A device for reducing the acidity and moisture of dichloromethane waste liquid

A dichloromethane and acidity technology, applied in the field of dichloromethane waste liquid recovery, to achieve the effects of reducing production costs, energy consumption, low requirements, and low corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

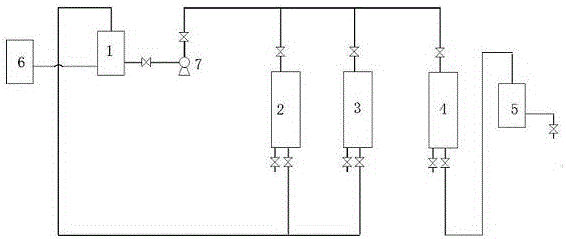

Image

Examples

Embodiment 1

[0028] Preparation of solid base loaded on mesoporous molecular sieve SBA-15: immerse 30g of mesoporous molecular sieve SBA-15 in 20mL magnesium nitrate solution with a concentration of 0.3mol / L, soak overnight at room temperature and normal pressure; evaporate to dryness in a constant temperature water bath at 95°C , placed in an oven at 120°C for 6 hours, and then baked in a muffle furnace, rising to 550°C at 10°C / min and maintaining for 3 hours. Investigate the treatment effect of different treatment temperatures on the acidity of dichloromethane waste liquid, the space velocity is controlled at 4 ~ 5h -1 , see Table 1 for details of the treatment effect.

[0029] Table 1

Embodiment 2

[0031] Preparation of solid base loaded on mesoporous molecular sieve SBA-15: immerse 20g of mesoporous molecular sieve SBA-15 in 20mL potassium hydroxide solution with a concentration of 0.1mol / L, soak overnight at room temperature and normal pressure; Dry it in an oven at 120°C for 6 hours, then bake it in a muffle furnace, raise it to 550°C at 10°C / min, and keep it for 3 hours. Investigate the treatment effects of different space velocities on the acidity of dichloromethane waste liquid. The treatment temperature is 60°C. See Table 2 for the treatment effects.

[0032] Table 2

Embodiment 3

[0034] Preparation of solid base loaded on mesoporous molecular sieve SBA-15: immerse 40g of mesoporous molecular sieve SBA-15 in 20mL sodium carbonate solution with a concentration of 0.5mol / L, soak overnight at room temperature and normal pressure; evaporate to dryness in a constant temperature water bath at 95°C , placed in an oven at 120°C for 6 hours, and then baked in a muffle furnace, rising to 550°C at 10°C / min and maintaining for 3 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com