Polycaprolactone high-molecular prepolymer and preparation method thereof

A polycaprolactone and polymer technology, applied in the field of polycaprolactone polymer prepolymer and its preparation, can solve the problems of poor wear resistance and service life improvement effect, affecting the production quality of enterprises, easy degumming and breaking, etc. , to achieve the effect of strong anti-aging performance, strong toughness and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

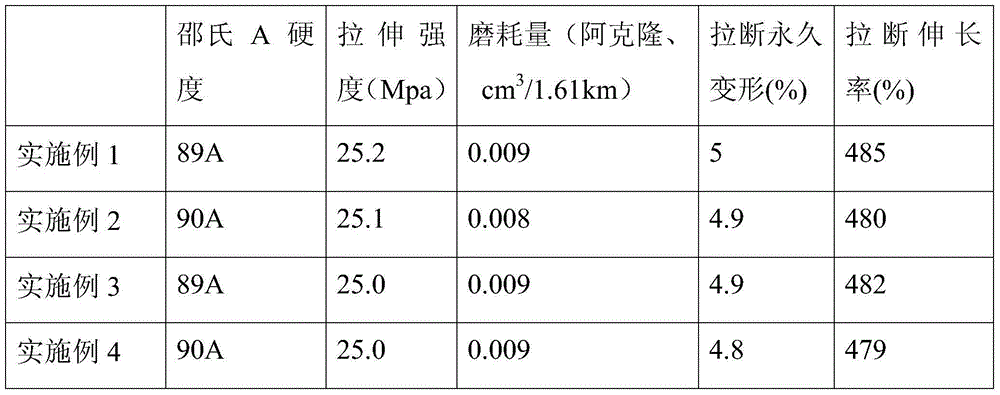

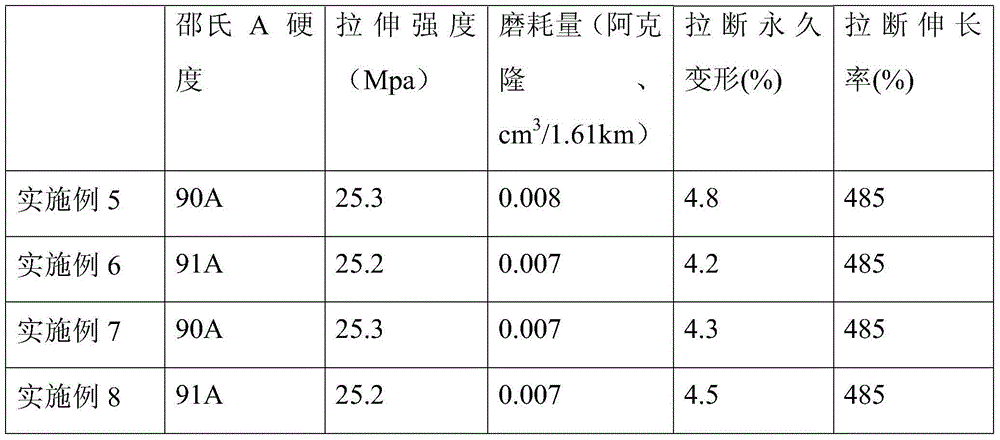

Examples

Embodiment 1

[0026] Embodiment 1 Polycaprolactone polymer prepolymer

[0027] Raw material preparation: 85 parts of polycaprolactone polyol, 15 parts of polymethylenephenyl polyisocyanate, 7 parts of graphite, 7 parts of 4,4'-diphenylmethane-5-maleimide. The preparation steps are as follows:

[0028] 1) Dehydrating polycaprolactone polyol for 3.5 hours at a reaction temperature of 110°C;

[0029] 2) The reaction temperature is lowered to 75°C, and the dehydrated polycaprolactone polyol is mixed with polymethylenephenyl polyisocyanate, graphite and 4,4'-diphenylmethane-5-maleimide, and the temperature is maintained React for 9 hours;

[0030] 3) Then, keep the vacuum for 1 hour; the preparation is complete.

Embodiment 2

[0031] Embodiment 2 Polycaprolactone polymer prepolymer

[0032] Raw material preparation: 75 parts of polycaprolactone polyol, 5 parts of hexamethylene diisocyanate, 3 parts of graphite, 3 parts of 3,3'-dichloro-4,4'-diphenylmethanediamine. The preparation steps are as follows:

[0033] 1) Dehydrating polycaprolactone polyol for 3.5 hours at a reaction temperature of 100°C;

[0034] 2) The reaction temperature is lowered to 65°C, and the dehydrated polycaprolactone polyol is mixed with hexamethylene diisocyanate, graphite and 3,3'-dichloro-4,4'-diphenylmethanediamine, and kept Temperature reaction for 7 hours;

[0035] 3) Then, keep the vacuum for 1 hour; the preparation is complete.

Embodiment 3

[0036] Embodiment 3 Polycaprolactone polymer prepolymer

[0037] Raw material preparation: 80 parts of polycaprolactone polyol, 10 parts of methylcyclohexyl diisocyanate, 5 parts of molybdenum disulfide, 5 parts of 4,4'-diphenylmethane-5-maleimide. The preparation steps are as follows:

[0038] 1) Dehydrating polycaprolactone polyol for 3 hours at a reaction temperature of 105°C;

[0039] 2) The reaction temperature is lowered to 75°C, and the dehydrated polycaprolactone polyol is mixed with methylcyclohexyl diisocyanate, molybdenum disulfide and 4,4'-diphenylmethane-5-maleimide to keep the temperature Reaction for 8 hours;

[0040] 3) Then, keep the vacuum for 1 hour; the preparation is complete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com