Patents

Literature

79results about How to "Good water and oil resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

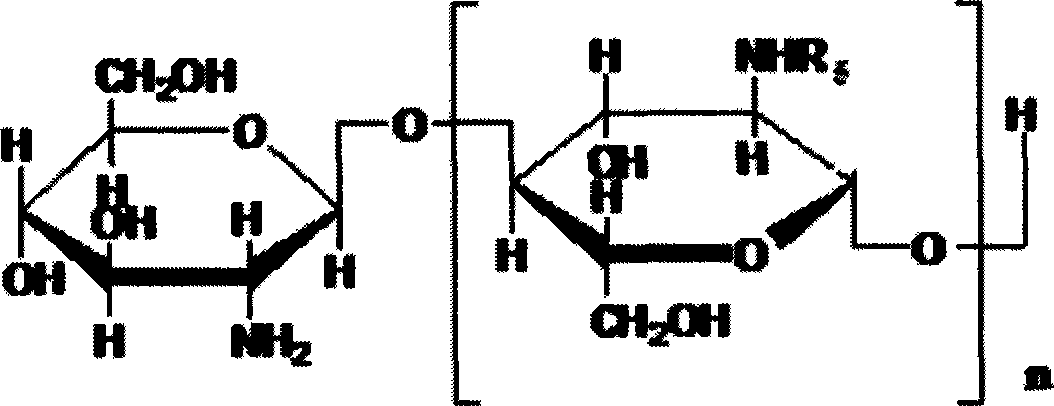

Preparation of chitosan-polyurethane ion complex elastomer material

The invention discloses a preparation method of chitosan-polyurethane ionic compound elastomeric material, which comprises the following steps: polyisocyanates reacts with polymer polylol and then reacts with diol or diamine, organic solvent and ionization reagent are added in the reactants to react with water for generating anionic waterborne polyurethane and further performs the ionic recombination reaction with cationic chitosan water solution to obtain the microemulsion or latex of chitosan-polyurethane ion composite, and finally the microemulsion or latex of chitosan-polyurethane ion composite is dried and solidified to obtain the chitosan-polyurethane ionic compoundelastomeric material. The chitosan-polyurethane ionic compoundelastomeric material has the advantages of good mechanical property, easy processing, good oil-water resistance property, good cohesive property with parent metal, controllable performance, good biocompatibility, biodegradable property, high biological activity, good blood contact property, good bacteriostatic property, good antibacterial property, and the like, can be applied in fields of mechanical industry, building industry, sport, medical treatment, and the like, and especially has wider purpose in aspects of life science research, medical materials and medical appliances.

Owner:NANJING UNIV

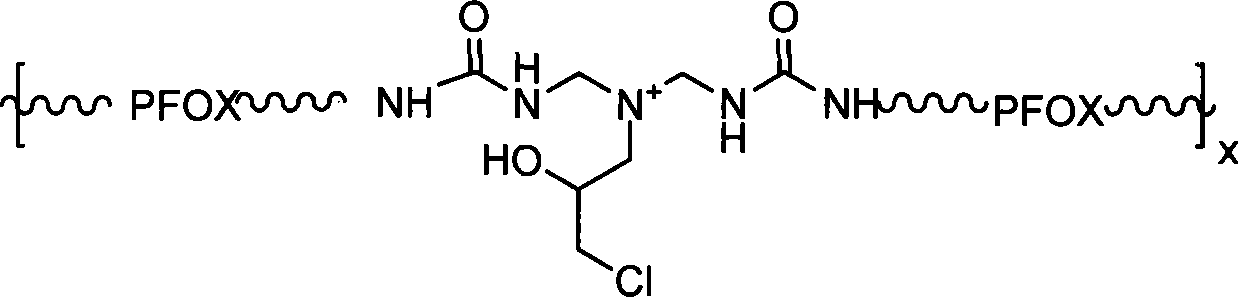

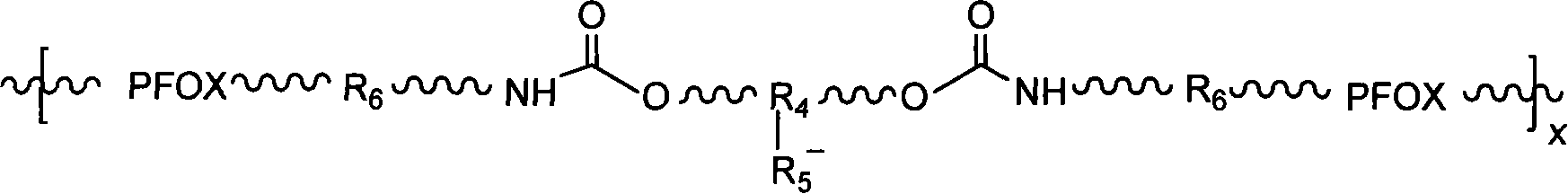

Fluorine-containing aqueous polyurethane and preparation method and application thereof

InactiveCN101041709AIncreased durabilityImprove waterproof performanceAntifouling/underwater paintsOther chemical processesGreen environmentFluorine containing

The invention discloses a making method and application of aqueous fluorine polyurethane, which contains cationic and anionic aqueous fluorine polyurethane with the making procedure comprises the following steps: (1) synthesizing bromoepoxybutane; (2) making fluoepoxybutane; (3) preparing fluorine polyether; (4) synthesizing aqueous polyurethane. The invention can be high-property green environment-protective water repellency, waterproof and stainproof paint, which possesses wide market prospect.

Owner:DONGHUA UNIV

Water and oil resistant agent for paper and paper treatment process

ActiveUS8992733B2Good water and oil resistanceNatural cellulose pulp/paperSpecial paperFluorine containingChemistry

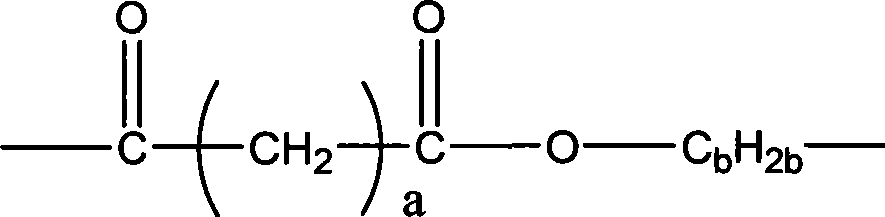

Disclosed is a water and oil resistant agent comprising a fluorine-containing copolymer obtained by copolymerizing a (meth)acrylate monomer having a polyfluoroalkyl group having 1 to 6 carbon atoms, the agent being able to afford a superior water and oil resistance to a paper. The invention also discloses a composition comprising the water and oil resistant agent, a process for treating a paper thereby and a treated paper thereby.

Owner:DAIKIN IND LTD

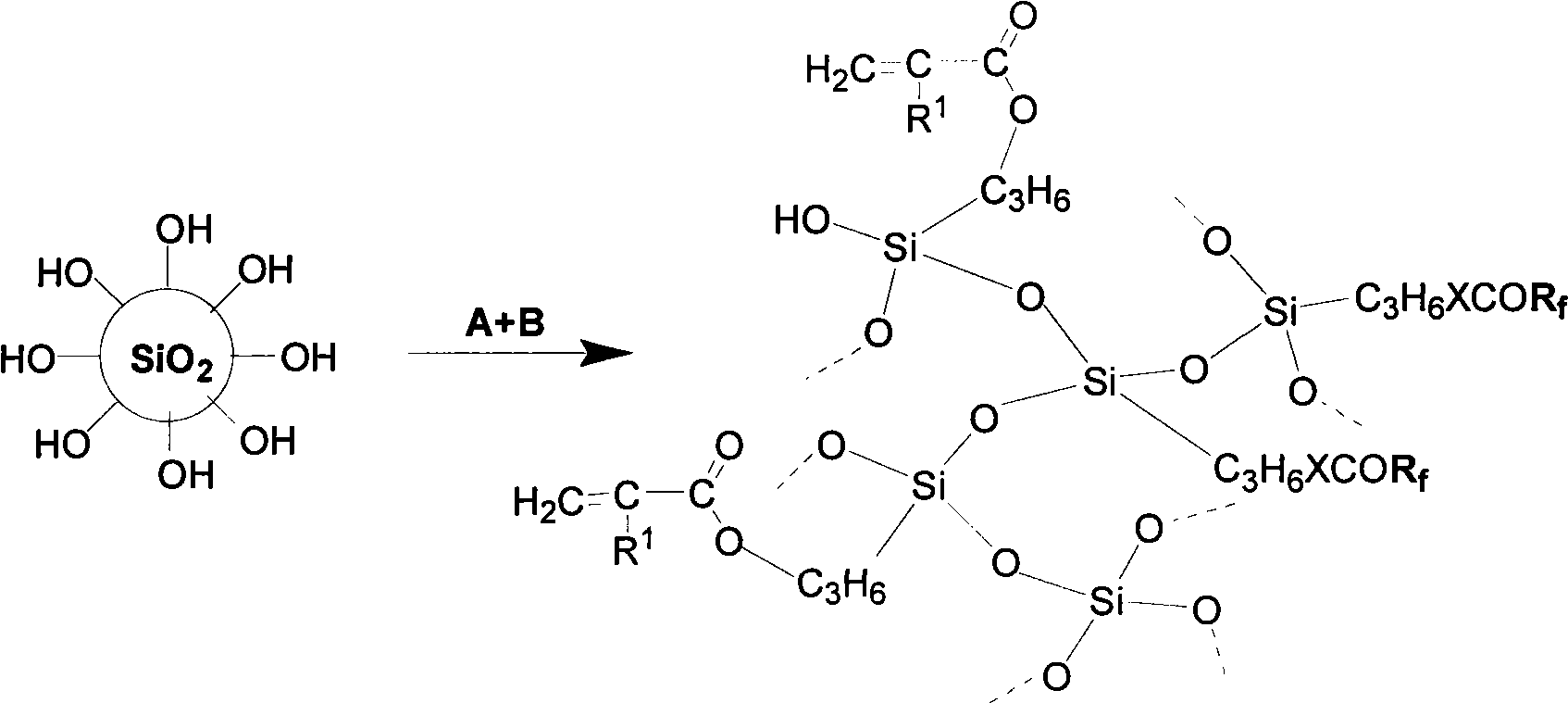

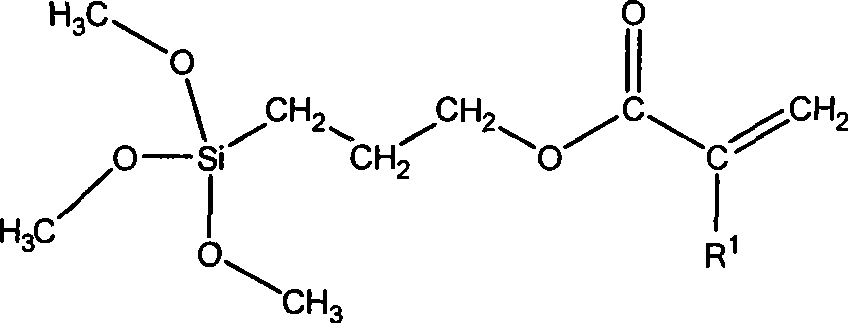

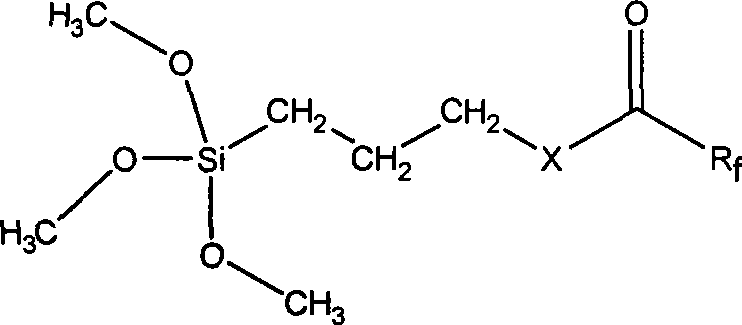

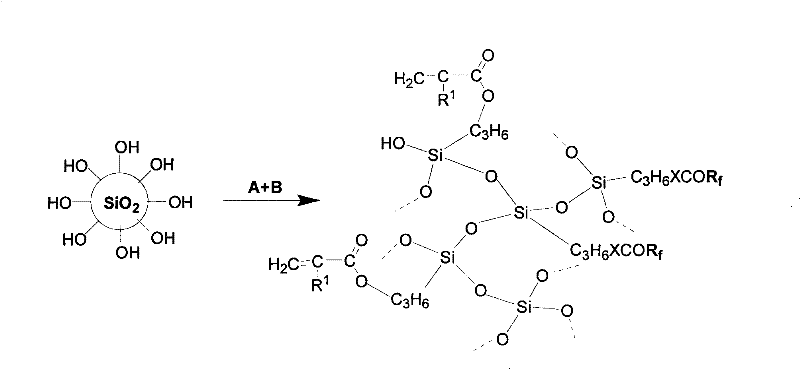

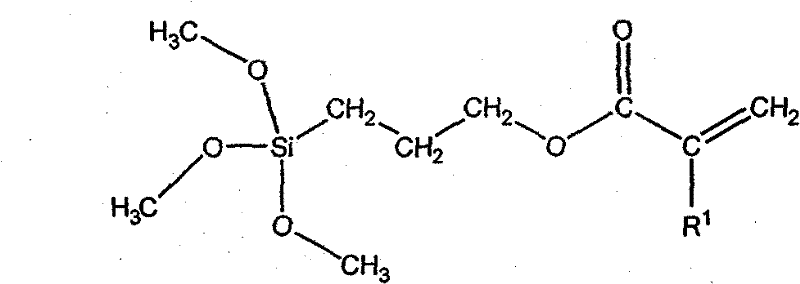

Surface modified nano silicon dioxide and acrylic resin coating containing the same

InactiveCN101497749AGood water and oil resistanceImprove stain resistanceCoatingsPigment treatment with non-polymer organic compoundsPolymer scienceWeather resistance

The invention discloses a nano-silicon dioxide which is functionalized by acrylic ester and modified on surface by perfluoro alkoxy, a method for preparing the nano-silicon dioxide, and an acrylic resin coating containing the nano-silicon dioxide. The acrylic resin coating containing the nano-silicon dioxide also contains single-functional acrylic ester, acrylic ester containing at least two acrylic ester groups, alcoholic solvent and evocating agent. The acrylic resin coating containing fluorine and silicon can be quickly solidified, and the coating film hereby formed has excellent oil resistance, water resistance, weather resistance, pollution resistance, surface hardness and surface gloss.

Owner:浙江池河科技有限公司

Waterborne polyester modified epoxy polyurethane anticorrosive paint and preparation method thereof

InactiveCN102108245AGood water and oil resistanceLow coating adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsPolyesterEpoxy

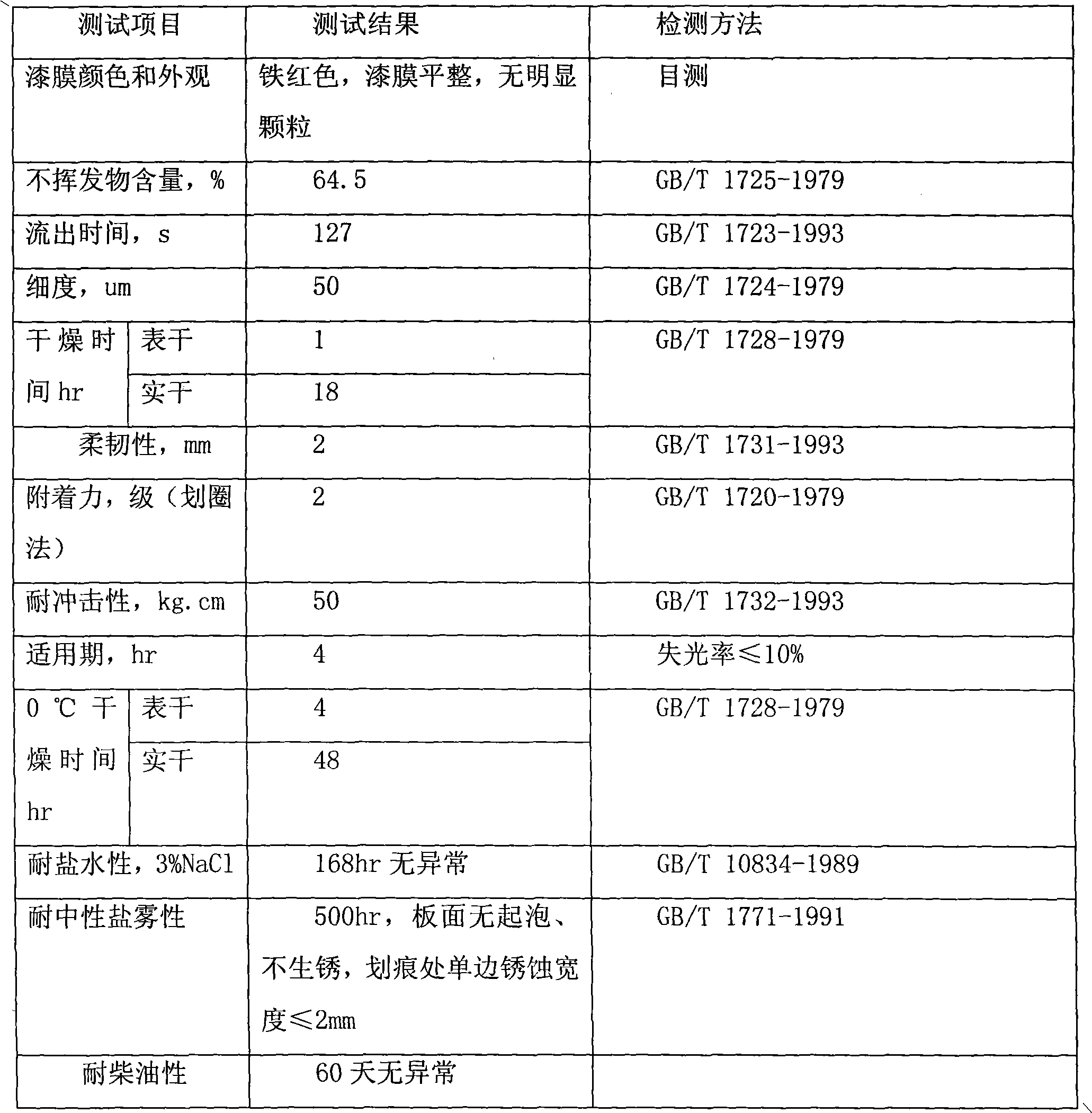

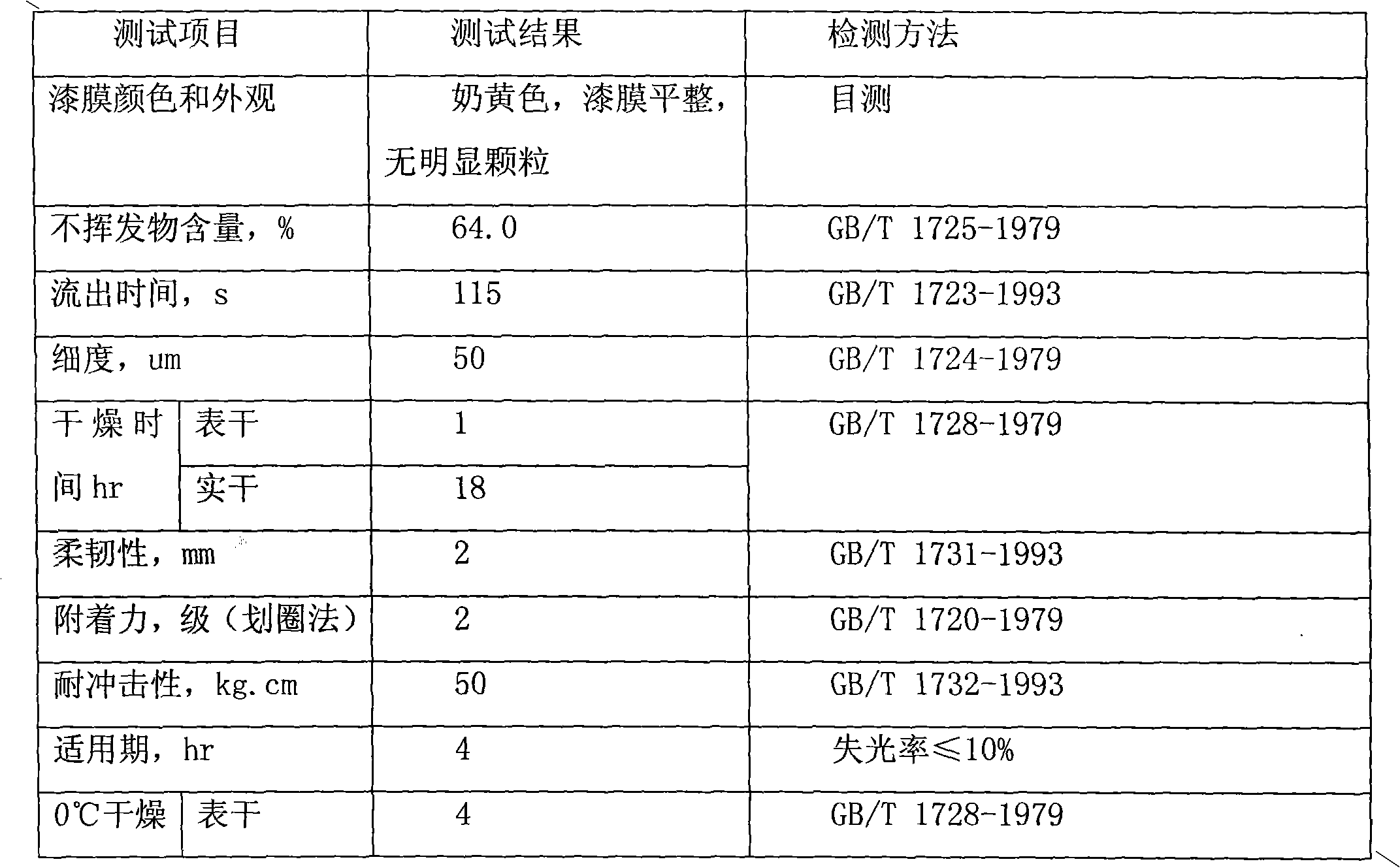

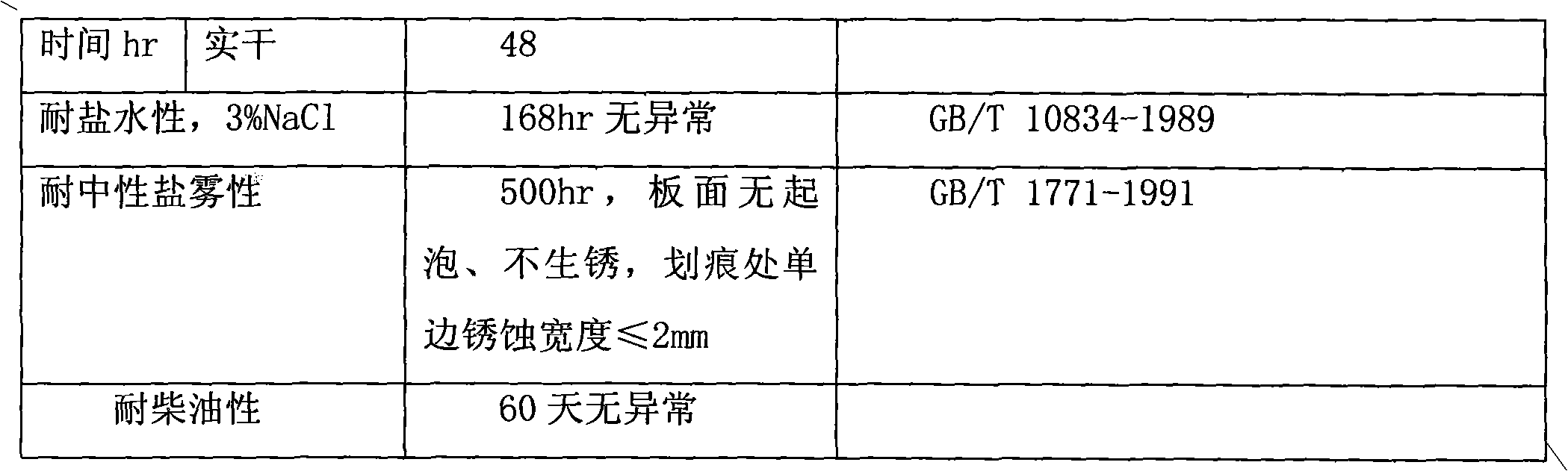

The invention relates to a waterborne polyester modified epoxy polyurethane anticorrosive paint and a preparation method thereof. The preparation method of the paint is as follows: a component A is composed of 25-50 parts by weight of waterborne polyester modified epoxy dispersion and other raw materials, a component B is composed of waterborne polyisocyanates dispersion, the component A and the component B are mixed in a ratio range of 7:1-3:1 to form the main film-forming material; 0-30 parts by weight of rustproof pigment, 0-20 parts by weight of coloring pigment and 5-20 parts by weight of filler are further added. The paint of the invention has the advantages similar to that of the common waterborne paint, overcomes some defects of the waterborne anticorrosive paint, combines the advantages of polyester paint, epoxy paint and polyurethane paint, has excellent low temperature fast curing property, oil resistance, chemical medium and anticorrosive properties and has wide application prospect in various steel structure fields such as bridges, pipes, storage tanks and industrial factory buildings.

Owner:SHENZHEN ZHONGKE LITAO TECH

Preprocessed wear-resistant and flame-retardant cable material

InactiveCN104194164AIncrease concentrationModerate vulcanization speedRubber insulatorsEpoxyWear resistant

The invention discloses a preprocessed wear-resistant and flame-retardant cable material, comprising the following raw materials in parts by weight: 48-52 parts of natural rubber, 55-58 parts of EPDM rubber, 12-15 parts of chlorobutyl rubber, 12-15 parts of chopped glass fiber, 3-6 parts of corn protein fiber, 3-5 parts of sulfur powder, 1.2-1.8 parts of an accelerant TBzTD, 3-4 parts of an accelerant NS, 7-12 parts of zinc oxide, 4-6 parts of magnesium oxide, 28-32 parts of preprocessed activated material, 30-33 parts of mica powder, 22-26 parts of heavy calcium carbonate, 5-8 parts of antimonous oxide, 12-16 parts of melamine cyanurate, 3-5 parts of barium stearate, 3-6 parts of di-(2-ethylhexyl)-4,5-epoxy tetrahydrophthalate EPS, 5-6 parts of liquid coumarone, 1.3-1.8 parts of an anti-ageing agent 800-B, and 1.5-2.1 parts of an anti-ageing agent BLE. The preprocessed wear-resistant and flame-retardant cable material has excellent wear-resisting property and flame retardant property.

Owner:ANHUI LAND GRP

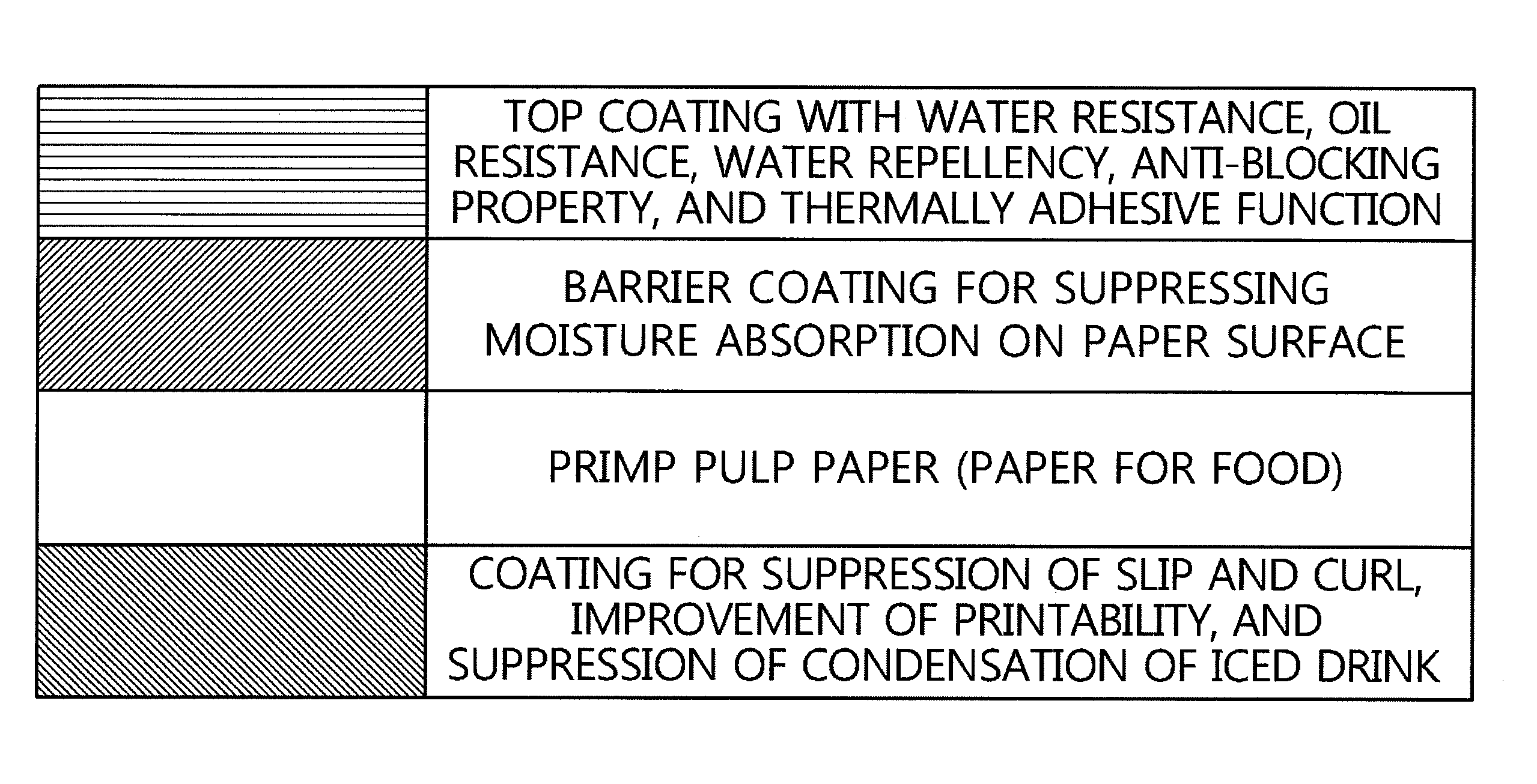

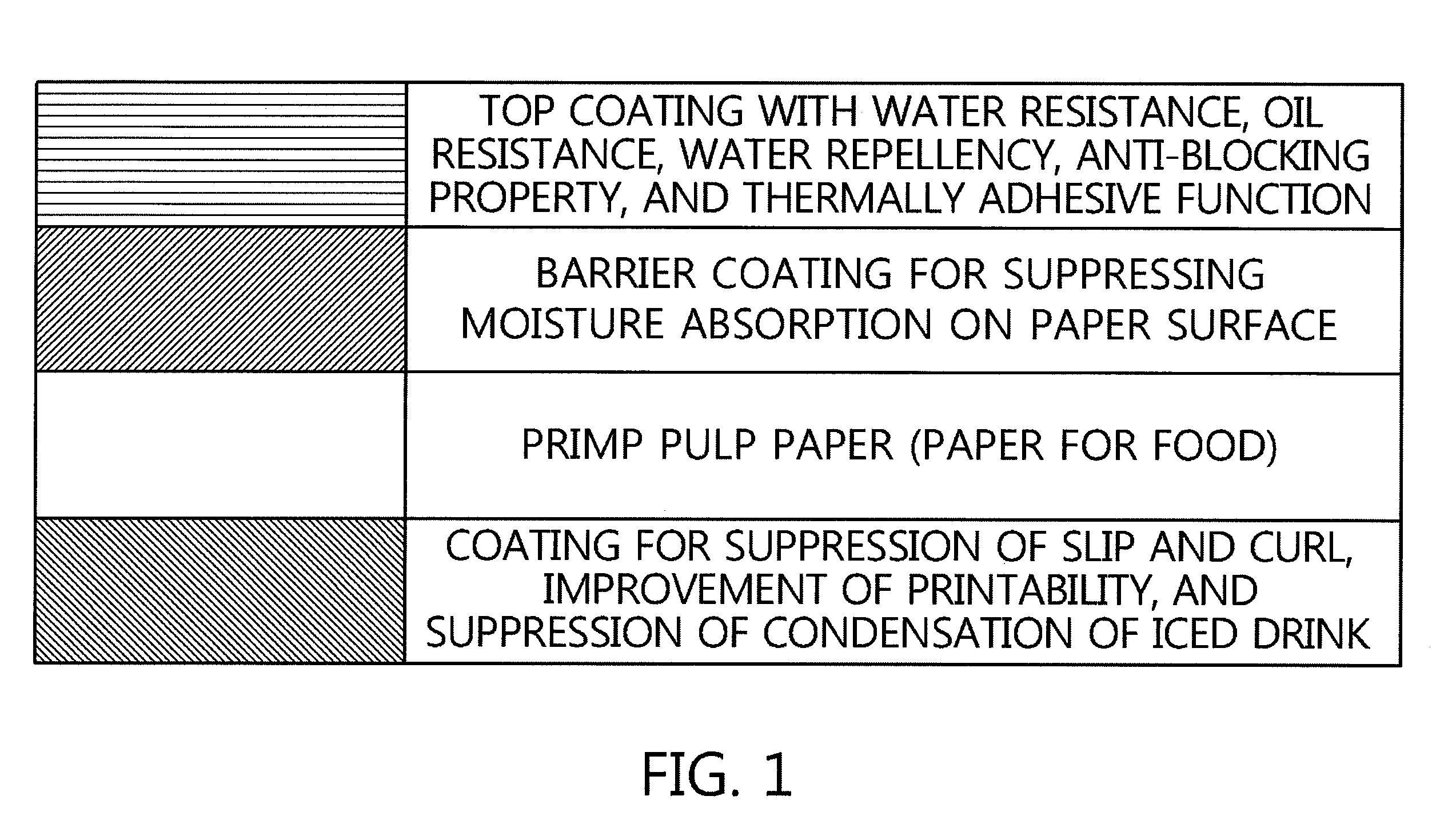

Method for preparing environmentally friendly paper coating agent by using water dispersible resin of ethylene-(METH)acrylic acid polymer, and use thereof

InactiveUS20160145806A1Good dispersionImprove uniformityWrappersSpecial paperWater dispersibleAlkali metal

There is provided a method of manufacturing a paper-forming product formed of an environmentally friendly paper coating agent, which is excellent in water resistance, oil resistance, thermally adhesive property, and alkaline water-dissociative property, the method including mixing alkali metal hydroxide, amines, ammonia water, or the like with each of an ethylene-acrylic acid copolymer or an ethylene-(meth)acrylic acid copolymer or a mixture of these polymers, and using a water-dispersible coating solution prepared by adding FDA-approved matting agent, slip agent, and anti-foaming agent into a water-dispersible resin solution prepared by neutralizing the mixed product in an aqueous medium.

Owner:RHEE BYEONG SEOK

Fluo-copolymer/polyacrylate blending emulsion and its production and use

A fluorine multi-polymer / polyacrylic acid ester blended emulsion, its production and use are disclosed. The mixed emulsion consists of fluorine multi-polymer dispersion liquid 1-95 proportion and polyacrylic emulsion or its monometer 5-99 proportion. It's cheap, has better performances of anti-foul, water and oil proofing, weather-resisting and / or acid and alkali-resisting.

Owner:3M INNOVATIVE PROPERTIES CO

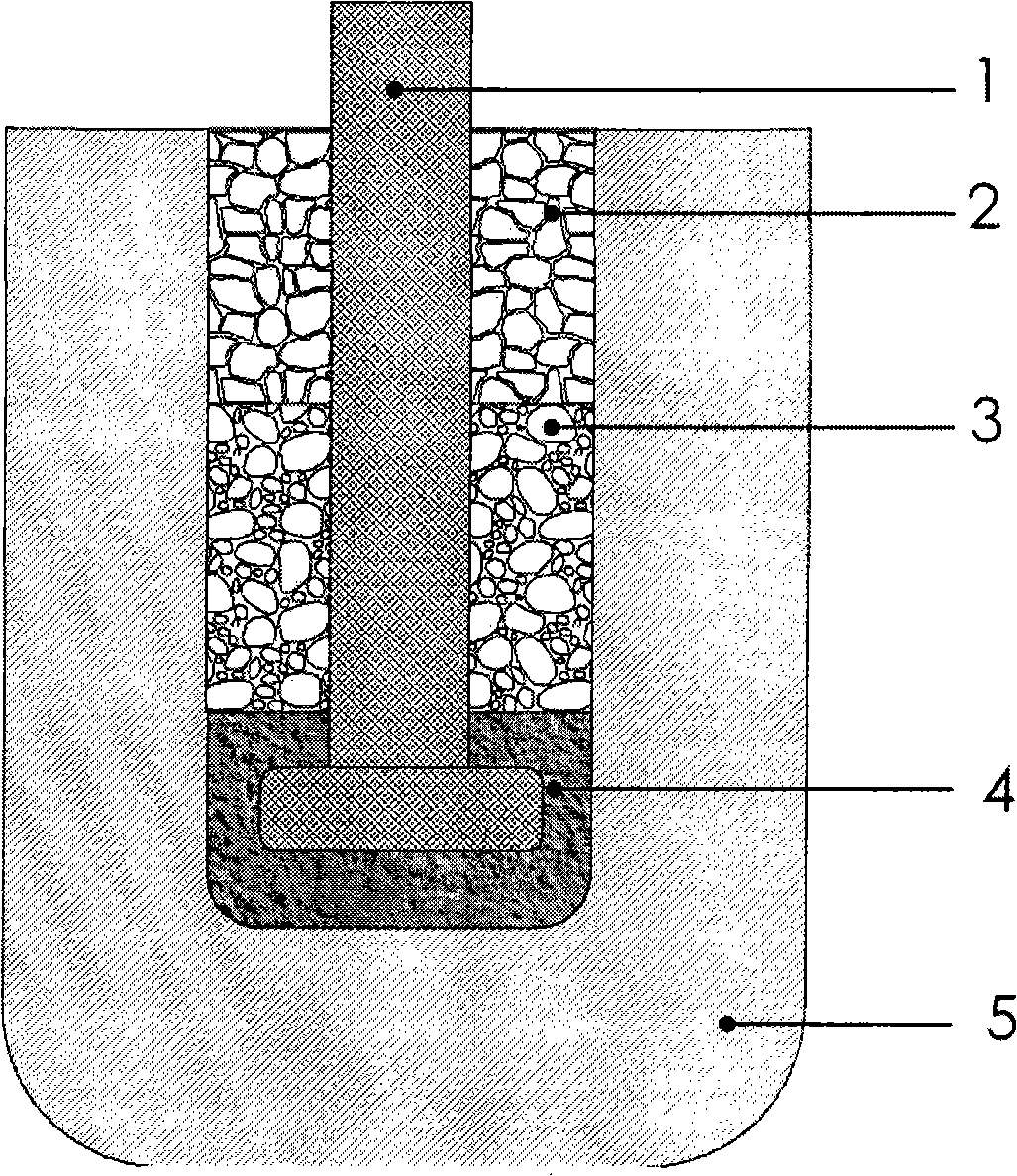

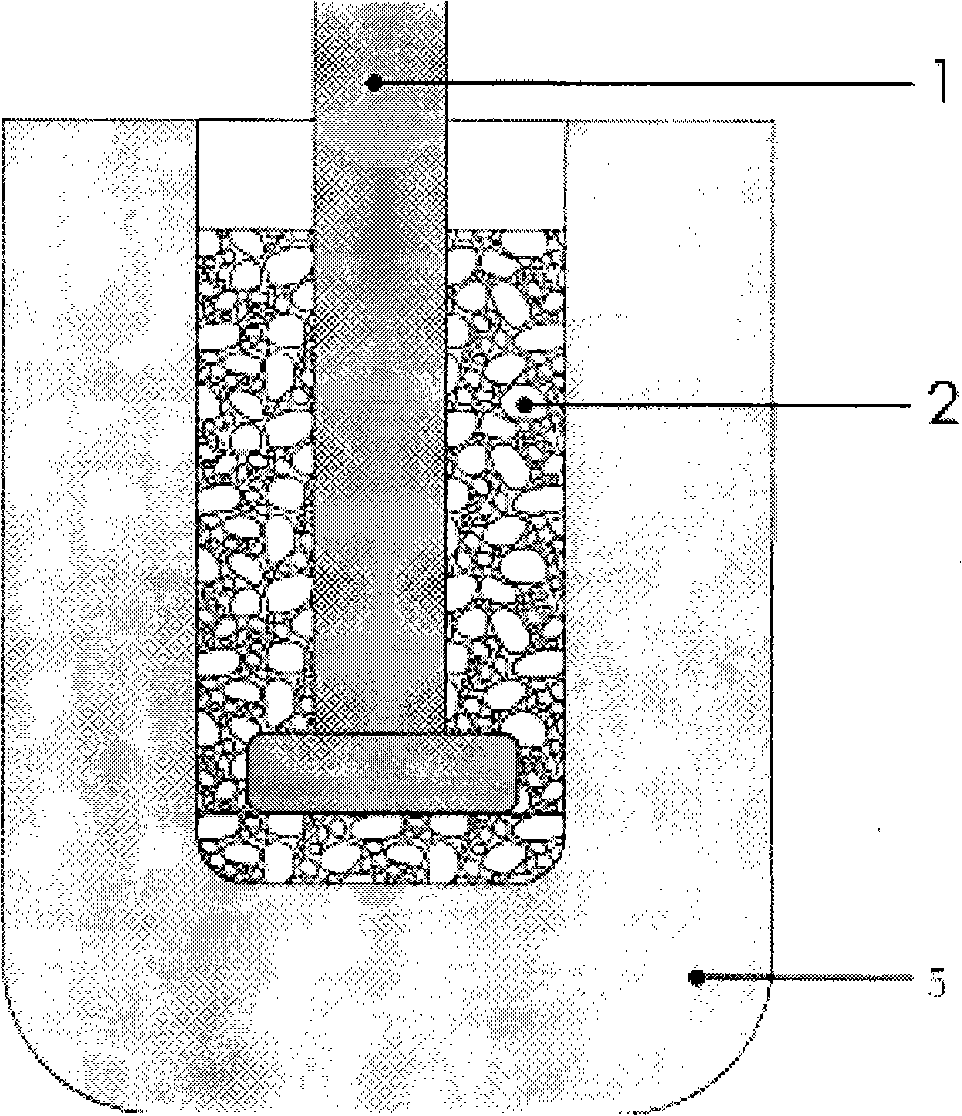

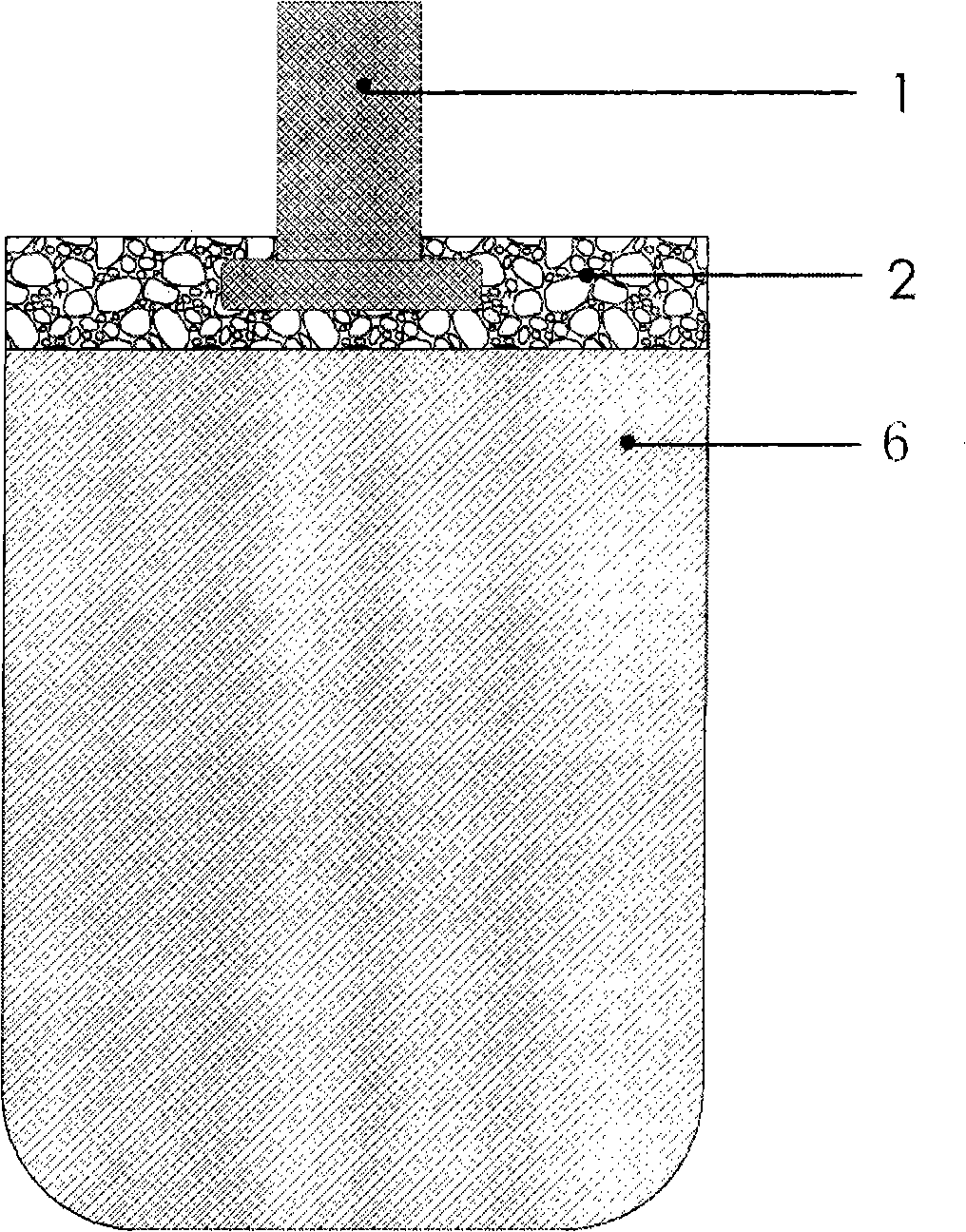

Connection structure of aluminum electrolysis ceramic matrix inert anode and metal guide rod, and preparation thereof

The invention discloses a connecting structure of an aluminium electrolysis ceramic based inert anode and a metal guide bar and a preparation method thereof. The ceramic based inert anode and the metal guide bar are connected by adopting a caking agent which consists of a filling material and a phosphate solution. The stable electricity conductive connection of the inert anode and the metal guide bar is realized by adopting the appropriate curing technology. The connecting structure has a connecting intensity more than between 5MPa and 20MPa, can stand severe hit of heat, electricity and hot aggressive gas for a long time, and can bear the current density with 0 to 10A / cm<2> for a long time.

Owner:CENT SOUTH UNIV

Rubber sheath for automobile universal joint

The invention discloses a rubber sheath for an automobile universal joint. The rubber sheath comprises the following raw materials in parts by weight: 96-100 parts of neoprene S40V, 0.6-1 part of imarcaptoacetate dioctyltin, 1-2 parts of chlorine fluorine ethofenprox, 2-3 parts of beta-hydroxyalkylamide, 6-8 parts of anhydrous calcium chloride, 6-8 parts of triethyl acetocitrate, 1-2 parts of iron oxide red, 2-3 parts of glycerol triacetate, 1-2 parts of sodium sulfide, 10-14 parts of coal ash, 3-5 parts of calcium stearate, 1-2 parts of 2,6-Di-tert-butyl-4-methylphenol, 1-2 parts of an accelerating agent CZ, 0.8-1.2 parts of sulphur and 16-20 parts of a composite filler. The rubber sheath for the automobile universal joint, provided by the invention, has the effects of vibration reduction and sound insulation, and is good in water proofing and oil resistance, strong in abrasion resistance and excellent in comprehensive performance.

Owner:WUHU JINYING MACHINERY SCI & TECH DEV

Process for producing material with equivalent heat-transfer performance of human body skin

InactiveCN101402718ASimple preparation processImprove biological activityPolymer scienceBiocompatibility Testing

The invention relates to a method for preparing a chitosan based polyurethane elastomer human skin equivalent material. The method comprises the following steps: (1) a diisocyanate prepolymer and polypropylene oxide are stirred at the temperature of 80 DEG C and at a high speed and a polyurethane prepolymer is obtained after 2.5 hours of isothermal reaction; (2) chitosan is added and stirred at a high speed forcefully to cause the chitosan to dissolve so as to obtain a thick liquid without precipitates precipitated; and (3) after 2 hours of reaction at the temperature of 80 DEG C, the liquid is cooled to 50 DEG C, multi-amine, a heat-sensitive material and a flame retardant are added, the mixture is poured into a die to be cured and deaerated for 24 hours so as to obtain the chitosan based polyurethane elastomer human skin equivalent material. The bulk polymerization method adopted by the invention has simple preparation technique, and is high efficient, nontoxic and environmentally friendly and the equivalent material prepared has thermal properties close to that of real skin tissue, can be easy to process, is biodegradable, has good biocompatibility, high biological activity, good high temperature, oil and water resistance, controllable performance and other excellent performance, can be widely applied to fields such as human simulation model, automobile, aerospace relevant performance testing and the like.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

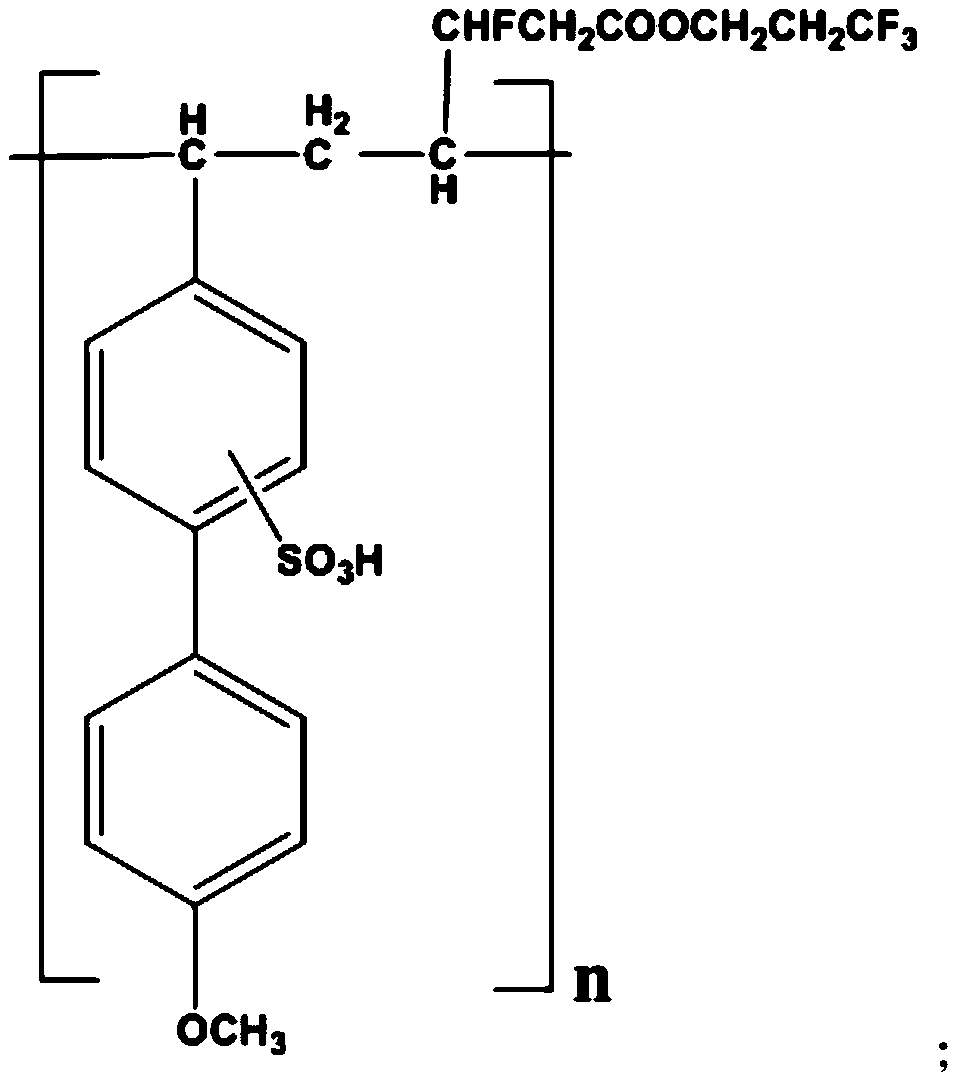

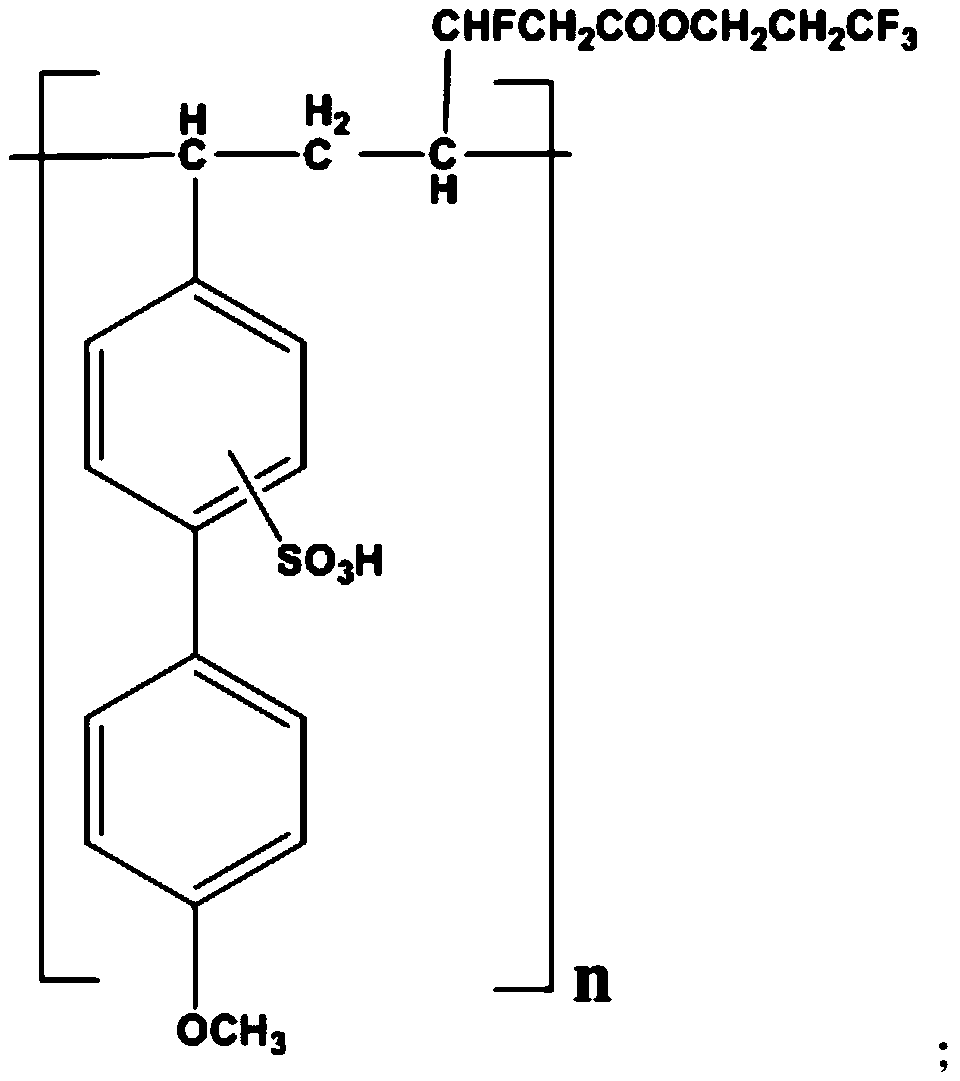

Water and oil resistant agent for paper, treatment process and paper

ActiveUS20120171495A1Good oil resistanceImprove water resistanceNatural cellulose pulp/paperSpecial paperHydrophilic monomerMeth-

Disclosed is a water and oil resistant agent comprising a fluorine-containing copolymer obtained by copolymerizing a (meth)acrylate monomer having a polyfluoroalkyl group having 1-6 carbon atoms, hydrophilic monomer, and monomer having an anion-donating group, which agent affords a superior water and oil resistance to a paper. The invention also discloses a process for treating a paper by the water and oil resistant agent and a treated paper thereby.

Owner:DAIKIN IND LTD

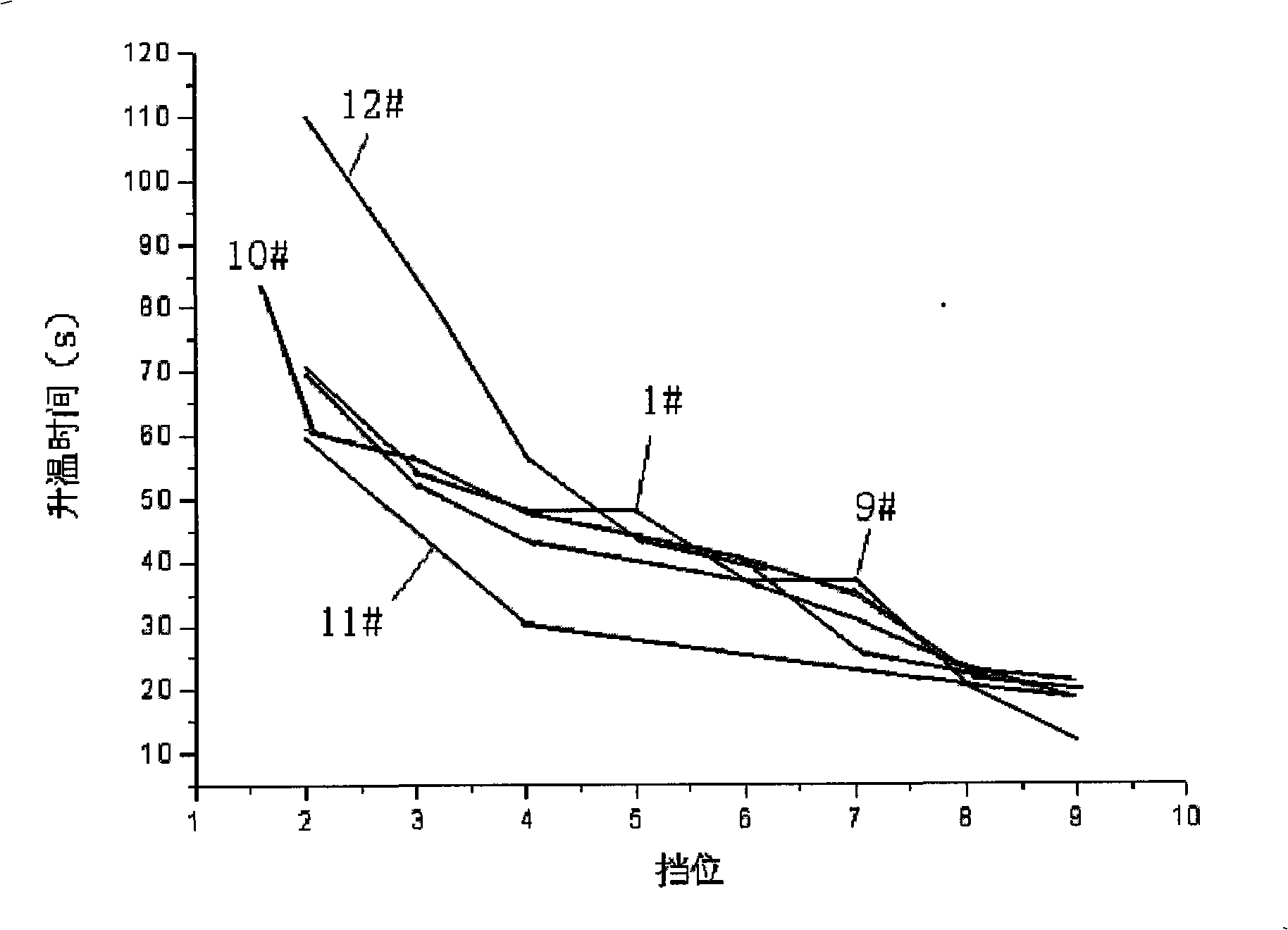

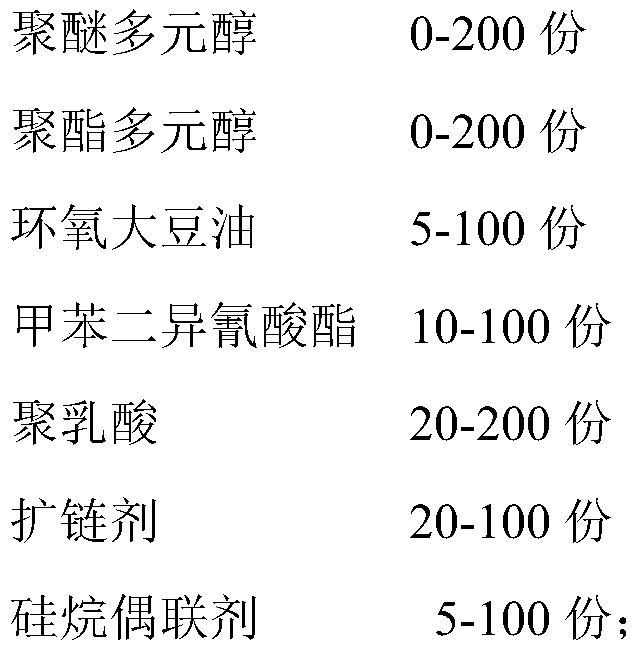

Silane modified epoxidized soybean oil-polylactic acid polyurethane composition and preparation method thereof

InactiveCN111040126AGood water and oil resistanceExcellent water resistance oil resistancePolyureas/polyurethane adhesivesSOYBEAN SEED OILPolyester

The invention relates to a silane modified epoxidized soybean oil-polylactic acid polyurethane composition and a preparation method thereof, belonging to the technical field of polyurethane modification. The silane modified epoxidized soybean oil-polylactic acid polyurethane composition comprises the following raw materials in parts by mass: 0 to 200 parts of polyether polyol, 0 to 200 parts of polyester polyol, 5 to 100 parts of epoxidized soybean oil, 10 to 100 parts of toluene diisocynate, 20 to 200 parts of polylactic acid, 20 to 100 parts of a chain extender and 5 to 100 parts of a silanecoupling agent. A polyurethane product prepared from the silane modified epoxidized soybean oil-polylactic acid polyurethane composition disclosed by the invention is good in storage stability, biocompatibility and degradability, excellent in physical and chemical properties, wide in raw material source, low in cost, saving in energy and friendly to the environment. The invention also provides asimple and feasible preparation method for polyurethane at the same time.

Owner:荆晓东

Edible printing ink and preparation method thereof

The invention discloses edible printing ink and a preparation method thereof. The edible printing ink is prepared from raw materials in percentage by weight as follows: 20%-35% of combined resin, 35%-54% of a combined solvent, 8%-16% of edible pigment and 1%-10% of auxiliaries, wherein the combined resin is prepared from gelatin, carrageenan, xanthan gum, active protein powder and anti-freezing protein, wherein the combined solvent is prepared from food-grade ethanol, water, soybean oil and glycerin; the auxiliaries comprise an anti-blocking agent, an anti-oxidation preservative, an anti-settling agent and a food-grade defoaming agent. The edible printing ink adopts natural concentrated pigment as the raw material, is safe and non-toxic and has bright color, ink and color are prevented from fading after repeated touch, and the edible printing ink is good in water resistance and oil resistance, wide in application range and suitable for gravure printing and spray printing, has excellentfluidity and cannot block a nozzle, thereby adapting to high-speed printing.

Owner:成都海瑞斯特新材料有限公司

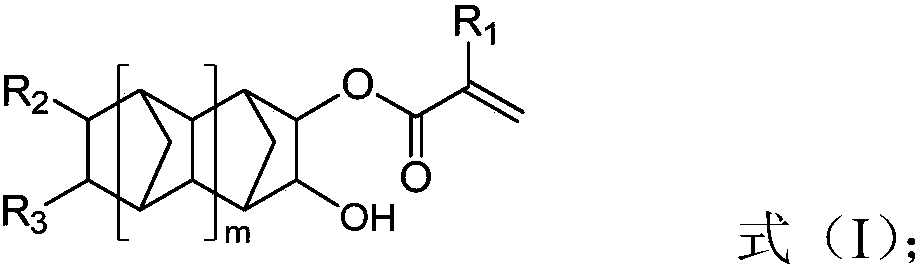

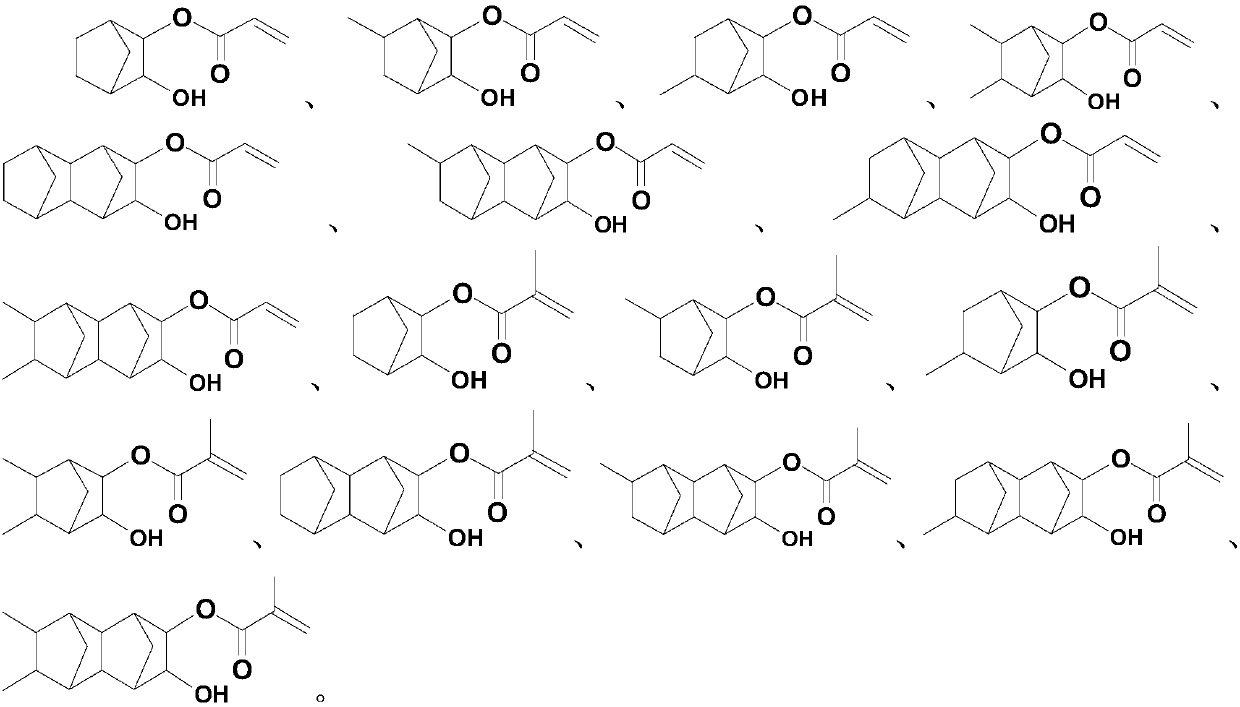

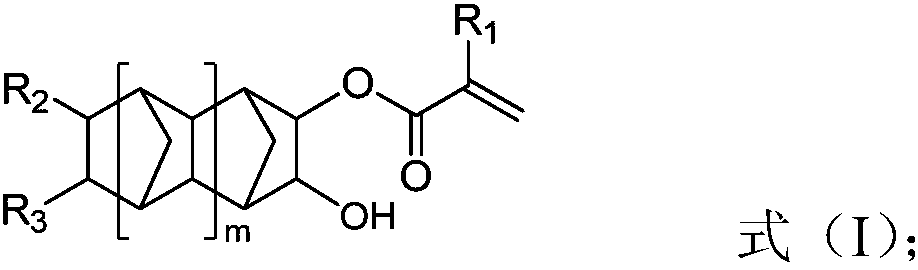

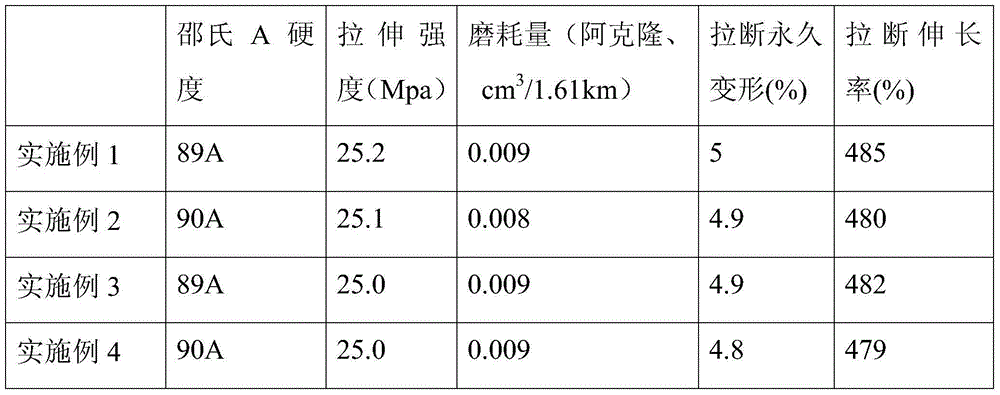

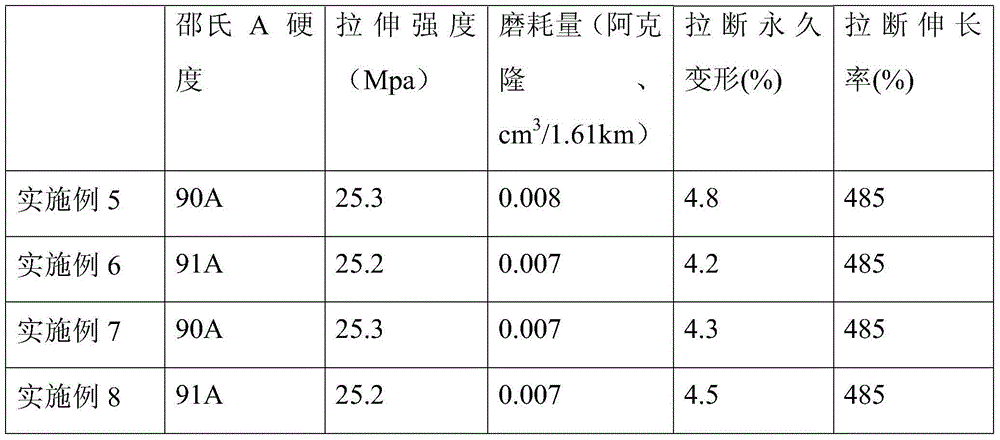

Acrylate compound for coatings, preparation method of acrylate compound, and coating comprising acrylate compound and application of coating

ActiveCN109956867AGood weather resistanceHigh weather resistanceAntifouling/underwater paintsOrganic compound preparationWater basedSolubility

The invention relates to an acrylate compound for coatings. The compound has a structure represented by a formula (I). The acrylate compound for coatings has lipophilic polycyclic aliphatic groups andhydrophilic hydroxyl groups at a same time and has high polymerization reaction activity. When the acrylate compound is used for a solvent-type acrylic coating, the coating layer shows relatively excellent weather resistance and wear resistance, high glossiness and fullness and the like. When the acrylate compound is used for a water-based acrylic coating, the hydrophilic hydroxyl groups and thelipophilic alicyclic groups of the compound show good solubility in an emulsion system, the polymerization activity is high, the monomer residue amount is low, and the coating after film forming showsexcellent weather resistance, water resistance, oil resistance, impact resistance, high glossiness and the like. The preparation method has the advantages that the technological process is simple, conditions are easy to control, side reactions are few, the raw material conversion rate of reactions is high, and purity of products is high.

Owner:WUXI ACRYL TECH

Polycaprolactone high-molecular prepolymer and preparation method thereof

The invention provides a polycaprolactone high-molecular prepolymer which is prepared from the following raw materials in parts by weight: 75-85 parts of polycaprolactone polyalcohol, 5-15 parts of isocyanate, 3-7 parts of anti-wear agent and 3-7 parts of temperature resisting agent. The Shore hardness of the polycaprolactone high-molecular prepolymer is controlled at 30A-63D, and the application range is -20-120 DEG C. The prepared prepolymer solidifies slowly, and is easy for operation and storage. The prepolymer product at the production site has the advantages of favorable wear resistance, long service life, high toughness, high aging resistance, favorable water-resistant and oil-resistant effects, favorable temperature resistance, and no degumming or rupture.

Owner:上海壹永聚氨酯制品厂

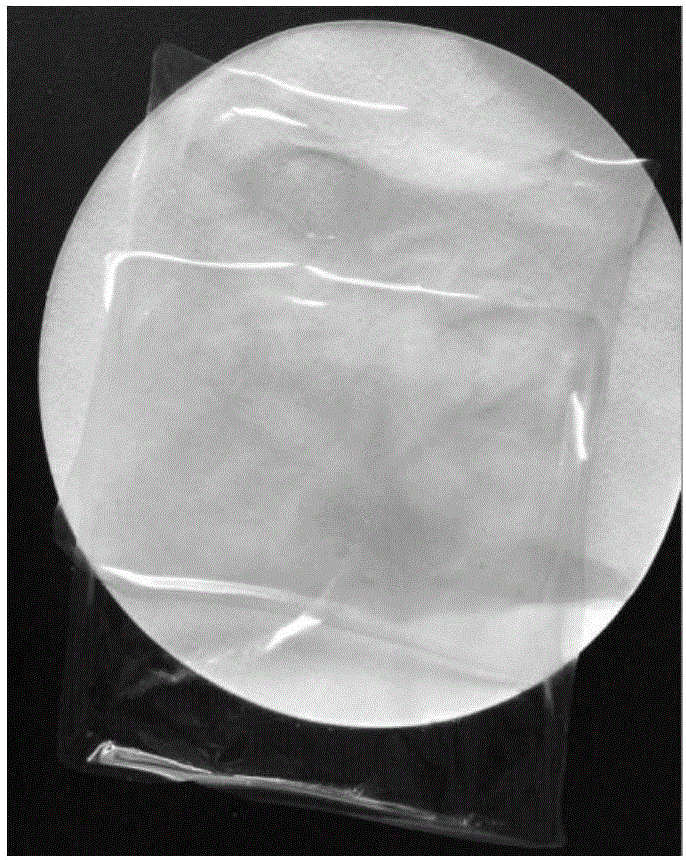

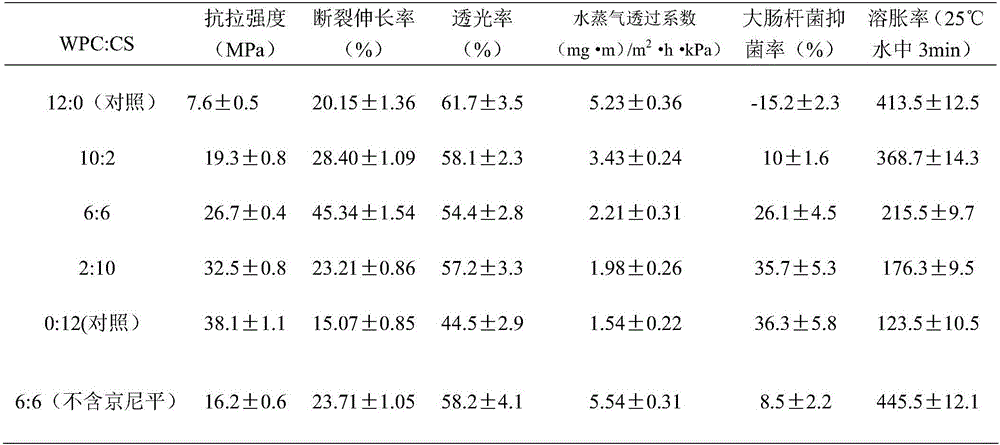

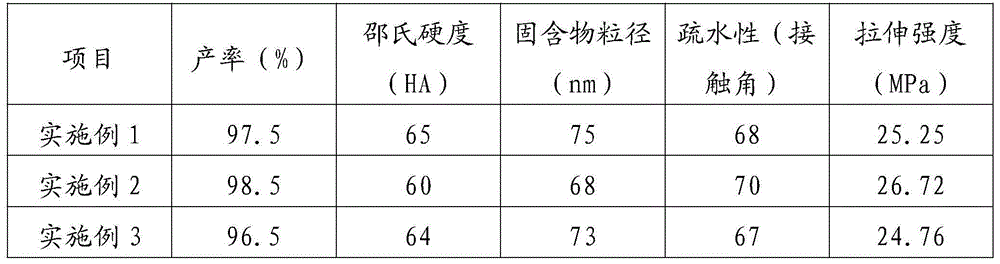

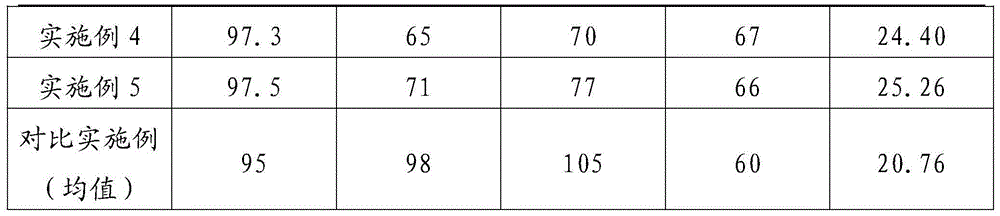

Edible sweet film and preparation method thereof

ActiveCN106565978AGood biocompatibilityGood gas and moisture barrierFlexible coversWrappersFood industryGenipin

The invention discloses an edible sweet film and a preparation method thereof and belongs to the technical field of food packaging and protective materials. According to the preparation method, chitosan and whey protein are used as film forming base materials, xylooligosaccharide is used as a sweetener and genipin is used as a crosslinker. A film forming liquid of the edible sweet film contains the chitosan and whey protein. In the invention, the chitosan and the whey protein are compounded creatively with addition of the crosslinker, so that the film remains the nutrients in the whey protein. The film has good insulation property, mechanical performance and long-acting antibacterial performance. The raw materials of the edible sweet film are all edible, wherein a chitosan acetic acid solution has a sour taste while the xylooligosaccharide enable the film to have a sweet taste, thereby forming the edible sweet film. The method is simple in operations and low in cost, and has a wide application prospect in food industry.

Owner:SHAANXI UNIV OF SCI & TECH

Fabric coating slurry and preparing method thereof

ActiveCN104141231AGood photostability and thermal stabilityGood water and oil resistanceFibre treatmentEmulsionMineralogy

The invention discloses fabric coating slurry which is prepared by the following components, by weight, of 100 parts of epoxidized soybean oil modified waterborne polyurethane, 5-10 parts of crosslink type macromolecule emulsion thickening agents BJ-100 and 5-10 parts of fabric coating extrusion dispersing agents PTFE D-210. The invention discloses a preparing method of the fabric coating slurry at the same time. The fabric coating slurry is well improved in light stability, heat stability, oil resistance and water resistance.

Owner:甄曰菊

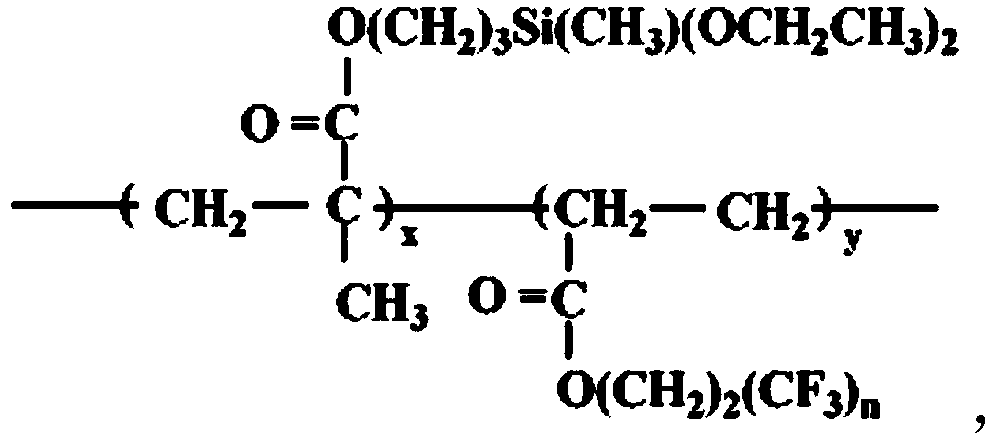

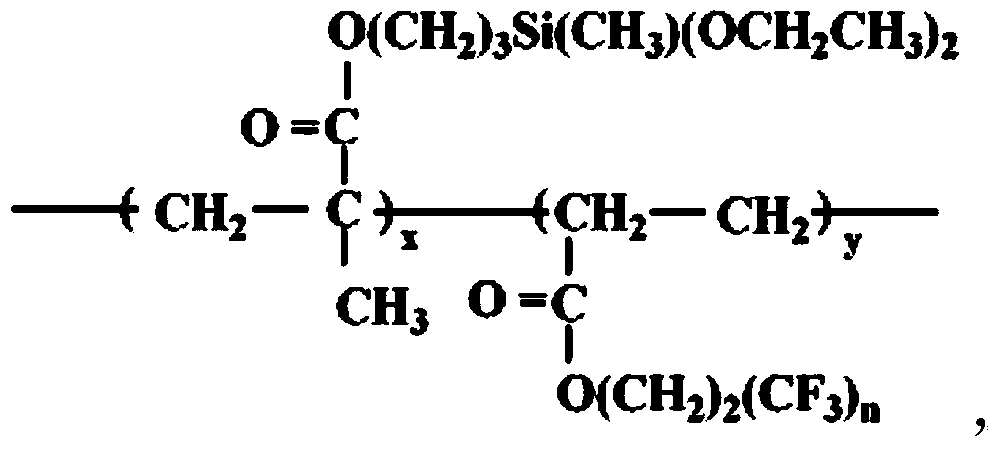

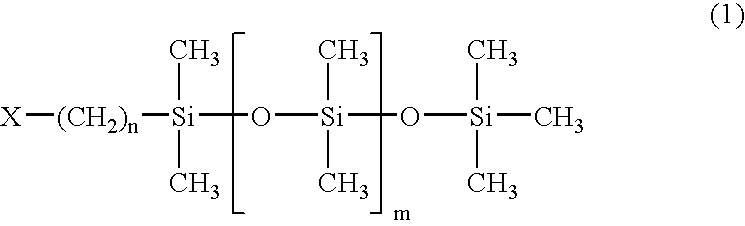

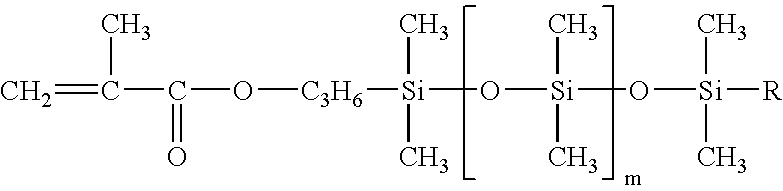

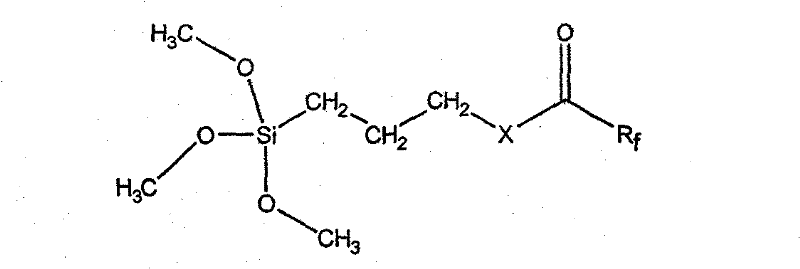

Silicon and fluorine-containing antifouling easy-cleaning agent

The invention provides a silicon and fluorine-containing antifouling easy-cleaning agent which is only composed of a silicon-fluorine copolymer and an FF31 type perfluorocarbon cyclic ether mixture solvent, wherein the silicon-fluorine copolymer is prepared through conventional solution type free radical polymerization by taking gamma-methylacrylyloxypropylmethylethoxy silane and perfluor C4-C18 alkyl acrylate as copolymerization monomers; the raw materials are simple, easily available and low in price, and the production process is mature and reliable; moreover, a finished product of the antifouling easy-cleaning agent is simple to use and low in price; after firm forming and curing, the antifouling easy-cleaning agent has good water / oil resistance and is not contaminated easily; a film layer has high strength and is not easy to wipe; the antifouling easy-cleaning agent can be widely applied to the surface of a glass substrate, a ceramic substrate or a plastic substrate, and is particularly applicable to the surface of an electronic touch screen.

Owner:KUNSHAN CITY BANMING ELECTRONICS SCI & TECH

Water and oil resistant agent for paper and paper treatment process

ActiveUS20120325419A1Good oil resistanceImprove water resistanceNon-fibrous pulp additionNatural cellulose pulp/paperMeth-Fluorine containing

Disclosed is a water and oil resistant agent comprising a fluorine-containing copolymer obtained by copolymerizing a (meth)acrylate monomer having a polyfluoroalkyl group having 1 to 6 carbon atoms, the agent being able to afford a superior water and oil resistance to a paper. The invention also discloses a composition comprising the water and oil resistant agent, a process for treating a paper thereby and a treated paper thereby.

Owner:DAIKIN IND LTD

Liquid non-aqueous dispersion and process for producing the same

ActiveUS7247672B2Good oil resistanceImprove water resistanceCosmetic preparationsHair cosmeticsMeth-Macromonomer

A liquid non-aqueous dispersion including a silicone oil and a copolymer dispersed therein, the copolymer including (A) at least one radical polymerizable macromonomer containing dimethyl polysiloxane, and (B) at least one radical copolymerizable monomer with the macromonomer (A), which includes at least one (meth)acrylate monomer and optionally at least one vinyl monomer. This liquid non-aqueous dispersion has excellent water resistance, oil resistance and adhesive properties, and when used as a component of cosmetics, it can meet both requirements for long lasting make-up and good feeling of use of cosmetics.

Owner:TAISEI HLDG CO LTD

Silicon-dioxide-added treating agent for metals

InactiveCN105860693AImprove thermal stabilityStrong water absorptionAnti-corrosive paintsCellulosePolyvinyl alcohol

The invention discloses a silicon-dioxide-added treating agent for metals. The treating agent is prepared from the following raw materials in parts by weight: 40-50 parts of polyvinyl alcohol, 12-15 parts of polyethyleneglycol, 0.4-0.6 part of emulsifier op10, 0.3-0.5 part of glycerol, 0.6-0.8 part of triethanolamine, 0.2-0.4 part of Tween 80, 6-8 parts of benzotriazole, 6-7 parts of sodium benzoate, 2-3 parts of lauryl sodium sulfate, 5-7 parts of 3-(trihydroxysilyl)propane-1-sulfonic acid, 3-4 parts of silica sol, 1.2-2 parts of sodium hydroxide, 10-14 parts of polyetheramine, 0.4-0.6 part of succinic aldehyde, 4-5 parts of nano cellulose, 2.2-3 parts of sodium isooctoate and a right amount of deionized water. The metal surface treating agent has the advantages of low production cost, high performance, favorable rust and corrosion resistance, high adhesive force, low shedding tendency, favorable water resistance, favorable oil resistance and long anticorrosion time, can form a film on the workpiece surface, and is worthy of popularization.

Owner:HEFEI ZHENGHAO MECHANICAL TECH

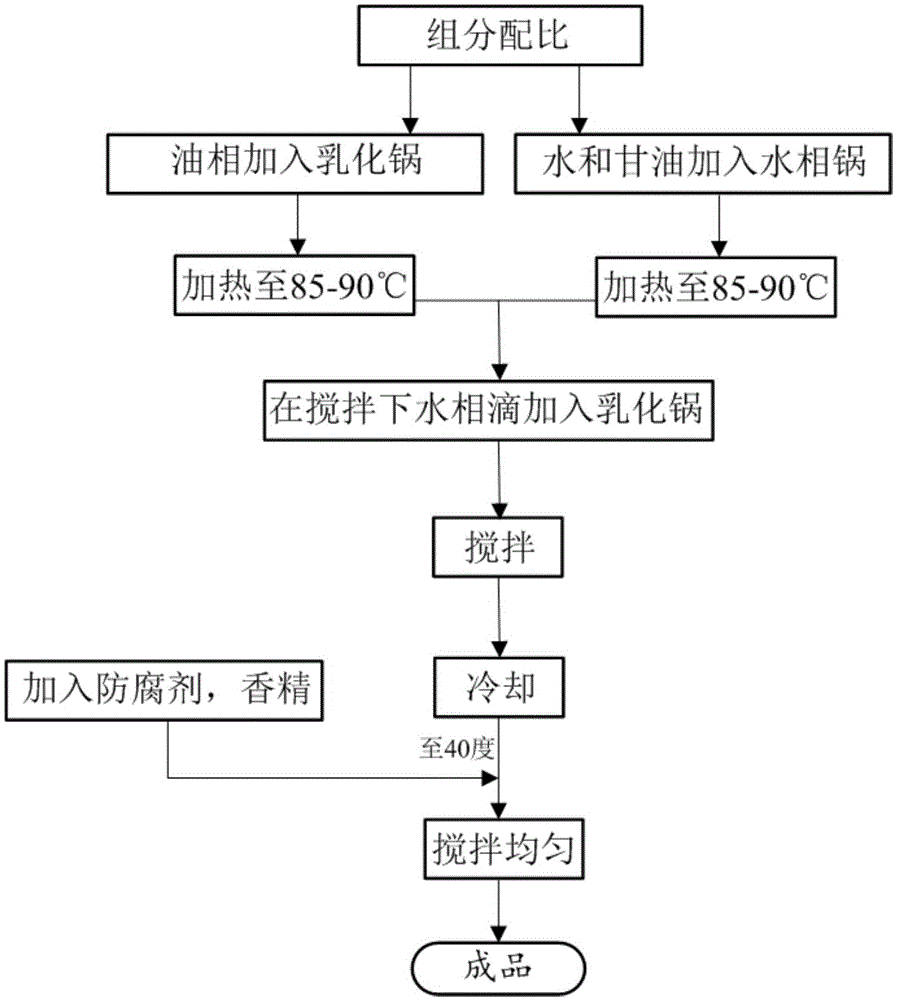

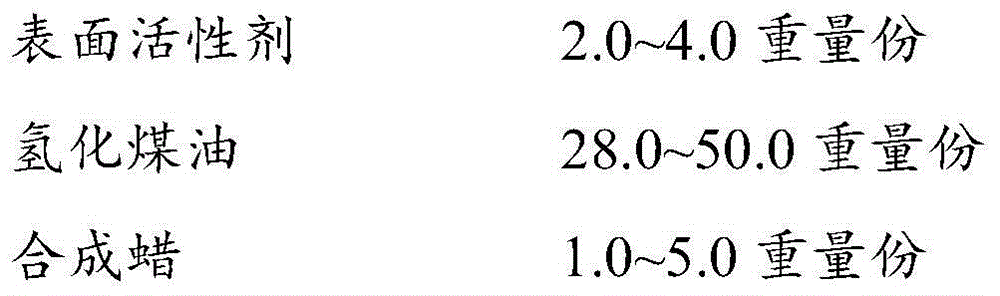

Nanoscale water-resisting oil-stain-resisting leather surface treatment agent and preparing method thereof

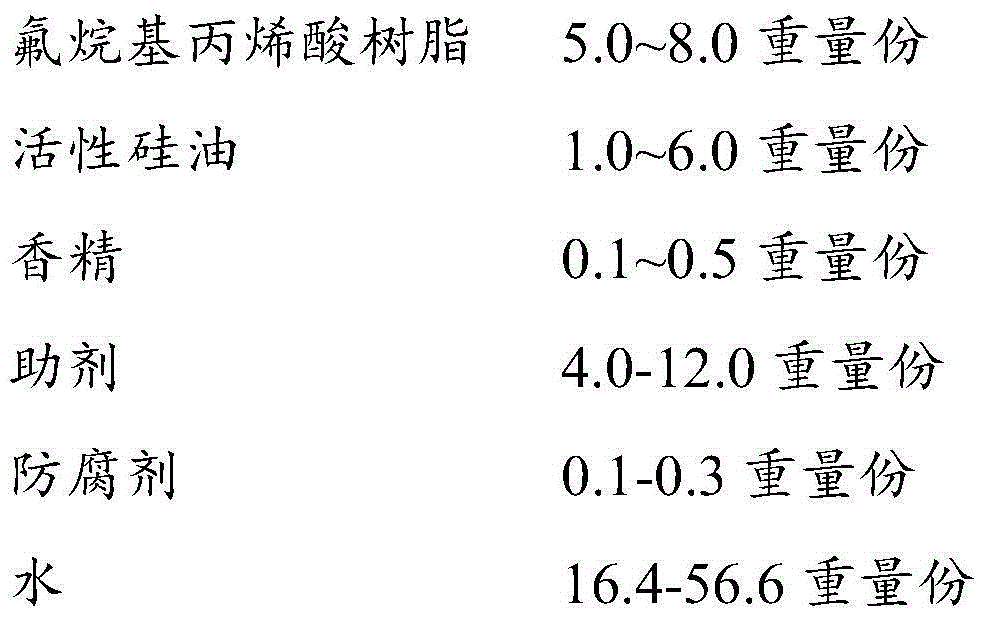

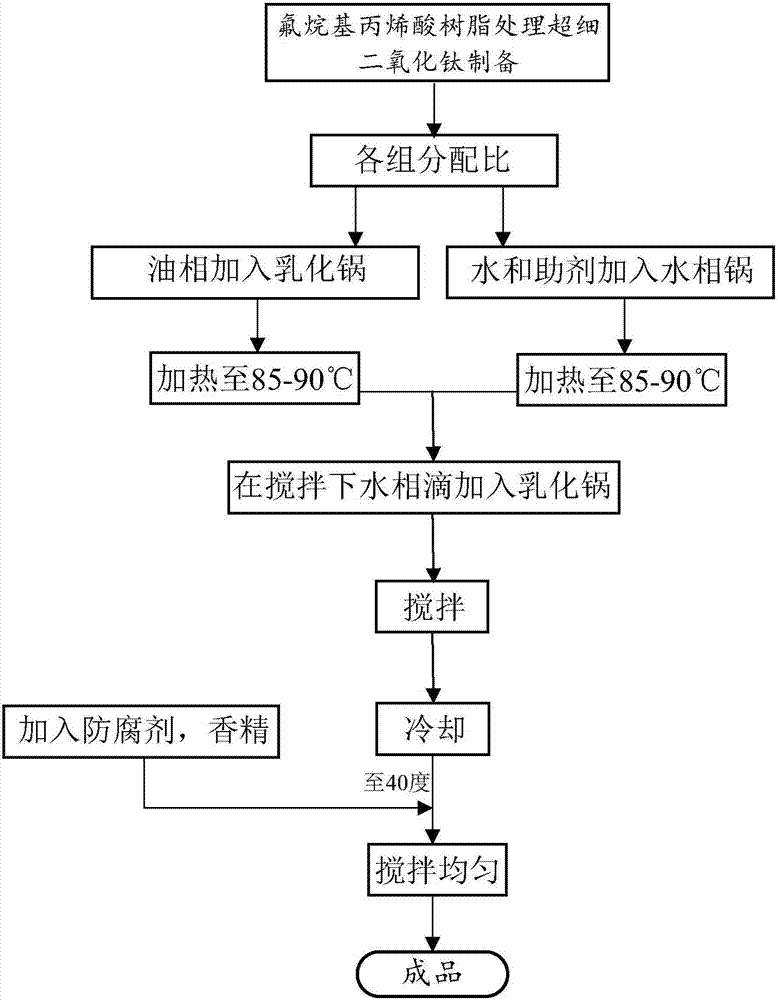

InactiveCN104946048AKeep the mirror effectGood water and oil resistanceCoatingsLeather surface finishingKeroseneOil phase

The invention discloses a nanoscale water-resisting oil-stain-resisting leather surface treatment agent and a preparing method thereof. The surface treatment agent comprises 2.0-4.0 parts of surface active agents, 28.0-50.0 parts of hydrogenated kerosene, 1.0-5.0 parts of synthetic wax, 5.0-8.0 parts of fluorine alkyl acrylate resin, 1.0-6.0 parts of active silicon oil, 0.1-0.5 part of essence, 4.0-12.0 parts of auxiliaries, 0.1-0.3 part of corrosion remover and 16.4-56.6 parts of water, wherein the surface active agents are water-in-oil type emulsifier. The preparing method includes the following steps that the surface active agents, the hydrogenated kerosene, the active silicon oil, the synthetic wax and the fluorine alkyl acrylate resin serve as the oil phase and are added into an emulsifying pot to be heated according to the ratio; water and glycerinum are added into a water phase pot to be heated, water phase drops are added into the emulsifying pot while stirring is conducted, and the mixture is evenly stirred and cooled; the corrosion remover and the essence are added to the mixture and evenly stirred. Water-in-oil type emulsifier transparent microemulsion is made through a special formula and process, the water-resisting performance and oil-stain-resisting performance are better, leather drape and tiny cracks can be effectively filled, and the mirror surface result of leather is kept.

Owner:HUANGBAO TECH SHANGHAI

High strength abrasion-resistant concrete

The invention discloses a high strength abrasion-resistant concrete, in particular to a concrete for construction. The high strength abrasion-resistant concrete provided by the invention is composed of steel slag, a cementitious material, water and a water reducing agent, wherein the cementitious material consists of cement accounting for 45% of the mass of the cementitious material, mineral powder accounting for 20% of the mass of the cementitious material, and silicon carbide accounting for 5% of the mass of the cementitious material. The steel slag and the cementitious material are in a mass ratio of 1.67:1, and the water and the cementitious material are in a mass ratio of 0.2:1. The concrete made by the invention has the advantages of high hardness and high abrasion resistance, also has good water resistance and oil resistance, and is suitable for various dry and wet internal and external environments.

Owner:XINJIANG YUXIN CONCRETE

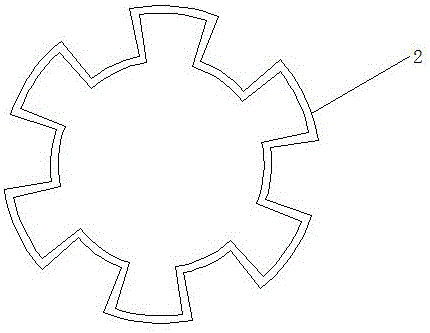

Inorganic membrane for filtering

InactiveCN107469641ALarge filter areaCapable of blockingSemi-permeable membranesDispersed particle filtrationCelluloseUltra fine

The invention discloses an inorganic membrane for filtering. The inorganic membrane is characterized in that the inorganic membrane is prepared from the following raw materials in percentage by mass: 50 to 85 percent of silicon carbide, 5 to 30 percent of aluminum oxide, 5 to 30 percent of kaolin, 2 to 20 percent of zirconium oxide and 0.05 to 0.3 percent of cellulose. According to the inorganic membrane disclosed by the invention, the inorganic membrane is prepared by adopting an inorganic material, and the filtering area of the inorganic material is increased by 3 times under a condition of the same volume, so that the inorganic membrane has the characteristics of the resistance ability to blocking of ultra-fine powder and excellent oil resistance and water resistance, high temperature resistance and the resistance to acid and alkali corrosion, low surface resistance, high dust removal efficiency, long service life and the like; moreover, the preparation difficulty of the inorganic membrane is small, and an application range is wide.

Owner:JIANGSU YAFENG TECH GRP CO LTD

Anti-aging, waterproof and oil-rub-resistant leather surface treating agent and preparation method thereof

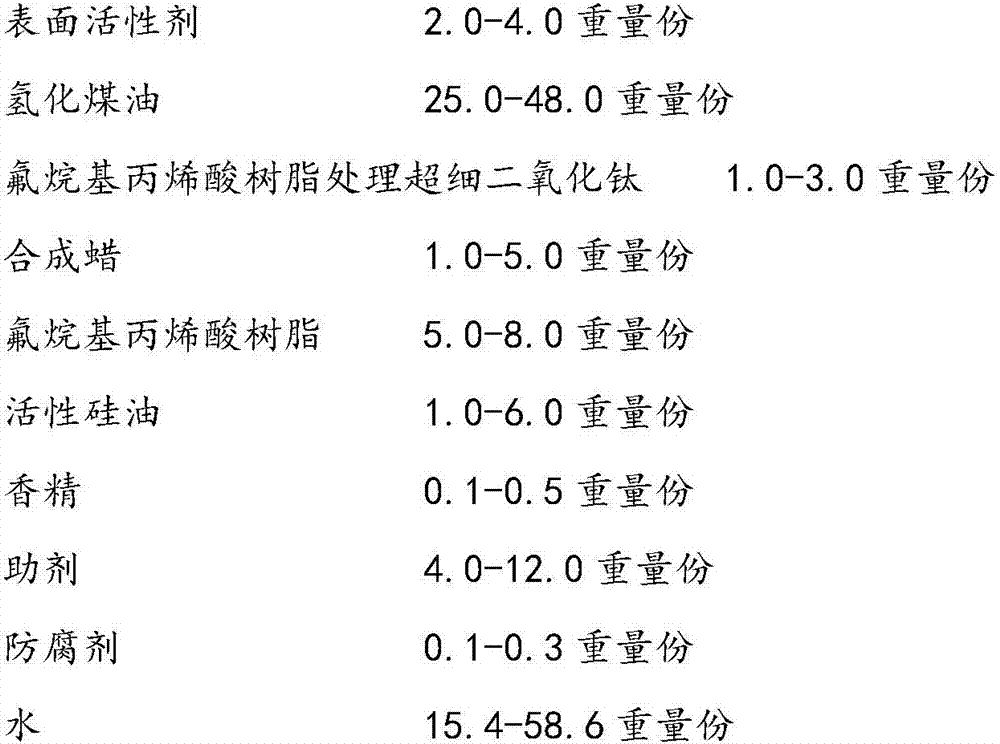

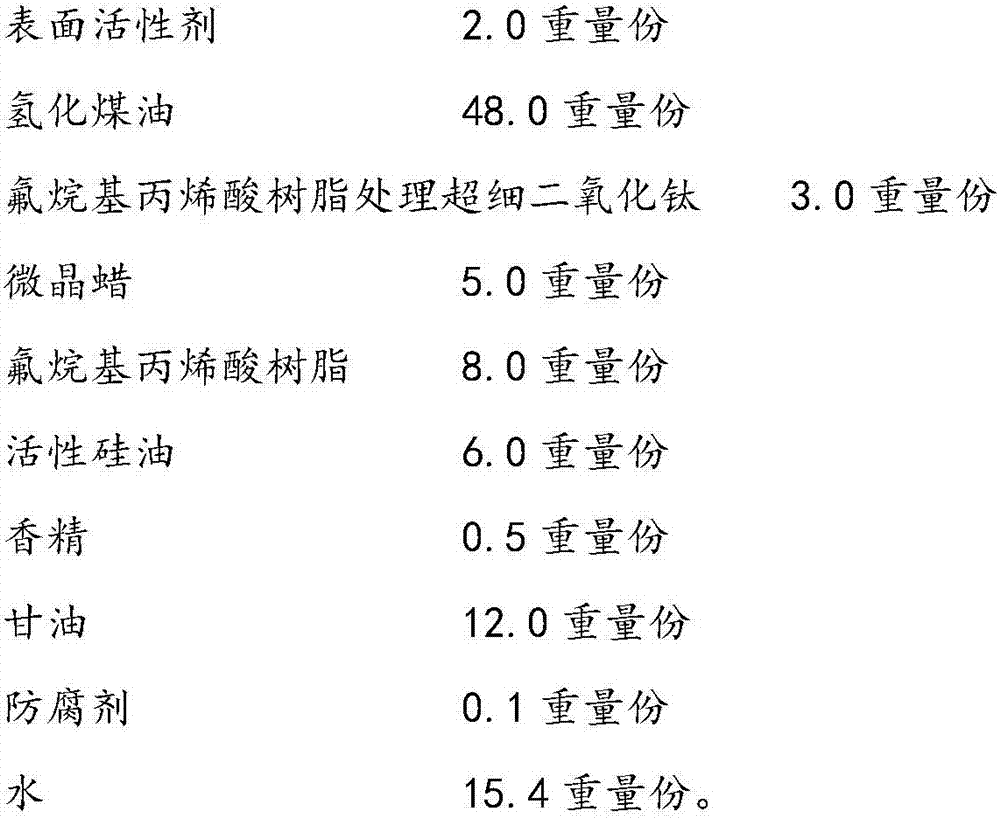

InactiveCN107189684AEffective water and oil resistanceStrong water and oil resistanceWax coatingsLeather surface finishingWrinkle skinAcrylic resin

The invention discloses an anti-aging, waterproof and oil-rub-resistant leather surface treating agent comprises, by weight, 2.0-4.0 parts of surface active agents, 25.0-48.0 parts of hydrogenated kerosene, 1.0-3.0 parts of fluoroalkyl acrylic resin treated superfine titanium dioxide, 1.0-5.0 parts of synthetic wax, 5.0-8.0 parts of fluoroalkyl acrylic resins, 1.0-6.0 parts of active silicon oil, 0.1-0.5 part of essence, 4.0-12.0 parts of additives, 0.1-0.3 part of anticorrosive agents and 15.4-58.6 parts of water. The surface active agents are water-in-oil emulsion agents, and the fluoroalkyl acrylic resin treated superfine titanium dioxide is prepared by a specific method. The invention discloses a specific preparation method of the treating agent. The leather surface treating agent of water-in-oil white emulsion is prepared by the aid of a unique composition and preparation process, so that leather is resistant in aging, sunshine, water and oil rub, wrinkles and small cracks of the leather can be filled, and the service life of the leather is prolonged.

Owner:HUANGBAO TECH SHANGHAI

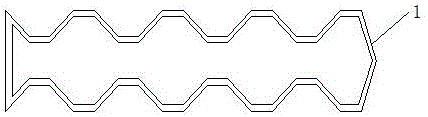

Trapezoidal efficient dust-removal inorganic film and manufacturing method thereof

InactiveCN106345321ALarge filter areaGood water and oil resistanceSemi-permeable membranesDispersed particle filtrationCelluloseTemperature resistance

The invention discloses a trapezoidal high-efficiency dust-removing inorganic membrane and a manufacturing method thereof, belonging to the field of dust-removing inorganic membranes. The inorganic membrane is prepared from the following raw materials: in terms of mass percentage, the raw materials include 50-85% of silicon carbide, 5-30% of aluminum oxide, 5-30% of kaolin, 2-20% of zirconia and 0.05-0.3% of cellulose %. The prepared inorganic membrane has a unique trapezoidal structure, and its filtration area increases three times under the same volume. The inorganic membrane has the ability to resist ultrafine dust clogging and excellent oil and water resistance, high temperature resistance, acid and alkali corrosion resistance, It has the characteristics of low surface resistance, high dust removal efficiency and long service life.

Owner:湖南银和高新环保陶瓷有限公司

Oil-proof pea protein powder-based full-degradable plastic film and preparation method thereof

InactiveCN104927265AIncrease compatibilityImprove water resistanceStress concentrationPolyvinyl alcohol

The invention discloses an oil-proof pea protein powder-based full-degradable plastic film. Polyvinyl alcohol and pea protein powder are used as main film forming matters, and compared with a traditional technology, the preparation method has the advantages that nano silica and pea protein powder are modified through physical and chemical methods and cooperate with other effective ingredients mutually, so that on one hand, hydroxyl groups in pea protein powder and polyvinyl alcohol molecules are preferentially combined with a proper amount of nano silica surface hydroxyl groups to form hydrogen bonds, therefore, the degree of compatibility of pea protein powder and polyvinyl alcohol is improved and the water resistance of the film is improved; on the other hand, uniformly-dispersed single nanoparticles and nano-clusters can generate stress concentration points, therefore, the strength of the film is improved, and the prepared full-degradable plastic film is transparent in appearance and smooth in surface and has the characteristics of heat resistance, excellent water resistance and oil resistance, high biodegradable speed and simple preparation method.

Owner:TONGLING FOUNDER PLASTICS TECH

Surface modified nano silicon dioxide and acrylic resin coating containing the silicon dioxide

InactiveCN101497749BGood water and oil resistanceImprove stain resistanceCoatingsPigment treatment with non-polymer organic compoundsWeather resistanceAcrylic resin

The invention discloses a nano-silica which is functionalized by acrylate and surface-modified by a perfluoroalkoxy group and a preparation method thereof, and discloses an acrylic resin coating containing the above-mentioned surface-modified nano-silica. The composition is: surface-modified nano silicon dioxide, monofunctional acrylate, acrylate containing at least 2 acrylate groups, alcohol solvent and initiator. The fluorine-containing silicon-containing acrylic resin coating of the present invention can be quickly cured, and the formed coating film has excellent oil and water resistance, weather resistance, stain resistance, surface hardness and good surface gloss.

Owner:浙江池河科技有限公司

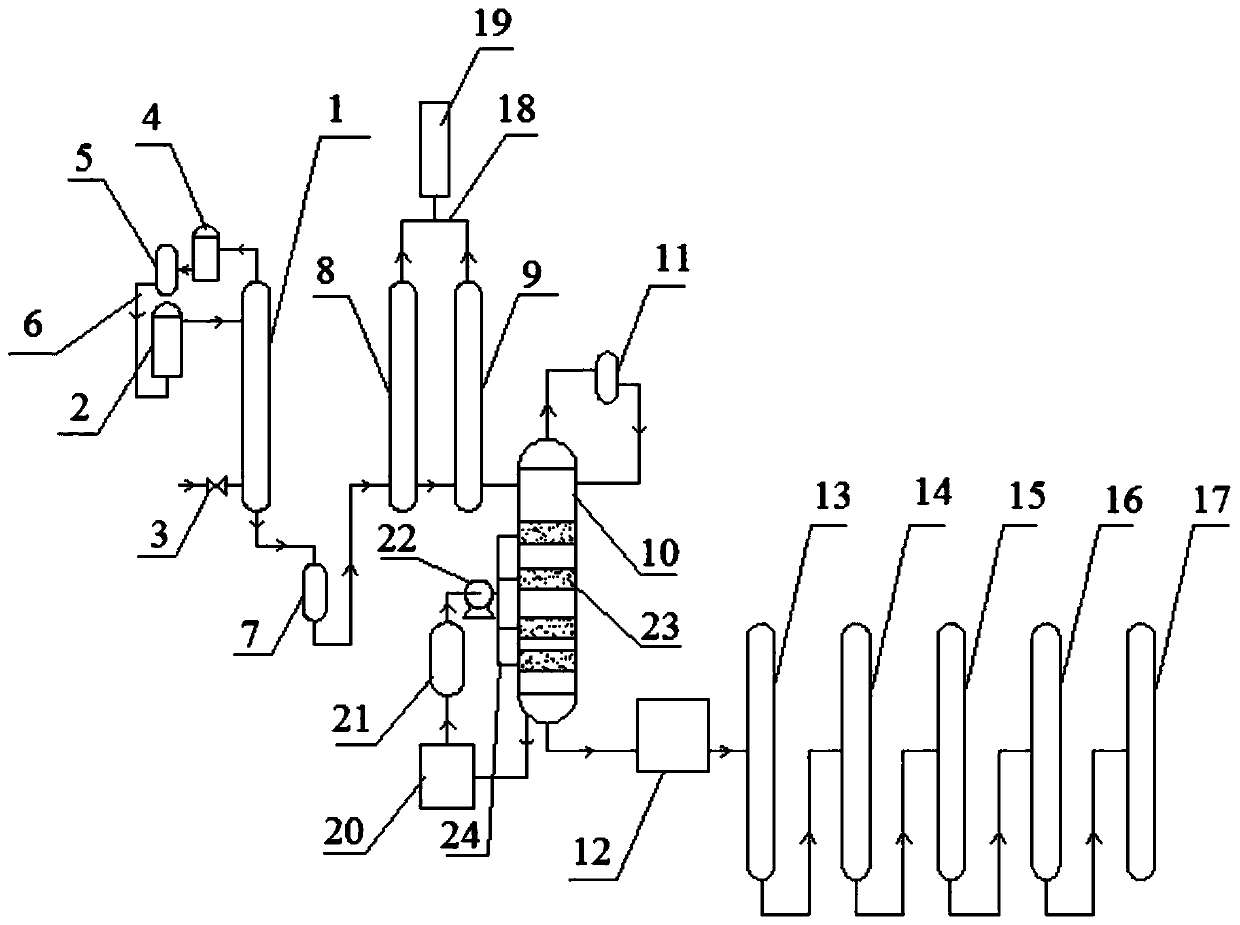

Manufacturing method of phenol and acetone

InactiveCN109776274ALower surface energyPlay a role of shielding protectionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic decompositionEvaporation

The invention discloses a manufacturing method for phenol and acetone, and relates to the technical field of chemical raw material synthesis. The manufacturing method comprises the steps that improvement is conducted on the basis of an existing method that phenol and acetone are synthesized through isopropyl benzene oxidation and selective acid catalytic decomposition, isopropyl benzene obtained after alkalization and pressurized air are subjected to a countercurrent contact reaction in an oxidation tower, falling film evaporation and two times of concentration are conducted, and then refinedcumene hydroperoxide is obtained; the refined cumene hydroperoxide is decomposed into the phenol and acetone in a moving bed reactor through catalysis of an acid resin catalyst, and then the refined phenol and acetone are obtained through water washing for deacidification, acetone roughing, acetone refining, coke cutting and secondary dealkylation. The manufacturing method has the good selectivityand yield of the phenol and acetone, the reaction conditions are not harsh and easy to control, the resin catalyst can be reused multiple times after collection and regeneration, and thus the production cost is lowered.

Owner:实友化工(扬州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com