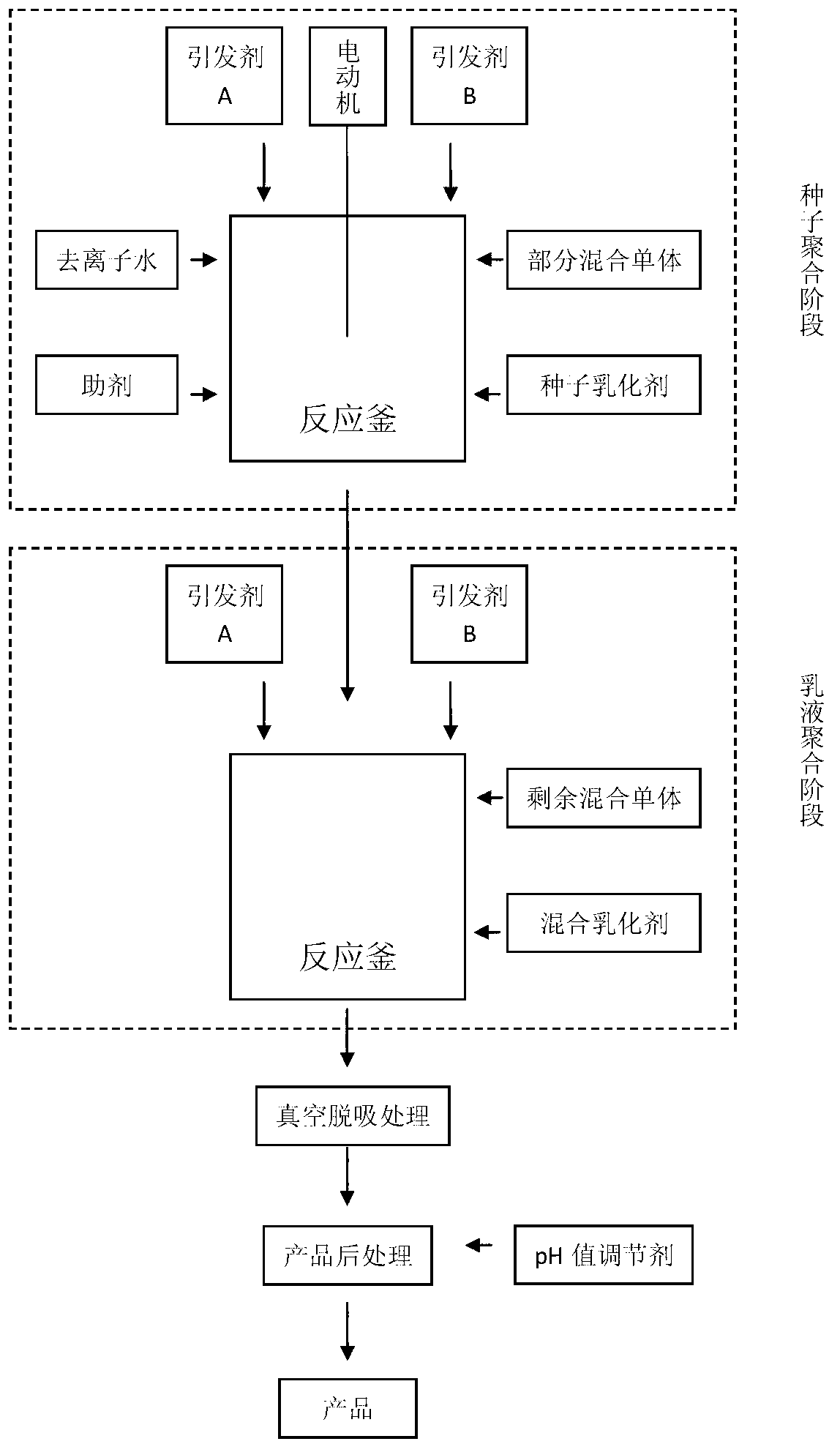

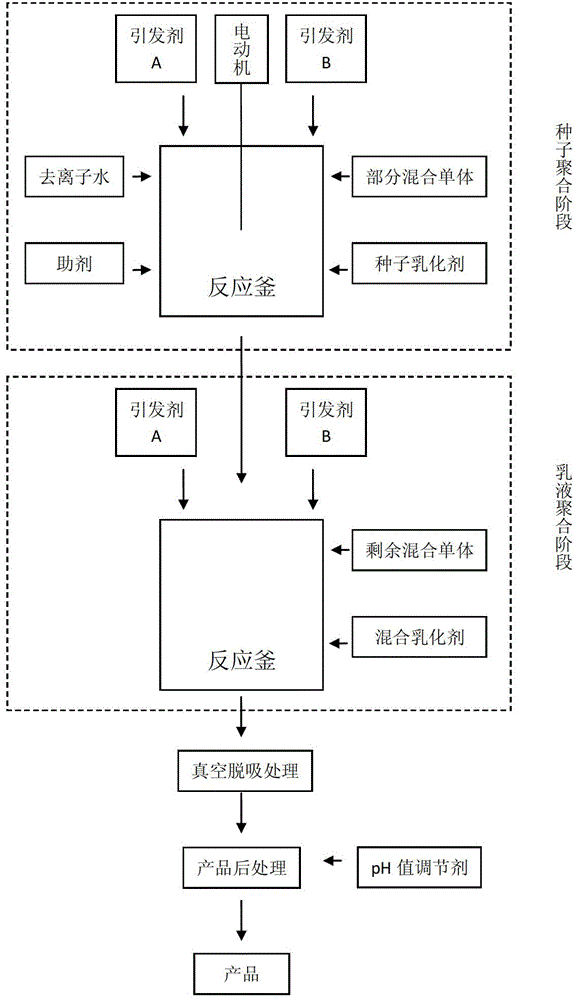

Paper coating water-based emulsion and preparation method and applications thereof

The invention discloses a paper coating water-based emulsion and a preparation method and applications thereof. Aiming at the problem that the barrier property of the current paper coating emulsion is not good, the invention provides the paper coating water-based emulsion. The method comprises the following steps: using a certain amount of vinylidene chloride, acrylonitrile, methacrylate and methacrylic acid as a mixed monomer, selecting a special seed emulsifier and a mixed emulsifier, adopting seed emulsion polymerization, and finally obtaining the paper coating water-based emulsion. The paper coating water-based emulsion has good stability, environmental protection and good barrier property. A vacuum desorption post-processing method is adopted in the later period of emulsion polymerization, so that the monomer residual quantity of the obtained water-based emulsion is low. The prepared coated paper has no foreign smell, cannot pollute food or drugs, and is more beneficial to applications to the package field of food, drugs and the like.

Owner:HAINAN BNK WATER BASED NEW MATERIAL CO LTD

Polyvinyl dichloride (PVDC) coating latex special for cigarette films and preparation method and application thereof

ActiveCN103059193AImprove stabilityLow monomer residueFlexible coversWrappersMicrocrystalline waxPolymer science

The invention discloses polyvinyl dichloride (PVDC) coating latex special for cigarette films and a preparation method and application of the PVDC coating latex special for the cigarette films. The PVDC latex is prepared from a certain amount of mixed monomers of vinylidene chloride, methyl acrylate and itaconic acid, a ptomotor, an initiator, an emulgator and a seed emulgator, and the preparation method is seed emulsion polymerization. According to the preparation method, microcrystalline wax capable of having a defoaming effect is added to enable the residual quantity of monomers in the latex is smaller. The cigarette films made of the latex has heat sealing performance and a high barrier property, and can maintain the scent of cigarettes and enable the cigarettes to not go bad and not be affected with damp. The heat sealing strength of the cigarette films is equal to or larger than 3N / 15mm, the coating weight is 3g / m<2>, the permeation amount of water vapor is equal to or smaller than 6g / m<2>*24h, the permeation volume of oxygen is equal to or smaller than 36g / m<2>*24h, and the residual quantity of vinylidene chloride monomers is equal to or smaller than 1mg / kg or is not detected.

Owner:海南聚能创新服务有限公司

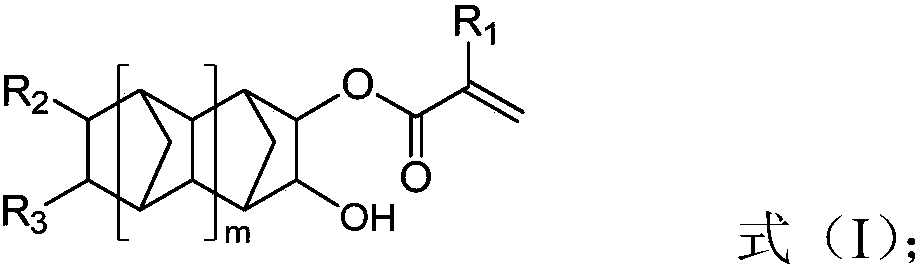

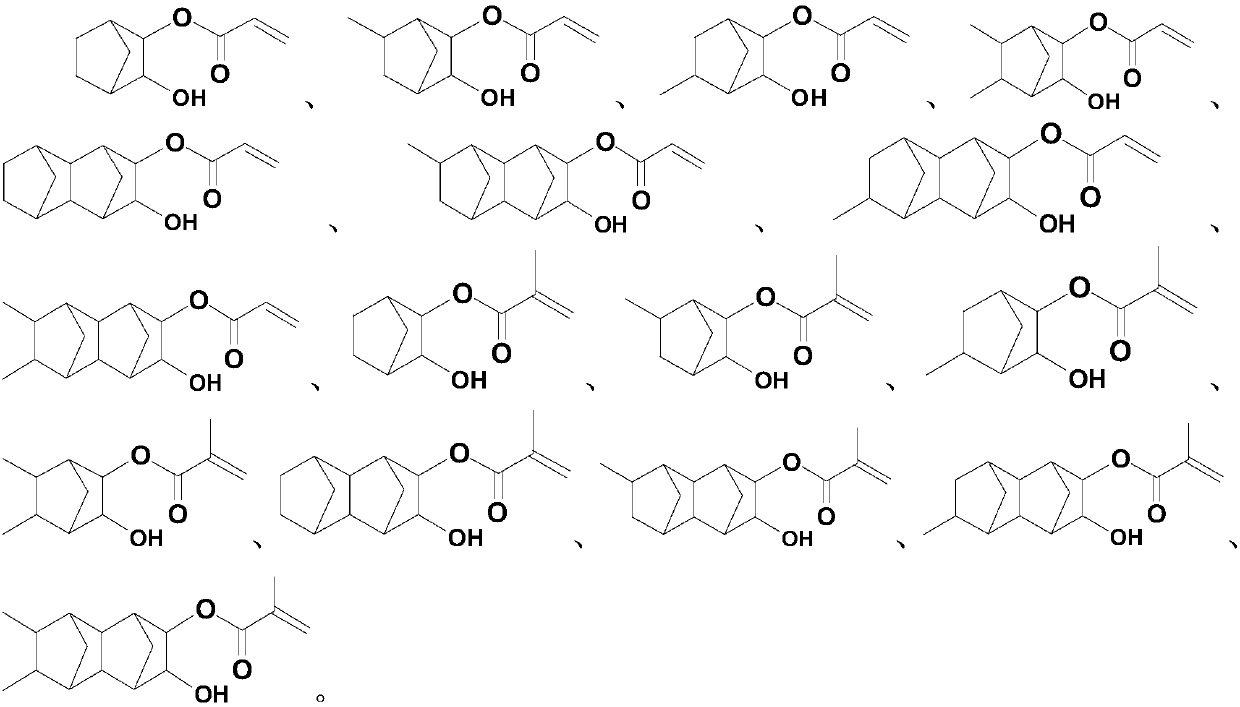

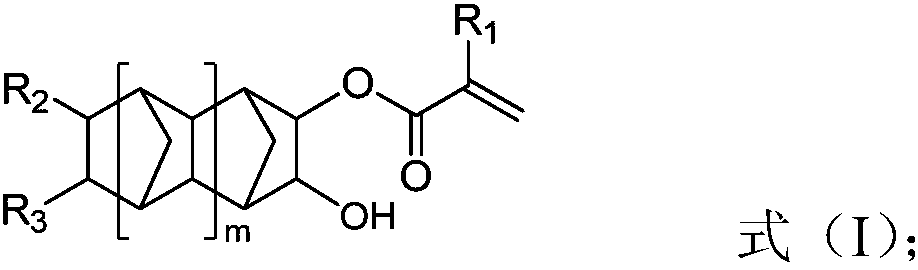

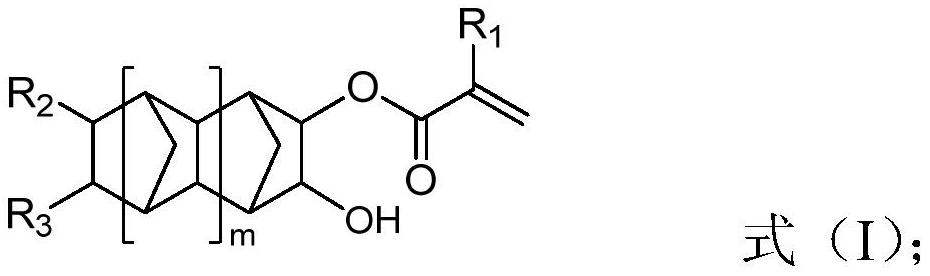

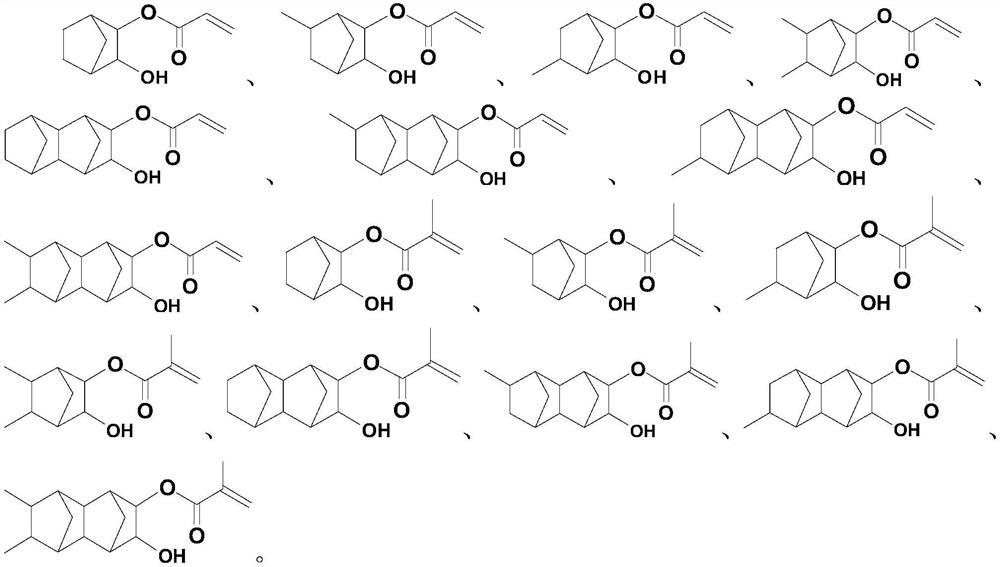

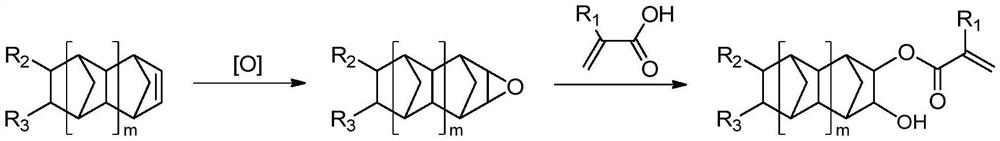

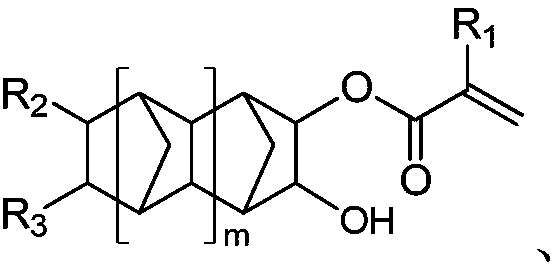

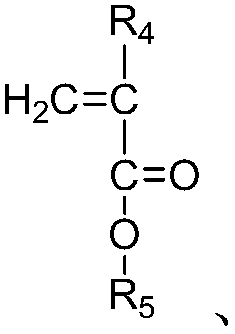

Acrylate compound for coatings, preparation method of acrylate compound, and coating comprising acrylate compound and application of coating

ActiveCN109956867AGood weather resistanceHigh weather resistanceAntifouling/underwater paintsOrganic compound preparationWater basedSolubility

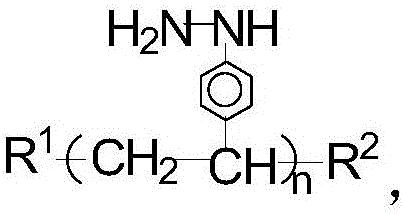

The invention relates to an acrylate compound for coatings. The compound has a structure represented by a formula (I). The acrylate compound for coatings has lipophilic polycyclic aliphatic groups andhydrophilic hydroxyl groups at a same time and has high polymerization reaction activity. When the acrylate compound is used for a solvent-type acrylic coating, the coating layer shows relatively excellent weather resistance and wear resistance, high glossiness and fullness and the like. When the acrylate compound is used for a water-based acrylic coating, the hydrophilic hydroxyl groups and thelipophilic alicyclic groups of the compound show good solubility in an emulsion system, the polymerization activity is high, the monomer residue amount is low, and the coating after film forming showsexcellent weather resistance, water resistance, oil resistance, impact resistance, high glossiness and the like. The preparation method has the advantages that the technological process is simple, conditions are easy to control, side reactions are few, the raw material conversion rate of reactions is high, and purity of products is high.

Owner:WUXI ACRYL TECH

Manufacturing method of polyacrylic acid-series water-absorbent resin

InactiveCN108192013AIncrease absorption rateEfficient and stable preparationCross-linkPolymer science

The invention discloses a manufacturing method of polyacrylic acid-series water-absorbent resin. The manufacturing method comprises the following steps: obtaining an aqueous solution which contains unsaturated acrylic monomers and a cross-linking agent; mixing foaming agent particles and / or a foaming agent solution, unsaturated acrylic monomers and a cross-linking agent aqueous solution; polymerizing a monomer water solution to form a porous gel-like cross-linked polymer; crushing the porous gel-like cross-linked polymer into gel particles through shearing and / or extruding acting force in a polymerizing process or after polymerizing, wherein the number average particle size of the gel particles is 0.5 to 20 mm, the weight percentage of the gel particles with the particle size of greater than 2 mm is 10 to 100 percent, and the porous structure destruction rate of the gel particles is 0 to 70 percent after the porous gel-like cross-linked polymer is subjected to the shearing and / or extruding acting force; further drying, fining and screening the manufactured gel particles. The liquid absorption characteristic of the water-absorbent resin is not influenced; the water-absorbent resin with high-speed liquid absorption rate and low monomer residue amount can be produced and obtained highly effectively.

Owner:宜兴丹森科技有限公司

Preparation method of salt-resistant acrylic superabsorbent resin

The invention discloses a preparation method of salt-resistant acrylic superabsorbent resin. The salt-resistant acrylic superabsorbent resin is prepared from the following raw materials in parts by weight: deionized water 100 parts, sodium hydroxide 33 parts, acrylic acid 63 parts, acrylamide 27 parts, ethylene glycol diglycidyl ether 5 parts, potassium persulfate 0.2 part, and ascorbic acid 0.05 part. The preparation process includes the following steps: (1) dissolving sodium hydroxide in deionized water, adding to acrylic acid for neutralizing to a neutralization degree of 75-85%, adding acrylamide, and stirring to dissolve; (2) adding ethylene glycol diglycidyl ether as a crosslinking agent, to the neutralization liquid, introducing nitrogen gas, adding potassium persulfate and ascorbic acid solutions in turn to initiate a polymerization reaction, keeping the temperature for 60-120min, carrying out extrusion granulation of the polymer, drying at 130-160 DEG C, pulverizing, and sieving to obtain granular resin; and (3) mixing the granular resin with aluminum sulfate powder, silica, ascorbic acid, sodium bisulfite, hydroquinone solution, while spraying ethanol, methanol and the self-made crosslinking agent for rapid surface treatment, drying at 140-160 DEG C, and sieving to obtain the superabsorbent resin product which is suitable for sanitary napkins, diapers and other health supplies materials.

Owner:HUBEI QIANFENG NEW MATERIAL TECH

Preparation method of water-in-water type cationic polyacrylamide emulsion

InactiveCN103601848AImprove stabilityOperational securityWater/sewage treatment by flocculation/precipitationSynthesis methodsDouble bond

The invention relates to a preparation method of a polyacrylamide emulsion. The method is characterized by comprising the following steps: taking dimethyl diallyl ammonia chloride (DMDAAC) as the cationic monomer, taking ammonium sulfate and PDMDAAC respectively as the dispersion medium and the dispersion agent for CPAM dispersion polymerization in a saline water medium, and making acrylamide to carry out free radical copolymerization reactions with quaternary ammonium salt organic compounds so as to generate the water-in-water type cationic polyacrylamide emulsion. The appearance of the emulsion is in a milk white color, and the particle size is smaller than 1 [mu]m, which is in the range of emulsion particle size value. The preparation method adopts a novel polymer synthesis method, and overcomes the shortages existing in the prior art that a large amount of organic solvent and surfactant used in the synthesis process generates secondary pollutions to the environment and the product cost is greatly increased. The emulsion can be widely applied to the fields of oil field, industrial or city sewage processing, sludge dehydration, paper making, and personal nursing and cosmetic.

Owner:SHANGHAI WSHINE CHEM

Polyolefin packaging film used for solar cell modules

InactiveCN109251689AExtends free radical lifeLow monomer residueNon-macromolecular adhesive additivesFilm/foil adhesives without carriersOxideSolar cell

The invention belongs to the technical field of solar energy packaging material, and especially discloses a polyolefin packaging film used for solar cell modules. The polyolefin packaging film used for solar cell modules comprises, by mass, 91 to 95 parts of modified polyolefin, 0.5 to 4.5 parts of a crosslinking agent (a peroxide cross-linking agent and a tackifier), 0.8 to 2.8 parts of a silanecoupling agent, 0.12 to 0.36 part of an anti-oxidant, 0.12 to 0.25 part of an ultraviolet light absorbent, 0.2 to 0.8 part of a light stabilizing agent, 0.02 to 0.08 part of a dispersant, and 0.01 to0.03 part of an initiator. According to a preparation method, the anti-oxidant, the ultraviolet light absorbent, and the light stabilizing agent are added, so that excess heat oxidation degradation yellowing of an obtained composition in blending extrusion process are avoided, packaging film yellowing aging is prevented effectively from packaging film production process, the aging yellowing resistance of packaging film under solar light radiation in using process is improved, packaging film anti-aging time is prolonged, and the influences on photovoltaic assembly cell output power is reduce.

Owner:CHANGZHOU SVECK PHOTOVOLTAIC NEW MATERIAL

Preparation method of polyolefin packaging film for solar cell module

InactiveCN109206653AExtends free radical lifeLow monomer residueFinal product manufacturePhotovoltaic energy generationPolyolefinElectrical battery

The invention belongs to the technical field of solar packaging materials, in particular to a preparation method of a polyolefin packaging film for a solar cell module. the preparation method comprises the following steps: (1) adding raw materials into a stirring device, uniformly mixing, then adding into a single-screw extruder to carry out reaction extrusion, controlling the extrusion temperature of the screw extruder to be 80-100 DEG c and the screw rotating speed of 20-30 rpm, then extruding, casting and cooling to form a film; and (2) carrying out radiation treatment on the surface of oneside of the prepared packaging film in the step (1), and finally cutting and winding to obtain the polyolefin packaging film for the solar cell module; an anti-oxidant, an ultraviolet light absorbentand a light stabilizer are added to prevent the composition from being subjected to yellowing caused by transition thermal oxidative degradation in the blending extrusion process, so that yellowing and aging of the packaging film can be effectively prevented at the beginning of production of the packaging film, the aging and yellowing resistance of the packaging film after being subjected to solar radiation in the using process can be also improved.

Owner:CHANGZHOU SVECK PHOTOVOLTAIC NEW MATERIAL

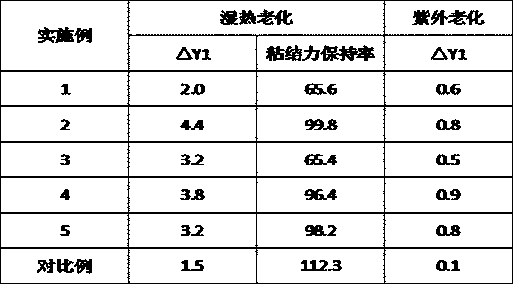

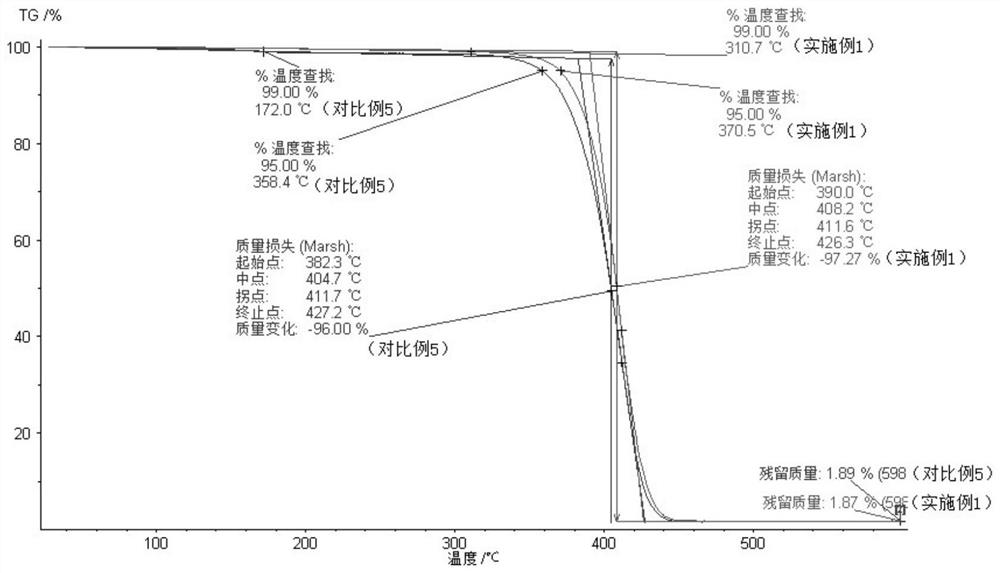

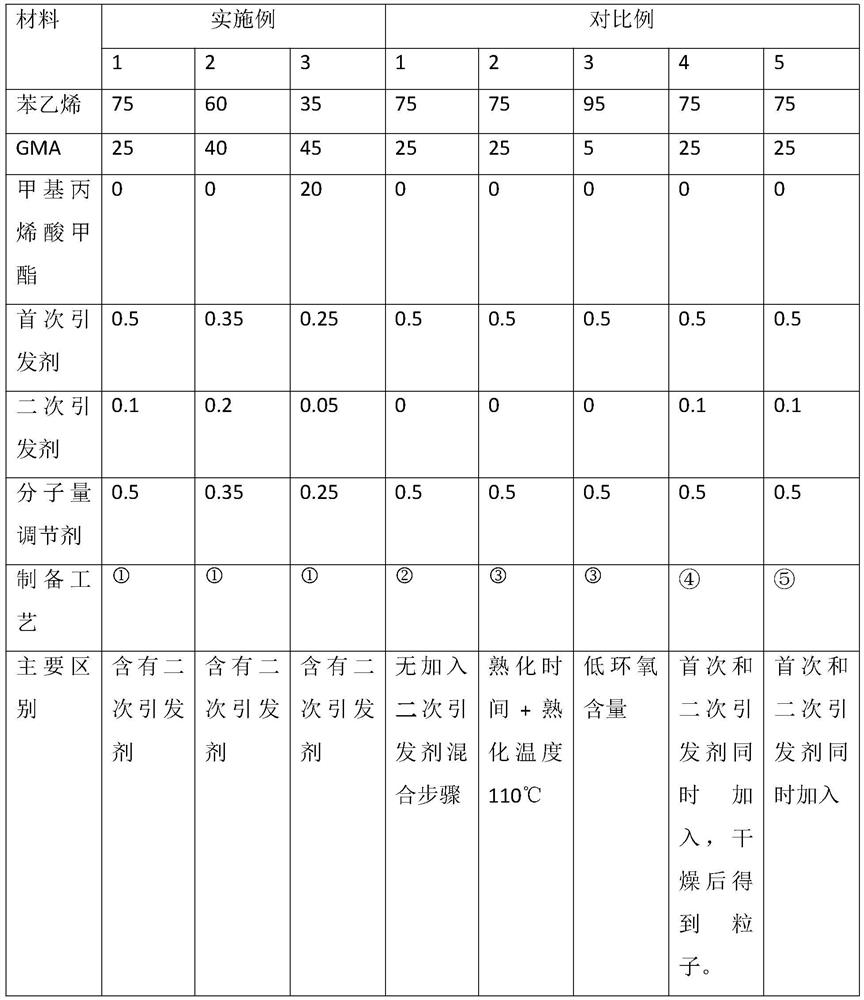

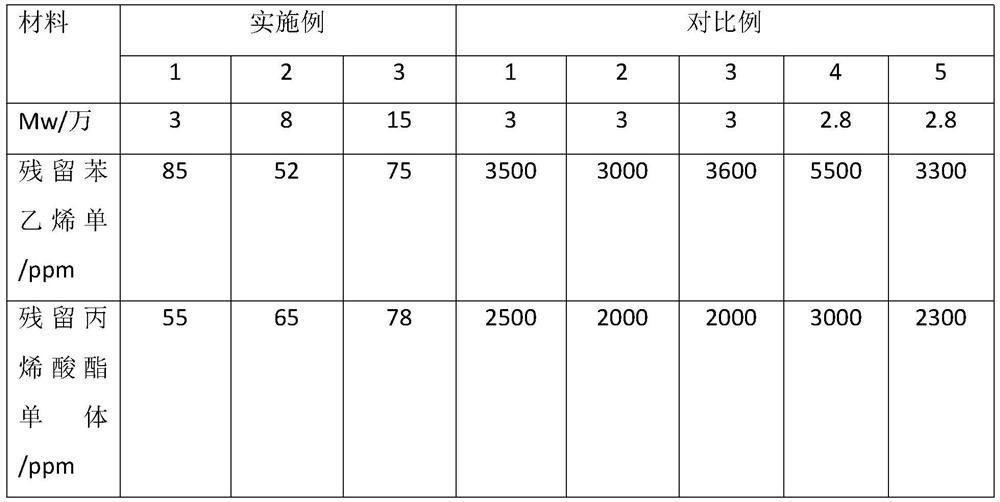

Preparation method and application of monomer-residue-free high-activity tackifying chain extender

PendingCN113943387ALow monomer residueImprove thermal stabilityPlastic recyclingPolyesterPolymer science

The invention provides a preparation method and application of a monomer-residue-free high-activity tackifying chain extender. The preparation method comprises the following steps: mixing an aromatic vinyl monomer, an acrylate monomer, an initiator and a solvent or water, carrying out heating for polymerization, and carrying out double-screw secondary reaction granulation to prepare the monomer-residue-free tackifying chain extender. The epoxy functionalized chain extender disclosed by the invention can be applied to recycled polyester structure materials, and can be applied to repair and growth of bio-based biodegradable plastic molecular chains with polyester structures. The preparation method is simple in process control and low in investment, and the produced monomer-residue-free high-activity tackifying chain extender is stable in composition, simple to use and widely applicable to the fields of medical treatment, packaging, household appliances, automobiles and the like. The method has very good application prospects and industrial values.

Owner:FINE BLEND POLYMER SHANGHAI CO LTD

Preparation method of water-absorbing resin

The invention discloses a preparation method of a water-absorbing resin. The water-absorbing resin is characterized by using 20-50 parts of methylacrylic acid as a monomer, 10-50 parts of starch as a substrate, 0.5-3 parts of azodiisobutyronitrile as an initiator, 0.2-4 parts of trimethylolpropane as a crosslinking agent, and 35-65 parts of a stearic acid compound as a dispersing agent. The preparation method comprises the following steps: adding water into the starch to be dissolved so as to be pasty, transferring the pasty starch into a reaction kettle, adding methylacrylic acid, azodiisobutyronitrile, trimethylolpropane and the stearic acid compound to the reaction kettle, mixing uniformly, introducing high-purity nitrogen, controlling the reaction temperature, performing a polymerization reaction, drying and crushing. The preparation method disclosed by the invention is simple, accessible to raw materials, low in production cost, easy for controlling the reaction temperature, and low in monomer residual quantity; the water absorption capability of the prepared water-absorbing resin is obviously improved; the tap water absorption capability is up to 850 ml / g above, and the normal saline absorption capability is up to 100 ml / g or above.

Owner:广西藤县通轩立信化学有限公司

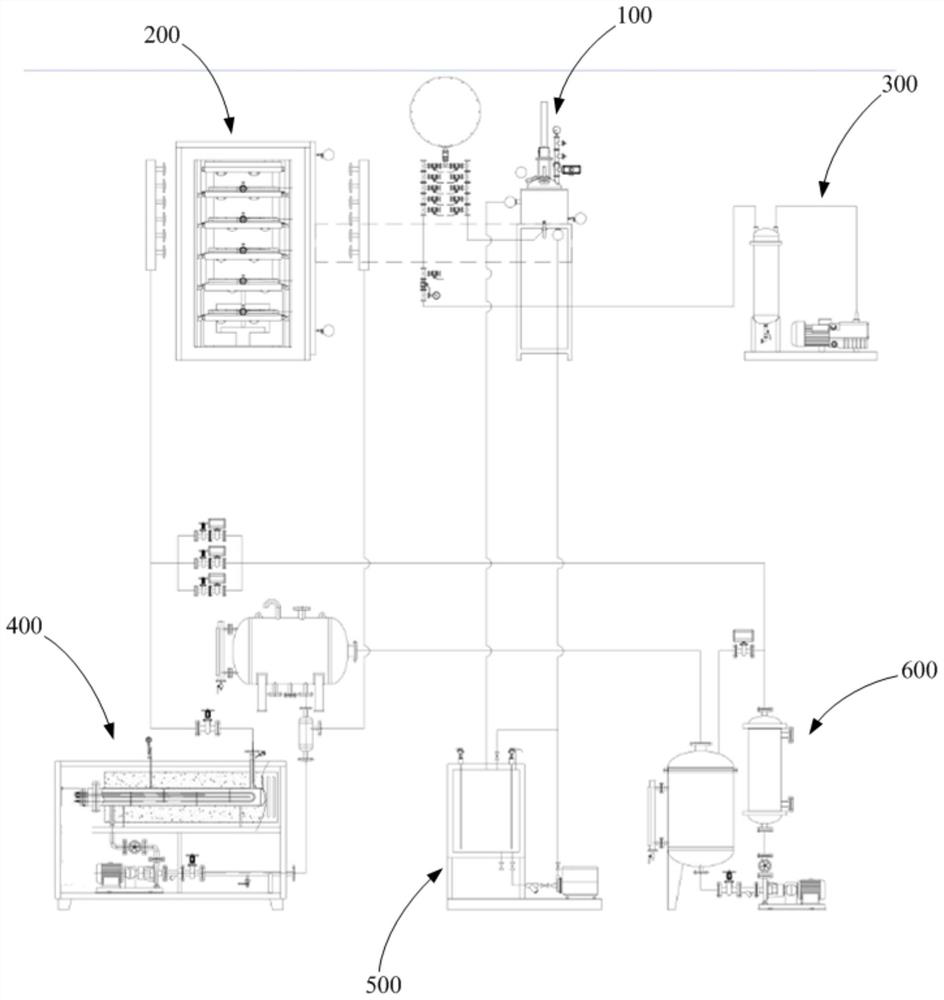

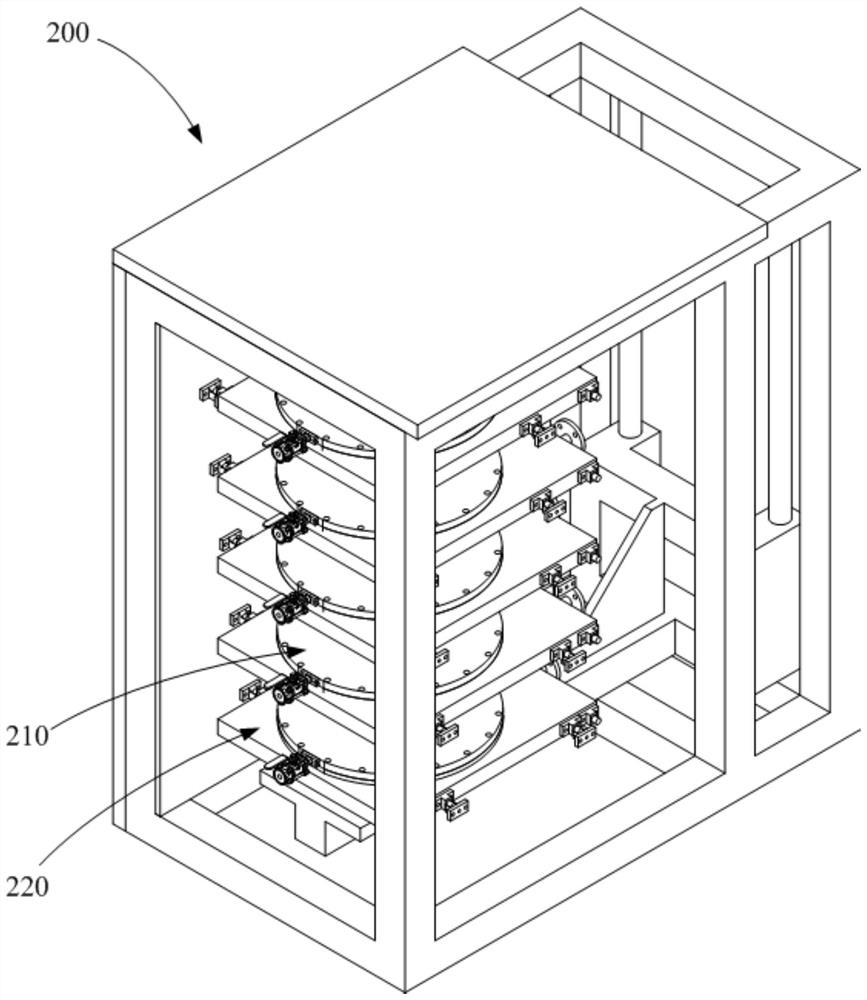

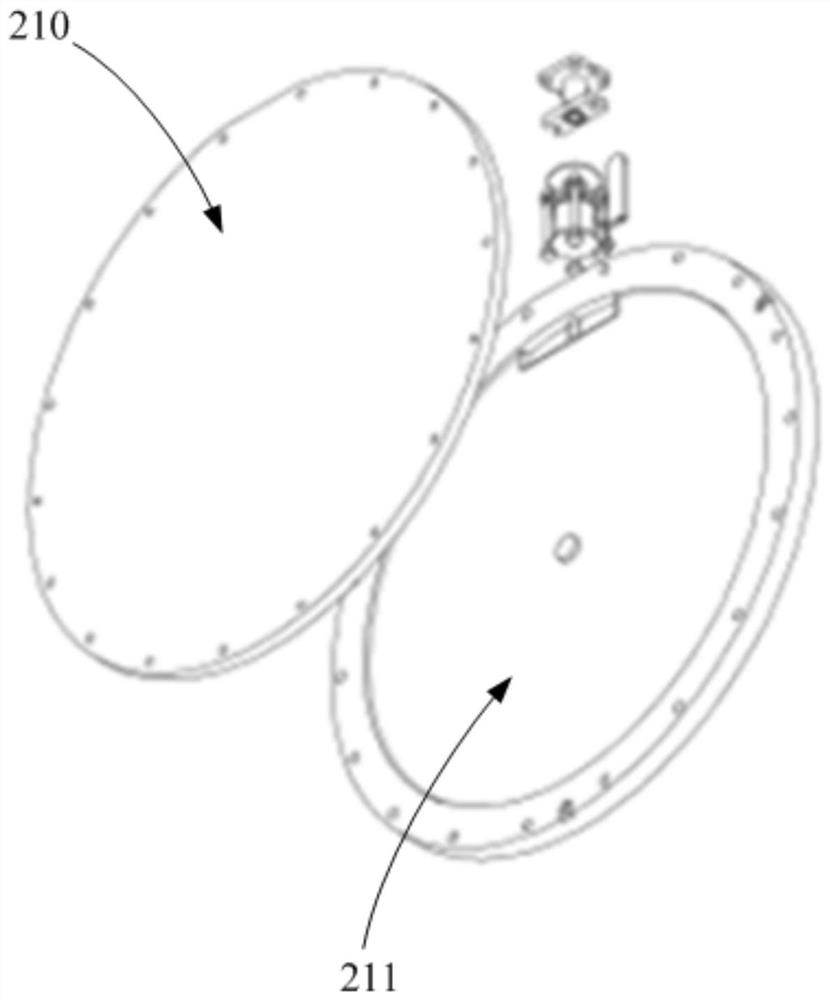

System for preparing absorbable polyester and method thereof

The invention discloses a system and a method for preparing absorbable polyester. The system for preparing absorbable polyester comprises a melting tank; and a polymerization reaction device which comprises a polymerization reactor and a polymerization heating plate which are arranged in a stacked mode, and the heating plate is provided with a heating flow channel so as to exchange heat with the polymerization reactor; the polymerization reactor is provided with a reaction cavity, the reaction cavity is communicated with the melting tank, and the shortest distance between cavity walls of the reaction cavity is less than 4cm. According to the technical scheme, a homopolymer of cyclic ester or a copolymer of different cyclic esters can be prepared, and the obtained polyester is high in molecular weight, narrow in molecular weight distribution and less in coloring.

Owner:SHENZHEN ANTMED CO LTD

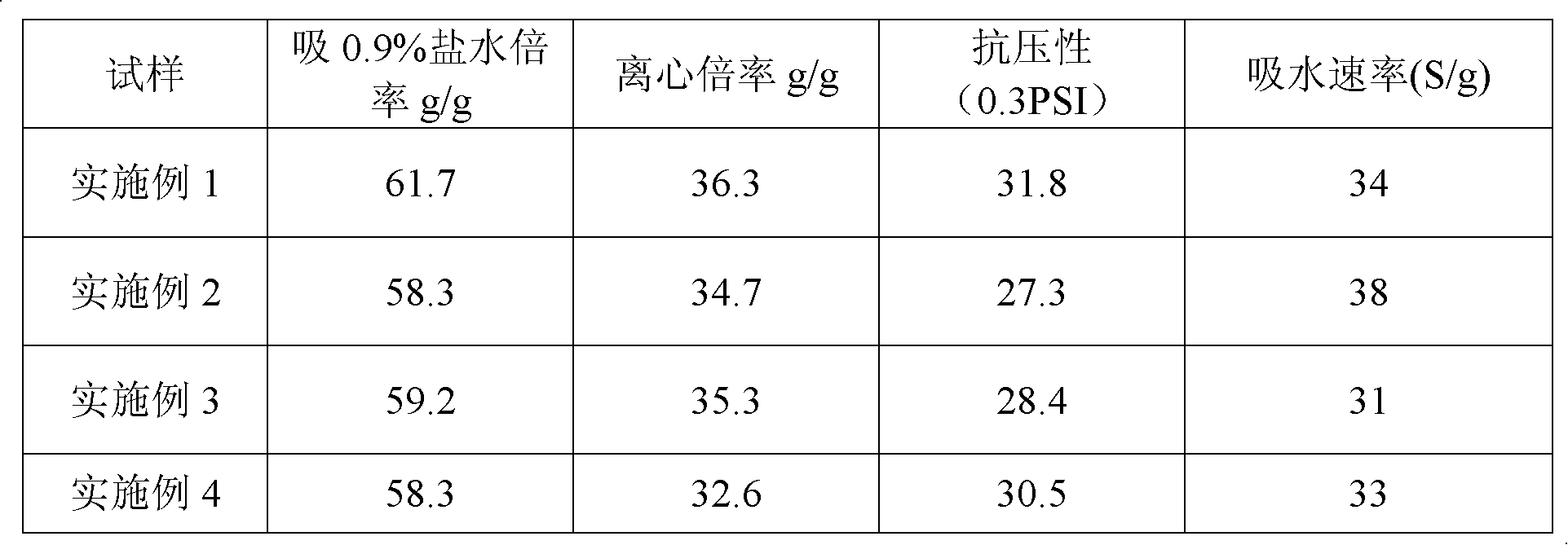

Preparation method for super absorbent resin

The invention discloses a preparation method for super absorbent resin. In the method, acrylic acid is used as a raw material; an alkaline aqueous liquid is used as a neutralizer to neutralize the acrylic acid; then a cross-linking agent and an initiator are added for implementing polymerization; after the polymerization is finished, resin grains are obtained in sequence through pelleting, drying and crashing; surface treatment is implemented on the resin grains to obtain the super absorbent resin with the advantages of low monomer residue, high pressure resistance and absorbency, fast absorbent speed, excellent condensation resistance and good flowability. The preparation method has fast rate of polymerization and is very stable. The polymer gel grains obtained through reaction can be independently dispersed and can not be mutually stuck and caked. The preparation method has simple technology, high efficiency and high energy utilization.

Owner:宜兴丹森科技有限公司

Preparation method of low monomer-residual acrylic ester modified aqueous polyurethane pressure-sensitive adhesive

ActiveCN102703015BLow monomer residueResidue reductionPolyureas/polyurethane adhesivesPolymer scienceOligomer

The invention provides a preparation method of low monomer-residual acrylic ester modified aqueous polyurethane pressure-sensitive adhesive and belongs to the technical field of adhesives. According to the method, 1) home-made and hydroxyl-containing acrylic ester oligomer is employed to replace acrylic ester monomer modified polyurethane, acrylic ester is subjected to grafting reaction with polyurethane, and then a net structure is formed based on the cross linking of a cross-linking agent, in comparison with the acrylic ester monomer modification, the reaction is more complete, the monomer residual is low, the preparation process is simple, and the purposes of energy saving and environmental protection are fulfilled; 2) the product is subjected to post-treatment by an oxidation-reduction initiator system in order to further reduce the monomer residual amount, and then obtain the green adhesive product with ultra-low monomer residual; and 3), the synthesized product is featured with good stability and excellent mechanical property, both the initial viscosity and the endurable viscosity are higher than that of the simple acrylic ester emulsion and simple acrylic ester monomer modified aqueous polyurethane, so that the adhesive is widely suitable for several fields such as production and daily life as pressure-sensitive adhesive.

Owner:溧阳常大技术转移中心有限公司

Special PVDC coating latex for cigarette film and its preparation method and application

ActiveCN103059193BImprove stabilityLow monomer residueFlexible coversWrappersPolymer scienceMicrocrystalline wax

The invention discloses polyvinyl dichloride (PVDC) coating latex special for cigarette films and a preparation method and application of the PVDC coating latex special for the cigarette films. The PVDC latex is prepared from a certain amount of mixed monomers of vinylidene chloride, methyl acrylate and itaconic acid, a ptomotor, an initiator, an emulgator and a seed emulgator, and the preparation method is seed emulsion polymerization. According to the preparation method, microcrystalline wax capable of having a defoaming effect is added to enable the residual quantity of monomers in the latex is smaller. The cigarette films made of the latex has heat sealing performance and a high barrier property, and can maintain the scent of cigarettes and enable the cigarettes to not go bad and not be affected with damp. The heat sealing strength of the cigarette films is equal to or larger than 3N / 15mm, the coating weight is 3g / m<2>, the permeation amount of water vapor is equal to or smaller than 6g / m<2>*24h, the permeation volume of oxygen is equal to or smaller than 36g / m<2>*24h, and the residual quantity of vinylidene chloride monomers is equal to or smaller than 1mg / kg or is not detected.

Owner:海南聚能创新服务有限公司

Paper coating water-based emulsion and preparation method and applications thereof

The invention discloses a paper coating water-based emulsion and a preparation method and applications thereof. Aiming at the problem that the barrier property of the current paper coating emulsion is not good, the invention provides the paper coating water-based emulsion. The method comprises the following steps: using a certain amount of vinylidene chloride, acrylonitrile, methacrylate and methacrylic acid as a mixed monomer, selecting a special seed emulsifier and a mixed emulsifier, adopting seed emulsion polymerization, and finally obtaining the paper coating water-based emulsion. The paper coating water-based emulsion has good stability, environmental protection and good barrier property. A vacuum desorption post-processing method is adopted in the later period of emulsion polymerization, so that the monomer residual quantity of the obtained water-based emulsion is low. The prepared coated paper has no foreign smell, cannot pollute food or drugs, and is more beneficial to applications to the package field of food, drugs and the like.

Owner:HAINAN BNK WATER BASED NEW MATERIAL CO LTD

Preparation method of ultrahigh molecular weight sulfonic acid-type polyacrylamide

ActiveCN102453192BHigh molecular weightLow free monomer contentDrilling compositionSolubilityWater soluble

The invention relates to a preparation method of water-soluble polymer, and especially relates to a preparation method of ultrahigh molecular weight sulfonic acid-type polyacrylamide copolymer used for tertiary oil recovery oil displacement agents. The ultrahigh molecular weight heatproof salt-resistant sulfonic acid-type acrylamide copolymer prepared by the invention has a high molecular weight, good solubility and a low monomer residual quantity, and thus can be used for polymer oil displacement agents for high-temperature high-salt oil reservoirs. The invention is used in the petroleum exploitation field.

Owner:CHINA PETROLEUM & CHEM CORP +1

Acrylic ester compound for coating, preparation method, coating containing same and use

ActiveCN109956867BGood weather resistanceImprove wear resistanceAntifouling/underwater paintsOrganic compound preparationPolymer scienceWeather resistance

The present invention relates to an acrylic ester compound used for coating, and the compound has the structure of formula (I). The acrylic ester compound used in coatings provided by the invention has lipophilic polycyclic aliphatic groups and hydrophilic hydroxyl groups at the same time, and high polymerization reactivity, and is used for solvent-based acrylic coatings, and the coatings exhibit excellent weather resistance Resistance, abrasion resistance, high gloss and fullness, etc.; for water-based acrylic coatings, the compound's hydrophilic hydroxyl groups and lipophilic alicyclic groups show good compatibility in emulsified systems, and polymerization activity High, low monomer residue, after film formation, the coating exhibits excellent properties such as weather resistance, water and oil resistance, impact resistance and high gloss. Moreover, the preparation method has simple technological process, easy control of conditions, less side reactions, high conversion rate of reaction raw materials, and high product purity.

Owner:WUXI ACRYL TECH

Method of preparing biodegradable super absorbent resin by using eggshell membrane

InactiveCN101974133BShort polymerization timeThe reaction steps are simplePolymer scienceEggshell membrane

The invention discloses a method of preparing a biodegradable super absorbent resin by using an eggshell membrane. The super absorbent resin is prepared by employing an ultrasonic irradiation polymerization technique to make a reaction in a water phase system. The super absorbent resin is prepared particularly by the following steps: 1. modifying the inner membrane of the egg; 2. polymerizing thesuper absorbent resin at room temperature. The method is characterized by realization of absorbent resin polymerization at room temperature, no need of external heating modes such as water bath and air, no limitation of a radiation source (e.g., Co60, etc.), and can realize the absorbent resin polymerization at room temperature only by modifying the eggshell membrane, a cross-linking agent and a single-component initiator. The method shortens reaction time, simplifies preparation technology, needs no nitrogen protection and prepares a product with strong water absorbing capacity. The preparedproduct can be used for medical supplies, personal hygiene items, agricultural water retention release agents and the like. The method of the invention has the advantages of uniform structure of prepared absorbent resin, high monomer conversion, simple preparation technology and low cost.

Owner:SUIHUA UNIV

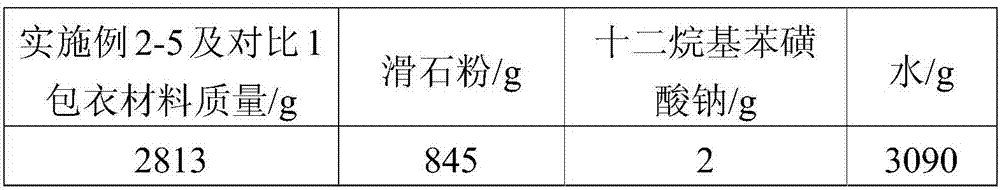

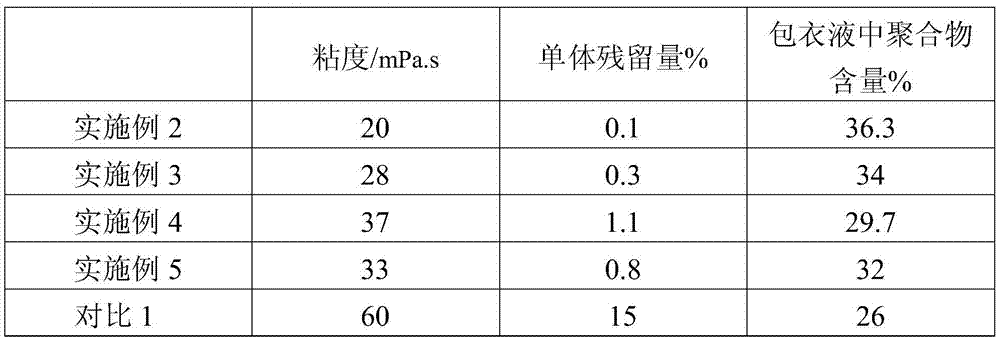

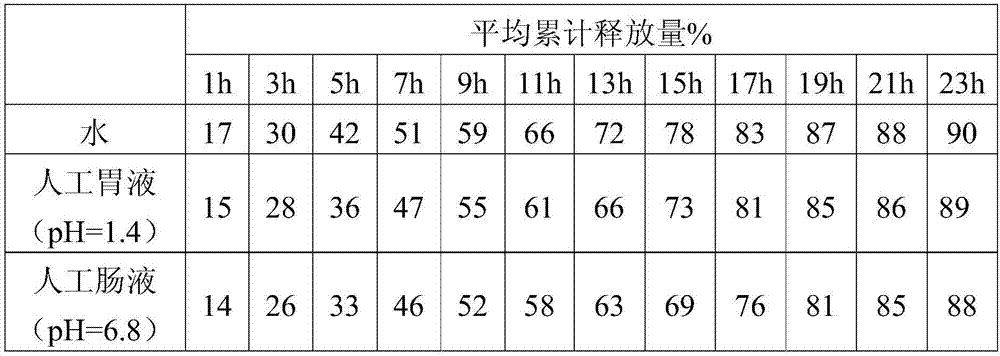

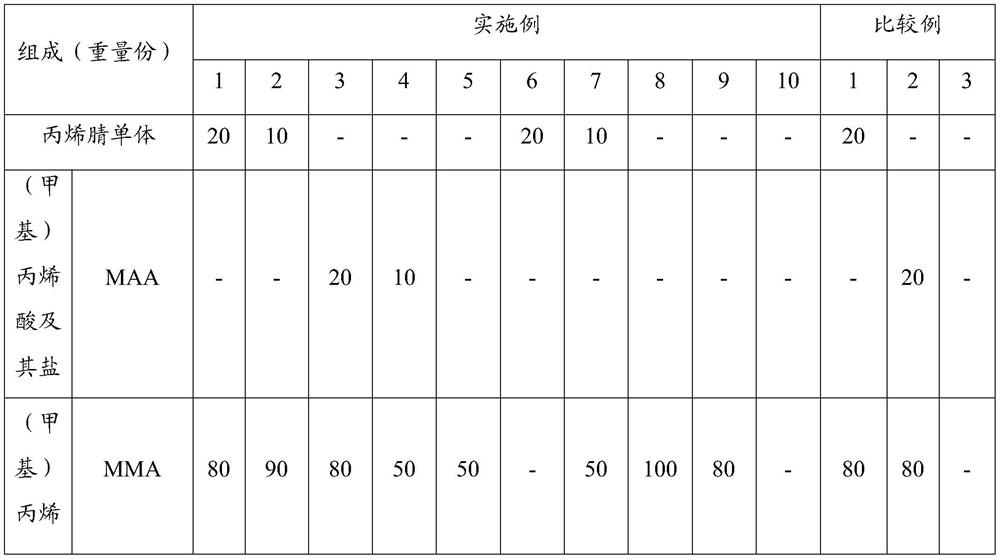

A kind of low permeability sustained-release coating material and preparation method thereof

ActiveCN106008788BRich varietyLow viscosityPharmaceutical non-active ingredientsRaw materialChemistry

The invention belongs to the technical field of coating materials and particularly relates to a low-permeability sustained-release coating material and a preparation method thereof. The coating material is mainly prepared from the following raw materials: methyl methacrylate, methacrylic acid chlorinated trimethylamino ethyl ester, butyl methacrylate and cellulose or a cellulose derivative. The preparation method of the coating material comprises specific steps as follows: (1) monomers including methyl methacrylate, methacrylic acid chlorinated trimethylamino ethyl ester, butyl methacrylate are polymerized at 40-60 DEG C; (2) cellulose or the cellulose derivative is added, polymerization is continued at 65-80 DEG C, and a finished product is obtained after being cooled to the room temperature. The coating material has better film forming property and coating quality. Sustained-release tablets prepared from the sustained-release coating material have better sustained-release effects in different environments, and drug taking times can be reduced.

Owner:连云港万泰医药辅料技术有限公司

A kind of ultrafine environment-friendly thermal expansion microcapsule and preparation method thereof

ActiveCN108097182BSimple and fast operationSimple preparation processMicroballoon preparationMicrocapsule preparationThermal dilatationPhysical chemistry

The invention discloses an ultrafine environmental-friendly thermal expansion microcapsule, which is prepared by a microwave radiation emulsion polymerization method from a suspension dispersion of an oil phase composition and an aqueous phase composition. High foaming rate, environmental protection and non-toxic, can be used in textile, paper, ink, engineering plastics and other fields. The invention also discloses a preparation method of ultrafine environment-friendly heat-expandable microcapsules. The heat-expandable microcapsules are prepared based on microwave radiation radical emulsion polymerization technology, and the operation is simple, the preparation process is simple, and the production efficiency is high.

Owner:三明市锦浪新材料科技有限公司

Acrylic resin and preparation method and application thereof

ActiveCN109456441AGood weather resistanceGood water and oil resistancePolyurea/polyurethane coatingsAcrylic resinSolution polymerization

The invention discloses acrylic resin and a preparation method and application thereof. The acrylic resin comprises at least one structural unit (A), at least one structural unit (B), at least one structural unit (C) and at least one structural unit (D). The acrylic resin is obtained by subjecting o-hydroxyl type bridge ring structure acrylate and other acrylate monomers to solution polymerizationand neutralizing dispersion. In addition, the invention further provides a film forming composition comprising polyisocyanate and the acrylic resin and a bi-component waterborne polyurethane coatingcomprising the film forming composition or the acrylic resin. A compact grid structure is formed after curing crosslinking, hydrophobic polycyclic ester group containing bridge ring structure of the acrylic resin endows a coating with higher waterproofness and better physical and mechanical performance.

Owner:WUXI ACRYL TECH

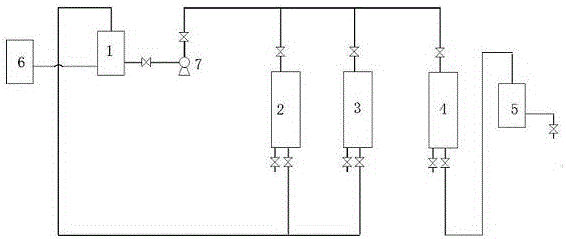

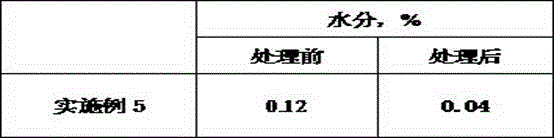

A device for reducing the acidity and moisture of dichloromethane waste liquid

ActiveCN104529006BReduce acidityIncrease throughputMultistage water/sewage treatmentLiquid wasteMolecular sieve

Owner:SUZHOU JIMCEL ELECTRONICS NEW MATERIAL

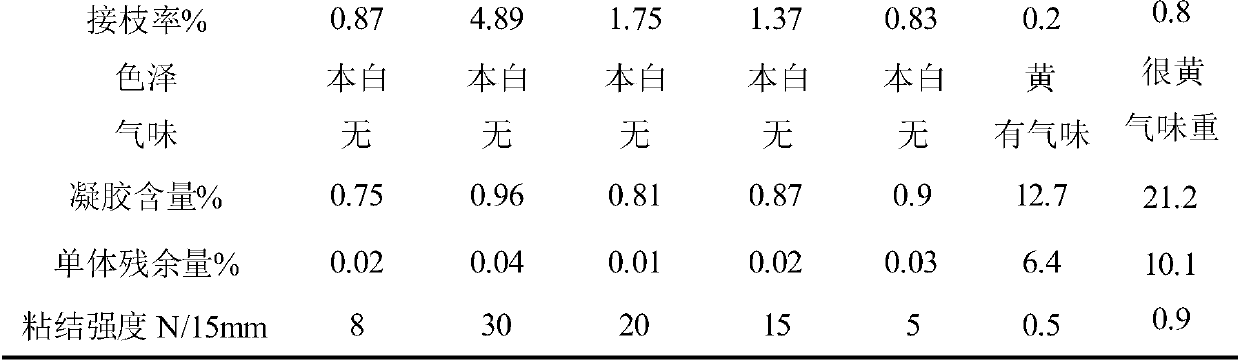

A kind of preparation method of high-grafting-rate polyolefin graft and application of the high-grafting-rate polyolefin graft

A preparing method of a polyolefin graft having a high grafting ratio is disclosed. The method includes (1) replacing air in a reaction kettle with nitrogen, and then heating the reaction kettle to 80-180 DEG C, (2) adding a polyolefin under nitrogen protection to the reaction kettle, adding a reaction monomer, an initiator and a crosslinking inhibiting agent after the polyolefin is melted, and reacting the mixture under stirring, and (3) vacuumizing the reaction kettle, then proceeding with the reaction, and subjecting a material prepared by the reaction to high-pressure extrusion, strip drawing and pelletizing to obtain the polyolefin graft. The polyolefin graft prepared by the method has advantages of the high grafting ratio, a low crosslinking degree, weak smell, light color, a low monomer residual amount, high adhesive force, and the like, wherein the grafting ratio of maleic anhydride can reach 4.89%, the monomer residual amount is 0.05% or below, and the adhesive strength can reach 30 N / 15mm.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Polyvinyl dichloride (PVDC) latex special for kraft paper used for food packaging and preparation method thereof and application thereof

ActiveCN103059195BImprove stabilityLow monomer residuePaper coatingCoatingsPolymer scienceAcrylonitrile

The invention discloses a polyvinyl dichloride (PVDC) latex special for kraft paper used for food packaging and a preparation method thereof and application thereof. The kraft paper coated by the PVDC latex can be used for packaging of foods such as peanuts, melon seeds and walnuts. The PVDC latex is obtained by a mixed monomer, an auxiliary, an initiating agent, an emulsifying agent and a seeded emulsifying agent, wherein the mixed monomer contains a certain amount of vinylidene chloride, vinyl cyanide, butyl acrylate and acrylic acid, and the seeded emulsifying agent contains sodium dodecyl benzene sulfonate and a 2A-1 emulsifying agent. The prepared PVDC latex is good in stability and free of emulsification breaking and sediment after placed for 24 months under temperature of 30 DEG C and relative humidity (RH) of 70%. Monomer residual volume in the latex is lower. The kraft paper coated by the PVDC latex has the advantages of being environment-friendly, degradable, good in heat tightness, waterproof, damp proof and the like. When coating amount of the latex is 20g / m2, steam transit amount is less than or equal to 3g / m2.24h and oxygen permeability is less than or equal to 6g / m2.24h, monomer residual amount of the vinylidene chloride is less than or equal to 1ppm or not detected, and heating sealing intensity can reach 3N / 15mm.

Owner:HAINAN BNK WATER BASED NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com