Low-smell environment-friendly polyurethane soft foam material as well as preparation method and application thereof

A polyurethane soft foam and low-odor technology, applied in the field of polyurethane soft foam, can solve the problems of unimproved odor and VOC, low odor, and inability to meet high environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

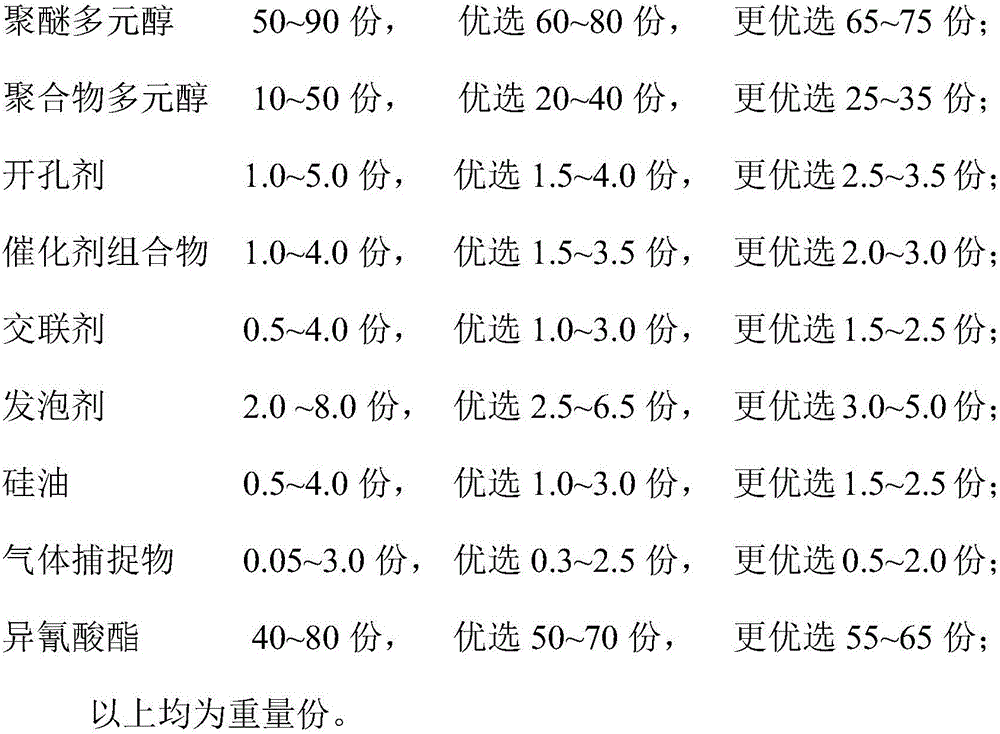

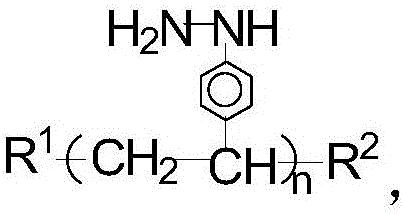

Method used

Image

Examples

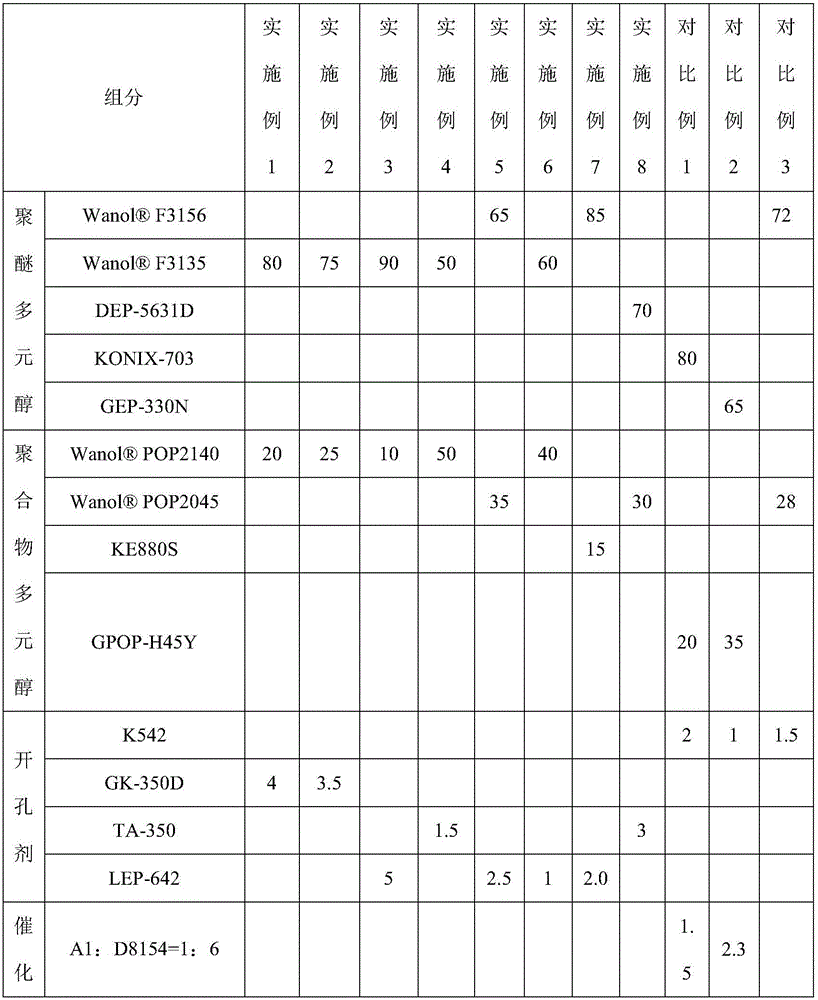

Embodiment 1

[0064] (1) Preparation of polyol component: according to F3135: POP2140=4:1 mass ratio, weighed separately F3135 80 parts by weight and Mix 20 parts by weight of POP2140 in the reactor, then add 2 parts of gas capture (silica: FM505 = 10:1) under heating (80°C), stir and mix until the capture is dissolved, cool to room temperature, and weigh in turn 1 part of silicone oil GK350D, after fully mixing, add 4.2 parts of water, 0.72 parts of UF5880, 0.71 parts of diethanolamine, catalyst combination ( ZF-10: NE1082=1:6) 1.2 parts, after mixing for 0.5~1.0h, seal and store;

[0065] (2) Foaming: at room temperature, 71 parts Add 8019 to the polyether polyol component, mix for 8-15 seconds under high-speed stirring at 2500r / min-3000r / min, pour it into the mold quickly for foaming, and take out the foam for aging after foaming.

Embodiment 2-7

[0067] The preparation method is basically the same as in Example 1, and the formula table and reaction conditions are shown in Table 1 for details.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of unsaturation | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com